ECD SYSTEM (w/o EGR Cooler), Diagnostic DTC:P0335, P0339

| DTC Code | DTC Name |

|---|---|

| P0335 | Crankshaft Position Sensor "A" Circuit |

| P0339 | Crankshaft Position Sensor "A" Circuit Intermittent |

DESCRIPTION

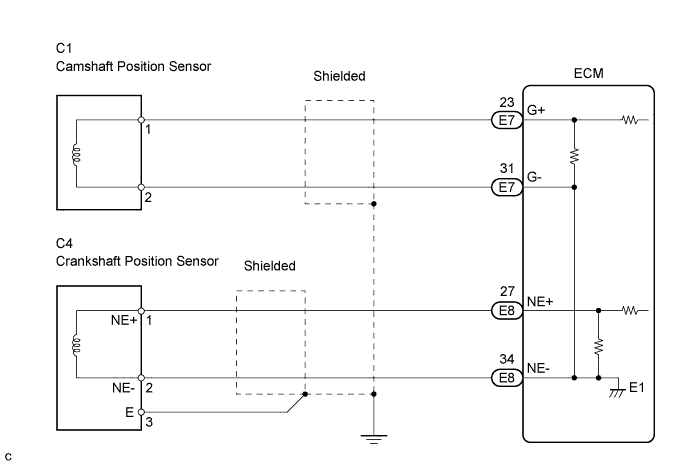

The crankshaft position sensor system consists of a crankshaft position sensor plate and pickup coil. The sensor plate has 34 teeth and is installed on the crankshaft. The pickup coil is made of wound copper wire, an iron core and magnet. The sensor plate rotates, and a pulse signal is created as each tooth passes by the pickup coil. The pickup coil generates 34 signals for each revolution. Based on these signals, the ECM calculates the crankshaft position and engine speed. Using these calculations, the common rail injection system is controlled.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0335 | When either condition below is met:

|

|

| P0339 | No crankshaft position sensor signal to ECM is input for 0.05 seconds or more, and conditions (a), (b) and (c) are met (1 trip detection logic):

|

|

WIRING DIAGRAM

INSPECTION PROCEDURE

Tech Tips

After performing the inspection procedure for the crankshaft position sensor, if DTC P0335 is output again, check the following items related to the camshaft position sensor.

-

Installation condition of the camshaft position sensor

-

Installation condition of the camshaft

-

Connection of the camshaft position sensor connector

Tech Tips

-

If no trouble is found in the diagnostic troubleshooting procedure of DTC P0335, troubleshoot the engine mechanical system.

-

Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, and other data from the time the malfunction occurred.

Note

If the ECM is replaced, the new ECM needs initialization Click here.

PROCEDURE

-

INSPECT CRANKSHAFT POSITION SENSOR (RESISTANCE)

-

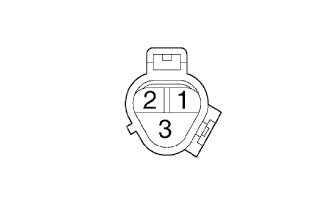

Disconnect the C4 sensor connector.

-

Measure the resistance of the sensor.

Standard resistance Tester Connection Condition Specified Condition 1 - 2 Cold 1,630 to 2,740 Ω 1 - 2 Hot 2,065 to 3,225 Ω Note

In the chart above, the terms "cold" and "hot" refer to the temperature of the sensor. "Cold" means approximately -10 to 50°C (14 to 122°F). "Hot" means approximately 50 to 100°C (122 to 212°F).

Tech Tips

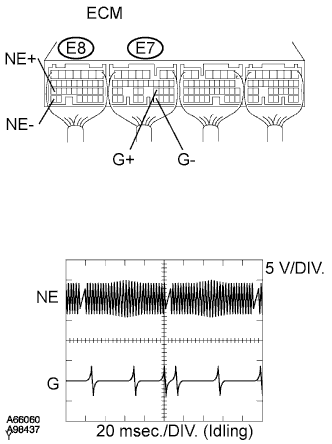

While cranking or idling the engine, check the waveform of the ECM connectors using an oscilloscope.

Reference Tester Connection Specified Condition E7-23 (G+) - E7-31 (G-)

E8-27 (NE+) - E8-34 (NE-)

Correct waveform is shown Tool Setting Condition 5 V/DIV., 20 msec./DIV. Idling with warm engine Tech Tips

The waveform varies depending on the engine speed.

NG

REPLACE CRANKSHAFT POSITION SENSOR

OK

-

-

CHECK WIRE HARNESS (CRANKSHAFT POSITION SENSOR - ECM)

-

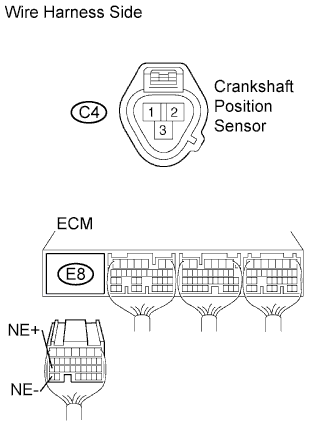

Disconnect the C4 sensor connector.

-

Disconnect the E8 ECM connector.

-

Measure the resistance of the wire harness side connectors.

Standard resistance Tester Connection Specified Condition C4-1 - E8-27 (NE+) Below 1 Ω C4-2 - E8-34 (NE-) Below 1 Ω C4-1 or E8-27 (NE+) - Body ground 10 kΩ or higher C4-2 or E8-34 (NE-) - Body ground 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS AND CONNECTOR

OK

-

-

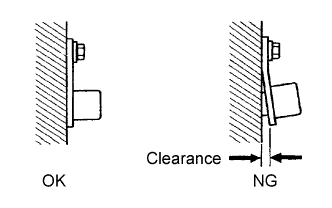

CHECK SENSOR INSTALLATION (CRANKSHAFT POSITION SENSOR)

-

Check the sensor installation.

OK Sensor is installed correctly.

NG

SECURELY REINSTALL SENSOR

OK

-

-

CHECK NO. 1 CRANKSHAFT POSITION SENSOR PLATE

-

Check the teeth of the crankshaft position sensor No. 1 plate.

OK Plate's teeth do not have any cracks or deformation.

NG

REPLACE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

OK

REPLACE ECM Click here

-