STOP AND START SYSTEM, Diagnostic DTC:P1545

| DTC Code | DTC Name |

|---|---|

| P1545 | Starter Maintenance |

DESCRIPTION

When the number of starter operations reaches the maximum number, the engine stop and start ECU stores DTC P1545 and blinks the stop and start cancel indicator light. When the STA signal detected by the ECM and the engine stop and start ECU do not match, the engine stop and start ECU stores DTC P1545 and blinks the stop and start cancel indicator light.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P1545 | The following conditions are met (1 trip detection logic):

Both of the following conditions continue for 2 seconds or more (1 trip detection logic):

|

|

CONFIRMATION DRIVING PATTERN

Tech Tips

DTCs for the stop and start system are not cleared even if the malfunction has been repaired. After repairing the malfunction, be sure to clear the DTCs Click here.

-

CONFIRMATION AFTER TROUBLESHOOTING

Tech Tips

-

If the cable is disconnected from the negative (-) battery terminal, stop and start control is prohibited until refresh charge is completed. In this case, drive the vehicle approximately 5 to 40 minutes until refresh charge is completed and stop and start control operation is permitted.

-

Allow the engine to idle for 3 minutes after the engine warms up and check that the engine speed is within 50 rpm of the target idle speed.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs Click here.

-

Start the engine and warm it up.

-

Drive the vehicle at 7 km/h (4.3 mph) or more.

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

-

Stop the vehicle, move the shift lever to neutral and release the clutch pedal.

-

Keep the engine stopped by stop and start control for 1 second or more.

-

Depress the clutch pedal and start the engine.

-

Check that DTCs are not output Click here.

-

-

STOP AND START SYSTEM OPERATION CHECK

Tech Tips

If the cable is disconnected from the negative (-) battery terminal, stop and start control is prohibited until refresh charge is completed. In this case, drive the vehicle approximately 5 to 40 minutes until refresh charge is completed and stop and start control operation is permitted.

-

Start the engine and warm it up.

-

Turn the air conditioning system off.

-

Drive the vehicle at 7 km/h (4.3 mph) or more.

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

-

Stop the vehicle, move the shift lever to neutral and release the clutch pedal.

-

Allow the engine to stop by stop and start control.

-

Depress the clutch pedal and start the engine.

-

WIRING DIAGRAM

Refer to DTC P0617 Click here.

CAUTION / NOTICE / HINT

Note

-

Before replacing the engine stop and start ECU, read the number of starter operations and write it into a new engine stop and start ECU Click here.

-

After replacing the starter assembly, perform initialization of the number of starter operations stored in the engine stop and start ECU Click here.

-

When the starter assembly is replaced, "ST relay"must be also replaced.

-

After replacing the engine stop and start ECU or air conditioning amplifier assembly, reset and perform learning of the air conditioning information in the engine stop and start ECU Click here.

-

After replacing the engine stop and start ECU or yaw rate sensor, perform deceleration sensor zero point clear and calibration Click here.

-

Inspect the fuses for circuits related to this system before performing the following procedure.

Tech Tips

Using the GTS, read the freeze frame data before troubleshooting. System condition information is recorded as freeze frame data the moment a DTC is stored. This information can be useful when troubleshooting Click here.

PROCEDURE

-

READ VALUE USING GTS (STARTER OPERATION #)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Stop and Start / Data List / Starter Operation #.

-

Read the Starter Operation # value displayed on the GTS.

Result Result Proceed to Below 254000 A 254000 or more

(Displays 1000000 or more)*

B Tech Tips

*: If "Starter Operation #" displays 1000000 or more, it is necessary to replace the engine stop and start ECU as there is an internal malfunction in the ECU.

B

REPLACE STARTER ASSEMBLY Click here

A

-

-

READ VALUE USING GTS (STARTER SIGNAL)

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Starter Signal.

-

Depress the clutch pedal fully.

-

Read the values displayed on the GTS when the ignition switch is turned to ON and the engine starts.

OK GTS Display Switch Condition Normal Condition Starter Signal Ignition switch ON OFF Engine start ON Result Result Proceed to OK A NG (for 1WW) B NG (for 2WW) C

B

GO TO ECD SYSTEM (STARTER SIGNAL CIRCUIT) Click here

C

GO TO ECD SYSTEM (STARTER SIGNAL CIRCUIT) Click here

A

-

-

CHECK ENGINE STOP AND START ECU (STA TERMINAL VOLTAGE)

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Tech Tips

If battery voltage drops below 8 V when cranking, CAN communication may be interrupted.

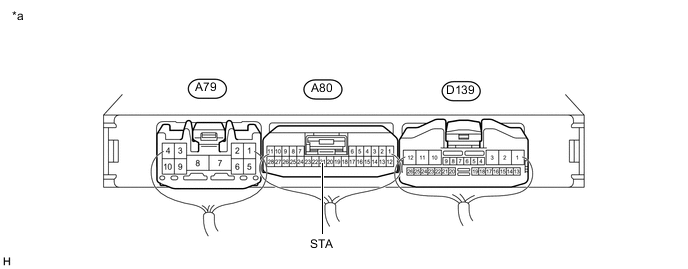

Text in Illustration *a Component with harness connected

(Engine Stop and Start ECU)

- - Standard Voltage Tester Connection Condition Specified Condition A80-21 (STA) - Body ground Ignition switch ON 0 to 1.5 V Cranking 6 to 14 V

OK

USE SIMULATION METHOD TO CHECK Click here

NG

-

-

INSPECT RELAY (ST RELAY)

-

Inspect the ST relay.

-

for 1WW: Click here

-

for 2WW: Click here

-

NG

REPLACE RELAY (ST RELAY)

OK

-

-

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ST RELAY)

-

w/ Entry and Start System:

Disconnect the power management control ECU connector.

-

Disconnect the A80 engine stop and start ECU connector.

-

Disconnect the ECM connector.

-

Disconnect the clutch start switch assembly connector.

-

Remove the ST relay from the No. 1 relay block assembly.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A80-21 (STA) - ST relay terminal 2 Always Below 1 Ω A80-21 (STA) - Body ground Always 10 kΩ or higher ST relay terminal 2- Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - CLUTCH START SWITCH ASSEMBLY)

-

w/ Entry and Start System:

Disconnect the power management control ECU connector.

-

Disconnect the A80 engine stop and start ECU connector.

-

Disconnect the ECM connector.

-

Disconnect the A3 clutch start switch assembly connector.

-

Remove the ST relay from the No. 1 relay block assembly.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A80-21 (STA) - A3-1 Always Below 1 Ω A3-1 - Body ground Always 10 kΩ or higher A80-21 (STA) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ECM)

-

w/ Entry and Start System:

Disconnect the power management control ECU connector.

-

Disconnect the A80 engine stop and start ECU connector.

-

Disconnect the A83 ECM connector.

-

Disconnect the clutch start switch assembly connector.

-

Remove the ST relay from the No. 1 relay block assembly.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A80-21 (STA) - A83-36 (STA) Always Below 1 Ω A83-36 (STA) - Body ground Always 10 kΩ or higher A80-21 (STA) - Body ground Always 10 kΩ or higher

OK

REPLACE ENGINE STOP AND START ECU Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

-

REPLACE STARTER ASSEMBLY

-

Replace the starter assembly.

-

for 1WW: Click here

-

for 2WW: Click here

Tech Tips

-

When the starter assembly is replaced, "ST relay" must be also replaced.

-

If "Starter Operation #" displays 1000000 or more, the engine stop and start ECU must also be replaced.

-

Clear the number of starter operations by performing "Starter Exchange" using the GTS Click here.

-

NEXT

END

-