OIL PUMP REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed, installed, or replaced during the oil pump removal/installation are shown below.

| Replacement Part or Procedure | Necessary Procedures | Effects/Inoperative when not Performed | Link |

|---|---|---|---|

| Replacement of ECM |

|

|

|

| Code registration (Immobiliser system) | Engine start function | See the Service Bulletin for the registration method. | |

| Replacement of engine assembly |

|

Engine starting | |

| Replacement of fuel supply pump assembly | Supply Pump Initialization | Engine startability | |

|

Perform initialization | - | |

| Replacement of timing belt | Mode reset operation |

|

|

for A750F: |

Reset memory |

|

|

for A750F: |

ATF thermal degradation estimate reset | The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly | |

w/ Automatic Headlight Beam Level Control System: |

Headlight leveling ECU assembly initialization | Headlight leveling function | |

for 4WD: |

|

VSC malfunctioning |

Note

-

When replacing the parts in the following chart (A), replace the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly, No. 3 injection pipe sub-assembly, No. 4 injection pipe sub-assembly and/or fuel inlet pipe sub-assembly with new ones.

Replaced Parts (A) Pipes Requiring New Replacement

-

Injector assembly (including shuffling the injector assemblies between the cylinders)

-

Common rail assembly

-

Cylinder head sub-assembly

-

No. 1 injection pipe sub-assembly

-

No. 2 injection pipe sub-assembly

-

No. 3 injection pipe sub-assembly

-

No. 4 injection pipe sub-assembly

-

Supply pump assembly

-

Common rail assembly

-

Cylinder block sub-assembly

-

Cylinder head sub-assembly

-

Cylinder head gasket

-

Timing Gear Case Assembly

Fuel inlet pipe sub-assembly -

-

After removing the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly, No. 3 injection pipe sub-assembly, No. 4 injection pipe sub-assembly and fuel inlet pipe sub-assembly, clean them with a brush and compressed air.

PROCEDURE

-

PRECAUTION

Note

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work.

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

DRAIN ENGINE OIL

-

DRAIN ENGINE COOLANT

-

REMOVE ENGINE ASSEMBLY

-

REMOVE NO. 1 TIMING BELT COVER

-

REMOVE TIMING BELT

-

REMOVE NO. 1 TIMING BELT IDLER SUB-ASSEMBLY

-

REMOVE NO. 2 IDLE PULLEY ASSEMBLY

-

REMOVE GENERATOR ASSEMBLY

-

REMOVE GENERATOR BRACKET

-

REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

-

REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

-

REMOVE MANIFOLD STAY

-

REMOVE NO. 1, NO. 2 AND NO. 3 INJECTION PIPE SUB-ASSEMBLY

-

REMOVE NO. 4 INJECTION PIPE SUB-ASSEMBLY

-

REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

-

REMOVE FUEL INLET PIPE SUB-ASSEMBLY

-

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

-

REMOVE CAMSHAFT TIMING PULLEY

-

REMOVE NO. 2 TIMING BELT COVER

-

REMOVE ENGINE WATER PUMP ASSEMBLY

-

REMOVE VACUUM PUMP ASSEMBLY

-

REMOVE VANE PUMP ASSEMBLY

-

REMOVE CAMSHAFT POSITION SENSOR

-

REMOVE CRANKSHAFT POSITION SENSOR

-

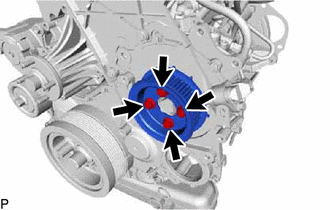

REMOVE PUMP DRIVE SHAFT PULLEY

-

Remove the 4 bolts, No. 2 camshaft timing pulley flange and pump drive shaft pulley from the timing gear cover.

-

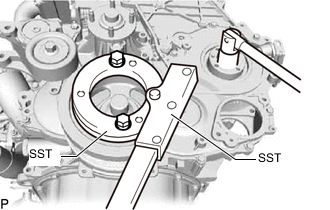

Using SST, hold the crankshaft pulley and remove the nut and O-ring.

- SST

- 09213-58014 ( 91551-80840 )

- 09330-00021

-

-

REMOVE CRANKSHAFT PULLEY SUB-ASSEMBLY

-

REMOVE TIMING GEAR COVER

-

REMOVE INJECTION GEAR

-

REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

-

REMOVE CRANKSHAFT TIMING GEAR

-

REMOVE IDLE GEAR THRUST PLATE

-

REMOVE NO. 1 IDLE GEAR

-

REMOVE NO. 1 IDLE GEAR SHAFT

-

REMOVE FUEL SUPPLY PUMP ASSEMBLY

-

REMOVE OIL PAN SUB-ASSEMBLY

-

REMOVE OIL STRAINER SUB-ASSEMBLY

-

REMOVE TIMING GEAR CASE ASSEMBLY