HYBRID CONTROL SYSTEM, Diagnostic DTC:P3004-800, P3004-801

Info Added 2017-08-02 ![]()

| DTC Code | DTC Name |

|---|---|

| P3004-800 | High Voltage Power Resource |

| P3004-801 | High Voltage Power Resource |

DESCRIPTION

Refer to the description for DTC P0AE6-225 Click here.

| DTC No. | INF Code | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| P3004 | 800 | Excessive overcurrent occurs during precharge (time from when SMRP turns on until when SMRG turns on). |

|

| 801 | Minimal overcurrent occurs during precharge (time from when SMRP turns on until when SMRG turns on). |

WIRING DIAGRAM

-

Refer to the wiring diagram for DTC P0A08-264 Click here.

-

Refer to the wiring diagram for DTC P0AA6-526 Click here.

-

Refer to the wiring diagram for DTC P0AE6-225 Click here.

CAUTION / NOTICE / HINT

CAUTION:

-

Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with converter assembly, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work Click here.

Tech Tips

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

Note

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work Click here.

PROCEDURE

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check for DTCs.

Result Result Proceed to P3004-800 or P3004-801 only is output, or DTCs except the ones in the tables below are also output. A Any of the following DTCs in table 1 below are also output. B Any of the following DTCs in table 2 below are also output. C Table 1 DTC No. Relevant Diagnosis P0A09-265 DC/DC Converter Status Circuit Low Input P0A10-263 DC/DC Converter Status Circuit High Input Table 2 DTC No. Relevant Diagnosis P0ABF-123 Hybrid Battery Pack Current Sensor Circuit P0AC0-123 Hybrid Battery Pack Current Sensor Circuit Range / Performance P0AC1-123 Hybrid Battery Pack Current Sensor Circuit Low P0AC2-123 Hybrid Battery Pack Current Sensor Circuit High P0AFC-123 Hybrid Battery Pack Sensor Module P0B3D-123 Hybrid Battery Voltage Sensor "A" Circuit Low P0B42-123 Hybrid Battery Voltage Sensor "B" Circuit Low P0B47-123 Hybrid Battery Voltage Sensor "C" Circuit Low P0B4C-123 Hybrid Battery Voltage Sensor "D" Circuit Low P0B51-123 Hybrid Battery Voltage Sensor "E" Circuit Low P0B56-123 Hybrid Battery Voltage Sensor "F" Circuit Low P0B5B-123 Hybrid Battery Voltage Sensor "G" Circuit Low P0B60-123 Hybrid Battery Voltage Sensor "H" Circuit Low P0B65-123 Hybrid Battery Voltage Sensor "I" Circuit Low P0B6A-123 Hybrid Battery Voltage Sensor "J" Circuit Low P0B6F-123 Hybrid Battery Voltage Sensor "K" Circuit Low P0B74-123 Hybrid Battery Voltage Sensor "L" Circuit Low P0B79-123 Hybrid Battery Voltage Sensor "M" Circuit Low P0B7E-123 Hybrid Battery Voltage Sensor "N" Circuit Low P0B83-123 Hybrid Battery Voltage Sensor "O" Circuit Low P0B88-123 Hybrid Battery Voltage Sensor "P" Circuit Low P0B8D-123 Hybrid Battery Voltage Sensor "Q" Circuit Low P0B92-123 Hybrid Battery Voltage Sensor "R" Circuit Low P308A-123 Hybrid Battery Voltage Sensor All Circuits Low U029A-123 Lost Communication with Hybrid Battery Pack Sensor Module Tech Tips

P3004-800 or P3004-801 may be stored due to a malfunction which causes the DTCs in either preceding table to be stored. In this case, first troubleshoot the output DTCs in the preceding table. Then, perform a reproduction test to check that no DTCs are output.

-

Turn the power switch off.

B

GO TO DTC CHART (HYBRID CONTROL SYSTEM) Click here

C

GO TO DTC CHART (HYBRID BATTERY SYSTEM) Click here

A

-

-

CHECK CONNECTOR CONNECTION CONDITION (POWER MANAGEMENT CONTROL ECU CONNECTOR)

-

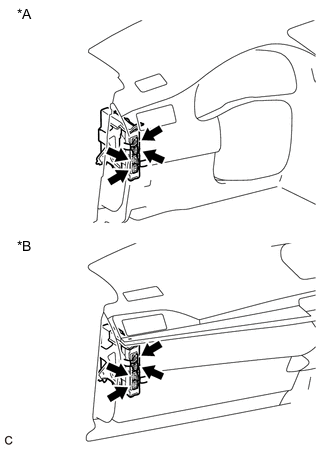

Text in Illustration *A for LHD *B for RHD Check the connector connections and contact pressure of the relevant terminals for the power management control ECU connectors Click here.

OK The connectors are connected securely and there are no contact pressure problems.

NG

CONNECT SECURELY

OK

-

-

CHECK COMPRESSOR WITH MOTOR ASSEMBLY

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

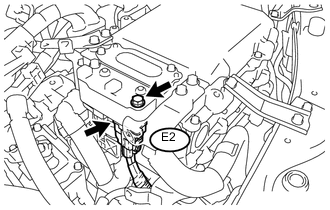

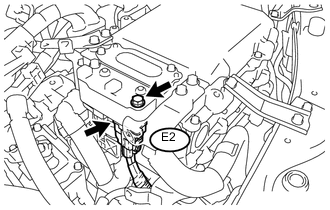

Disconnect the E2 inverter with converter assembly connector.

-

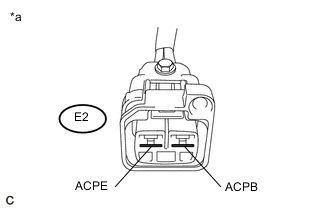

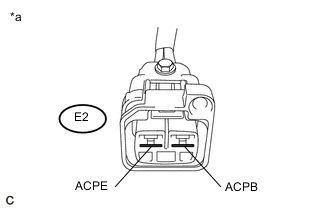

Text in Illustration *a Front view of No. 4 engine wire (Air Conditioning Harness) connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection

(Tester Probe Polarity)

Condition Specified Condition E2-1 (ACPE) (Negative probe) - E2-2 (ACPB) (Positive probe) Power switch off 100 kΩ or higher Note

-

Do not use a megohmmeter.

-

Read the resistance after the value has stabilized.

Tech Tips

The polarities of the tester probes may differ depending on the tester. Use the current output probe of the tester as the positive probe for this measurement. To determine the polarity, use another voltmeter to confirm the current output probe of the tester. When measuring the output of the tester, the voltmeter positive probe indicates the tester current output probe.

-

-

Reconnect the E2 inverter with converter assembly connector.

NG

CHECK NO. 4 ENGINE WIRE Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - POWER MANAGEMENT CONTROL ECU)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

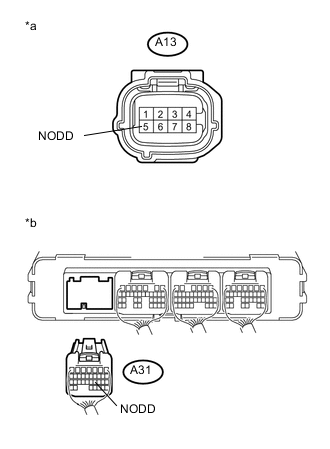

Disconnect the A13 inverter with converter assembly connector.

-

Disconnect the A31 power management control ECU connector.

-

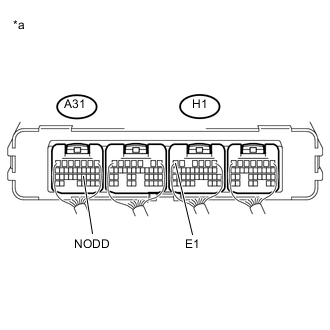

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

*b Rear view of wire harness connector

(to Power Management Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Condition Specified Condition A13-5 (NODD) - A31-21 (NODD) Power switch off Below 1 Ω Standard Resistance (Check for Short) Tester Connection Condition Specified Condition A13-5 (NODD) or A31-21 (NODD) - Body ground and other terminals Power switch off 10 kΩ or higher -

Reconnect the A31 power management control ECU connector.

-

Reconnect the A13 inverter with converter assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK POWER MANAGEMENT CONTROL ECU (NODD)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Connect the cable to the negative (-) auxiliary battery terminal.

-

Turn the power switch on (IG).

-

Text in Illustration *a Component with harness connected

(Power Management Control ECU)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A31-21 (NODD) - H1-6 (E1) Power switch on (IG) Less than 1.5 V -

Turn the power switch off.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

NG

REPLACE POWER MANAGEMENT CONTROL ECU Click here

OK

-

-

CHECK FRAME WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

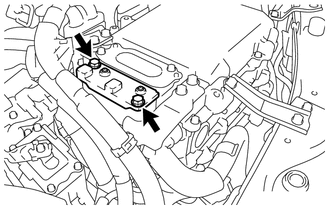

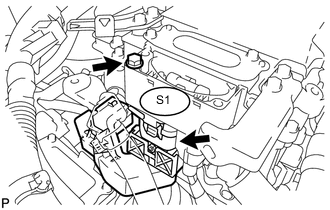

Remove the connector cover assembly from the inverter with converter assembly.

-

Disconnect the S1 inverter with converter assembly connector.

-

Remove the No. 4 hybrid battery shield panel Click here.

-

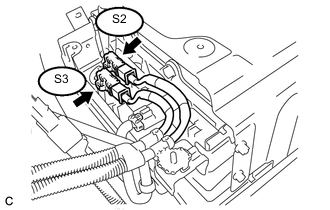

Measure the resistance according to the value(s) in the table below.

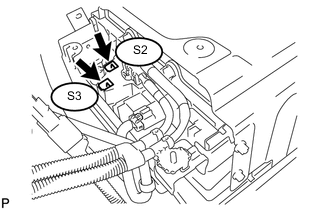

Standard Resistance Tester Connection Condition Specified Condition S2-1 (CBI) - S3-1 (CEI) Power switch off 10 kΩ or higher -

Install the No. 4 hybrid battery shield panel.

-

Reconnect the S1 inverter with converter assembly connector.

-

Install the connector cover assembly.

OK

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here

NG

CHECK HYBRID BATTERY JUNCTION BLOCK ASSEMBLY Click here

-

-

CHECK NO. 4 ENGINE WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the E2 inverter with converter assembly connector.

-

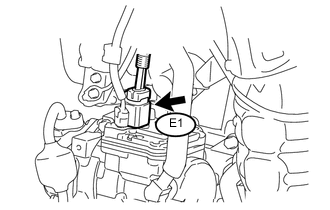

Disconnect the E1 compressor with motor assembly connector Click here.

-

Text in Illustration *a Front view of No. 4 engine wire (Air Conditioning Harness) connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition E2-1 (ACPE) - E2-2 (ACPB) Power switch off 10 kΩ or higher -

Reconnect the E1 compressor with motor assembly connector.

-

Reconnect the E2 inverter with converter assembly connector.

OK

REPLACE COMPRESSOR WITH MOTOR ASSEMBLY Click here

NG

REPLACE NO. 4 ENGINE WIRE

-

-

CHECK HYBRID BATTERY JUNCTION BLOCK ASSEMBLY

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

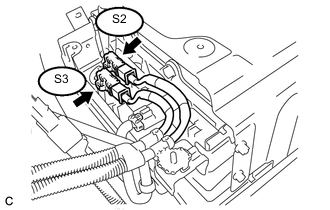

-

Remove the No. 4 hybrid battery shield panel Click here.

-

Disconnect the S2 and S3 hybrid battery junction block assembly connectors.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition S3-1 (CEI) - S2-1 (CBI) Power switch off 10 kΩ or higher -

Reconnect the S2 and S3 hybrid battery junction block assembly connectors.

-

Install the No. 4 hybrid battery shield panel.

OK

REPLACE FRAME WIRE Click here

NG

REPLACE HYBRID BATTERY JUNCTION BLOCK ASSEMBLY Click here

-