METER / GAUGE SYSTEM Fuel Receiver Gauge Display Malfunction

DESCRIPTION

-

OPERATION

The combination meter assembly uses the fuel injection volume signal from the ECM and fuel sender gauge assembly to detect the amount of fuel remaining in the fuel tank sub-assembly. Each gauge assembly has a variable resistor whose resistance changes according to the amount of fuel remaining. The gauge assemblies receive voltage from the combination meter assembly and change the voltage based on the resistance that changes according to the amount of fuel remaining in the fuel tank sub-assembly. The combination meter assembly receives a fuel injection volume signal from the ECM and detects the voltage between each variable resistor and each resistor in the combination meter assembly, and operates the fuel receiver gauge.

-

FUEL RECEIVER GAUGE READING

-

During normal driving:

As the fuel level in the fuel tank sub-assembly changes when driving on a hill or applying brakes, the fuel receiver gauge reading is updated according to the fuel injection volume during normal driving. However, as the fuel injection volume measurement has a margin of error, the value is indicated after correction by input values from the fuel sender gauge assembly.

-

During refueling:

The fuel level in the fuel tank sub-assembly rises rapidly when fuel is added. If the averaging process that is used during normal driving is used in this case, the fuel receiver gauge reading cannot be updated promptly. Therefore, when it is judged that fuel is being added to the vehicle based on the shift lever position and changes in the fuel level, output values from the fuel sender gauge assembly are immediately reflected in the fuel receiver gauge reading. This control is called refueling judgment.

-

-

REFUELING JUDGMENT CONDITIONS

Note

Add fuel with the ignition switch off to ensure safety and to enable refueling judgment so that an appropriate fuel receiver gauge reading is obtained. If it is necessary to add fuel with the ignition switch ON, move the shift lever to P or N.

-

Normal judgment condition (When normal refueling method is used)

With the ignition switch off, the fuel sender gauge assembly detects a change of 5.0 liters (5.3 US qts, 4.4 Imp. qts) or more in the fuel level.

-

Other judgment conditions (When other refueling method is used)

Any of the following conditions is met:

-

With the vehicle and engine stopped and the ignition switch ON, the fuel sender gauge assembly detects a change of 5.0 liters (5.3 US qts, 4.4 Imp. qts) or more in the fuel level.

-

With the vehicle stopped, the engine running, the ignition switch ON and the shift lever in P or N, the fuel sender gauge assembly detects a change of 5.0 liters (5.3 US qts, 4.4 Imp. qts) or more in the fuel level.

-

With the vehicle stopped, the engine running, the ignition switch ON and the shift lever in any driving position, the fuel sender gauge assembly detects a change of 15.0 liters (15.9 US qts, 13.2 Imp. qts) or more in the fuel level.

-

-

-

PRECAUTION FOR REFUELING

The fuel sender gauge assembly cannot detect changes in the fuel level within certain ranges (around points E and F). Therefore, even though 5.0 liters (5.3 US qts, 4.4 Imp. qts) or more of fuel is added, refueling judgment may not be performed and the fuel receiver gauge reading may not change when fuel level is within such ranges.

-

FORCED RESET OF FUEL RECEIVER GAUGE

When driving at 20 km/h (12 mph) or more, if the output values from the fuel sender gauge assembly are different from the fuel receiver gauge reading by 15.0 liters (15.9 US qts, 13.2 Imp. qts) or more for approximately 2 minutes, output values from both gauge assemblies are immediately reflected in the fuel receiver gauge reading to compensate for a situation when refueling judgment cannot be made.

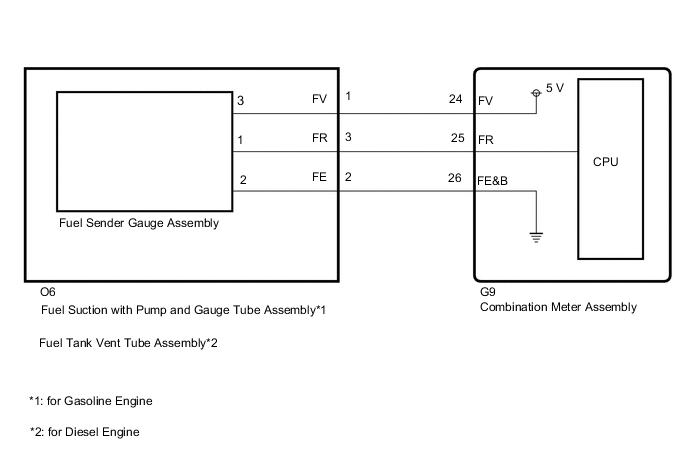

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

Be careful of flames.

Note

When replacing the combination meter assembly, make sure to replace it with a new one.

PROCEDURE

-

CHECK SYMPTOMS

-

Ask the customer about the problem symptoms.

Result Result Proceed to Malfunction occurs when adding fuel (Even after adding fuel, reading does not increase at all or increases very slowly, etc.) A Malfunction occurs during normal driving (The reading does not change, decreases quickly or decreases when the vehicle is not being driven, etc.) (The problem symptom recurs) B Malfunction occurs during normal driving (The reading does not change, decreases quickly or decreases when the vehicle is not being driven, etc.) (The problem symptom does not recur) (for Diesel Engine) C Malfunction occurs during normal driving (The reading does not change, decreases quickly or decreases when the vehicle is not being driven, etc.) (The problem symptom does not recur) (for Gasoline Engine) D

B

PERFORM ACTIVE TEST USING GTS (FUEL METER OPERATION) Click here

C

CHECK FOR DTC (ECD SYSTEM) Click here

D

CHECK FOR DTC (SFI SYSTEM) Click here

A

-

-

PERFORM ACTIVE TEST USING GTS (FUEL METER OPERATION)

-

Using the GTS, perform the Active Test.

Body Electrical > Combination Meter > Active TestTester Display Measurement Item Control Range Diagnostic Note Fuel Meter Operation Fuel receiver gauge OFF, Sender E, Empty, Warning, 1/4, 1/2, 3/4, Full or Sender F -

Body Electrical > Combination Meter > Active TestTester Display Fuel Meter Operation OK Fuel receiver gauge indication is normal. Result Result Proceed to OK (for Diesel Engine) A OK (for Gasoline Engine) B NG C

B

CHECK FOR DTC (SFI SYSTEM) Click here

C

REPLACE COMBINATION METER ASSEMBLY Click here

A

-

-

CHECK FOR DTC (ECD SYSTEM)

-

Check for DTCs.

for 1GD-FTV: Click here

for 1GD-FTV, w/ DPF: Click here

for 2GD-FTV: Click here

for 2GD-FTV, w/ DPF: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

Powertrain > Engine > Trouble CodesOK No DTCs are output. Result Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

B

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM) Click here

C

GO TO STEP 5 Click here

D

GO TO ECD SYSTEM for 1GD-FTV: Click here

GO TO ECD SYSTEM for 1GD-FTV, DPF: Click here

GO TO ECD SYSTEM for 2GD-FTV: Click here

GO TO ECD SYSTEM for 2GD-FTV, DPF: Click here

GO TO ECD SYSTEM for 1KD-FTV: Click here

GO TO ECD SYSTEM for 2KD-FTV: Click hereA

-

-

CHECK FOR DTC (VEHICLE STABILITY CONTROL SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

NG

GO TO VEHICLE STABILITY CONTROL SYSTEM Click here

OK

-

-

CHECK FUEL RECEIVER GAUGE OPERATION BY ADDING FUEL

-

Record the fuel receiver gauge reading.

-

If the fuel tank sub-assembly is almost full, drain 20 liters or more of fuel. (This is not necessary when the fuel tank sub-assembly is sufficiently below full.)

-

Disconnect the cable from the negative (-) battery terminal to reset the fuel receiver gauge.

Tech Tips

Check that the ignition switch is turned off before disconnecting the cable from the negative (-) battery terminal.

-

Connect the cable to the negative (-) battery terminal and turn the ignition switch to ON.

-

Check that the fuel receiver gauge has been reset.

-

Drive the vehicle at 1.75 km/h (1.09 mph) or more, then move the shift lever to P and turn the ignition switch off.

-

Add 5.0 liters or more of fuel, turn the ignition switch to ON, and check that the fuel receiver gauge reading increases in proportion to the amount of fuel added.

Result Result Proceed to Fuel receiver gauge reading increases in proportion to the amount of fuel added A Fuel receiver gauge reading does not change even when fuel is added B

B

GO TO STEP 7 Click here

A

-

-

INSPECT FUEL TANK SUB-ASSEMBLY

Tech Tips

Inspect the fuel tank sub-assembly for deformation, foreign matter or an improperly installed fuel receiver gauge, as this may be the cause of a fuel receiver gauge malfunction.

-

Visually check the fuel tank sub-assembly for any abnormalities.

-

Check if there is an excessive amount of foreign matter in the fuel tank sub-assembly.

-

Check the installation condition of the fuel tank sub-assembly and fuel sender gauge assembly.

Result Result Proceed to Normal A Appearance of the fuel tank sub-assembly is abnormal. (for Diesel Engine) B Appearance of the fuel tank sub-assembly is abnormal. (for Gasoline Engine) C There is an excessive amount of foreign matter in the fuel tank sub-assembly. D The fuel tank sub-assembly or fuel sender gauge assembly is not installed correctly. E

B

REPLACE FUEL TANK SUB-ASSEMBLY for 1GD-FTV: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2GD-FTV, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2GD-FTV, Short Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2KD-FTV, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1KD-FTV: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2KD-FTV, Short Wheelbase: Click hereC

REPLACE FUEL TANK SUB-ASSEMBLY for 1GR-FE: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1TR-FE, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1TR-FE, Short Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2TR-FE, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2TR-FE, Short Wheelbase: Click hereD

CLEAN INSIDE OF FUEL TANK SUB-ASSEMBLY

E

INSTALL FUEL TANK SUB-ASSEMBLY OR FUEL SENDER GAUGE ASSEMBLY CORRECTLY

A

-

-

READ VALUE USING GTS (FUEL INPUT)

-

Using the GTS, read the Data List.

Body Electrical > Combination Meter > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Fuel Input Fuel input Min.: 0, Max.: 127.5 Current fuel level displayed Unit: Liter

Body Electrical > Combination Meter > Data ListTester Display Fuel Input OK Fuel level data displayed on the GTS is almost the same as the fuel receiver gauge indication. Result Proceed to OK NG

NG

REPLACE COMBINATION METER ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (FUEL GAUGE CIRCUIT)

-

Disconnect the G9 combination meter assembly connector.

-

Disconnect the O6 fuel suction tube with pump and gauge assembly*1 or fuel tank vent tube assembly*2 connector.

-

*1: for Gasoline Engine

-

*2: for Diesel Engine

-

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G9-25 (FR) - O6-3 (FR) Always Below 1 Ω G9-24 (FV) - O6-1 (FV) Always Below 1 Ω G9-26 (FE&B) - O6-2 (FE) Always Below 1 Ω G9-25 (FR) or O6-3 (FR) - Body ground Always 10 kΩ or higher G9-24 (FV) or O6-1 (FV) - Body ground Always 10 kΩ or higher G9-26 (FE&B) or O6-2 (FE) - Body ground Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT FUEL SENDER GAUGE ASSEMBLY

-

Remove the fuel sender gauge assembly.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

for 1GD-FTV: Click here

for 2GD-FTV: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

-

Inspect the fuel sender gauge assembly.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

for 1GD-FTV: Click here

for 2GD-FTV: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

Result Result Proceed to OK (for Gasoline Engine) A OK (for Diesel Engine) B NG C

B

INSPECT FUEL TANK VENT TUBE ASSEMBLY Click here

C

REPLACE FUEL SENDER GAUGE ASSEMBLY for 1TR-FE: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 2TR-FE: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 1GR-FE: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 1GD-FTV: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 2GD-FTV: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 1KD-FTV: Click here

REPLACE FUEL SENDER GAUGE ASSEMBLY for 2KD-FTV: Click hereA

-

-

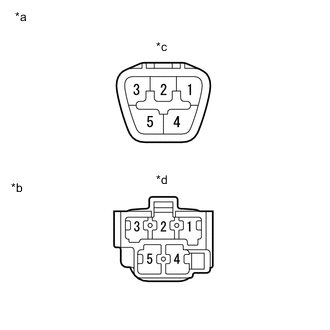

INSPECT FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY

-

*a Upper Side *b Lower Side

(to Fuel Sender Gauge Assembly)

*c Connector A *d Connector B Remove the fuel suction with pump and gauge tube assembly.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A-2 - B-2 Always Below 1 Ω A-3 - B-1 Always Below 1 Ω A-1 - B-3 Always Below 1 Ω A-2 - B-1 Always 10 kΩ or higher A-2 - B-3 Always 10 kΩ or higher A-3 - B-3 Always 10 kΩ or higher Result Proceed to OK NG

OK

REPLACE COMBINATION METER ASSEMBLY Click here

NG

REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY for 1TR-FE: Click here

REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY for 2TR-FE: Click here

REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY for 1GR-FE: Click here -

-

CHECK FOR DTC (SFI SYSTEM)

-

Check for DTCs.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

Powertrain > Engine > Trouble CodesOK No DTCs are output. Result Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

A

GO TO STEP 4 Click here

C

GO TO STEP 5 Click here

D

GO TO SFI SYSTEM for 1TR-FE: Click here

GO TO SFI SYSTEM for 2TR-FE: Click here

GO TO SFI SYSTEM for 1GR-FE: Click hereB

-

-

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

OK

GO TO STEP 5 Click here

NG

GO TO ANTI-LOCK BRAKE SYSTEM Click here

-

-

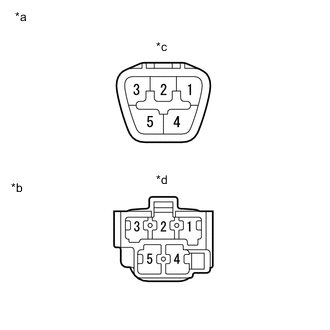

INSPECT FUEL TANK VENT TUBE ASSEMBLY

-

*a Upper Side *b Lower Side

(to Fuel Sender Gauge Assembly)

*c Connector A *d Connector B Remove the fuel tank vent tube assembly.

for 1GD-FTV: Click here

for 2GD-FTV: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A-2 - B-2 Always Below 1 Ω A-3 - B-1 Always Below 1 Ω A-1 - B-3 Always Below 1 Ω A-2 - B-1 Always 10 kΩ or higher A-2 - B-3 Always 10 kΩ or higher A-3 - B-3 Always 10 kΩ or higher Result Proceed to OK NG

OK

REPLACE COMBINATION METER ASSEMBLY Click here

NG

REPLACE FUEL TANK VENT TUBE ASSEMBLY for 1GD-FTV: Click here

REPLACE FUEL TANK VENT TUBE ASSEMBLY for 2GD-FTV: Click here

REPLACE FUEL TANK VENT TUBE ASSEMBLY for 1KD-FTV: Click here

REPLACE FUEL TANK VENT TUBE ASSEMBLY for 2KD-FTV: Click here -

-

PERFORM ACTIVE TEST USING GTS (FUEL METER OPERATION)

-

Using the GTS, perform the Active Test.

Body Electrical > Combination Meter > Active TestTester Display Measurement Item Control Range Diagnostic Note Fuel Meter Operation Fuel receiver gauge OFF, Sender E, Empty, Warning, 1/4, 1/2, 3/4, Full or Sender F -

Body Electrical > Combination Meter > Active TestTester Display Fuel Meter Operation OK Fuel receiver gauge indication is normal. Result Result Proceed to OK (for Diesel Engine) A OK (for Gasoline Engine) B NG C

B

CHECK FOR DTC (SFI SYSTEM) Click here

C

REPLACE COMBINATION METER ASSEMBLY

A

-

-

CHECK FOR DTC (ECD SYSTEM)

-

Check for DTCs.

for 1GD-FTV: Click here

for 1GD-FTV, w/ DPF: Click here

for 2GD-FTV: Click here

for 2GD-FTV, w/ DPF: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

OK No DTCs are output.

Powertrain > Engine > Trouble CodesResult Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

B

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM) Click here

C

GO TO STEP 17 Click here

D

GO TO ECD SYSTEM for 1GD-FTV: Click here

GO TO ECD SYSTEM for 1GD-FTV, w/ DPF: Click here

GO TO ECD SYSTEM for 2GD-FTV: Click here

GO TO ECD SYSTEM for 2GD-FTV, w/ DPF: Click here

GO TO ECD SYSTEM for 1KD-FTV: Click here

GO TO ECD SYSTEM for 2KD-FTV: Click hereA

-

-

CHECK FOR DTC (VEHICLE STABILITY CONTROL SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

NG

GO TO VEHICLE STABILITY CONTROL SYSTEM Click here

OK

-

-

CHECK FOR DTC

-

Check for DTC.

Body Electrical > Combination Meter > Trouble CodesOK DTC B1500 is not output. Result Proceed to OK NG

NG

GO TO DTC B1500 Click here

OK

-

-

INSPECT FUEL RECEIVER GAUGE

-

Disconnect the cable from the negative (-) battery terminal to reset the fuel receiver gauge.

Tech Tips

Check that the ignition switch is turned off before disconnecting the cable from the negative (-) battery terminal.

-

Connect the cable to the negative (-) battery terminal and turn the ignition switch to ON.

-

Check if the fuel receiver gauge reading corresponds with the amount of fuel remaining in the fuel tank sub-assembly.

Result Result Proceed to Fuel receiver gauge reading corresponds with the amount of fuel remaining in the fuel tank sub-assembly. A Fuel receiver gauge reading does not correspond with the amount of fuel remaining in the fuel tank sub-assembly. B

A

END

B

GO TO STEP 7 Click here

-

-

CHECK FOR DTC (SFI SYSTEM)

-

Check for DTCs.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

Powertrain > Engine > Trouble CodesOK No DTCs are output. Result Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

A

GO TO STEP 16 Click here

C

GO TO STEP 17 Click here

D

GO TO SFI SYSTEM for 1TR-FE: Click here

GO TO SFI SYSTEM for 2TR-FE: Click here

GO TO SFI SYSTEM for 1GR-FE: Click hereB

-

-

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

OK

GO TO STEP 17 Click here

NG

GO TO ANTI-LOCK BRAKE SYSTEM Click here

-

-

CHECK FOR DTC (ECD SYSTEM)

-

Check for DTCs.

for 1GD-FTV: Click here

for 1GD-FTV, w/ DPF: Click here

for 2GD-FTV: Click here

for 2GD-FTV, w/ DPF: Click here

for 1KD-FTV: Click here

for 2KD-FTV: Click here

Powertrain > Engine > Trouble CodesOK No DTCs are output. Result Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

B

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM) Click here

C

GO TO STEP 23 Click here

D

GO TO ECD SYSTEM for 1GD-FTV: Click here

GO TO ECD SYSTEM for 1GD-FTV, w/ DPF: Click here

GO TO ECD SYSTEM for 2GD-FTV: Click here

GO TO ECD SYSTEM for 2GD-FTV, w/ DPF: Click here

GO TO ECD SYSTEM for 1KD-FTV: Click here

GO TO ECD SYSTEM for 2KD-FTV: Click hereA

-

-

CHECK FOR DTC (VEHICLE STABILITY CONTROL SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

NG

GO TO VEHICLE STABILITY CONTROL SYSTEM Click here

OK

-

-

INSPECT FUEL TANK SUB-ASSEMBLY

Tech Tips

Inspect the fuel tank sub-assembly for deformation, foreign matter or an improperly installed fuel receiver gauge, as this may be the cause of a fuel receiver gauge malfunction.

-

Visually check the fuel tank sub-assembly for any abnormalities.

-

Check if there is an excessive amount of foreign matter in the fuel tank sub-assembly.

-

Check the installation condition of the fuel tank sub-assembly and fuel sender gauge assembly.

Result Result Proceed to Normal A Appearance of the fuel tank sub-assembly is abnormal. (for Diesel Engine) B Appearance of the fuel tank sub-assembly is abnormal. (for Gasoline Engine) C There is an excessive amount of foreign matter in the fuel tank sub-assembly. D The fuel tank sub-assembly or fuel sender gauge assembly is not installed correctly. E

A

REPLACE COMBINATION METER ASSEMBLY Click here

B

REPLACE FUEL TANK SUB-ASSEMBLY for 1GD-FTV: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2GD-FTV, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2GD-FTV, Short Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2KD-FTV, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1KD-FTV: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2KD-FTV, Short Wheelbase: Click hereC

REPLACE FUEL TANK SUB-ASSEMBLY for 1GR-FE: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1TR-FE, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 1TR-FE, Short Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2TR-FE, Long Wheelbase: Click here

REPLACE FUEL TANK SUB-ASSEMBLY for 2TR-FE, Short Wheelbase: Click hereD

CLEAN INSIDE OF FUEL TANK SUB-ASSEMBLY

E

INSTALL FUEL TANK SUB-ASSEMBLY OR FUEL SENDER GAUGE ASSEMBLY CORRECTLY

-

-

CHECK FOR DTC (SFI SYSTEM)

-

Check for DTCs.

for 1TR-FE: Click here

for 2TR-FE: Click here

for 1GR-FE: Click here

Powertrain > Engine > Trouble CodesOK No DTCs are output. Result Result Proceed to OK (w/ VSC) A OK (w/o VSC, w/ ABS) B OK (w/o ABS) C NG D

A

GO TO STEP 22 Click here

C

GO TO STEP 23 Click here

D

GO TO SFI SYSTEM for 1TR-FE: Click here

GO TO SFI SYSTEM for 2TR-FE: Click here

GO TO SFI SYSTEM for 1GR-FE: Click hereB

-

-

CHECK FOR DTC (ANTI-LOCK BRAKE SYSTEM)

-

Check for DTCs.

Chassis > ABS/VSC/TRC > Trouble CodesOK No DTCs are output. Result Proceed to OK NG

OK

GO TO STEP 23 Click here

NG

GO TO ANTI-LOCK BRAKE SYSTEM Click here

-