FC BOOST CONTROL SYSTEM, Diagnostic DTC:U1161-450

| DTC Code | DTC Name |

|---|---|

| U1161-450 | Lost Communication with FC System |

DESCRIPTION

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | Warning Indicate |

|---|---|---|---|---|

| U1161-450 | Lost Communication with FC System | Communication error occurs between FC boost control ECU and FC control ECU. (1 trip detection logic) |

|

Master Warning Light: Comes on |

-

*1: w/ Diagnosis Recorder ECU

WIRING DIAGRAM

CAUTION / NOTICE / HINT

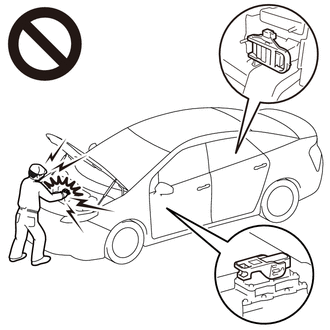

CAUTION:

-

Before the following operations are conducted, take precautions to prevent electric shock by turning the power switch off, wearing insulated gloves, and removing the service plug grips from both FC stack assembly and EV battery.

-

Inspecting the high-voltage system

-

Disconnecting the low voltage connector of the inverter with converter assembly

-

Disconnecting the low voltage connector of the EV battery.

-

Disconnecting the low voltage connector of the FC stack assembly

-

Disconnecting the low voltage connector of the FC converter assembly

Tech Tips

No removal order is specified for the service plug grips of the FC stack assembly and EV battery.

-

After removing the service plug grip from the EV battery, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system. After removing the service grip from the FC stack assembly, store it in a safe location and use the "HIGH-VOLTAGE, DO NOT TOUCH" sign to notify other technicians that you are working on the high-voltage system.

-

*a Without waiting for 10 minutes After removal of the service plug grips of both FC stack assembly and EV battery, wait for at least 10 minutes before touching the high-voltage connectors and terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work.

Tech Tips

At least 10 minutes are necessary to discharge the high-voltage capacitors inside the inverter with converter assembly and FC stack assembly.

Note

-

When reinstalling the service plug grip to the FC stack assembly or the EV battery, slide the lever of the service plug until the letters "UNLOCK" are completely hidden, and insert it firmly.

-

When the vehicle is parked with the power switch off, if the FC control ECU judges that the FC stack temperature will go below 0°C (32°F), it activates the FC air compressor, hydrogen pump and FC cooling water pump for a maximum of 180 seconds and drains water from the FC stack assembly. When performing inspection or repairs with the power switch off (not on (IG) or on (READY)), disconnect the cable from the negative (-) auxiliary battery terminal before performing work (If the auxiliary battery voltage is needed to conduct inspection, warm up the FC system beforehand).

-

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

-

Before measuring the resistance of the CAN bus, turn the power switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) auxiliary battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

Tech Tips

After the repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

-

Turn the power switch on (IG) and wait for 2 minutes or more.

PROCEDURE

-

CHECK CAN BUS (FC LOCAL BUS)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed to FC stack assembly and EV battery.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

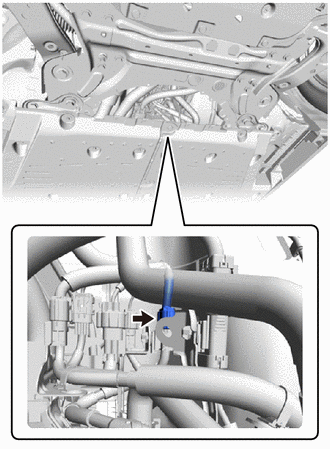

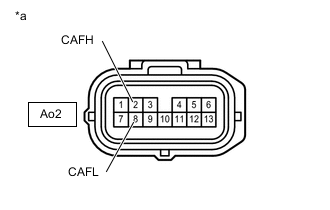

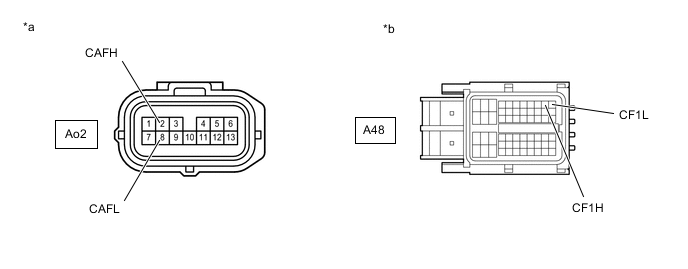

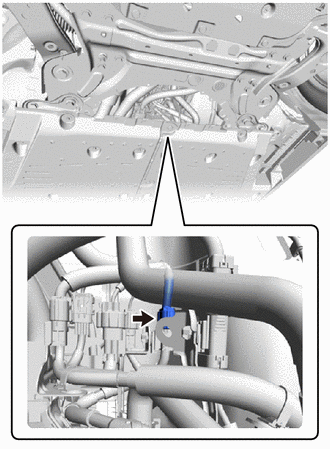

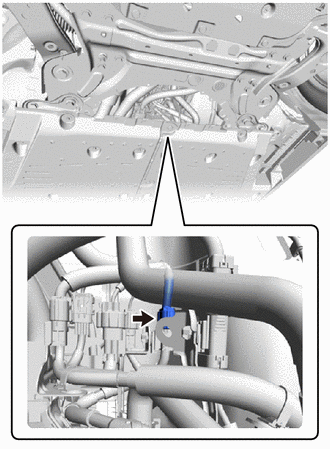

Disconnect the Ao2 FC converter assembly connector.

-

*a Front view of wire harness connector

(to FC Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition Ao2-2 (CAFH) - Ao2-8 (CAFL) Negative (-) auxiliary battery terminal disconnected 108 to 132 Ω Ao2-2 (CAFH) or Ao2-8 (CAFL) - Body ground and other terminals Negative (-) auxiliary battery terminal disconnected 10 kΩ or higher -

Connect the FC converter assembly connector.

Result Result Proceed to OK A NG (w/ Diagnosis Recorder ECU) B NG (w/o Diagnosis Recorder ECU) C

B

CHECK HARNESS AND CONNECTOR (FC LOCAL BUS) Click here

C

CHECK HARNESS AND CONNECTOR (FC LOCAL BUS) Click here

A

-

-

CHECK HARNESS AND CONNECTOR (FC CONVERTER ASSEMBLY - FC CONTROL ECU)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed to FC stack assembly and EV battery.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the Ao2 FC converter assembly connector.

-

Disconnect the FC control ECU connector.

-

Measure the resistance according to the value(s) in the table below.

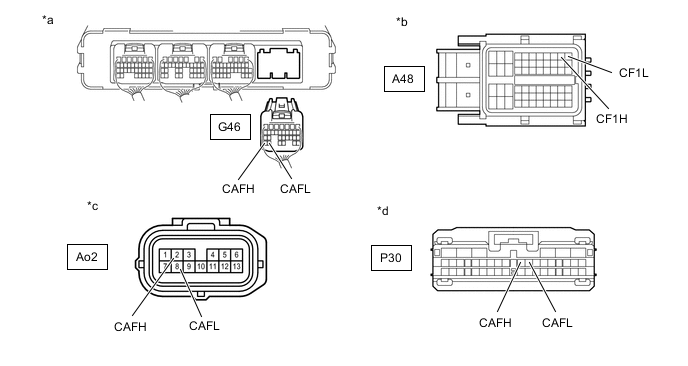

*a Front view of wire harness connector

(to FC Converter Assembly)

*b Front view of wire harness connector

(to FC Control ECU)

Standard Resistance Tester Connection Switch Condition Specified Condition Ao2-2 (CAFH) - A48-10 (CF1H) Power switch off Below 1 Ω Ao2-8 (CAFL) - A48-11 (CF1L) Power switch off Below 1 Ω -

Connect the FC control ECU connector.

-

Connect the FC converter assembly connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

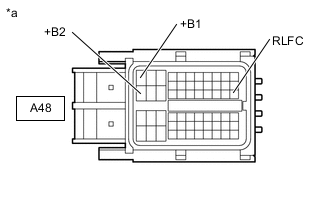

CHECK TERMINAL VOLTAGE (+B1, +B2)

Result Proceed to OK NG

-

Disconnect the FC control ECU connector.

-

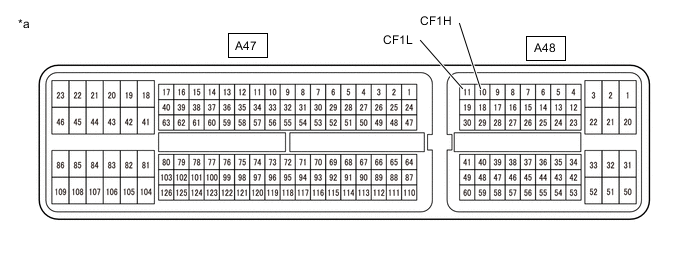

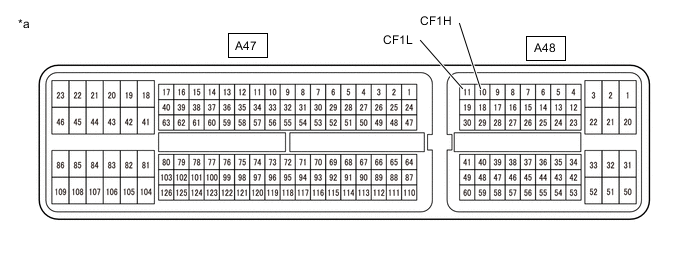

*a Front view of wire harness connector

(to FC Control ECU)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A48-1 (+B1) - Body ground Apply the auxiliary battery voltage between A48-30 (RLFC) and the body ground 11 to 14 V A48-20 (+B2) - Body ground Apply the auxiliary battery voltage between A48-30 (RLFC) and the body ground 11 to 14 V -

Reconnect the FC control ECU connector.

Result Proceed to OK NG

NG

CHECK ECU POWER SOURCE CIRCUIT (FC CONTROL SYSTEM) Click here

OK

-

-

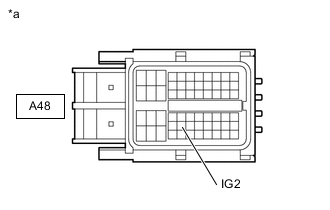

CHECK TERMINAL VOLTAGE (IG2)

Result Proceed to OK NG

-

Disconnect the FC control ECU connector.

-

Turn the power switch on (IG).

-

*a Front view of wire harness connector

(to FC Control ECU)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A48-43 (IG2) - Body ground Power switch on (IG) 11 to 14 V -

Turn the power switch off.

-

Reconnect the FC control ECU connector.

Result Proceed to OK NG

NG

CHECK ECU POWER SOURCE CIRCUIT (FC CONTROL SYSTEM) Click here

OK

-

-

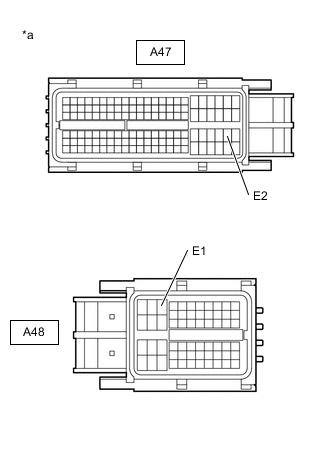

CHECK HARNESS AND CONNECTOR (FC CONTROL ECU - BODY GROUND)

Result Proceed to OK NG

-

Disconnect the FC control ECU connector.

-

*a Front view of wire harness connector

(to FC Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A48-3 (E1) - Body ground Power switch off Below 1 Ω A47-85 (E2) - Body ground Power switch off Below 1 Ω -

Reconnect the FC control ECU connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

REPLACE FC CONTROL ECU

-

Replace the FC control ECU.

Result Proceed to NEXT

NEXT

-

-

CLEAR DTC

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / FCDC / Trouble Codes.

Powertrain > FCDC > Clear DTCs -

Clear the DTCs.

Result Proceed to NEXT -

Turn the power switch off and wait for 3 minutes or more.

NEXT

-

-

CHECK DTC OUTPUT (FCDC)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG) and wait for 2 minutes or more.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / FCDC / Trouble Codes.

Powertrain > FCDC > Trouble Codes -

Check for DTCs.

Result Result Proceed to DTC U1161-450 is not output A DTC U1161-450 is output B -

Turn the power switch off.

A

END

B

REPLACE FC CONVERTER ASSEMBLY Click here

-

-

CHECK HARNESS AND CONNECTOR (FC LOCAL BUS)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed to FC stack assembly and EV battery.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the EV control ECU connector.

-

Disconnect the FC control ECU connector.

-

Disconnect the hydrogen fuel control ECU assembly connector.

-

Disconnect the diagnosis recorder ECU connector.

-

Disconnect the Ao2 FC converter assembly connector.

-

Measure the resistance according to the value(s) in the table below.

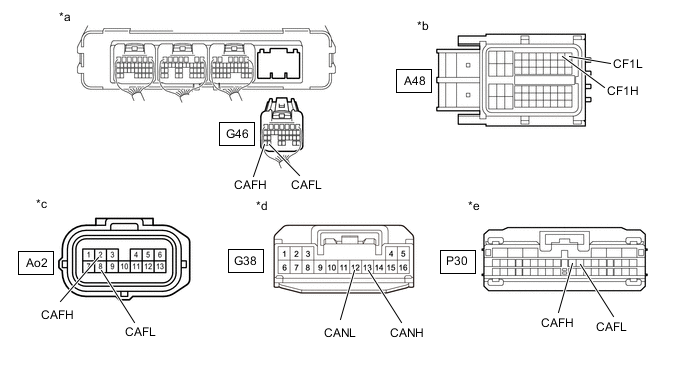

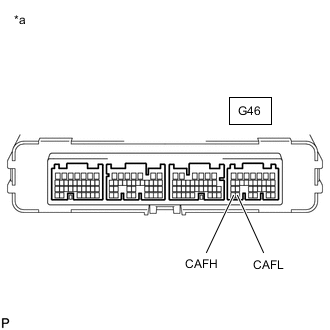

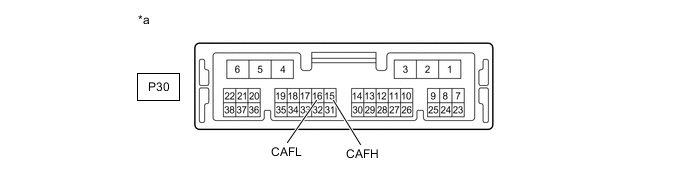

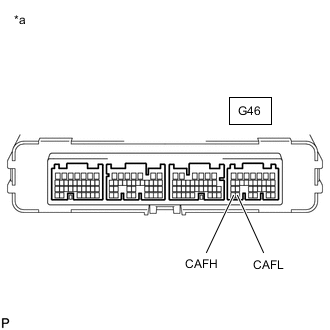

*a Rear view of wire harness connector

(to EV Control ECU)

*b Front view of wire harness connector

(to FC Control ECU)

*c Front view of wire harness connector

(to FC Converter Assembly)

*d Front view of wire harness connector

(to Diagnosis Recorder ECU)

*e Front view of wire harness connector

(to Hydrogen Fuel Control ECU Assembly)

- - Standard Resistance Tester Connection Switch Condition Specified Condition G46-31 (CAFH) - Ao2-2 (CAFH) Power switch off Below 1 Ω G46-31 (CAFH) - P30-15 (CAFH) Power switch off Below 1 Ω G46-31 (CAFH) - A48-10 (CF1H) Power switch off Below 1 Ω G46-31 (CAFH) - G38-13 (CANH) Power switch off Below 1 Ω G46-30 (CAFL) - Ao2-8 (CAFL) Power switch off Below 1 Ω G46-30 (CAFL) - P30-16 (CAFL) Power switch off Below 1 Ω G46-30 (CAFL) - A48-11 (CF1L) Power switch off Below 1 Ω G46-30 (CAFL) - G38-12 (CANL) Power switch off Below 1 Ω G46-31 (CAFH), A48-10 (CF1H), Ao2-2 (CAFH), P30-15 (CAFH) or G38-13 (CANH) - Body ground and other terminals Power switch off 10 kΩ or higher G46-30 (CAFL), A48-11 (CF1L), Ao2-8 (CAFL), P30-16 (CAFL) or G38-12 (CANL) - Body ground and other terminals Power switch off 10 kΩ or higher -

Connect the EV control ECU connector.

-

Connect the FC control ECU connector.

-

Connect the hydrogen fuel control ECU assembly connector.

-

Connect the FC converter assembly connector.

-

Connect the diagnosis recorder ECU connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT FC CONTROL ECU

-

Disconnect all connectors from the FC control ECU.

-

Measure the resistance according to the value(s) in the table below.

*a Component without harness connected

(FC Control ECU)

- - Standard Resistance Tester Connection Condition Specified Condition A48-10 (CF1H) - A48-11 (CF1L) Always 10 kΩ or higher A48-10 (CF1H) or A48-11 (CF1L) - Body ground and other terminals Always 10 kΩ or higher -

Connect the FC control ECU connector.

Result Proceed to OK NG

NG

REPLACE FC CONTROL ECU Click here

OK

-

-

INSPECT EV CONTROL ECU

-

Disconnect all connectors from the EV control ECU.

-

*a Component without harness connected

(EV Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Standard Voltage Condition Specified Condition G46-31 (CAFH) - G46-30 (CAFL) Always 10 kΩ or higher G46-31 (CAFH) or G46-30 (CAFL) - Body ground and other terminals Always 10 kΩ or higher -

Connect the EV control ECU connector.

Result Proceed to OK NG

NG

REPLACE EV CONTROL ECU Click here

OK

-

-

INSPECT HYDROGEN FUEL CONTROL ECU ASSEMBLY

-

Disconnect the hydrogen fuel control ECU assembly connector.

-

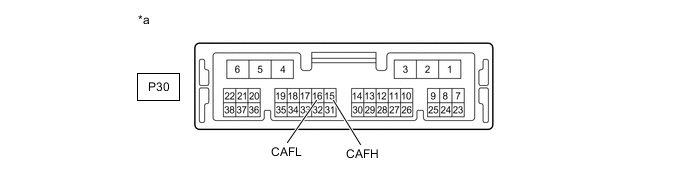

Measure the resistance according to the value(s) in the table below.

*a Component without harness connected

(Hydrogen Fuel Control ECU Assembly)

- - Standard Resistance Tester Connection Condition Specified Condition P30-15 (CAFH) - P30-16 (CAFL) Always 108 to 132 Ω P30-15 (CAFH) or P30-16 (CAFL) - Body ground and other terminals Always 10 kΩ or higher -

Connect the hydrogen fuel control ECU assembly connector.

Result Proceed to OK NG

OK

REPLACE DIAGNOSIS RECORDER ECU Click here

NG

REPLACE HYDROGEN FUEL CONTROL ECU ASSEMBLY Click here

-

-

CHECK HARNESS AND CONNECTOR (FC LOCAL BUS)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed to FC stack assembly and EV battery.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the EV control ECU connector.

-

Disconnect the FC control ECU connector.

-

Disconnect the hydrogen fuel control ECU assembly connector.

-

Disconnect the Ao2 FC converter assembly connector.

-

Measure the resistance according to the value(s) in the table below.

*a Rear view of wire harness connector

(to EV Control ECU)

*b Front view of wire harness connector

(to FC Control ECU)

*c Front view of wire harness connector

(to FC Converter Assembly)

*d Front view of wire harness connector

(to Hydrogen Fuel Control ECU Assembly)

Standard Resistance Tester Connection Switch Condition Specified Condition G46-31 (CAFH) - Ao2-2 (CAFH) Power switch off Below 1 Ω G46-31 (CAFH) - P30-15 (CAFH) Power switch off Below 1 Ω G46-31 (CAFH) - A48-10 (CF1H) Power switch off Below 1 Ω G46-30 (CAFL) - Ao2-8 (CAFL) Power switch off Below 1 Ω G46-30 (CAFL) - P30-16 (CAFL) Power switch off Below 1 Ω G46-30 (CAFL) - A48-11 (CF1L) Power switch off Below 1 Ω G46-31 (CAFH), A48-10 (CF1H), Ao2-2 (CAFH) or P30-15 (CAFH) - Body ground and other terminals Power switch off 10 kΩ or higher G46-30 (CAFL), A48-11 (CF1L), Ao2-8 (CAFL) or P30-16 (CAFL) - Body ground and other terminals Power switch off 10 kΩ or higher -

Connect the EV control ECU connector.

-

Connect the FC control ECU connector.

-

Connect the hydrogen fuel control ECU assembly connector.

-

Connect the FC converter assembly connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT FC CONTROL ECU

-

Disconnect all connectors from the FC control ECU.

-

Measure the resistance according to the value(s) in the table below.

*a Component without harness connected

(FC Control ECU)

- - Standard Resistance Tester Connection Condition Specified Condition A48-10 (CF1H) - A48-11 (CF1L) Always 10 kΩ or higher A48-10 (CF1H) or A48-11 (CF1L) - Body ground and other terminals Always 10 kΩ or higher -

Connect the FC control ECU connector.

Result Proceed to OK NG

NG

REPLACE FC CONTROL ECU Click here

OK

-

-

INSPECT EV CONTROL ECU

-

Disconnect all connectors from the EV control ECU.

-

*a Component without harness connected

(EV Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Standard Voltage Condition Specified Condition G46-31 (CAFH) - G46-30 (CAFL) Always 10 kΩ or higher G46-31 (CAFH) or G46-30 (CAFL) - Body ground and other terminals Always 10 kΩ or higher -

Connect the EV control ECU connector.

Result Proceed to OK NG

NG

REPLACE EV CONTROL ECU Click here

OK

-

-

INSPECT HYDROGEN FUEL CONTROL ECU ASSEMBLY

-

Disconnect the hydrogen fuel control ECU assembly connector.

-

Measure the resistance according to the value(s) in the table below.

*a Component without harness connected

(Hydrogen Fuel Control ECU Assembly)

- - Standard Resistance Tester Connection Condition Specified Condition P30-15 (CAFH) - P30-16 (CAFL) Always 108 to 132 Ω P30-15 (CAFH) or P30-16 (CAFL) - Body ground and other terminals Always 10 kΩ or higher -

Connect the hydrogen fuel control ECU assembly connector.

Result Proceed to OK NG

OK

CHECK FOR INTERMITTENT PROBLEMS Click here

NG

REPLACE HYDROGEN FUEL CONTROL ECU ASSEMBLY Click here

-