REAR WHEEL ALIGNMENT ADJUSTMENT

CAUTION / NOTICE / HINT

Note

If a wheel alignment has been performed, or if suspension or underbody components have been removed/installed or replaced, be sure to perform the following initialization procedure in order for the system to function normally:

-

Perform zero point calibration of the yaw rate and acceleration sensor.

PROCEDURE

-

INSPECT TIRES

-

MEASURE VEHICLE HEIGHT

-

INSPECT CAMBER

Note

Inspect while the vehicle is unloaded.

-

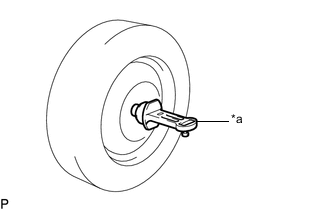

*a Camber-caster-kingpin Gauge Install a camber-caster-kingpin gauge.

-

Inspect the camber.

Camber (Unloaded Vehicle) Camber Inclination Right-left Difference -0.51° +/- 0.75°(-0°31' +/- 0°45') 0.75°(0°45') or less Tech Tips

Camber is not adjustable. If the measurement is not within the specified range, inspect the suspension parts for damage and/or wear, and replace them if necessary.

-

-

INSPECT TOE-IN

Note

Inspect while the vehicle is unloaded.

-

Bounce the vehicle up and down at the corners to stabilize the suspension.

-

Release the parking brake and move the shift lever to N.

-

Push the vehicle straight ahead approximately 5 m (16.4 ft.). (Step A)

-

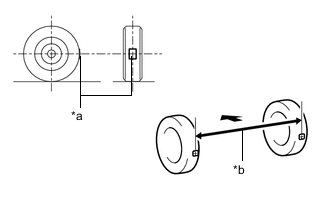

*a Tread Center Mark *b Dimension B

Front of the Vehicle Put tread center marks on the rearmost points of the rear wheels and measure the distance between the marks (dimension B).

-

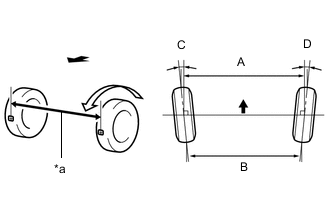

Slowly push the vehicle straight ahead to cause the rear wheels to rotate 180°. Use the rear tire valve as a reference point.

Tech Tips

Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from step A again.

-

*a Dimension A

Front of the Vehicle Measure the distance between the tread center marks on the front of the rear wheels (dimension A).

Toe-in (Unloaded Vehicle) Specified Condition C + D: -0.08° +/- 0.17° (-0°05' +/- 0°10') B - A: -1.0 +/- 2.0 mm (-0.0394 +/- 0.0787 in.) Tech Tips

Measure "B - A" only when "C + D" cannot be measured.

If the toe-in is not within the specified range, adjust it by following the procedures below.

-

-

ADJUST TOE-IN

-

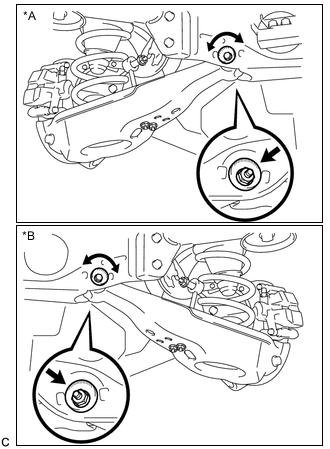

*A LH Side *B RH Side Loosen the nut of the rear No. 2 suspension arm assembly (on the rear suspension member sub-assembly side).

Note

Hold the toe adjust cam sub-assembly while rotating the nut.

-

Rotate the toe adjust cam sub-assembly to adjust the toe-in.

Toe-in (Unloaded Vehicle) Specified Condition C + D: -0.08° +/- 0.17° (-0°05' +/- 0°10') B - A: -1.0 +/- 2.0 mm (-0.0394 +/- 0.0787 in.) Tech Tips

Rotating the rear suspension toe adjust cam sub-assembly by one notch changes the toe by approximately 2.1 mm (0.0827 in.).

-

Tighten the nut of the rear No. 2 suspension arm assembly (on the rear suspension member sub-assembly side).

- Torque:

- 100 N*m { 1020 kgf*cm, 74 ft.*lbf }

Note

-

Hold the toe adjust cam sub-assembly while rotating the nut.

-

Tighten the nut of the rear No. 2 suspension arm assembly while the vehicle is unloaded.

-

-

PLACE FRONT WHEELS FACING STRAIGHT AHEAD

-

PERFORM YAW RATE AND ACCELERATION SENSOR CALIBRATION

-

ADJUST LANE DEPARTURE WARNING CAMERA (w/ Lane Departure Alert System)