СИСТЕМА МЕХАНИЧЕСКОЙ ТРАНСМИССИИ "MULTIMODE", Diagnostic DTC:P0910

| DTC Code | DTC Name |

|---|---|

| P0910 | Gate Select Actuator Circuit |

DESCRIPTION

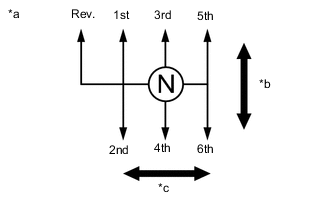

| *a | Shift and Select Actuator Operation |

| *b | Shift Direction |

| *c | Select Direction |

The shift and select actuator is operated by the TCM and changes the transaxle gear by moving the shift and select lever shaft. An electric motor (select motor) moves the shift and select lever shaft in the select direction, and the select stroke sensor, which is mounted on the shift and select actuator assembly, detects the select position. The TCM monitors the electrical current and select motor output terminal voltage, and detects malfunctions in the select motor circuit.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Warning Indicate | Memory |

|---|---|---|---|---|---|---|

| P0910 | Gate Select Actuator Circuit | The TCM detects the following conditions: (1-trip detection logic)

The TCM detects the following conditions: (1-trip detection logic)

The TCM detects the following conditions: (1-trip detection logic)

|

|

Does not come on | Comes on | DTC stored |

-

*1: A short between the select motor circuit and the body ground is suspected.

-

*2: A short between the select motor circuit and the +B circuit is suspected.

-

*3: An open in the select motor circuit is suspected. When the motor current does not flow to the ECU terminals despite the ECU ordering the select motor to operate, the ECU stores this DTC.

-

*4: An open in the select motor circuit is suspected. When the difference is more than the threshold despite the ECU not ordering the select motor to operate, the ECU stores this DTC.

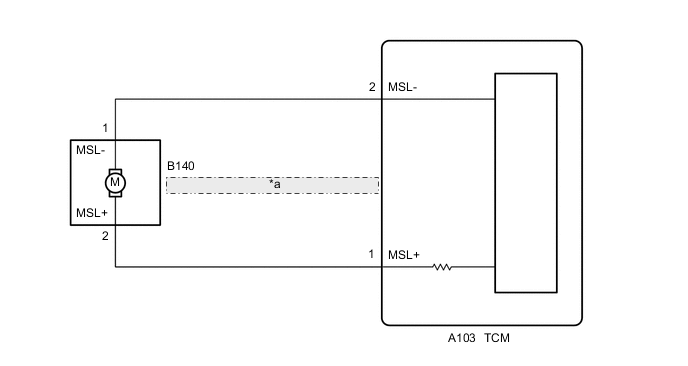

WIRING DIAGRAM

| *a | Shift and Select Actuator Assembly (Select Motor) |

CAUTION / NOTICE / HINT

Note

When installing parts related to the multi-mode manual transaxle system, perform the initialization and learning and synchronization position calibration procedures. In addition, the required operations differ according to the parts to be installed. Proceed with the operation in the order shown in the table below.

| Part Installed | Operation Order | See Procedure |

|---|---|---|

|

1. Initialization and learning of multi-mode manual transaxle system | |

| 2. Synchronization position calibration | ||

|

1. Initialization and learning of multi-mode manual transaxle system |

If the sensor or actuator is installed without the initialization and learning procedures, it may cause driving performance degradation or system component breakage.

PROCEDURE

-

INSPECT TCM (MSL TERMINAL VOLTAGE)

Result Proceed to OK NG

-

Turn the ignition switch to ON.

-

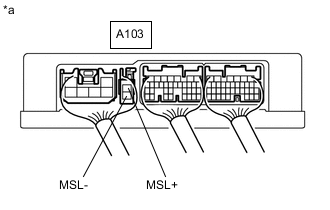

*a Component with harness connected

(TCM)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A103-1 (MSL+) - Body ground Ignition switch ON 4.0 to 7.0 V A103-2 (MSL-) - Body ground Ignition switch ON 4.0 to 7.0 V -

Turn the ignition switch off.

Result Proceed to OK NG

OK

CHECK INTERMITTENT PROBLEMS Click here

NG

-

-

CHECK TERMINAL CONDITION (TCM)

Result Proceed to OK NG

-

Disconnect the TCM connector.

-

Check the connections of the TCM connector.

OK The TCM and wire harness connectors and connector terminals are connected securely and are not bent, rusted, or damaged. Result Proceed to OK NG

NG

CONNECT CORRECTLY

OK

-

-

INSPECT SELECT MOTOR CIRCUIT

Result Proceed to OK NG

-

Disconnect the TCM connector.

-

*a Front view of wire harness connector

(to TCM)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A103-1 (MSL+) - A103-2 (MSL-) Always Below 10 Ω A103-1 (MSL+) - Body ground Always 10 kΩ or higher A103-2 (MSL-) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

NG

CHECK TERMINAL CONDITION (SELECT MOTOR) Click here

OK

-

-

REPLACE TCM

-

Replace the TCM.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-

-

CHECK TERMINAL CONDITION (SELECT MOTOR)

Result Proceed to OK NG

-

Disconnect the select motor connector.

-

Check the connections of the select motor connector.

OK The select motor and wire harness connectors and connector terminals are connected securely and are not bent, rusted, or damaged. Result Proceed to OK NG

NG

CONNECT CORRECTLY

OK

-

-

CHECK HARNESS AND CONNECTOR (TCM - SELECT MOTOR)

Result Proceed to OK NG

-

Disconnect the TCM connector.

-

Disconnect the select motor connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A103-1 (MSL+) - B140-2 (MSL+) Always Below 1 Ω A103-2 (MSL-) - B140-1 (MSL-) Always Below 1 Ω A103-1 (MSL+) or B140-2 (MSL+) - Body ground Always 10 kΩ or higher A103-2 (MSL-) or B140-1 (MSL-) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT SHIFT AND SELECT ACTUATOR ASSEMBLY (SELECT MOTOR)

Result Proceed to OK NG

-

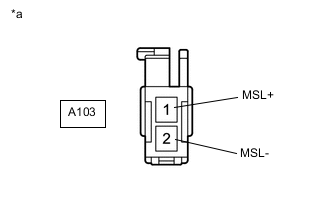

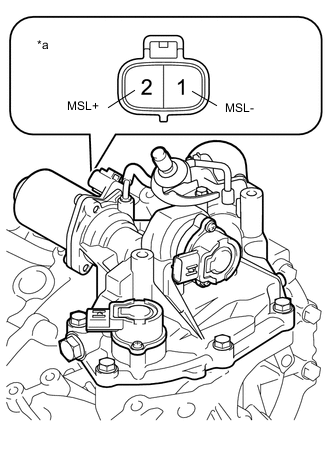

*a Component without harness connected

(Shift and Select Actuator Assembly (Select Motor))

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 (MSL-) - 2 (MSL+) Always Below 10 Ω 1 (MSL-) - Body ground Always 10 kΩ or higher 2 (MSL+) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

OK

CHECK INTERMITTENT PROBLEMS Click here

NG

-

-

REPLACE SHIFT AND SELECT ACTUATOR ASSEMBLY

-

Replace the shift and select actuator assembly.

Result Proceed to NEXT

NEXT

PERFORM INITIALIZATION Click here

-