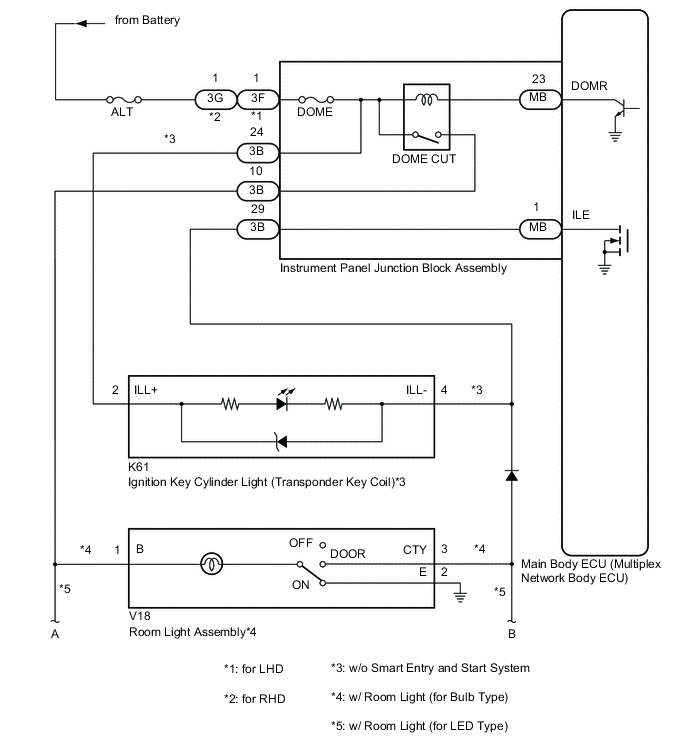

LIGHTING SYSTEM Interior Light Circuit

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the operation of the following lights:

-

Ignition Key Cylinder Light (Transponder Key Coil)*1

-

Map Light (Roof Console Box Sub-assembly)*2

-

Spot Light Assembly*2

-

Room Light Assembly*3

-

*1: w/o Smart Entry and Start System

-

*2: w/ Room Light (for LED Type)

-

*3: w/ Room Light (for Bulb Type)

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

-

Inspect the fuses for circuits related to this system before performing the following procedure.

-

Before replacing the main body ECU (multiplex network body ECU), refer to Service Bulletin.*1

-

The vehicle battery supplies power to the main body ECU (multiplex network body ECU) via the door control battery. Therefore, before performing this troubleshooting procedure, make sure to perform an on-vehicle inspection to confirm that the main body ECU (multiplex network body ECU) power source circuit is normal.*2

-

*1: w/ Smart Entry and Start System

-

*2: w/ Door Control Battery

Tech Tips

The DOME CUT relay supplies power to the interior lights. If all the lights that use power from the DOME CUT relay do not turn on, check the interior light auto cut circuit first.

PROCEDURE

-

PERFORM ACTIVE TEST USING GTS

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Main Body / Active Test.

-

Perform the Active Test according to the display on the GTS.

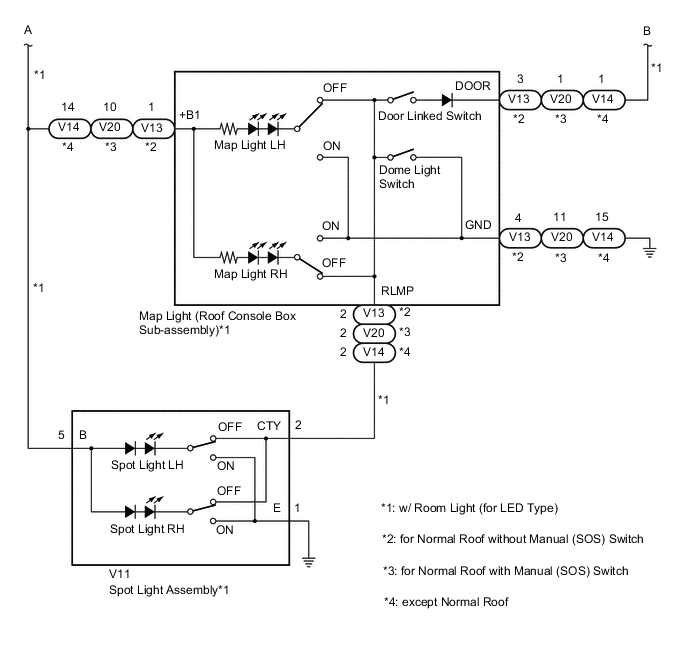

Body Electrical > Main Body > Active TestTester Display Measurement Item Control Range Diagnostic Note Illuminated Entry System Turns on the lights that are controlled by the illuminated entry system* OFF or ON w/ Room Light (for LED Type):

Perform the Active Test with the door linked switch of the map light (roof console box sub-assembly) on and switches of the spot light assembly LH and RH off.

w/ Room Light (for Bulb Type):

Perform the Active Test with switch of the room light assembly in the DOOR position.

-

*: Refer to System Description for the lights that are controlled by the illuminated entry system.

Body Electrical > Main Body > Active TestTester Display Illuminated Entry System OK All lights that are controlled by the illuminated entry system come on. Result Result Proceed to OK A NG (Map light (roof console box sub-assembly) and/or spot light assembly do not come on (w/ Room Light (for LED Type))) B NG (Room light assembly does not come on (w/ Room Light (for Bulb Type))) C NG (Ignition key cylinder light (transponder key coil) does not come on) D NG (All lights that are controlled by the illuminated entry system do not come on) E -

A

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE Click here

C

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) Click here

D

INSPECT IGNITION KEY CYLINDER LIGHT (TRANSPONDER KEY COIL) Click here

E

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY Click here

B

-

-

INSPECT MAP LIGHT (ROOF CONSOLE BOX SUB-ASSEMBLY)

-

Remove the map light (roof console box sub-assembly).

-

Inspect the map light (roof console box sub-assembly).

Result Proceed to OK NG

NG

REPLACE MAP LIGHT (ROOF CONSOLE BOX SUB-ASSEMBLY) Click here

OK

-

-

INSPECT SPOT LIGHT ASSEMBLY

-

Remove the spot light assembly.

-

Inspect the spot light assembly.

Result Proceed to OK NG

NG

REPLACE SPOT LIGHT ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (MAP LIGHT (ROOF CONSOLE BOX SUB-ASSEMBLY) - SPOT LIGHT ASSEMBLY)

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance for Normal Roof without Manual (SOS) Switch Tester Connection Condition Specified Condition V13-1 (+B1) - V11-5 (B) Always Below 1 Ω V13-2 (RLMP) - V11-2 (CTY) Always Below 1 Ω V13-1 (+B1) or V11-5 (B) - Body ground Always 10 kΩ or higher V13-2 (RLMP) or V11-2 (CTY) - Body ground Always 10 kΩ or higher for Normal Roof with Manual (SOS) Switch Tester Connection Condition Specified Condition V20-10 (+B1) - V11-5 (B) Always Below 1 Ω V20-2 (RLMP) - V11-2 (CTY) Always Below 1 Ω V20-10 (+B1) or V11-5 (B) - Body ground Always 10 kΩ or higher V20-2 (RLMP) or V11-2 (CTY) - Body ground Always 10 kΩ or higher except Normal Roof Tester Connection Condition Specified Condition V14-14 (+B1) - V11-5 (B) Always Below 1 Ω V14-2 (RLMP) - V11-2 (CTY) Always Below 1 Ω V14-14 (+B1) or V11-5 (B) - Body ground Always 10 kΩ or higher V14-2 (RLMP) or V11-2 (CTY) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - MAP LIGHT (ROOF CONSOLE BOX SUB-ASSEMBLY))

-

Disconnect the 3B instrument panel junction block assembly connector.

-

Connect the V13*1, V20*2 or V14*3 map light (roof console box sub-assembly) connector.

-

*1: for Normal Roof without Manual (SOS) Switch

-

*2: for Normal Roof with Manual (SOS) Switch

-

*3: except Normal Roof

-

-

Apply battery voltage to the connector and check that the map light comes on.

OK Measurement Condition Condition Specified Condition Battery positive (+) → 3B-10

Battery negative (-) → 3B-29

Door linked switch on and map light switch LH and RH off Map light LH and RH come on Result Proceed to OK NG

OK

GO TO STEP 11 Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

-

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

-

Disconnect the 3B instrument panel junction block assembly connector.

-

Apply battery voltage to the connector and check that the room light comes on.

OK Measurement Condition Condition Specified Condition Battery positive (+) → 3B-10

Battery negative (-) → 3B-29

Room light switch in DOOR position Room light comes on Result Proceed to OK NG

OK

GO TO STEP 11 Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (INCLUDING BULB HOLDER OF THE ROOM LIGHT ASSEMBLY THAT ARE PART OF THE WIRE HARNESS)

-

-

INSPECT IGNITION KEY CYLINDER LIGHT (TRANSPONDER KEY COIL)

-

Remove the ignition key cylinder light (transponder key coil).

-

Inspect the ignition key cylinder light (transponder key coil).

Result Proceed to OK NG

NG

REPLACE IGNITION KEY CYLINDER LIGHT (TRANSPONDER KEY COIL) Click here

OK

-

-

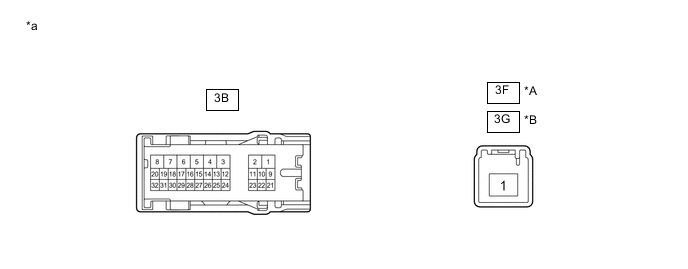

CHECK HARNESS AND CONNECTOR (BATTERY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

-

Disconnect the 3F*1 or 3G*2 instrument panel junction block assembly connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition 3F-1 - Body ground*1 Always 11 to 14 V 3G-1 - Body ground*2 Always 11 to 14 V

-

*1: for LHD

-

*2: for RHD

Result Proceed to OK NG -

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

*A for LHD *B for RHD *a Component without harness connected

(Instrument Panel Junction Block Assembly)

- -

-

Disconnect the 3B instrument panel junction block assembly connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 3B-24 - 3F-1*1 Always Below 1 Ω 3B-24 - 3G-1*2 Always Below 1 Ω

-

*1: for LHD

-

*2: for RHD

Result Proceed to OK NG -

NG

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (IGNITION KEY CYLINDER LIGHT (TRANSPONDER KEY COIL) - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition K61-2 (ILL+) - 3B-24 Always Below 1 Ω K61-4 (ILL-) - 3B-29 Always Below 1 Ω K61-2 (ILL+) or 3B-24 - Body ground Always 10 kΩ or higher K61-4 (ILL-) or 3B-29 - Body ground Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

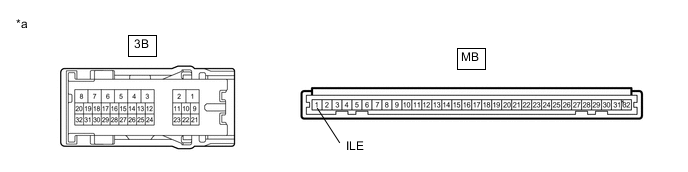

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

*a Component without harness connected

(Instrument Panel Junction Block Assembly)

- -

-

Remove the instrument panel junction block assembly.

-

Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 3B-29 - MB-1 (ILE) Always Below 1 Ω Result Proceed to OK NG

OK

REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) Click here

NG

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY Click here

-