BLACK OUT TAPE (for Front Door) INSTALLATION

Tech Tips

-

Use the same procedure for the RH side and LH side.

-

The procedure listed below is for the LH side.

-

A bolt without a torque specification is shown in the standard bolt chart Click here.

-

When installing the black out tape, heat the vehicle body surface and black out tape using a heat light.

| Standard | ||||||

|---|---|---|---|---|---|---|

|

Note

Do not heat the vehicle body or black out tape excessively.

-

REPAIR INSTRUCTION

-

Clean the vehicle body surface.

-

Using a heat light, heat the vehicle body surface.

-

Wipe off any tape adhesive residue with cleaner.

-

-

Installation temperature.

-

When the ambient temperature is below 15°C (59°F), perform the installation procedure after warming the vehicle body surface (installation surface of the door frame) and tape to between 20 and 30°C (68 and 86°F) using a heat light. When the ambient temperature is above 35°C (95°F), cool the vehicle body surface (installation surface of the door frame) and tape to between 20 and 30°C (68 and 86°F) prior to installation.

Tech Tips

-

The most appropriate temperature for installing the tape is 25°C (77°F).

-

When the temperature is low, the tape turns stiff and falls off easily. When the temperature is high, the tape loses elasticity.

-

-

-

Before installation.

-

Make sure any dirt on and around the vehicle body surface where the tape will be installed (installation surface of the door frame) is removed, and that the surface is smooth. If the surface is rough or dirt remains when pressing the tape onto the surface, air will be trapped under the tape and result in a poor appearance.

Tech Tips

Spray water on the shop floor to settle any dust.

-

-

Key points for handling the tape.

-

The tape bends and rolls up easily. Store the tape between flat pieces of cardboard or other similar objects and keep it dry and level.

Note

Do not bend the tape or leave it in high temperature places.

-

-

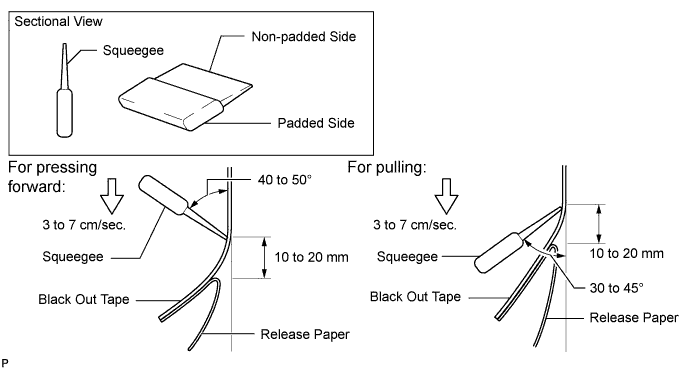

Key points for the installation of the tape (how to use a squeegee and the installation procedure for flat surfaces).

Note

-

Position the tape with a high level of accuracy to achieve a neat finish and to avoid peeling.

-

The tape cannot be reused because it deforms and will not fit after removal.

-

To avoid air bubbles, slightly raise the part of the tape that is going to be applied so that its adhesive surface does not touch the vehicle body while applying the tape. Tilt the squeegee 40 to 50° (for pressing forward) or 30 to 45° (for pulling) from the vehicle body surface and press with a force of 20 to 30 N (2 to 3 kgf) while moving the squeegee at a constant slow speed of 3 to 7 cm (1.2 to 2.8 in.) per second.

Note

Be sure to observe the specified pressing speed, force and angle of the squeegee to avoid wrinkles and air bubbles.

Tech Tips

-

Either angle of the squeegee (for pressing forward or for pulling) is acceptable.

-

Be sure to apply the tape while removing the release paper 10 to 20 mm (0.393 to 0.787 in.) from the edge of the squeegee.

-

-

-

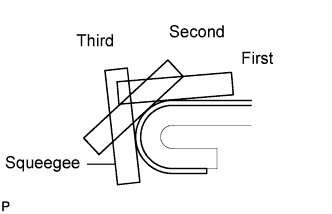

Key points for the installation of the tape (how to use a squeegee and the installation procedure for hemming surfaces).

-

If it is difficult to press the tape, press it in several steps as shown in the illustration. Use your fingers or the padded surface of a squeegee to slowly apply the tape to the hem of the vehicle, especially for a small hem.

Tech Tips

When applying tape to the backside of a hem, remove the release paper and use your fingers or the padded surface of a squeegee.

-

-

Key points for the installation of the tape (how to use a squeegee and the installation procedure for corners).

-

Remove the release paper and apply the tape carefully with your fingers.

-

Before applying the tape to each corner, heat the tape using a heat light and gradually apply it to avoid wrinkles on the tape and achieve a neat finish.

-

-

Check after installation.

-

After completing the application, check if the tape is applied neatly. If the tape is not applied neatly, apply new tape.

Note

Do not reuse the tape.

-

-

-

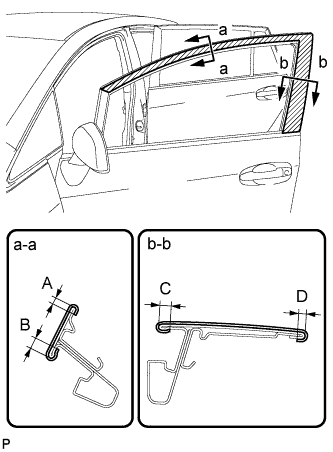

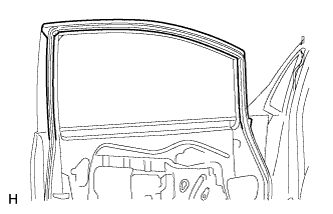

INSTALL NO. 2 BLACK OUT TAPE LH

-

Refer to the illustration to position a new No. 2 black out tape.

Standard Area Dimension A 2 to 4 mm (0.078 to 0.158 in.) B 5 mm (0.197 in.) C 5 mm (0.197 in.) D 2 to 4 mm (0.078 to 0.158 in.) -

Remove the release paper and apply the tape.

-

-

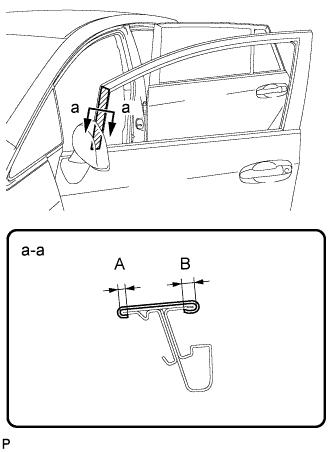

INSTALL NO. 1 BLACK OUT TAPE LH

-

Refer to the illustration to position a new No. 1 black out tape.

Standard Area Dimension A 2 to 4 mm (0.078 to 0.158 in.) B 5 mm (0.197 in.) -

Remove the release paper and apply the tape.

-

-

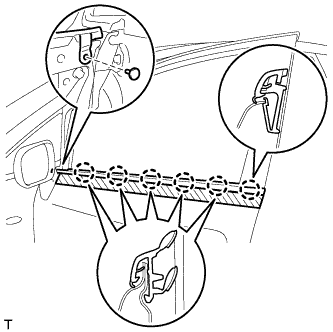

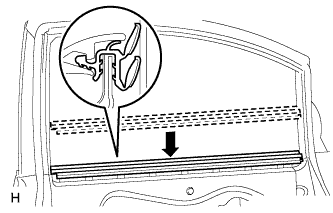

INSTALL FRONT DOOR WEATHERSTRIP LH

-

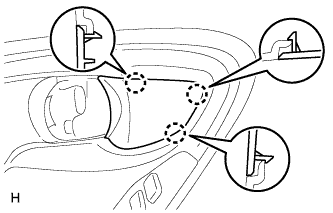

Install the upper part of the front door weatherstrip.

-

-

INSTALL FRONT DOOR BELT MOULDING ASSEMBLY LH

-

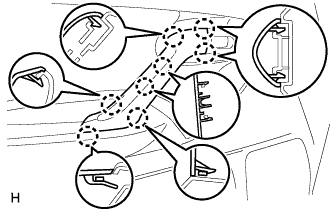

Attach the 6 claws to install the front door belt moulding.

-

Install the clip.

-

-

INSTALL FRONT DOOR GLASS RUN LH

-

Install the front door glass run.

-

-

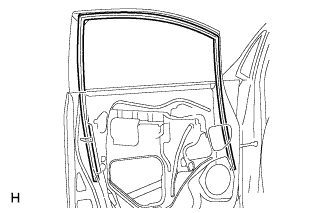

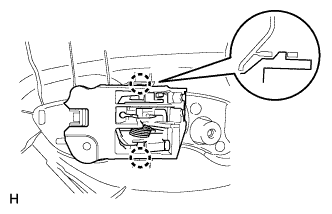

INSTALL FRONT DOOR GLASS SUB-ASSEMBLY LH

-

for Driver Side:

Temporarily install the master switch assembly.

-

for Front Passenger Side:

Temporarily install the regulator switch assembly.

-

Connect the cable to the negative (-) battery terminal.

-

Move the door glass until the bolts appear in the service holes.

-

Disconnect the cable from the negative (-) battery terminal.

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

Insert the door glass into the door panel along the glass run as indicated by the arrows in the illustration.

Note

Be careful not to damage the glass.

-

Install the door glass to the window regulator with the 2 bolts.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

-

INSTALL FRONT DOOR INNER GLASS WEATHERSTRIP LH

-

Install the front door inner glass weatherstrip.

-

-

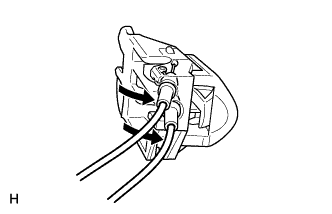

INSTALL FRONT DOOR INSIDE HANDLE SUB-ASSEMBLY LH

-

Connect the front door lock remote control cable and front door inside locking cable to the front door inside handle sub-assembly to install the inside handle.

-

-

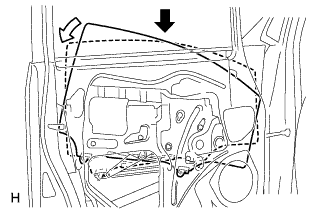

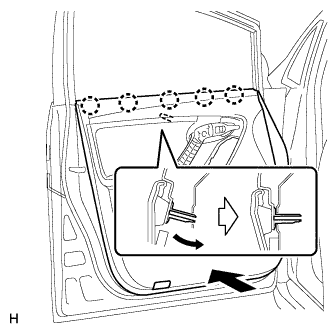

INSTALL FRONT DOOR TRIM BOARD SUB-ASSEMBLY LH

-

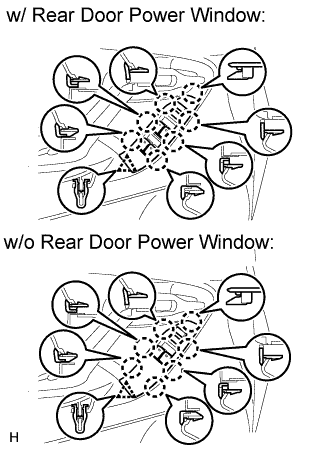

Attach the 2 claws to install the front door inside handle sub-assembly to the door trim board.

-

Attach the front door trim board with the 5 claws of the front door inner glass weatherstrip and the reference boss.

-

w/ Courtesy Light:

-

Connect the courtesy light connector.

-

-

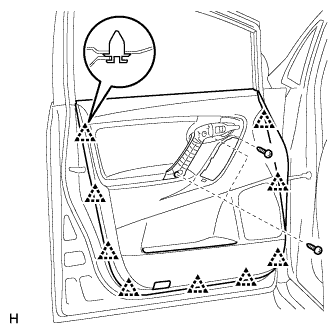

Attach the 9 clips to install the trim board.

-

Install the 3 screws.

-

-

INSTALL POWER WINDOW REGULATOR MASTER SWITCH ASSEMBLY WITH FRONT DOOR ARMREST BASE PANEL

-

Connect the connector.

-

Attach the 7 claws and clip to install the power window regulator master switch assembly with front door armrest base panel.

-

-

INSTALL FRONT DOOR TRIM MOULDING LH

-

Attach the 8 claws to install the front door trim moulding.

-

-

INSTALL FRONT DOOR INSIDE HANDLE BEZEL LH

-

Attach the 3 claws to install the inside handle bezel.

-

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.