ENGINE ASSEMBLY INSTALLATION

PROCEDURE

-

INSTALL ENGINE HANGER

-

INSTALL FRONT ENGINE MOUNTING INSULATOR

Tech Tips

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

-

Install the 2 front engine mounting insulator to the 2 front No. 1 engine mounting brackets with the 2 nuts.

- Torque:

- 58 N*m { 591 kgf*cm, 43 ft.*lbf }

-

-

INSTALL FRONT ENGINE MOUNTING HEAT INSULATOR RH

-

Install the front engine mounting heat insulator RH to the front engine mounting insulator with the bolt.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

INSTALL ENGINE WIRE

-

Install the engine wire to the engine assembly.

-

-

REMOVE ENGINE FROM ENGINE STAND

Note

-

Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

-

With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

-

Attach the engine sling device and hang the engine assembly with the chain block.

-

Remove the engine assembly from the engine stand.

-

-

INSTALL ENGINE ASSEMBLY

-

Slowly lower the engine assembly into the engine compartment.

-

Install the engine assembly to the body with the 4 bolts and 4 nuts.

- Torque:

- 42 N*m { 428 kgf*cm, 31 ft.*lbf }

Tech Tips

-

Make sure to tighten the side with the nut.

-

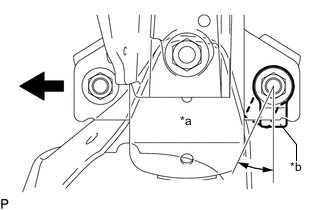

When installing a bolt with a claw (stopper), make sure to install the bolt with the claw (stopper) as shown in the illustration so that a clearance is maintained between the claw (stopper) and the intermediate shaft.

*a Front Engine Mounting Insulator

(LH Side)

*b Claw (Stopper)

Front -

Remove the 2 bolts and 2 engine hangers.

-

-

INSTALL REAR END PLATE

-

Install the rear end plate to the cylinder block with the bolt.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

-

Connect the No. 1 water by-pass pipe to the rear end plate with the bolt.

- Torque:

- 17.5 N*m { 178 kgf*cm, 13 ft.*lbf }

-

-

INSTALL FLYWHEEL SUB-ASSEMBLY

-

INSTALL CLUTCH DISC ASSEMBLY

-

INSTALL CLUTCH COVER ASSEMBLY

-

INSPECT AND ADJUST CLUTCH COVER ASSEMBLY

-

INSTALL MANUAL TRANSMISSION UNIT ASSEMBLY

-

INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

-

INSTALL PROPELLER SHAFT GUARD

-

INSTALL FRONT EXHAUST PIPE ASSEMBLY

-

CONNECT ENGINE WIRE

-

Connect the sensor bracket to the right side of the frame with the bolt.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

-

Connect the air fuel ratio sensor connector.

-

Connect the wire clamp to the front engine mounting bracket LH with the bolt.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Connect the 2 connectors to the engine room relay block.

-

Attach the clamp.

-

Connect the engine wire to the engine room relay block with the nut.

- Torque:

- 12.5 N*m { 127 kgf*cm, 9 ft.*lbf }

-

Attach the 2 claws and install the No. 1 relay block cover side to the engine room relay block.

-

Attach the 3 claws and install the No. 1 relay block cover upper to the engine room relay block.

-

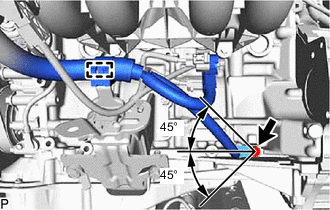

Attach the clamp and install the No. 2 engine wire with the bolt.

- Torque:

- 27 N*m { 275 kgf*cm, 20 ft.*lbf }

Tech Tips

Position the No. 2 engine wire as shown in the illustration.

-

Attach the 2 clamps and connect the No. 2 engine wire with the 2 bolts.

- Torque:

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

-

Install the battery tray.

-

Install the battery.

-

Install the battery hold down clamp with the 2 nuts.

- Torque:

- 5.4 N*m { 55 kgf*cm, 48 in.*lbf }

-

Tighten the nut and install the positive (+) battery terminal.

- Torque:

- 5.35 N*m { 55 kgf*cm, 47 in.*lbf }

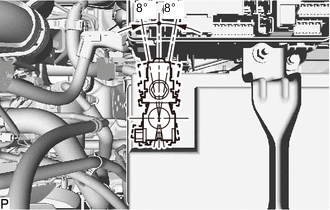

Tech Tips

Position the positive (+) battery terminal as shown in the illustration.

-

Connect the engine room main wire to the positive (+) battery terminal with the nut.

- Torque:

- 7.55 N*m { 77 kgf*cm, 67 in.*lbf }

-

Connect the connector to the engine room main wire.

-

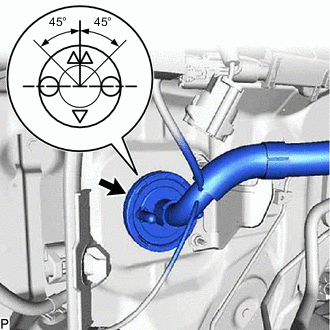

Push the engine wire through the dash panel into the cabin.

Tech Tips

The wire should be within the range shown in the illustration.

-

Connect the engine wire with the bolt.

- Torque:

- 8.3 N*m { 85 kgf*cm, 73 in.*lbf }

-

Attach the 2 clamps and connect the 3 connectors to the instrument panel wire.

-

-

INSTALL ECM

-

INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY

-

CONNECT NO. 1 FUEL HOSE

-

CONNECT NO. 2 FUEL HOSE

-

CONNECT UNION TO CONNECTOR TUBE HOSE

-

Connect the union to connector tube hose to the intake manifold, and slide the clip to secure the hose.

-

-

CONNECT PURGE LINE HOSE

-

Connect the purge line hose to the purge VSV, and slide the clip to secure the hose.

-

-

INSTALL STARTER ASSEMBLY

-

for DENSO Made:

-

for BOSCH Made:

-

-

CONNECT COOLER COMPRESSOR ASSEMBLY (w/ Air Conditioning System)

-

INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

-

Install a new O-ring and the engine oil level dipstick guide with the bolt.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

-

INSTALL ENGINE OIL LEVEL DIPSTICK

-

CONNECT VANE PUMP ASSEMBLY

-

Connect the vane pump assembly with the 2 bolts.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

Connect the power steering oil pressure switch connector.

-

-

CONNECT HEATER HOSE

-

Connect the heater water outlet hose to the heater radiator unit sub-assembly, and slide the clamp to secure the hose.

-

Connect the heater water inlet hose to the heater radiator unit sub-assembly, and slide the clamp to secure the hose.

-

-

INSTALL RADIATOR ASSEMBLY

-

INSTALL FAN SHROUD

-

INSTALL RADIATOR RESERVOIR

-

INSTALL RADIATOR HOSE OUTLET

-

INSTALL RADIATOR HOSE INLET

-

INSTALL NO. 1 RADIATOR AIR GUIDE

-

INSTALL RADIATOR SIDE DEFLECTOR LH

-

for Resin Type Bumper:

-

for Steel Type Bumper:

-

-

INSTALL RADIATOR SIDE DEFLECTOR RH

Tech Tips

Use the same procedure described for the LH side.

-

INSTALL INTAKE AIR CONNECTOR

-

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

-

Install the air cleaner case sub-assembly with the 3 bolts.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

Attach the 3 wire harness clamps.

-

-

INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

-

Install the air cleaner filter element sub-assembly to the air cleaner cap sub-assembly.

-

-

INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH NO. 1 AIR CLEANER HOSE

-

Install the air cleaner cap sub-assembly with No. 1 air cleaner hose and tighten the hose clamp.

- Torque:

- 4.0 N*m { 41 kgf*cm, 35 in.*lbf }

-

Attach the 4 clamps.

-

Connect the intake mass air flow meter connector and attach the 2 wire harness clamps.

-

-

INSTALL HOOD SUB-ASSEMBLY

-

Install the hood sub-assembly to the 2 hood hinge assemblies with the 4 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Connect the washer nozzle hose to the hood sub-assembly.

-

Adjust the hood sub-assembly.

-

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

ADD ENGINE OIL

-

ADD ENGINE COOLANT

-

ADD MANUAL TRANSMISSION OIL

-

INSPECT FOR FUEL LEAK

-

INSPECT FOR OIL LEAK

-

INSPECT FOR COOLANT LEAK

-

INSPECT FOR EXHAUST GAS LEAK

-

INSPECT IGNITION TIMING

-

INSPECT ENGINE IDLE SPEED

-

CHECK CO/HC

-

CHECK THROTTLE BODY WITH MOTOR ASSEMBLY

-

INSTALL NO. 1 ENGINE UNDER COVER (w/ Cover)

- Torque:

- 28 N*m { 286 kgf*cm, 21 ft.*lbf }

-

INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY (w/ Cover)

-

INSTALL FRONT FENDER SEAL LH

-

Install the front fender seal LH with the 5 new clips.

-

-

INSTALL FRONT FENDER SEAL RH

-

Install the front fender seal RH with the 5 new clips.

-

-

INSTALL FRONT UPPER FENDER APRON SEAL LH

-

Install the front upper fender apron seal LH with the 6 new clips.

-

-

INSTALL FRONT UPPER FENDER APRON SEAL RH

-

Install the front upper fender apron seal RH with the 6 new clips.

-