SFI SYSTEM (w/ EGR System) INITIALIZATION

-

Inspection After Repair

Perform learning value reset and idle learning after replacing or servicing parts related to engine operation. Details on procedures required are indicated by an asterisk and a number, and are explained in detail following the table.

Part Replaced Engine Operation Learning Value Reset*1 Idle Learning*2

-

Throttle body with motor assembly*3

-

Cleaning the deposits from the throttle body with motor assembly*3

- ○ ○ Engine assembly - ○ ○

-

Cylinder head sub-assembly

-

Camshaft (for intake or exhaust camshaft)

-

Camshaft timing gear assembly

-

Camshaft timing exhaust gear assembly

-

Piston or piston ring

-

Mass air flow meter sub-assembly

-

Fuel injector assembly (for direct injection)

-

Fuel injector assembly (for port injection)

-

Fuel pump (for high pressure)

-

Fuel pump (for low pressure)

-

Air fuel ratio sensor

-

Engine coolant temperature sensor

-

Spark plug

-

Ignition coil assembly

-

EGR valve assembly

-

Air leaks from intake system

-

Gas leaks from exhaust system

Confirm the following:

Perform learning value reset and idle learning when one or more of the following conditions is met.

-

A DTC was output before component replacement.

-

An air fuel ratio learned value (one of A/F Learn Value Idle #1, A/F Learn Value Low #1, A/F Learn Value Mid1 #1, A/F Learn Value Mid2 #1, A/F Learn Value High #1, A/F Learn Value Idle #1 (Dual), A/F Learn Value Mid1 #1 (Dual), A/F Learn Value Mid2 #1 (Dual) and A/F Learn Value High #1 (Dual)) displayed in the Data List was higher than +/- 20% before component replacement.

-

Starting failure, rough idle, or engine stalls after component replacement.

○ ○ The items in the list above do not apply. - - Knock control sensor*4 - - -

-

○: Necessary.

-

-: Unnecessary.

Note

Engine learned values cannot be reset by disconnecting the auxiliary battery negative (-) terminal or removing the EFI MAIN and ETCS fuses.

-

*1: Learning Value Reset

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Learning Value Reset.

-

Confirm the following conditions as instructed on the screen.

-

- Power switch on (IG)

-

- Engine stopped

-

- Auxiliary battery voltage is higher than 9 V

-

After confirming, select "Next" and initialize the learned value.

Tech Tips

If a message indicating learned value initialization failure is displayed on the screen, confirm the execution conditions, and perform learned value initialization again.

-

After the completion of learned value initialization, confirm the air fuel ratio learned values (A/F Learn Value Idle #1, A/F Learn Value Low #1, A/F Learn Value Mid1 #1, A/F Learn Value Mid2 #1, A/F Learn Value High #1, A/F Learn Value Idle #1 (Dual), A/F Learn Value Mid1 #1 (Dual), A/F Learn Value Mid2 #1 (Dual) and A/F Learn Value High #1 (Dual)) in the Data List.

Result If 0 is displayed for all the air fuel ratio learned values, initialization has completed correctly. If a value other than 0 is displayed for one of the air fuel ratio learned values, perform initialization again. After initialization, confirm the air fuel ratio learned values. If a value other than 0 is displayed, replace the ECM. -

*2: Idle Learning

-

Turn the power switch off and wait for at least 30 seconds.

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Put the engine in inspection mode (maintenance mode) Click here.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Coolant Temp.

-

Start the engine and warm it up until the engine coolant temperature is 70°C (158°F) or higher.

-

Turn the power switch off, and then on (READY).

-

With the shift lever in P, lightly depress the accelerator pedal to start the engine.

-

Wait until the engine stops.

Tech Tips

The engine normally stops within 1 minute. However, when the HV battery SOC is low, the engine may remain running for approximately 3 minutes.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / ISC Learning.

-

Confirm that the display on GTS is Compl.

-

Put the engine in inspection mode (maintenance mode) Click here.

-

Start the engine.

-

Confirm that the idle speed is within the standard range.

Standard Engine Idle Speed 950 to 1050 rpm Tech Tips

-

Be sure to perform this step with all accessories off.

-

Make sure that the shift lever is in P.

-

-

*3: Perform memory reset and idle learning after replacing the throttle body with motor assembly or cleaning deposits from the throttle body with motor assembly.

After that, check the idle speed. If the value is out of the specified range, perform the procedure below.

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

Tech Tips

History information for driving and stopping is necessary to update idle learning.

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Put the engine in inspection mode (maintenance mode) Click here.

-

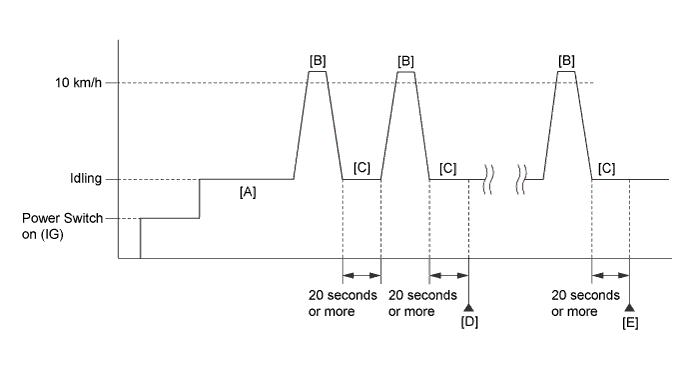

Warm up the engine (engine coolant temperature is 80°C (176°F) or higher, air conditioning and all accessories are off) [A].

-

Drive the vehicle at 10 km/h (6 mph) or more [B].

-

Idle the engine for 20 seconds or more [C].

-

Repeat procedure [B] and [C], and check that the idle speed is within the specified range [D].

Standard Engine Idle Speed 950 to 1050 rpm Tech Tips

-

Be sure to perform this step with all accessories off.

-

Make sure that the shift lever is in P or N.

-

If the idle speed is still out of the specified range, repeat procedure [B] and [C] until the idle speed is within the specified range [E].

-

-

*4: Drive the vehicle for a short while after replacing the knock control sensor, and check if knocking occurs. If knocking occurs, drive the vehicle until knocking stops.

-