CAMSHAFT INSTALLATION

PROCEDURE

-

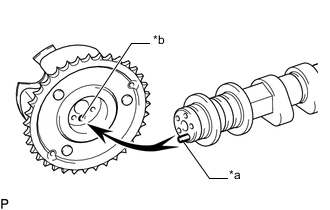

INSTALL CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

Tech Tips

Perform "Inspection After Repairs" after replacing the camshaft timing exhaust gear assembly.

-

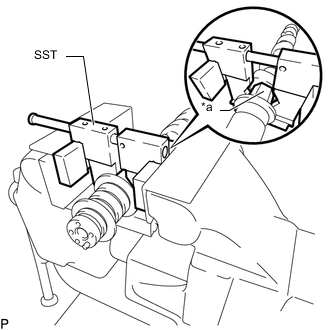

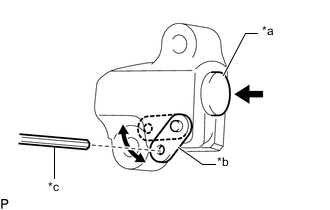

*a Hexagonal Portion Using SST, grip the hexagonal portion, and then secure SST and No. 2 camshaft in a vise as shown in the illustration.

- SST

- 09212-31010

Note

-

Do not damage the No. 2 camshaft.

-

Never grip areas other than the hexagonal portion, as this may cause damage.

-

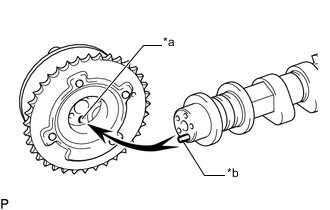

*a Straight Pin Hole *b Straight Pin Align and attach the straight pin of the No. 2 camshaft with the straight pin hole of the camshaft timing exhaust gear assembly.

-

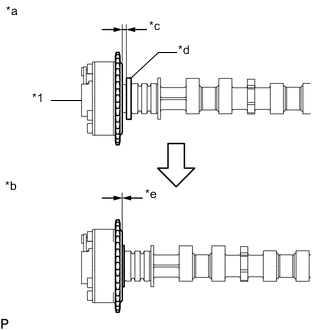

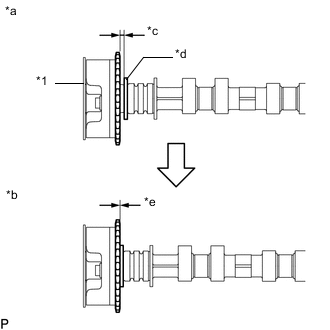

*1 Camshaft Timing Exhaust Gear Assembly *a INCORRECT *b CORRECT *c Clearance *d Camshaft Flange *e No Clearance Check that there is no clearance between the camshaft timing exhaust gear assembly and camshaft flange.

Note

-

Since the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head receiving the shaft thrust may crack or be damaged, causing the camshaft to seize or break.

-

Be sure not to remove the other 4 bolts. If removing the bolts, exchange the camshaft timing exhaust gear assembly.

-

-

Fix the camshaft timing exhaust gear assembly with the flange bolt.

- Torque:

- 78 N*m { 795 kgf*cm, 58 ft.*lbf }

-

-

INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

Tech Tips

Perform "Inspection After Repairs" after replacing the camshaft timing gear assembly.

-

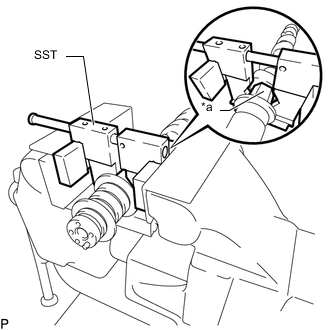

*a Hexagonal Portion Using SST, grip the hexagonal portion, and then secure SST and camshaft in a vise as shown in the illustration.

- SST

- 09212-31010

Note

-

Do not damage the camshaft.

-

Never grip areas other than the hexagonal portion, as this may cause damage.

-

*a Straight Pin *b Straight Pin Hole Align the straight pin hole and straight pin and install the camshaft timing gear assembly to the camshaft.

-

Lightly press the gear against the camshaft and turn the gear. Push further at the position where the straight pin enters the straight pin hole.

Note

Be sure not to turn the camshaft timing gear assembly in the retard direction (the right angle).

-

*1 Camshaft Timing Gear Assembly *a INCORRECT *b CORRECT *c Clearance *d Camshaft Flange *e No Clearance Check that there is no clearance between the camshaft timing gear assembly and the flange of the camshaft.

Note

-

Since the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being removed. If the camshaft is not kept level, the portion of the cylinder head receiving the shaft thrust may crack or be damaged, causing the camshaft to seize or break.

-

Be sure not to remove the other 3 bolts. If removing the bolts, exchange the camshaft timing gear assembly.

-

-

With the camshaft timing gear assembly fixed in place, install the flange bolt.

- Torque:

- 78 N*m { 795 kgf*cm, 58 ft.*lbf }

-

Check that the camshaft timing gear assembly can move in the retard direction (the right angle), and is locked at the most retarded position.

-

-

INSTALL CAMSHAFT AND NO. 2 CAMSHAFT

Tech Tips

Perform "Inspection After Repairs" after replacing the camshaft or No. 2 camshaft.

-

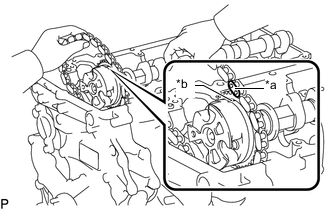

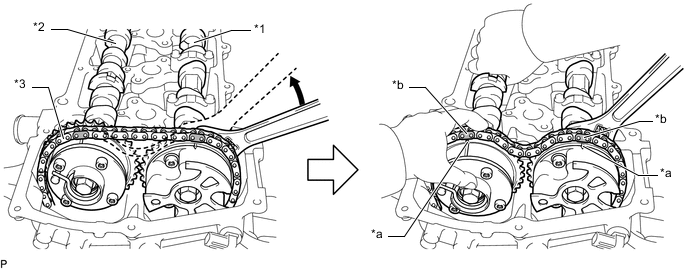

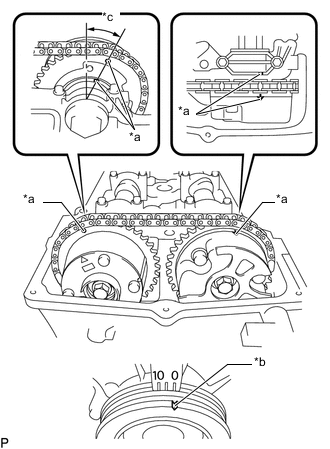

*a Paint Mark *b Timing Mark Apply clean engine oil to the camshaft cams and cylinder head journals.

-

Install the chain sub-assembly to the camshaft timing gear assembly with the paint mark of the link aligned with the timing mark of the camshaft timing gear assembly.

-

Temporarily install the 4 No. 2 camshaft bearing caps using the 8 bolts as shown in the illustration.

-

Install the chain sub-assembly to the No. 2 camshaft, and then install the No. 2 camshaft to the cylinder head sub-assembly.

Tech Tips

Place the chain sub-assembly on the camshaft timing gear assembly but do not engage the teeth of the sprocket and the chain sub-assembly.

-

Move the camshaft in the direction shown in the illustration to loosen the chain sub-assembly, and align the paint mark on the camshaft timing gear assembly and chain sub-assembly and connect the chain sub-assembly to the camshaft timing gear assembly.

*1 Camshaft *2 No. 2 Camshaft *3 Chain Sub-assembly - - *a Timing Mark *b Paint Mark -

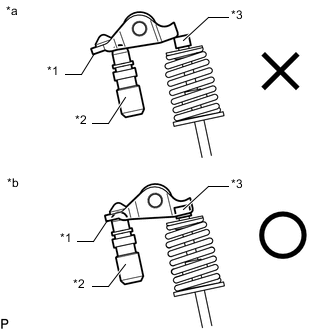

*1 No. 1 Valve Rocker Arm Sub-assembly *2 Valve Lash Adjuster Assembly *3 Valve Stem Cap *a INCORRECT *b CORRECT Make sure that the No. 1 valve rocker arm sub-assemblies are installed as shown in the illustration.

-

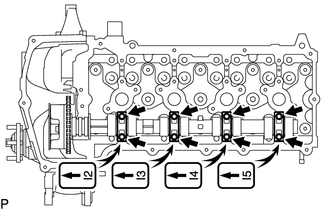

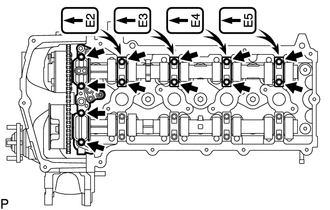

Temporarily install the No. 1 camshaft bearing cap and 4 No. 2 camshaft bearing caps using the 12 bolts.

-

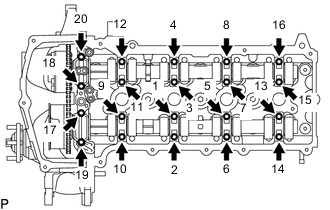

Tighten the 20 bolts in the order shown in the illustration.

- Torque:

- 15.5 N*m { 158 kgf*cm, 11 ft.*lbf }

-

-

INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

-

*a Plunger *b Stopper Plate *c Hexagon Wrench Move the stopper plate upward to release the lock and push the plunger deep into the tensioner.

-

Move the stopper plate downward to set the lock and insert a hexagon wrench into the hole of the stopper plate.

-

Install a new gasket and the No. 1 chain tensioner assembly with the bolt and nut.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

Note

Remove the hexagon wrench after installing the timing chain guide.

-

Install a new gasket to the timing chain cover plate.

-

Install the timing chain cover plate to the timing chain cover sub-assembly with the 2 bolts.

- Torque:

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

-

INSTALL TIMING CHAIN GUIDE

-

CHECK NO. 1 CYLINDER TO TDC/COMPRESSION

-

*a Timing Mark *b Groove *c Approximately 13° Check that the No. 1 cylinder is set to TDC/compression.

-

Rotate the crankshaft two full rotations, and then check that all timing marks are in the position shown in the illustration.

Tech Tips

If the timing marks do not match, set the chain sub-assembly again.

-

-

-

INSTALL CYLINDER HEAD COVER CONNECTOR SUB-ASSEMBLY

-

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

-

INSTALL IGNITION COIL ASSEMBLY

-

INSTALL INTAKE AIR CONNECTOR

-

INSTALL FAN AND GENERATOR V BELT

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

INSPECT FOR OIL LEAK

-

INSPECT FOR COOLANT LEAK

-

INSPECT IGNITION TIMING

-

INSPECT ENGINE IDLE SPEED

-

CHECK CO/HC