ENGINE ASSEMBLY REMOVAL

CAUTION:

As the engine assembly with transmission is extremely heavy, the engine lifter may suddenly drop if the instructions listed in the repair manual are not followed. Therefore, always follow the instructions listed in the repair manual when performing this procedure.

-

DISCHARGE FUEL SYSTEM PRESSURE

-

PRECAUTION

Note

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work Click here.

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

REMOVE NO. 1 ENGINE UNDER COVER

-

Remove the 4 bolts and No. 1 engine under cover.

-

-

DRAIN ENGINE COOLANT

CAUTION:

Do not remove the radiator reservoir cap sub-assembly while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Tech Tips

Collect the engine coolant in a container and dispose of it according to the local regulations.

-

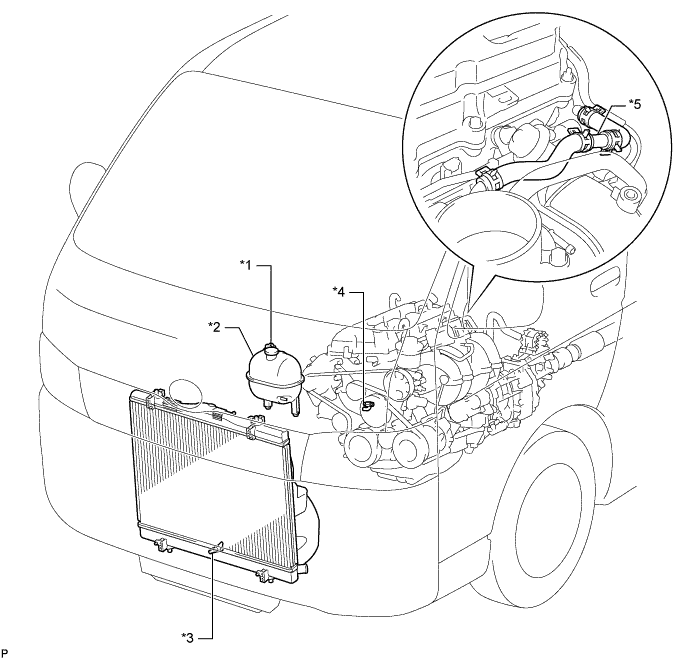

Loosen the radiator drain cock plug and drain the engine coolant.

Text in Illustration *1 Radiator Reservoir Cap Sub-assembly *2 Radiator Reservoir Assembly *3 Radiator Drain Cock Plug *4 Cylinder Block Water Drain Cock Plug *5 2-Way - - -

Remove the radiator reservoir cap sub-assembly.

-

Loosen the cylinder block water drain cock plug and drain the engine coolant from the engine.

-

-

DRAIN ENGINE OIL

-

Remove the oil filler cap.

-

Remove the oil pan drain plug and gasket, and then drain the engine oil into a container.

Note

Collect the oil in a disposable oil container.

-

Clean the oil pan drain plug and install it with a new gasket.

- Torque:

- 38 N*m { 382 kgf*cm, 28 ft.*lbf }

-

-

REMOVE FRONT SEAT ASSEMBLY RH

-

REMOVE FRONT DOOR SCUFF PLATE

-

REMOVE ENGINE SERVICE HOLE SUB COVER SUB-ASSEMBLY

-

Roll up the carpet, and remove the 5 bolts and engine service hole sub cover sub-assembly.

-

-

REMOVE FAN AND GENERATOR V BELT

-

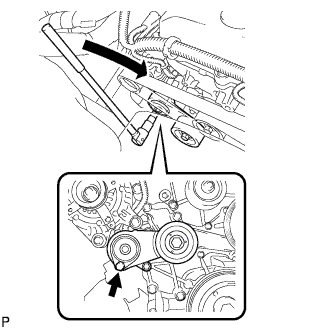

Use the hexagon-shaped part indicated by the arrow in the illustration to move the tensioner pulley downward and decrease the tension in the drive belt. Then remove the drive belt.

Note

When removing the drive belt, do not use the idle pulley's bolt.

Tech Tips

After removing the drive belt, move the tensioner upward to the maximum amount.

-

-

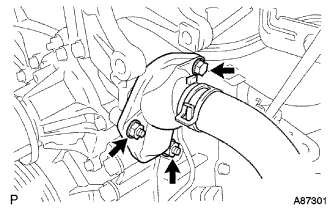

DISCONNECT NO. 4 RADIATOR HOSE

-

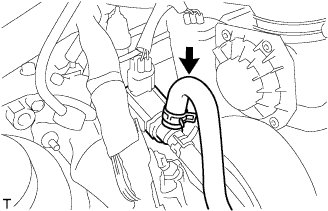

Slide the clamp and disconnect the No. 4 radiator hose from the engine.

-

-

DISCONNECT NO. 2 RADIATOR HOSE

-

Slide the clamp and disconnect the No. 2 radiator hose from the No. 1 radiator pipe.

-

-

DISCONNECT INLET HEATER WATER HOSE A

-

Slide the clamp and disconnect the inlet heater water hose A from the heater unit.

-

-

DISCONNECT OUTLET HEATER WATER HOSE B

-

Slide the clamp and disconnect the outlet heater water hose B from the heater unit.

-

-

DISCONNECT FUEL VAPOR FEED HOSE ASSEMBLY

-

Slide the clamp and disconnect the fuel vapor feed hose from the purge VSV.

-

-

DISCONNECT UNION TO CONNECTOR TUBE HOSE

-

Slide the clamp and disconnect the union to connector tube hose from the intake manifold.

-

-

REMOVE INTAKE AIR CONNECTOR

-

Slide the clamp and disconnect the No. 2 PCV hose from the cylinder head cover sub-assembly.

-

Disconnect the vacuum hose from the intake air connector.

-

Loosen the 2 hose clamps.

-

Remove the 2 bolts and intake air connector.

-

-

DISCONNECT NO. 5 AIR HOSE

-

Slide the clamp and disconnect the No. 5 air hose from the air switching valve assembly.

-

-

DISCONNECT NO. 1 FUEL HOSE

-

Connect the No. 1 fuel hose to the fuel pressure pulsation damper assembly Click here.

-

-

DISCONNECT NO. 2 FUEL HOSE

-

Disconnect the No. 2 fuel hose from the fuel delivery pipe sub-assembly Click here.

-

-

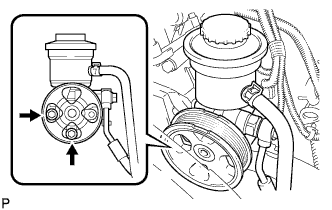

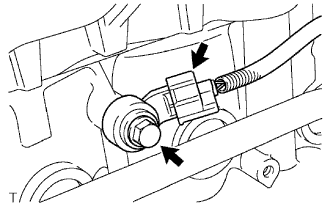

DISCONNECT VANE PUMP ASSEMBLY

-

Disconnect the oil pressure switch connector.

-

Remove the 2 bolts and disconnect the vane pump assembly from the engine.

-

Support the vane pump assembly securely.

-

-

REMOVE ENGINE OIL LEVEL DIPSTICK

-

REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

-

Remove the bolt, engine oil level dipstick guide and O-ring.

-

-

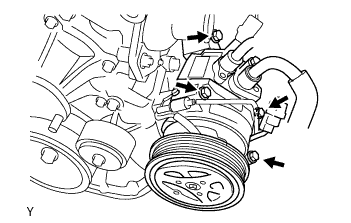

DISCONNECT COMPRESSOR AND MAGNETIC CLUTCH

-

Disconnect the compressor and magnetic clutch connector.

-

Remove the 4 bolts and disconnect the compressor and magnetic clutch from the engine.

Tech Tips

Disconnect the compressor and magnetic clutch with the No. 1 cooler refrigerant suction hose and No. 1 cooler refrigerant discharge hose stuck by suspended from the rope.

-

Support the compressor and magnetic clutch securely.

-

-

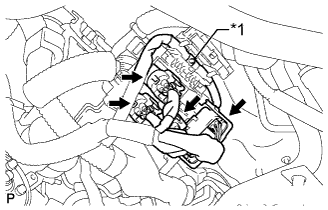

DISCONNECT ENGINE WIRE

-

Disconnect the wire harness support of the ECM.

-

Disconnect the connectors of the ECM.

-

Disconnect the clamps of the engine wire and ground cable.

-

Disconnect the starter connector Click here.

-

Disconnect the generator connector Click here.

-

Text in Illustration *1 Nut Remove the nut and disconnect the 4 connectors from the engine room junction block.

-

-

REMOVE FRONT EXHAUST PIPE ASSEMBLY

-

REMOVE PROPELLER SHAFT ASSEMBLY

-

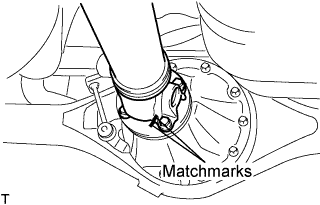

Put matchmarks on both flanges.

-

Remove the 4 nuts, bolts and washers.

Tech Tips

If the flange connection is hard to separate, temporarily tighten one nut only and evenly tap the flange with a brass bar and hammer to separate the propeller shaft assembly from the differential companion flange.

-

Remove the propeller shaft assembly.

-

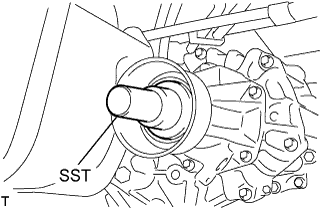

Insert SST in the transmission to prevent oil leakage.

Note

Do not damage the oil seal.

-

Use the following SST for the automatic transmission

- SST

- 09325-40010

-

Use the following SST for the manual transmission

- SST

- 09325-20010

-

-

-

REMOVE FRONT SPEED SENSOR LH

-

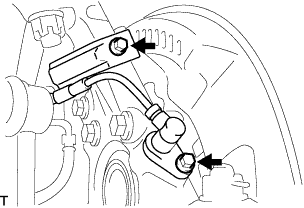

Remove the 2 bolts, and separate the speed sensor from the steering knuckle.

Note

-

Be careful not to damage the speed sensor.

-

Prevent foreign matter from adhering to the speed sensor.

-

-

-

REMOVE FRONT SPEED SENSOR RH

Tech Tips

Use the same procedure described for the LH side.

-

REMOVE FRONT DISC BRAKE CALIPER ASSEMBLY LH

-

Remove the 2 bolts, and disconnect the brake caliper assembly.

Note

Use a wire or an equivalent to keep the brake caliper from hanging down by the flexible hose.

-

-

REMOVE FRONT DISC BRAKE CALIPER ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

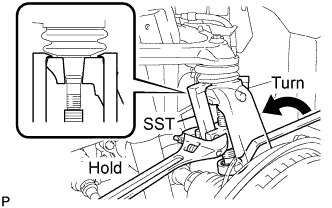

SEPARATE FRONT SUSPENSION SUB-ASSEMBLY UPPER LH

-

Remove the cotter pin and loosen the nut.

- SST

- 09628-62011

Note

Do not remove the nut.

-

Using SST, separate the steering knuckle from the suspension upper arm and remove the nut.

Note

-

Fix the steering knuckle with a wire so that the flexible hose does not receive excessive force.

-

Do not damage the ball joint dust cover.

-

-

-

SEPARATE FRONT SUSPENSION SUB-ASSEMBLY UPPER RH

Tech Tips

Use the same procedure described for the LH side.

-

SEPARATE FRONT SHOCK ABSORBER ASSEMBLY LH

-

Remove the bolt and separate the front shock absorber from the front suspension lower arm.

-

-

SEPARATE FRONT SHOCK ABSORBER ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

REMOVE TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY

-

Remove the 2 bolts and transmission oil filler tube sub-assembly.

-

Remove the O-ring from the transmission oil filler tube sub-assembly.

-

-

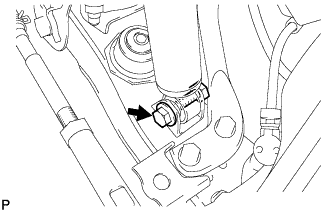

DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

-

Remove the nut and disconnect the transmission control cable assembly from the transmission control shaft lever LH.

-

Remove the clip and disconnect the transmission control cable assembly from the transmission control cable bracket.

-

-

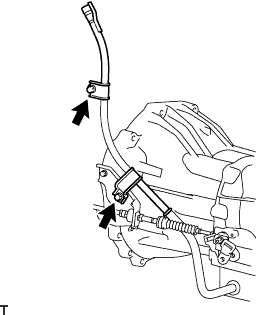

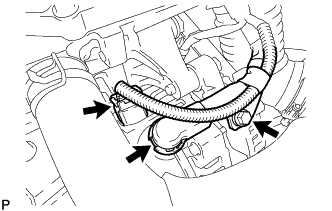

DISCONNECT OIL COOLER HOSE

-

Slide the 2 clamps and disconnect the inlet oil cooler hose and outlet oil cooler hose from the oil cooler tube.

-

-

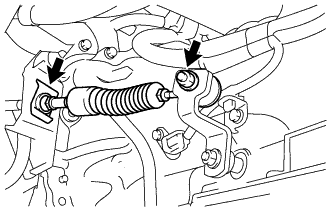

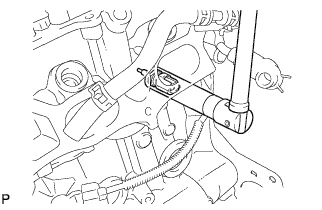

SEPARATE STEERING TORQUE SHAFT ASSEMBLY

-

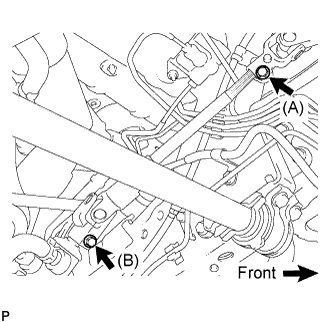

Loosen bolt (A) and remove bolt (B), then slide the steering torque shaft assembly.

Tech Tips

-

Do not remove bolt (A).

-

Do not disconnect the steering torque shaft assembly from the power steering link assembly.

-

-

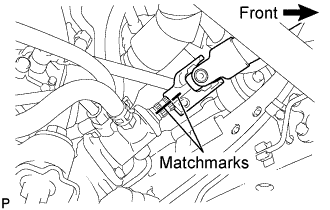

Put matchmarks on the steering torque shaft assembly and the power steering link assembly.

-

Separate the steering torque shaft assembly from the power steering link assembly.

-

-

INSTALL ENGINE HANGER

-

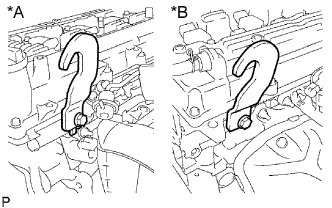

Text in Illustration *A LH Side *B RH Side Install the 2 engine hangers with the 2 bolts.

- Torque:

- 42 N*m { 428 kgf*cm, 31 ft.*lbf }

Tech Tips

Engine Hangers 12281-75040 Bolt 91552-A1020 Note

Use new 2 bolts for the 2 engine hangers.

-

-

REMOVE ENGINE ASSEMBLY WITH TRANSMISSION

-

Using the engine lifter, hold the engine assembly and separate the rear engine mount.

Note

-

Place wooden blocks or plate lift attachments so that the engine is level.

-

With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

-

Never install attachments to the oil pan of the engine assembly or transmission as doing so may deform the oil pan.

-

-

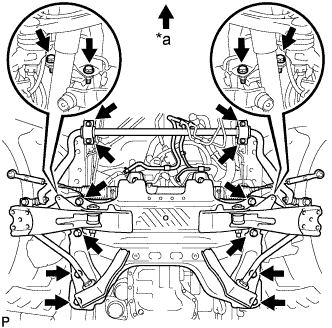

Text in Illustration *a Front Side Remove the stabilizer brackets and 16 bolts of the front suspension crossmember.

-

Operate the engine lifter, and then slowly remove the engine from the vehicle.

Note

-

Make sure the engine is clear of all wiring and hoses.

-

While lowering the engine from the vehicle, do not allow it to contact the vehicle.

-

-

Attach an engine sling device and hang the engine with a chain block.

Note

Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

-

-

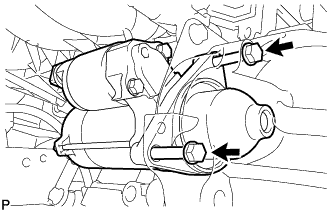

REMOVE STARTER ASSEMBLY

-

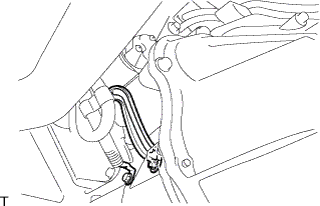

Detach the wire harness clamp from the wire harness bracket.

-

Remove the bolt and wire harness bracket.

-

Remove the bolt and disconnect the wire harness.

-

Disconnect the starter connector.

-

Remove the terminal cap.

-

Remove the nut and disconnect the wire harness.

-

Remove the 2 bolts and starter assembly.

-

-

REMOVE AUTOMATIC TRANSMISSION ASSEMBLY

-

FIX ENGINE ASSEMBLY

-

Using wooden blocks or plate lift attachments, set the engine on a flat surface.

Note

-

Place wooden blocks or plate lift attachments so that the engine is level.

-

Never install attachments to the oil pan of the engine assembly or transmission as doing so may deform the oil pan.

-

Perform this step while supporting the engine assembly using a sling device and chain block.

-

-

-

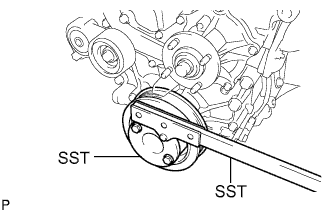

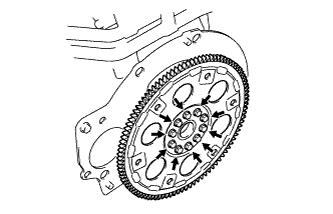

REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

-

Using SST, hold the crankshaft.

- SST

- 09213-54015 ( 91651-60855 )

- 09330-00021

-

Remove the 10 bolts, rear drive plate spacer, drive plate and ring gear sub-assembly and front drive plate spacer.

-

-

REMOVE REAR END PLATE

-

Remove the bolt and disconnect the No. 1 water by-pass pipe from rear end plate.

-

Remove the bolt and rear end plate.

-

-

REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

-

Hold the engine with the engine sling device and chain block.

-

Remove the 4 bolts from the engine mounting insulator.

-

Remove the engine assembly by operating the engine sling device and chain block.

-

-

REMOVE ENGINE WIRE

-

Remove the engine wire from the engine assembly.

-

-

INSTALL ENGINE TO ENGINE STAND

Note

-

Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

-

With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

-

Install the engine to an engine stand with the bolts.

-

Remove the 2 bolts and 2 engine hangers.

-

-

REMOVE PCV PIPE

-

Remove the bolt and PCV pipe.

-

-

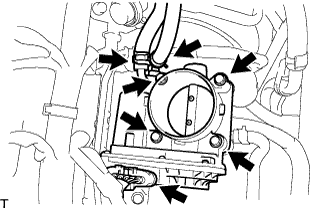

REMOVE THROTTLE WITH MOTOR BODY ASSEMBLY

-

Disconnect the throttle motor connector.

-

Slide the clamp and disconnect the water by-pass hose from the throttle body.

-

Slide the clamp and disconnect the No. 2 water by-pass hose from the throttle body.

-

Remove the 4 bolts and throttle body assembly.

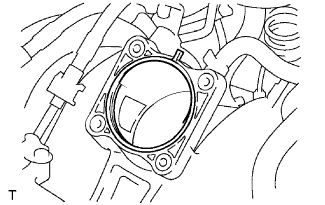

-

Remove the gasket from the intake manifold.

-

-

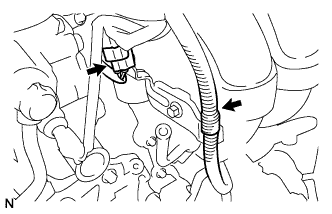

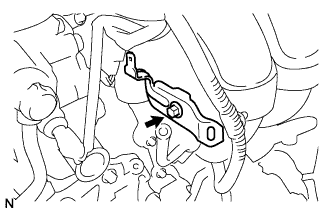

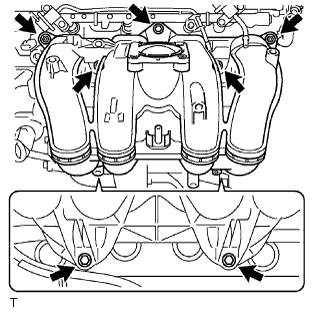

REMOVE INTAKE MANIFOLD

-

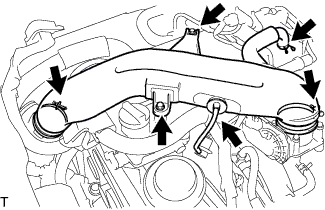

Disconnect the vacuum switching valve connector.

-

Slide the clamp and disconnect the purge line hose from the vacuum switching valve.

-

Detach the 2 wire harness clamps from the wire harness bracket.

-

Slide the clamp and disconnect the No. 3 PCV hose from the intake manifold.

-

Slide the clamp and disconnect the vacuum hose from the intake manifold.

-

Remove the bolt and wire harness bracket from the intake manifold.

-

Remove the 5 bolts, 2 nuts and intake manifold.

-

Remove the gasket from the intake manifold.

-

-

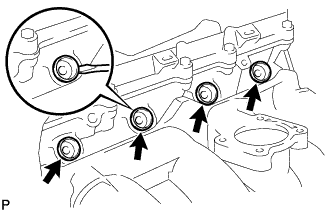

REMOVE IGNITION COIL ASSEMBLY

-

Remove the 4 bolts and 4 ignition coil assemblies.

-

-

REMOVE SPARK PLUG

-

Using a 16 mm spark plug wrench, remove the 4 spark plugs.

-

-

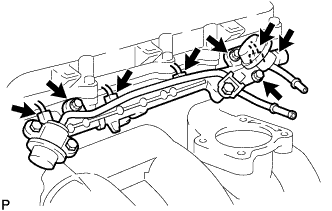

REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

Note

Be careful not to drop the fuel injector assemblies when removing the fuel delivery pipe sub-assembly.

-

Disconnect the vacuum hose from the fuel pressure regulator assembly.

-

Slide the clamp and disconnect the No. 2 fuel hose from the fuel pressure regulator assembly.

-

Disconnect the 4 fuel injector connectors.

-

Remove the 2 bolts, fuel pressure pulsation damper assembly and O-ring.

-

Remove the 2 bolts and fuel delivery pipe sub-assembly together with the 4 fuel injector assemblies.

Note

Be careful not to drop the fuel injector assemblies when removing the fuel delivery pipe sub-assembly.

-

Remove the 2 No. 1 delivery pipe spacers from the cylinder head sub-assembly.

-

Remove the 4 injector vibration insulators.

-

Using a screwdriver, pry out the 4 injector spacers and 4 O-rings from the cylinder head sub-assembly.

-

-

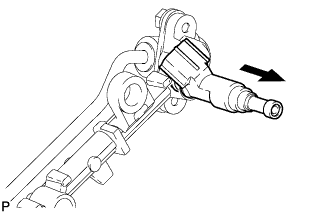

REMOVE FUEL INJECTOR ASSEMBLY

-

Pull out the 4 fuel injector assemblies from the fuel delivery pipe sub-assembly.

Text in Illustration

Pull Out -

Remove the O-rings from the fuel injector assemblies.

-

-

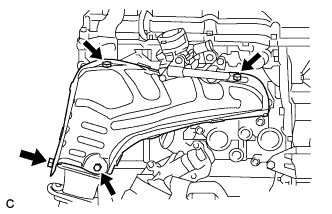

REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

-

Remove the 4 bolts and No. 1 exhaust manifold heat insulator.

-

-

REMOVE NO. 4 INTAKE PIPE

-

Remove the 4 nuts and No. 4 intake pipe.

-

Remove the 2 gaskets.

-

-

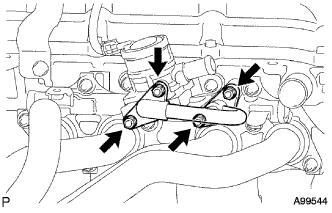

REMOVE AIR SWITCHING VALVE ASSEMBLY

-

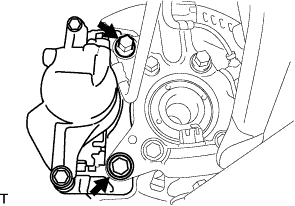

Disconnect the air switching valve connector.

-

Remove the 2 nuts and air switching valve assembly.

-

-

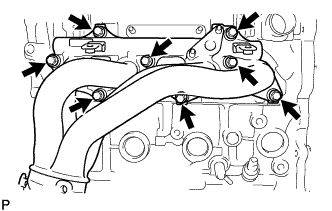

REMOVE EXHAUST MANIFOLD

-

Remove the 8 nuts, exhaust manifold and gasket.

-

-

REMOVE FAN PULLEY

-

Remove the 4 nuts, fan pulley and fan spacer.

-

-

REMOVE NO. 1 WATER BY-PASS PIPE

-

Remove the bolt, 2 nuts, water by-pass pipe and gasket.

-

-

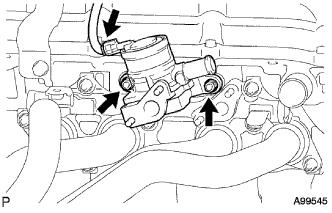

REMOVE WATER INLET

-

Remove the 2 nuts and bolt and disconnect the water inlet.

-

Remove the gasket.

-

-

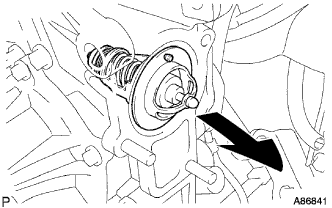

REMOVE THERMOSTAT

-

Remove the thermostat and gasket.

-

-

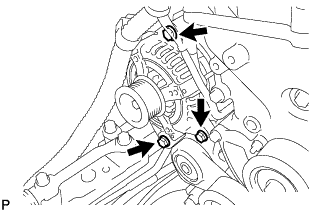

REMOVE GENERATOR ASSEMBLY

-

Disconnect the generator connector.

-

Remove the terminal cap.

-

Remove the nut and disconnect the wire harness from terminal B.

-

Remove the bolt and disconnect the wire harness clamp.

-

Remove the 3 bolts and generator assembly.

-

-

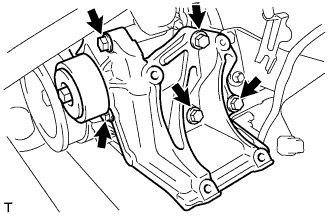

REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

-

Remove the 5 bolts and No. 1 compressor mounting bracket.

-

-

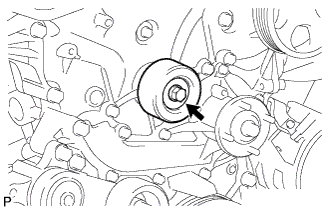

REMOVE NO. 1 IDLER PULLEY SUB-ASSEMBLY

-

Remove the bolt, pulley plate, collar and No. 1 idler pulley sub-assembly.

-

-

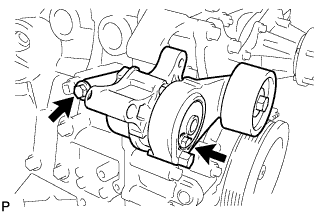

REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

-

Remove the 2 bolts and V-ribbed belt tensioner assembly.

-

-

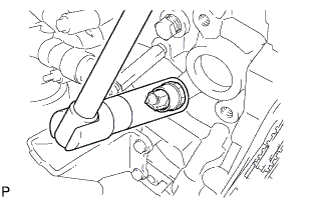

REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

-

Using a 24 mm deep socket wrench, remove the engine oil pressure switch assembly.

-

-

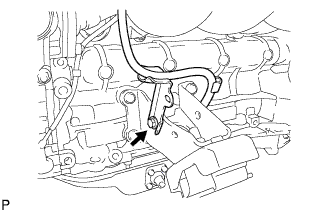

REMOVE KNOCK CONTROL SENSOR

-

Disconnect the knock control sensor connector.

-

Remove the bolt and knock control sensor.

-

-

REMOVE ENGINE COOLANT TEMPERATURE SENSOR

-

Disconnect the engine coolant temperature sensor connector.

-

Using a 19 mm deep socket wrench, remove the engine coolant temperature sensor and gasket.

-

-

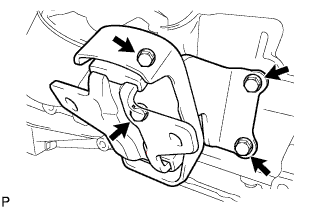

REMOVE FRONT NO.1 ENGINE MOUNTING BRACKET RH

Tech Tips

Perform this procedure only when replacement of the No. 1 engine mounting bracket RH is necessary.

-

Remove the 4 bolts and front No. 1 mounting bracket RH.

-

-

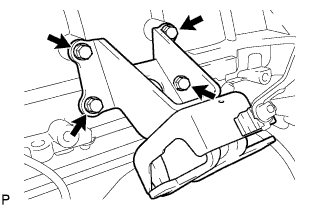

REMOVE FRONT NO.1 ENGINE MOUNTING BRACKET LH

Tech Tips

Perform this procedure only when replacement of the No. 1 engine mounting bracket LH is necessary.

-

Remove the 4 bolts and front No. 1 mounting bracket LH.

-

-

REMOVE ENGINE OIL LEVEL SENSOR

-

Remove the 4 bolts and engine oil level sensor.

-