ГОЛОВКА БЛОКА ЦИЛИНДРОВ СНЯТИЕ

-

REMOVE AUTOMATIC TRANSMISSION ASSEMBLY

-

REMOVE TIMING CHAIN COVER SUB-ASSEMBLY

-

REMOVE INTAKE MANIFOLD

-

REMOVE EXHAUST MANIFOLD

-

SET NO. 1 CYLINDER TO TDC/COMPRESSION

-

Temporarily install the crankshaft pulley bolt.

-

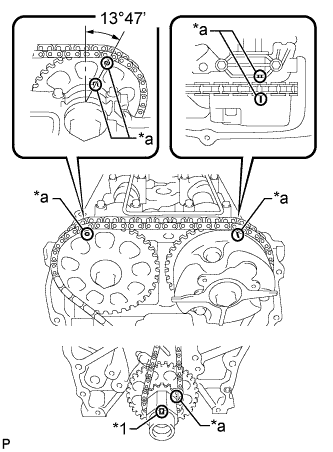

Text in Illustration *1 Key *a Timing Mark Rotate the crankshaft clockwise so that the timing marks on the crankshaft timing gear and camshaft timing gears are as shown in the illustration.

Tech Tips

If the timing marks do not align, rotate the crankshaft clockwise again and align the timing marks.

-

-

REMOVE TIMING CHAIN GUIDE

-

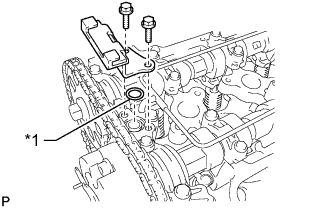

Text in Illustration *1 O-Ring Remove the 2 bolts, timing chain guide and O-ring.

-

-

REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

Note

-

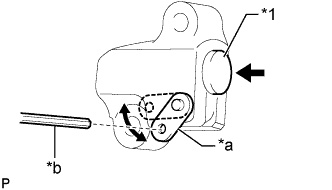

When the No. 1 chain tensioner assembly is removed, do not rotate the crankshaft.

-

When the chain is removed and the camshaft needs to be rotated, rotate the crankshaft 90° to the right.

-

Text in Illustration *1 Plunger *a Stopper Plate *b Hexagon Wrench Move the stopper plate upward to release the lock and push the plunger deep into the tensioner.

-

Move the stopper plate downward to set the lock and insert a hexagon wrench into the stopper plate hole.

-

Remove the bolt, nut, No. 1 chain tensioner assembly and gasket.

-

-

REMOVE CHAIN TENSIONER SLIPPER

-

Remove the bolt and chain tensioner slipper.

-

-

REMOVE NO. 1 CHAIN VIBRATION DAMPER

-

Remove the 2 bolts and No. 1 chain vibration damper.

-

-

REMOVE CHAIN SUB-ASSEMBLY

-

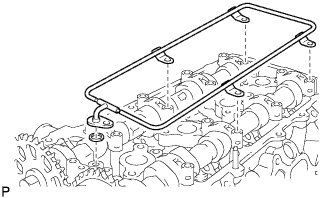

REMOVE CAMSHAFT BEARING CAP

-

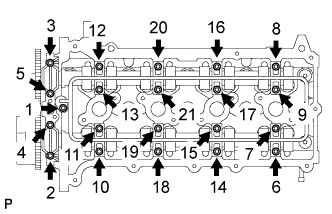

Uniformly loosen and remove the 21 bearing cap bolts in the sequence shown in the illustration.

Note

Uniformly loosen the bolts while keeping the camshafts level.

-

Remove the oil delivery pipe and O-ring from the bearing caps.

-

Remove the 9 bearing caps.

Tech Tips

Arrange the removed parts in the correct order.

-

-

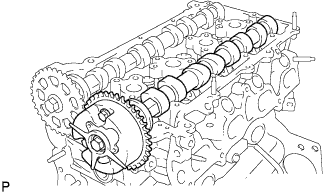

REMOVE CAMSHAFT

-

Remove the camshaft.

-

-

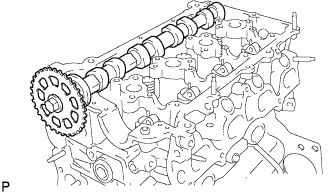

REMOVE NO. 2 CAMSHAFT

-

Remove the No.2 camshaft.

-

-

REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

-

Remove the 16 No. 1 valve rocker arm sub-assemblies from the cylinder head sub-assembly.

Tech Tips

Arrange the removed parts in the correct order.

-

-

REMOVE VALVE LASH ADJUSTER ASSEMBLY

-

Remove the 16 valve lash adjuster assemblies from the cylinder head sub-assembly.

Tech Tips

Arrange the removed parts in the correct order.

-

-

REMOVE VALVE STEM CAP

-

Remove the 16 valve stem caps from the cylinder head sub-assembly.

Tech Tips

Arrange the removed parts in the correct order.

-

-

REMOVE CYLINDER HEAD SUB-ASSEMBLY

-

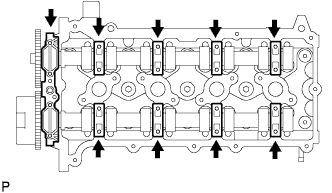

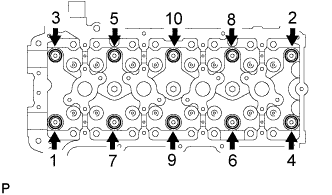

Uniformly loosen the 10 bolts in the sequence shown in the illustration. Remove the 10 cylinder head set bolts and plate washers.

Note

-

Be careful not to drop plate washers into the cylinder head sub-assembly.

-

Head warpage or cracking could result from removing bolts in incorrect order.

-

-

Remove the cylinder head sub-assembly.

-

-

REMOVE CYLINDER HEAD GASKET

-

INSPECT CYLINDER HEAD SET BOLT

-

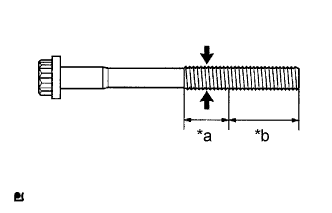

Text in Illustration *a Measuring area *b Distance Using a vernier caliper, measure the diameter of the most elongated threads in the measuring area.

Standard outside diameter 10.76 to 10.97 mm (0.424 to 0.432 in.) Minimum outside diameter 10.40 mm (0.409 in.) Distance 30 mm (1.18 in.) If a visual check reveals no excessively thin areas, check the center of the measuring area (see illustration) and find the area that has the smallest diameter.

If the diameter is less than the minimum, replace the cylinder head set bolt.

-

-

INSPECT CYLINDER HEAD SUB-ASSEMBLY

-

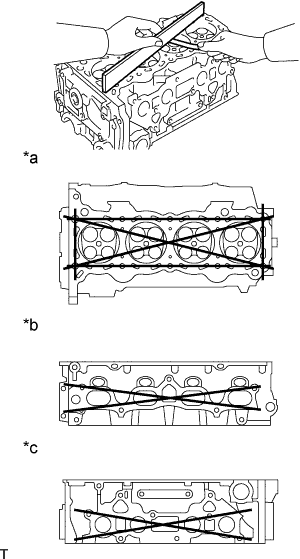

Text in Illustration *a Cylinder Head Lower Side *b Intake Manifold Side *c Exhaust Manifold Side Using a precision straightedge and feeler gauge, measure the warpage of the contact surface of the cylinder block and manifolds.

Maximum warpage 0.05 mm (0.00197 in.) If the warpage is more than the maximum, replace the cylinder head sub-assembly.

-

Using a dye penetrant, check the intake ports, exhaust ports and cylinder surface for cracks.

If cracked, replace the cylinder head sub-assembly.

-