ДВИГАТЕЛЬ В СБОРЕ (для моделей с контроллером свечей накаливания) СНЯТИЕ

CAUTION / NOTICE / HINT

CAUTION:

Some of these service operations affect the multi-mode manual transaxle system. Read the precautionary notices concerning the multi-mode manual transaxle system before servicing.

Note

-

When the manual transaxle assembly or multi-mode manual transaxle assembly is removed, be sure to use a new clutch release with bearing cylinder assembly and new installation bolts. Removal of the manual transaxle assembly or multi-mode manual transaxle assembly allows the compressed clutch release with bearing cylinder assembly to return to its original position, and dust could damage the seal of the clutch release with bearing cylinder assembly, possibly causing clutch fluid leaks.

-

After replacing the engine assembly, perform both "Injector Compensation" and "Pilot Quantity Learning Values Reset" using the GTS.

PROCEDURE

-

PRECAUTION

Note

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

-

REMOVE FRONT WHEELS

-

REMOVE FRONT LOWER BUMPER ABSORBER

-

Remove the 8 bolts, 4 screws and front lower bumper absorber.

-

-

REMOVE NO. 1 ENGINE UNDER COVER (for Half Cover Type)

-

Remove the 2 bolts, 7 clips and No. 1 engine under cover.

-

-

REMOVE NO. 1 ENGINE UNDER COVER (for Full Cover Type)

-

Remove the 2 bolts, 11 clips and No. 1 engine under cover.

-

-

REMOVE CENTER NO. 4 ENGINE UNDER COVER (for Half Cover Type)

-

Remove the 5 clips and center No. 4 engine under cover.

-

-

REMOVE CENTER NO. 4 ENGINE UNDER COVER (for Full Cover Type)

-

Remove the 2 clips and center No. 4 engine under cover.

-

-

REMOVE FRONT NO. 3 ENGINE UNDER COVER (for Full Cover Type)

-

Remove the 4 clips and front No. 3 engine under cover.

-

-

REMOVE REAR ENGINE UNDER COVER LH

-

Remove the 5 clips and rear engine under cover LH.

-

-

REMOVE REAR ENGINE UNDER COVER RH

-

Remove the 5 clips and rear engine under cover RH.

-

-

DRAIN ENGINE OIL

-

DRAIN ENGINE COOLANT

-

DRAIN MANUAL TRANSAXLE OIL (for Manual Transaxle)

-

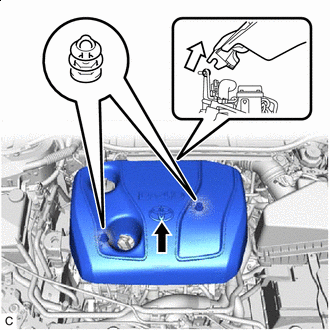

REMOVE NO. 1 ENGINE COVER (w/ No. 1 Engine Cover)

-

Disengage the 2 grommets first

Disengage the 2 hooks next Lift the front of the No. 1 engine cover to disengage the 2 grommets from the 2 pins. Then disengage the 2 hooks from the No. 2 engine cover bracket, and remove the No. 1 engine cover.

-

-

REMOVE OUTER COWL TOP PANEL (for LHD)

-

REMOVE OUTER COWL TOP PANEL (for RHD)

-

REMOVE BATTERY

-

Loosen the nut, and separate the cable from the positive (+) battery terminal.

-

Remove the nut, bolt, battery clamp sub-assembly and battery clamp bolt.

-

Remove the battery.

-

Remove the battery tray.

-

-

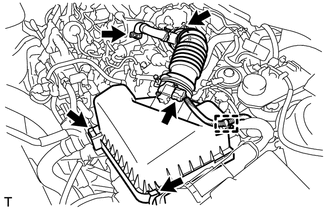

REMOVE AIR CLEANER CAP SUB-ASSEMBLY

-

Disconnect the wire harness clamp, connector and ventilation hose.

-

Loosen the hose clamp.

-

Unlock the 2 lock clamps and remove the air cleaner cap sub-assembly.

-

-

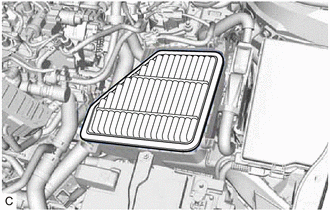

REMOVE AIR CLEANER CASE SUB-ASSEMBLY

-

Remove the air cleaner filter element sub-assembly.

-

Remove the 3 bolts and air cleaner case sub-assembly.

-

-

REMOVE FUEL FILTER ASSEMBLY

-

DISCONNECT ENGINE WIRE

-

Pull up the lever to disengage the ECM connector.

-

Disengage the 3 wire harness clamps from the fuel filter support.

-

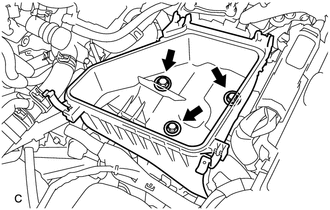

Remove the No. 1 relay block cover from the engine room relay block and junction block assembly.

-

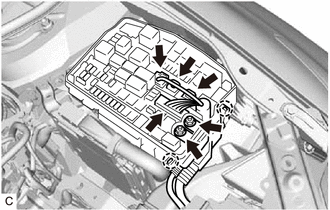

Remove the 2 nuts from the engine room relay block and junction block assembly.

-

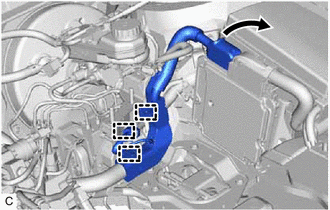

Disengage the 2 claws, and disconnect the 4 wire harness connectors and wire harness from the engine room relay block and junction block assembly.

-

Disengage the 2 wire harness clamps.

-

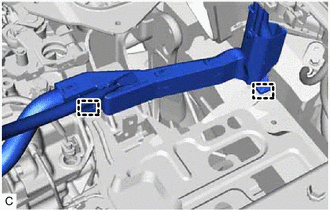

Remove the bolt and disconnect the No. 3 engine wire from the manual transaxle assembly.

-

-

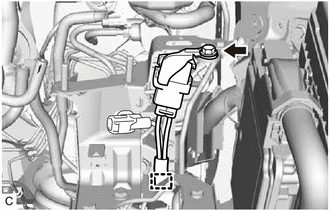

REMOVE GLOW PLUG RELAY ASSEMBLY

-

Remove the bolt and disconnect the glow plug relay assembly from the fuel filter support.

-

Disconnect the wire harness clamp from the fuel filter support.

-

-

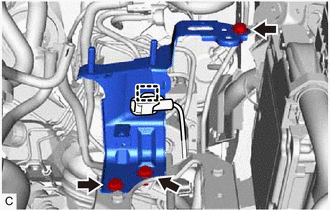

REMOVE FUEL FILTER SUPPORT

-

Disconnect the wire harness clamp from the fuel filter support.

-

Remove the 3 bolts and fuel filter support.

-

-

REMOVE AIR CLEANER BRACKET

-

Remove the 3 bolts and air cleaner bracket.

-

-

REMOVE NO. 2 BATTERY CARRIER

-

Remove the 4 bolts and No. 2 battery carrier.

-

-

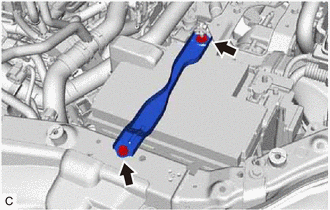

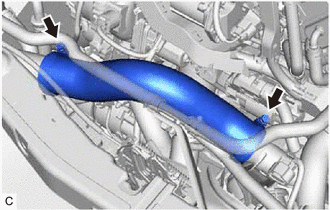

REMOVE NO. 3 AIR HOSE

-

Loosen the 2 hose clamps and remove the No. 3 air hose.

-

-

REMOVE INTERCOOLER AIR HOSE

-

Loosen the 2 hose clamps and remove the intercooler air hose.

-

-

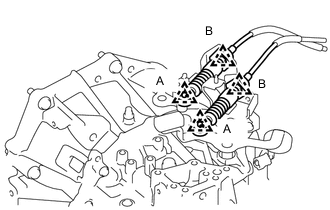

SEPARATE TRANSMISSION CONTROL CABLE ASSEMBLY (for Manual Transaxle)

-

Remove the 2 clips (A) and disconnect the transmission control cable assembly from the manual transaxle assembly.

-

Remove the 2 clips (B) and disconnect the transmission control cable assembly from the control cable bracket assembly.

-

Remove the bolt and disconnect the transmission control cable assembly from the rear engine mounting bracket.

-

-

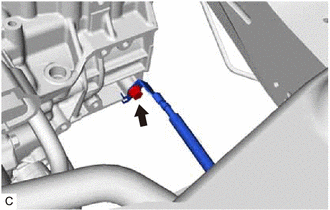

DISCONNECT UNION TO CONNECTOR TUBE HOSE

-

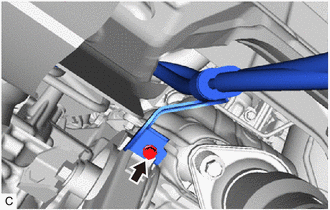

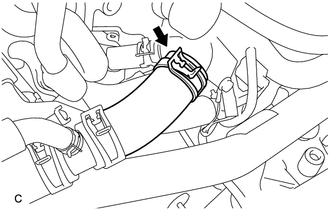

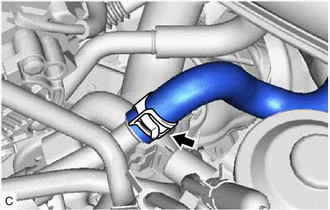

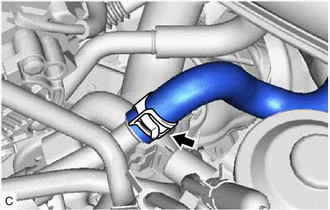

Slide the clip and disconnect the union to connector tube hose from the cylinder head cover sub-assembly.

-

-

DISCONNECT WATER BY-PASS HOSE

-

Slide the clip and disconnect the water by-pass hose from the water inlet.

-

-

DISCONNECT NO. 2 RADIATOR HOSE

-

Slide the clip and disconnect the No. 2 radiator hose from the water inlet.

-

-

DISCONNECT NO. 1 RADIATOR HOSE

-

Slide the clip and disconnect the No. 1 radiator hose from the outlet water sub-assembly.

-

-

DISCONNECT INLET HEATER WATER HOSE A (w/o Combustion Type Power Heater)

-

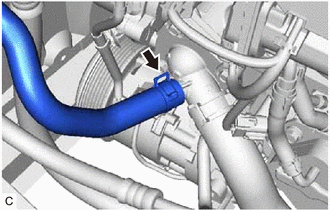

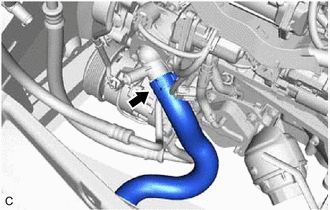

Slide the clip and disconnect the inlet heater water hose A from the inlet heater water pipe A.

-

-

DISCONNECT INLET HEATER WATER HOSE D (w/ Combustion Type Power Heater)

-

Slide the clip and disconnect the inlet heater water hose D from the inlet heater water pipe A.

-

-

DISCONNECT OUTLET HEATER WATER HOSE

-

Slide the clip and disconnect the outlet heater water hose from the water by-pass pipe sub-assembly.

-

-

REMOVE V-RIBBED BELT

-

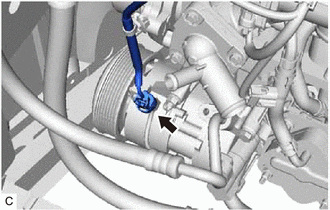

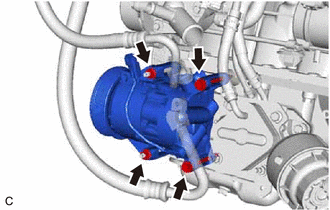

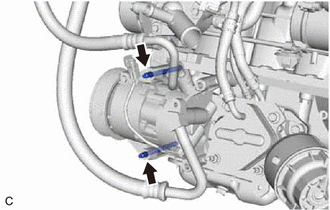

SEPARATE COMPRESSOR ASSEMBLY WITH PULLEY (w/ Air Conditioning System)

-

Disconnect the connector.

-

Remove the 2 bolts and 2 nuts.

-

Using an E8 "TORX" socket wrench, remove the 2 stud bolts.

-

Separate the compressor assembly with pulley.

Tech Tips

It is not necessary to completely remove the compressor assembly with pulley. With the hoses connected to the compressor assembly with pulley, hang the compressor assembly with pulley on the vehicle body with a rope.

-

-

SECURE STEERING WHEEL

-

REMOVE COLUMN HOLE COVER SILENCER SHEET

-

SEPARATE NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

-

SEPARATE NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

-

REMOVE FRONT CENTER FLOOR BRACE SUB-ASSEMBLY

-

REMOVE FRONT EXHAUST PIPE ASSEMBLY

-

REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

-

REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

-

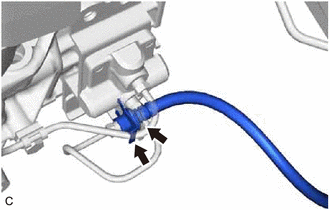

DISCONNECT NO. 1 CLUTCH HOSE (for Manual Transaxle)

-

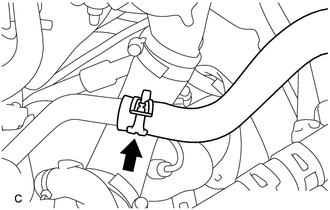

Using a 10 mm union nut wrench, disconnect the No. 1 clutch hose from the accumulator to flexible hose tube.

-

Remove the clip and separate the No. 1 clutch hose from the flexible hose bracket.

-

-

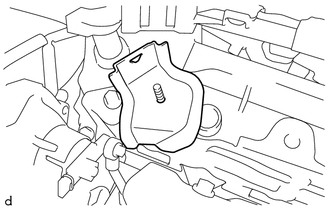

REMOVE FRONT ENGINE MOUNTING BRACKET LOWER REINFORCEMENT (w/ Reinforcement)

-

REMOVE FRONT SUSPENSION MEMBER REINFORCEMENT LH

-

REMOVE FRONT SUSPENSION MEMBER REINFORCEMENT RH

Tech Tips

Perform the same procedure as for the LH side.

-

REMOVE FRONT SUSPENSION MEMBER REAR BRACE LH

-

REMOVE FRONT SUSPENSION MEMBER REAR BRACE RH

Tech Tips

Perform the same procedure as for the LH side.

-

REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

-

REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

-

Set an engine lifter.

Note

-

Place the height adjustment attachments and plate lift attachments under the engine assembly with transaxle.

-

Do not place the height adjustment attachments or plate lift attachments under the front crossmember sub-assembly.

-

Do not perform any procedure while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

-

-

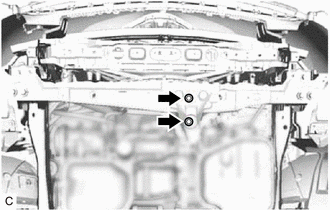

Remove the 2 bolts to separate the front engine mounting insulator from the front crossmember sub-assembly.

-

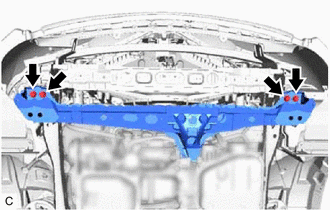

Remove the 4 bolts and front crossmember sub-assembly.

-

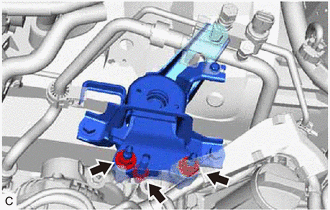

Remove the 3 nuts and separate the engine mounting insulator sub-assembly RH.

-

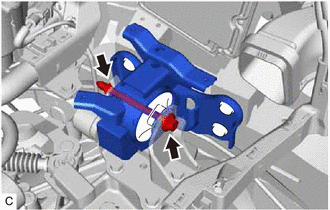

Remove the through bolt and nut, and separate the engine mounting insulator LH.

Tech Tips

When removing the through bolt, keep the nut from rotating.

-

Carefully remove the engine assembly with transaxle from the vehicle.

Note

Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

-

-

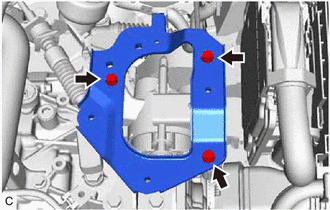

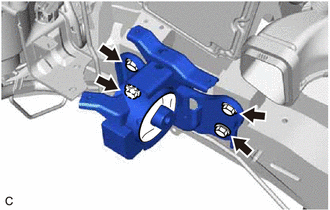

INSTALL ENGINE HANGER

-

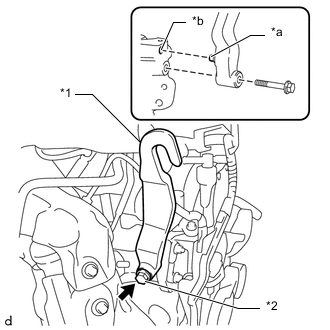

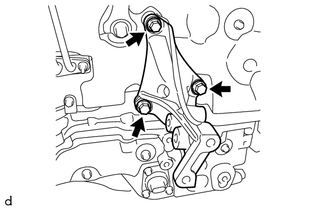

*1 No. 1 Engine Hanger *2 Bolt *a Tab *b Hole Install the No. 1 engine hanger with a new bolt as shown in the illustration.

- Torque:

- 40 N*m { 408 kgf*cm, 30 ft.*lbf }

Note

-

Be sure to install the No. 1 engine hanger with the tab contacting the rear side of the hole.

-

Be sure to use a new bolt to install the No. 1 engine hanger.

Tech Tips

No. 1 Engine Hanger 12281-33080 Bolt 91552-81050 -

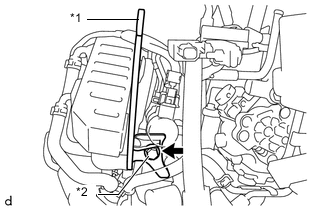

*1 No. 2 Engine Hanger *2 Bolt Install the No. 2 engine hanger with a new bolt as shown in the illustration.

- Torque:

- 50 N*m { 510 kgf*cm, 37 ft.*lbf }

Note

Be sure to use a new bolt to install the No. 2 engine hanger.

Tech Tips

No. 2 Engine Hanger 12282-0N010 Bolt 91672-81025

90119-W0026

-

Using an engine sling device and a chain block, suspend the engine assembly with transaxle.

-

-

REMOVE FRONT ENGINE MOUNTING INSULATOR

-

Remove the through bolt, nut and front engine mounting insulator.

Tech Tips

When removing the through bolt, keep the nut from rotating.

-

-

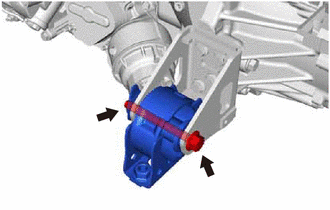

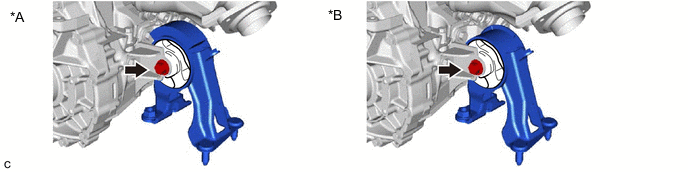

REMOVE REAR ENGINE MOUNTING INSULATOR

-

Remove the through bolt and rear engine mounting insulator.

*A Type A *B Type B

-

-

REMOVE ENGINE MOUNTING INSULATOR LH

Tech Tips

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

-

Remove the 4 bolts and engine mounting insulator LH.

-

-

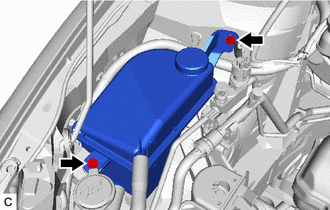

REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

Tech Tips

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

-

Remove the 2 bolts and separate the radiator reserve tank assembly.

-

Remove the bolt and separate the cooler pipe clamp bracket from the engine mounting insulator sub-assembly RH.

-

Disconnect the cooler pipe clamp from the engine mounting insulator sub-assembly RH.

-

Remove the 3 bolts and engine mounting insulator sub-assembly RH.

-

-

REMOVE NO. 1 AIR TUBE

-

REMOVE STARTER ASSEMBLY (w/o Stop And Start System)

-

REMOVE STARTER ASSEMBLY (w/ Stop And Start System)

-

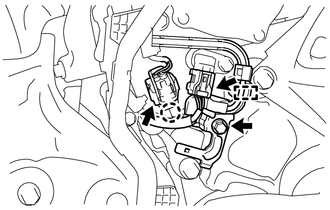

DISCONNECT WIRE HARNESS

-

Disconnect all the wire harnesses and connectors. Make sure that no wire harnesses are connected to the engine.

-

-

REMOVE MANUAL TRANSAXLE ASSEMBLY (for Manual Transaxle)

-

REMOVE BLEEDER TO ACCUMULATOR TUBE (for Manual Transaxle)

-

REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY (for Manual Transaxle)

-

REMOVE CLUTCH RELEASE WITH BEARING CYLINDER ASSEMBLY (for Manual Transaxle)

-

REMOVE CLUTCH RELEASE CYLINDER TO BLEEDER TUBE (for Manual Transaxle)

-

REMOVE CLUTCH COVER ASSEMBLY (for Manual Transaxle)

-

REMOVE CLUTCH DISC ASSEMBLY (for Manual Transaxle)

-

REMOVE ENGINE WIRE

-

Disconnect all the wire harnesses and connectors. Make sure that no wire harnesses are connected to the engine.

-

-

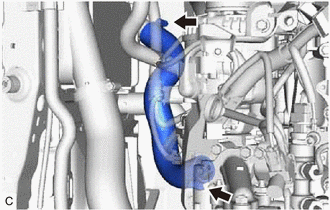

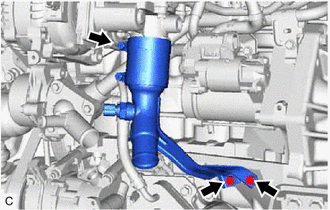

REMOVE NO. 2 AIR TUBE

-

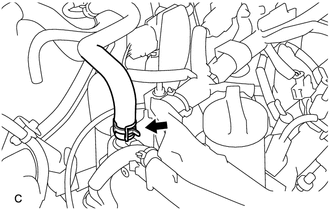

Loosen the hose clamp.

-

Remove the 2 bolts and No. 2 air tube from the diesel throttle body assembly and cylinder block sub-assembly.

-

-

REMOVE NO. 1 WIRING HARNESS HEAT INSULATOR

-

REMOVE WIRING HARNESS CLAMP BRACKET

-

REMOVE DIFFERENTIAL PRESSURE SENSOR ASSEMBLY

-

REMOVE NO. 2 ENGINE COVER BRACKET

-

REMOVE WIRING HARNESS CLAMP BRACKET

-

Remove the wiring harness clamp bracket from the cylinder head cover sub-assembly.

-

-

REMOVE SENSOR BRACKET

-

REMOVE NO. 1 TURBO INSULATOR

-

REMOVE NO. 2 VACUUM PIPE

-

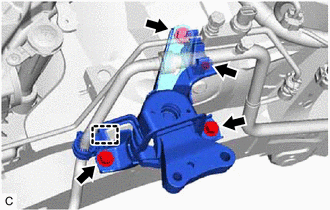

REMOVE NO. 5 MANIFOLD SUPPORT BRACKET

-

REMOVE NO. 4 MANIFOLD SUPPORT BRACKET

-

REMOVE DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY

-

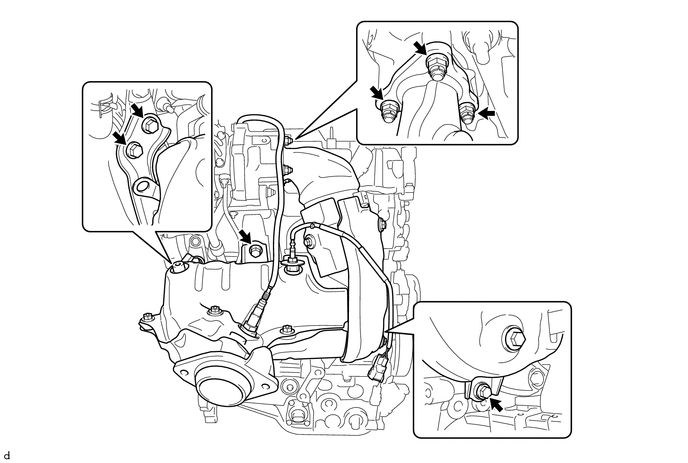

REMOVE NO. 2 EXHAUST MANIFOLD

-

Disconnect the camshaft position sensor connector.

-

Disconnect the exhaust gas temperature sensor connector.

-

Remove the bolt and wiring harness clamp bracket from the timing chain cover sub-assembly.

-

Disengage the claw to disconnect the exhaust gas temperature sensor wire connector from the wiring harness clamp bracket.

-

Disengage the clamp to disconnect the exhaust gas temperature sensor wire from the wiring harness clamp bracket.

-

Remove the 4 bolts, 3 nuts and No. 2 exhaust manifold from the turbocharger sub-assembly, No. 1 converter support bracket, manifold stay and No. 2 converter support bracket.

-

Remove the outlet turbine elbow gasket from the turbocharger sub-assembly.

-

-

REMOVE MANIFOLD SUPPORT BRACKET

-

Remove the 3 bolts and manifold support bracket from the cylinder block sub-assembly.

-

-

DISCONNECT NO. 1 TURBO WATER HOSE

-

DISCONNECT NO. 2 TURBO WATER HOSE

-

REMOVE NO. 1 TURBO WATER PIPE SUB-ASSEMBLY

-

REMOVE TURBOCHARGER STAY

-

REMOVE MANIFOLD STAY

-

REMOVE TURBOCHARGER SUB-ASSEMBLY

-

REMOVE EXHAUST MANIFOLD

-

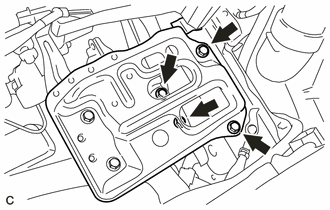

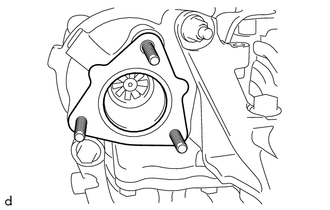

REMOVE CYLINDER BLOCK SIDE COVER

-

Remove the bolt, plate washer and cylinder block side cover from the cylinder block sub-assembly.

-

-

REMOVE CRANK POSITION SENSOR

-

REMOVE FLYWHEEL SUB-ASSEMBLY

-

REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

-

INSTALL ENGINE ASSEMBLY TO ENGINE STAND

-

Install the engine assembly to an engine stand.

Note

-

Adjust the angle of the sling device carefully to prevent the engine assembly or engine hangers from deforming or becoming damaged.

-

Servicing an engine assembly while it is hanging is dangerous. This can be done only when installing/removing the engine assembly to/from an engine stand.

-

-

-

REMOVE ENGINE HANGERS

-

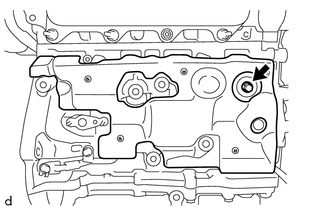

Remove the 2 bolts, No. 1 engine hanger and No. 2 engine hanger from the cylinder head sub-assembly.

-