AUTOMATIC TRANSMISSION ASSEMBLY INSTALLATION

PROCEDURE

-

INSTALL TORQUE CONVERTER ASSEMBLY

-

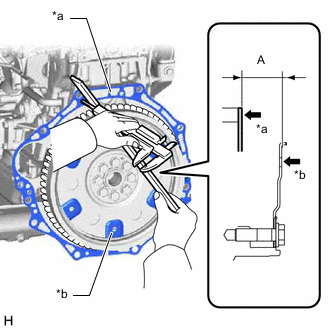

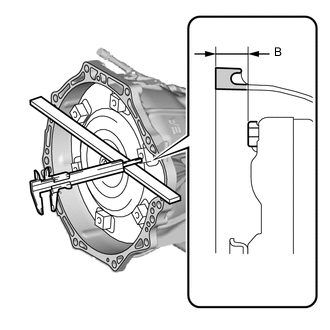

*a Engine Assembly Surface *b Pump Impeller Drive Plate Surface Using a vernier caliper and straightedge, measure the dimension (A) between the automatic transmission assembly contact surface of the engine assembly*a and the torque converter assembly contact surface of the pump impeller drive plate*b.

-

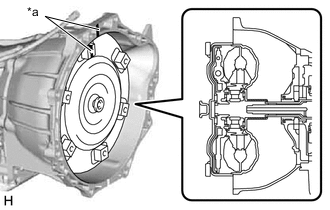

*a Matchmark Align the matchmark on the automatic transmission case sub-assembly with the one on the torque converter assembly and engage the splines of the input shaft with the turbine runner splines.

Note

Install the torque converter assembly to the input shaft while keeping it horizontal.

-

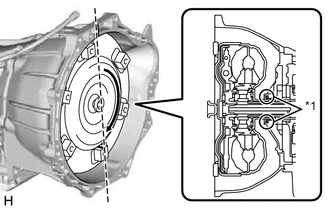

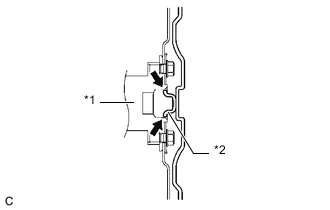

*1 Front Oil Pump Oil Seal Rotate the torque converter assembly approximately 180° and engage the splines of the stator shaft with the stator assembly.

Note

-

Do not damage the front oil pump oil seal.

-

Install the torque converter assembly to the input shaft while keeping it horizontal.

-

-

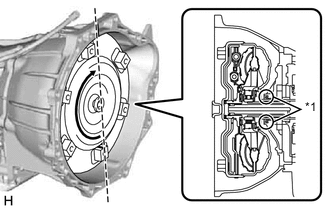

*1 Front Oil Pump Oil Seal Rotate the torque converter assembly approximately 180° again, align the matchmark on the torque converter assembly with the one on the automatic transmission case sub-assembly and insert the key of the torque converter assembly into the groove of the oil pump drive gear.

Note

-

Do not push the torque converter assembly excessively when rotating it.

-

Do not damage the front oil pump oil seal.

-

Install the torque converter assembly to the input shaft while keeping it horizontal.

-

-

Using a vernier caliper and straightedge, measure the dimension (B) shown in the illustration and check that the dimension (B) is more than the dimension (A), which was measured in the previous step.

Standard A + 1 mm (0.0394 in.) or more Note

-

Make sure to deduct the thickness of the straightedge.

-

If the automatic transmission assembly is installed to the engine assembly with the torque converter assembly not sufficiently inserted, the torque converter assembly may be damaged.

-

-

-

INSTALL TRANSMISSION CONTROL CABLE BRACKET

Tech Tips

It is not necessary to remove the transmission control cable bracket unless it is being replaced.

-

Install the transmission control cable bracket to the automatic transmission assembly with the 2 bolts.

- Torque:

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

-

-

INSTALL WIRE HARNESS CLAMP BRACKET

Tech Tips

It is not necessary to remove the wire harness clamp brackets unless they are being replaced.

-

Install the 3 wire harness clamp brackets to the automatic transmission assembly with the 4 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

INSTALL TRANSFER ASSEMBLY

-

INSTALL TRANSMISSION BREATHER BRACKET

Tech Tips

It is not necessary to remove the transmission breather bracket unless it is being replaced.

-

Install the 2 clamps to the transmission breather bracket.

-

Install the transmission breather bracket to the automatic transmission assembly with the bolt.

- Torque:

- 6.5 N*m { 66 kgf*cm, 58 in.*lbf }

-

Connect the 3 breather hoses to the clamp.

-

-

INSTALL AUTOMATIC TRANSMISSION ASSEMBLY

-

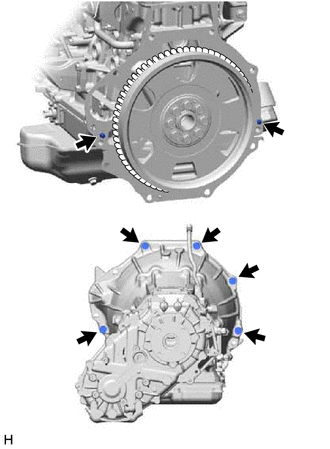

*1 Crankshaft *2 Torque Converter Assembly Centerpiece

Clutch Spline Grease Apply clutch spline grease to the surface of the crankshaft that contacts the torque converter assembly centerpiece.

Clutch spline grease Toyota Genuine Clutch Spline Grease or equivalent Maximum grease amount Approximately 1 g (0.0353 oz.) -

Confirm that the 2 knock pins are installed on the engine assembly and are not damaged.

-

While keeping the engine assembly and automatic transmission assembly horizontal, align the 2 knock pins with the holes in the automatic transmission assembly and install the 5 bolts.

- Torque:

- 71 N*m { 724 kgf*cm, 52 ft.*lbf }

Note

-

Do not use excessive force when installing the automatic transmission assembly.

-

Check that the torque converter assembly rotates.

-

Make sure that the wire harness or other similar items are not pinched between the contact surfaces.

-

Make sure that the cooling fan and fan shroud do not contact the engine assembly when tilting the automatic transmission assembly.

-

-

CONNECT WIRE HARNESS

-

Tilt down the automatic transmission assembly.

Note

Make sure that the cooling fan and fan shroud do not contact the engine assembly when tilting the automatic transmission assembly.

-

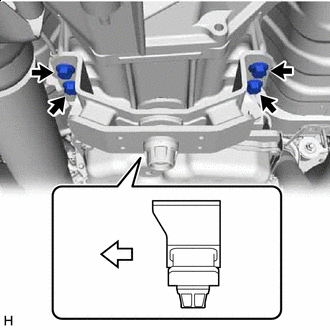

Connect the wire harness to the automatic transmission assembly with the 2 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Connect the park/neutral position switch connector, transmission wire connector, 2 transmission revolution sensor connectors and transfer connector.

Tech Tips

Push up the lever until the claw of the transmission wire connector makes a connection sound.

-

Connect the 9 wire harness clamps.

-

-

INSTALL REAR ENGINE MOUNTING INSULATOR

Tech Tips

It is not necessary to remove the rear engine mounting insulator unless it is being replaced.

-

Front of the Vehicle Install the rear engine mounting insulator to the automatic transmission assembly with the 4 bolts.

- Torque:

- 47 N*m { 479 kgf*cm, 35 ft.*lbf }

-

-

INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY

-

Install the No. 3 frame crossmember to the vehicle body with the 4 bolts and 4 nuts.

- Torque:

- 57 N*m { 581 kgf*cm, 42 ft.*lbf }

Note

Install the nuts so that they face the rear of the vehicle.

Tech Tips

Hold the bolts while tightening the nuts.

-

Connect the No. 3 frame crossmember sub-assembly to the rear engine mounting insulator with the 4 bolts.

- Torque:

- 18.5 N*m { 189 kgf*cm, 14 ft.*lbf }

-

-

INSTALL DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

-

Turn the crankshaft to gain access to the installation locations of the 6 drive plate and torque converter assembly setting bolts and install each bolt while holding the crankshaft pulley bolt with a wrench.

- Torque:

- 48 N*m { 489 kgf*cm, 35 ft.*lbf }

Note

Install the black colored bolt first, and then the remaining 5 silver colored bolts.

-

-

INSTALL STIFFENER PLATE

-

Temporarily install the No. 2 end plate and stiffener plate RH (with clamp) to the automatic transmission assembly and engine assembly with the 4 bolts

-

Temporarily install the stiffener plate LH to the automatic transmission assembly and engine assembly.

-

Tighten the 8 bolts.

- Torque:

- 71 N*m { 724 kgf*cm, 52 ft.*lbf }

-

Install the No. 4 cylinder block insulator to the engine assembly.

-

-

INSTALL TRANSMISSION INSULATOR RH

-

Install the transmission insulator RH to the automatic transmission assembly with the 6 bolts.

- Torque:

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

-

-

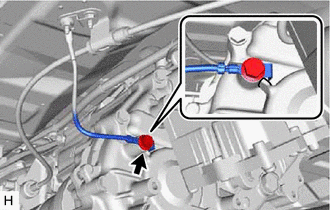

CONNECT GROUND WIRE

-

Connect the ground wire to the automatic transmission assembly with the bolt as shown in the illustration.

- Torque:

- 19.5 N*m { 199 kgf*cm, 14 ft.*lbf }

Tech Tips

Make contact with the terminal stopper.

-

-

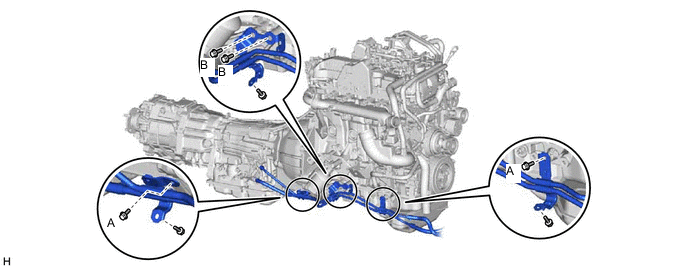

CONNECT OIL COOLER TUBE

-

Connect the ends of the 2 oil cooler tubes to the automatic transmission assembly by hand.

-

Install the 3 oil cooler tube clamps to the automatic transmission assembly and engine assembly with the 4 bolts.

- Torque:

- for bolt A (M8 bolt)

- 13.5 N*m { 138 kgf*cm, 10 ft.*lbf }

- for bolt B (M12 bolt)

- 71 N*m { 724 kgf*cm, 52 ft.*lbf }

Tech Tips

It is not necessary to remove the oil cooler tube clamps unless they are being replaced.

-

Connect the 2 oil cooler tubes to the 3 oil cooler tube clamps with the 3 bolts.

- Torque:

- 5.5 N*m { 56 kgf*cm, 49 in.*lbf }

-

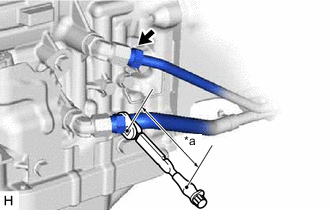

*a Torque Wrench Fulcrum Length Using a 17 mm union nut wrench, tighten the 2 oil cooler tubes.

- Torque:

- Specified tightening torque

- 34.3 N*m { 350 kgf*cm, 25 ft.*lbf }

Tech Tips

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

-

When using a union nut wrench (fulcrum length of 30 mm (1.1811 in.)) + torque wrench (fulcrum length of 180 mm (7.0866 in.)): 29.4 N*m (300 kgf*cm, 22 ft.*lbf)

-

-

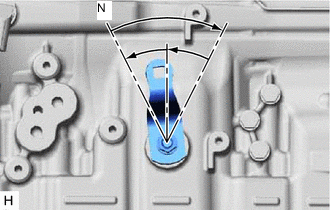

CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

-

Turn the control shaft lever clockwise until it stops, and then return the control shaft lever counterclockwise 2 notches to N.

-

Move the shift lever to N, and with the cable end lightly pushed toward the rear of the vehicle, install the transmission control cable assembly to the transmission control shaft lever LH with the nut.

- Torque:

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

Tighten the nut with no slack in the transmission control cable assembly.

-

Connect the transmission control shift cable assembly to the transmission control cable bracket with a new clip.

-

-

INSTALL FRONT EXHAUST PIPE ASSEMBLY

-

INSTALL STARTER ASSEMBLY

-

for 2.0 kW Type:

-

for 2.2 kW Type:

-

-

INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

-

ADD TRANSFER OIL

-

ADD AUTOMATIC TRANSMISSION FLUID

-

INSTALL FRONT DIFFERENTIAL CARRIER ASSEMBLY

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

INSPECT SHIFT LEVER POSITION

-

ADJUST AUTOMATIC TRANSMISSION FLUID

-

INSPECT FOR EXHAUST GAS LEAK

-

INSPECT FOR OIL LEAK

-

Start the engine. Make sure that there are no oil leaks from the areas that were worked on.

-

-

RESET MEMORY

Note

If automatic transmission parts have been replaced, refer to the Parts Replacement Compensation Table to determine if any additional operations are necessary.