SPEED SENSOR REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the speed sensor removal/installation are shown below.

| Replaced Part or Performed Procedure | Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed | Link | |

|---|---|---|---|---|

| Battery terminal is disconnected/reconnected | Memorize steering angle neutral point | LKA/LDA System | ||

| Intelligent clearance sonar system*4 | ||||

| Pre-crash safety system | ||||

| Lighting system (EXT)

|

||||

| Adaptive high beam system | ||||

| Drive the vehicle until stop and start control is permitted (approximately 15 to 60 minutes) | Stop and start system | |||

| Memorize steering angle neutral point | Parking Assist Monitor System (w/ Parallel Parking Assist Function) | |||

| Parking Assist Monitor System (w/o Parallel Parking Assist Function) | ||||

| Panoramic view monitor system | ||||

| Initialize back door lock | Power door lock control system | |||

| Reset back door close position | Power back door system | |||

| Replacement of ECM | Perform Vehicle Identification Number (VIN) or frame number registration |

|

||

| ECU Communication ID Registration (Immobiliser system) | Engine start function | See Service Bulletin for the registration method. | ||

| Perform code registration (Immobiliser system) |

|

|||

|

Inspection After Repair |

|

||

| Replacement of starter assembly*1 Note When the starter assembly is replaced, "ST relay" and "ST NO. 2 relay" must be also replaced. |

Clear Number of Starter Operations | Stop and start system | ||

| Replacement of battery*1 |

|

|||

|

Bleed the oil pump assembly with motor (continuously variable transaxle assembly) | |||

| Replacement of automatic transaxle assembly | Perform the following procedures in the order shown:

|

|

Click here for Initialization Click here for Registration |

|

| Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

Possible to read transaxle compensation code | Perform the following procedures in the order shown:

|

||

| Impossible to read transaxle compensation code | Perform the following procedures in the order shown:

|

|||

| Suspension, tires, etc.*2 |

|

|

||

| Rear television camera assembly optical axis (Back camera position setting) | Parking assist monitor system (w/ Parallel Parking Assist Function) | Click here for Initialization Click here for Calibration |

||

| Parking assist monitor system (w/o Parallel Parking Assist Function) | Click here for Initialization Click here for Calibration |

|||

|

Panoramic view monitor system | Click here for Initialization Click here for Calibration |

||

| Initialize headlight ECU sub-assembly LH |

|

|||

| Front wheel alignment adjustment | Perform the following procedures in the order shown:

|

|

||

*1: w/ Stop and Start System

*2: The vehicle height changes because of suspension or tire replacement

*3: w/ TFT Meter Type

*4: When performing learning using the GTS.

CAUTION:

-

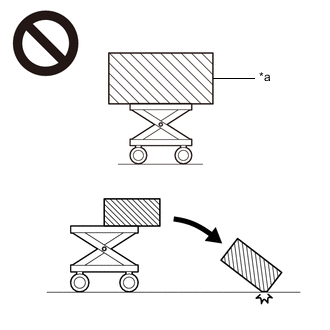

*a An Object Exceeding Weight Limit of Engine Lifter The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop or the engine assembly with transaxle may fall off the engine lifter.

-

To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

-

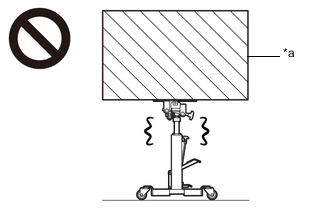

*a Object Exceeding Weight Limit of Transmission Jack The automatic transaxle assembly is very heavy. Be sure to follow the procedure described in the repair manual, or the transmission jack may suddenly drop.

PROCEDURE

-

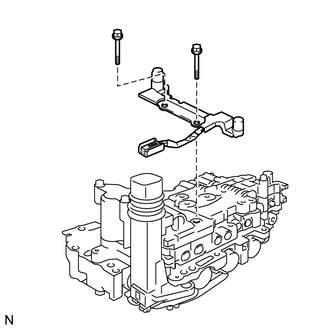

REMOVE TRANSMISSION VALVE BODY ASSEMBLY

-

REMOVE TRANSMISSION REVOLUTION SENSOR

-

Disconnect the transmission revolution sensor connector.

-

Remove the 2 bolts and transmission revolution sensor from the transmission valve body assembly.

-