BRAKE MASTER CYLINDER(for LHD) INSTALLATION

PROCEDURE

-

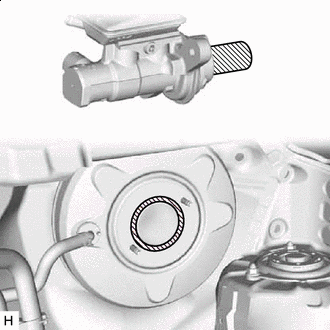

INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

Note

When installing a new brake master cylinder sub-assembly, remove the protectors from the master cylinder piston and outlet ports.

-

Install a new brake master cylinder O-ring to the brake master cylinder sub-assembly.

-

Apply Grease Apply a light layer of a grease enclosed with a new brake master cylinder sub-assembly or lithium soap base glycol grease to the circumference of the brake master cylinder sub-assembly and inner surface of the brake booster assembly as shown in the illustration.

-

Install the brake master cylinder sub-assembly to the brake booster assembly with the 2 nuts.

- Torque:

- 12.7 N*m { 130 kgf*cm, 9 ft.*lbf }

Note

-

The brake master cylinder sub-assembly requires careful handling. Do not drop or subject the brake master cylinder sub-assembly to any impact. Do not reuse a brake master cylinder sub-assembly that has been dropped.

-

Do not hold the brake master cylinder sub-assembly by the master cylinder piston. Hold the brake master cylinder sub-assembly by its body or its reservoir when carrying it.

-

Do not pull out the master cylinder piston.

-

Do not strike or pinch the master cylinder piston, or cause any damage to the master cylinder piston by any other means.

-

When installing the brake master cylinder sub-assembly to the brake booster assembly, or when removing the brake master cylinder sub-assembly from the brake booster assembly, make sure that the brake master cylinder sub-assembly is kept horizontal or with its tip facing downward (the master cylinder piston is facing upward) to prevent the master cylinder piston from falling out.

-

Do not allow any foreign matter to contaminate the master cylinder piston. If any foreign matter gets on the master cylinder piston, remove it by using a piece of cloth and then apply an even layer of lithium soap base glycol grease around the circumference (sliding part) of the master cylinder piston.

-

Do not kink or damage the brake lines.

-

Do not allow the brake lines to twist or interfere with other parts or the vehicle body during tightening.

-

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

-

Do not use any other type of grease or fluid.

-

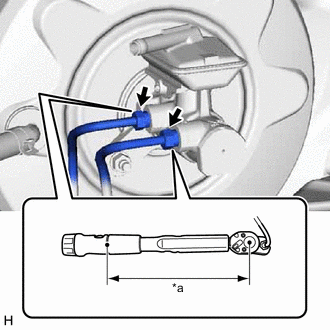

*a Torque Wrench Fulcrum Length Using a union nut wrench, connect the 2 brake lines to the brake master cylinder sub-assembly.

- Torque:

- Specified tightening torque

- 19.5 N*m { 199 kgf*cm, 14 ft.*lbf }

Note

-

Do not kink or damage the brake lines.

-

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

Tech Tips

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

-

When using a union nut wrench (fulcrum length of 20 mm (0.787 in.)) + torque wrench (fulcrum length of 162 mm (6.38 in.)):

17.36 N*m (177 kgf*cm, 13 ft.*lbf)

-

-

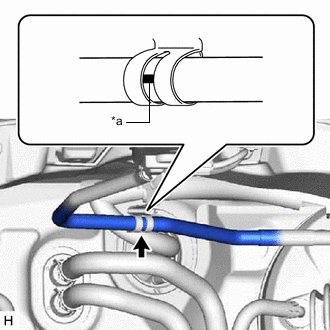

CONNECT NO. 1 RESERVOIR TUBE

-

Connect the No. 1 reservoir tube to the brake master cylinder sub-assembly and slide the clip to secure it.

-

*a Paint Mark Install the No. 1 reservoir tube to the hose clamp bracket.

Note

Install the No. 1 reservoir tube so that the paint mark on the No. 1 reservoir tube is positioned as shown in the illustration.

-

-

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

-

INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

-

INSTALL V-BANK COVER SUB-ASSEMBLY

-

INSTALL BATTERY

-

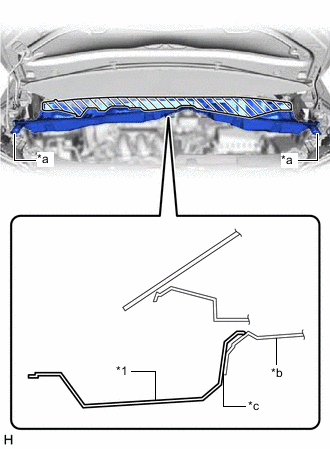

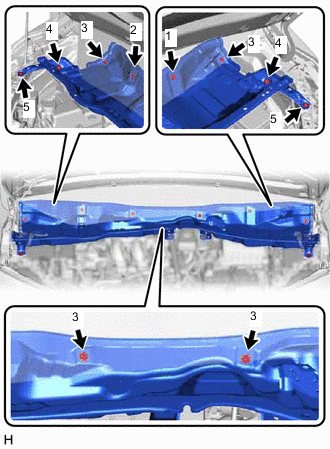

INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

-

*1 Outer Cowl Top Panel Sub-assembly *a Outer Cowl Top Panel Sub-assembly Bracket *b Vehicle Body *c Align contact surfaces Install the outer cowl top panel sub-assembly to the vehicle body.

Note

-

Make sure to fully insert the outer cowl top panel sub-assembly so that the outer cowl top panel sub-assembly fully contacts the vehicle body in the shaded area shown in the illustration.

-

Check that there are no gaps between the contact surfaces of the outer cowl top panel sub-assembly bracket and vehicle body.

-

-

Install the 10 bolts in the order shown in the illustration.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

Tech Tips

Tighten the bolts of the same number in any order.

-

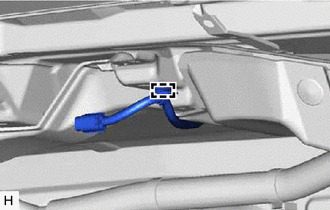

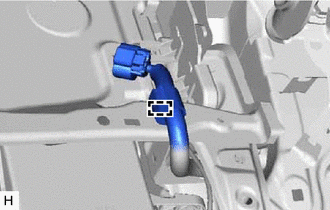

Engage the clamp to install the wire harness to the outer cowl top panel sub-assembly.

-

Engage the clamp to install the wire harness to the outer cowl top panel sub-assembly.

-

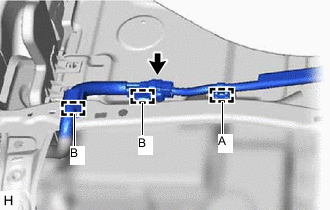

Engage the 2 clamps (B) to install the wire harness to the outer cowl top panel sub-assembly.

-

w/ Wiper Deicer System:

-

Engage the clamp (A) to install the wire harness to the outer cowl top panel sub-assembly.

-

Connect the connector.

-

-

-

INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

-

Engage the 2 claws to install the No. 1 heater air duct splash shield seal to the outer cowl top panel sub-assembly.

-

-

INSTALL NO. 2 HEATER AIR DUCT SPLASH SHIELD SEAL

-

Engage the 2 claws to install the No. 2 heater air duct splash shield seal to the outer cowl top panel sub-assembly.

-

-

INSTALL BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY

-

Install the brake master cylinder reservoir assembly to the outer cowl top panel sub-assembly with the 2 bolts.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

Connect the connector to the brake master cylinder reservoir assembly.

-

-

INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

-

INSPECT WASHER NOZZLE

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

BLEED BRAKE SYSTEM