RADIATOR ON-VEHICLE INSPECTION

PROCEDURE

-

CHECK RADIATOR CAP SUB-ASSEMBLY

-

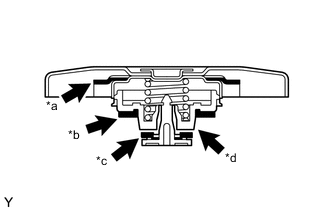

*a Rubber Packing (1) *b Rubber Packing (2) *c Rubber Packing (3) *d Valve Seat Measure the valve opening pressure.

-

If there are water stains or foreign matter on the rubber packings (1), (2) or (3), clean the part(s) with water and finger scouring.

-

Check that the rubber packings (1), (2) and (3) are not deformed, cracked or swollen.

-

Check that the rubber packing (3) and valve seat are not stuck together.

-

Apply engine coolant to the rubber packings (2) and (3) before using a radiator cap tester.

-

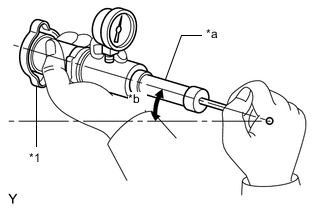

*1 Radiator Cap Sub-assembly *a Radiator Cap Tester *b 30° or more When using the radiator cap tester, tilt it upward 30° or more.

-

Pump the radiator cap tester several times, and check the maximum pressure.

Pumping Speed 1 pump per second Tech Tips

Even if the radiator cap sub-assembly cannot maintain the maximum pressure, it is not a defect.

Result Item Specified Condition Standard value

(for brand-new radiator cap sub-assembly)

94 to 122 kPa (1.0 to 1.2 kgf/cm2, 13.6 to 18 psi)

Minimum standard value

(for used radiator cap sub-assembly)

94 kPa (1.0 kgf/cm2, 13.6 psi)

If the maximum pressure is less than the minimum pressure, replace the radiator cap sub-assembly.

-

-

-

CHECK RADIATOR ASSEMBLY FOR CLOGGING

CAUTION:

To prevent burns, do not touch the engine or other high temperature components while the engine is hot.

-

Remove the radiator side deflector seal LH.

-

Remove the radiator side seal RH.

-

Remove the cool air intake duct seal.

-

Remove the inlet air cleaner assembly.

-

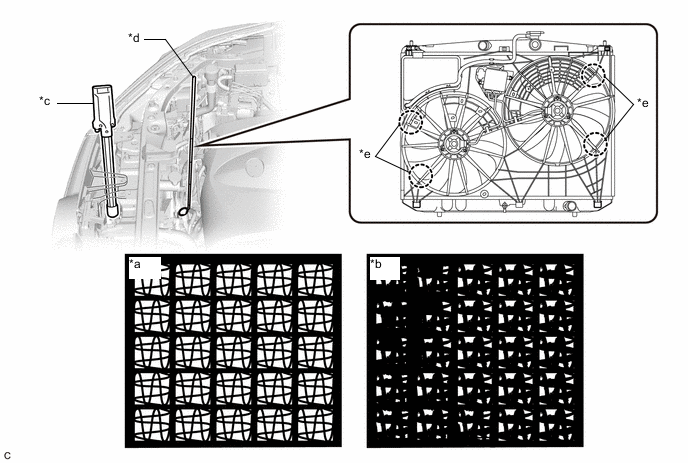

Shine a flashlight at the radiator assembly and cooler condenser assembly from the front of the cooler condenser assembly and check the radiator assembly for clogging using a mirror.

*a OK *b NG *c Flashlight *d Mirror *e Areas to be checked - - OK The radiator assembly is not clogged. If the radiator assembly is clogged, clean it.

-

Install the inlet air cleaner assembly.

-

Install the cool air intake duct seal.

-

Install the radiator side seal RH.

-

Install the radiator side deflector seal LH.

-

-

CLEAN RADIATOR ASSEMBLY

CAUTION:

To prevent burns, do not touch the engine or other high temperature components while the engine is hot.

-

Remove the radiator side deflector seal LH.

-

Remove the radiator side seal RH.

-

Remove the cool air intake duct seal.

-

Remove the inlet air cleaner assembly.

-

Cover the opening of each air duct with a piece of cloth.

-

Clean the cooler condenser assembly.

-

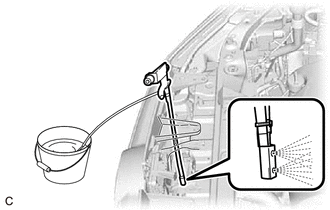

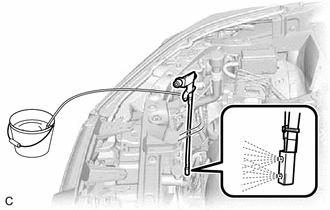

Check that the washer nozzle is not clogged.

-

Insert the washer nozzle into the space in front of the cooler condenser assembly and spray it.

Note

-

Clean the fins of the cooler condenser assembly by spraying the entire area for 150 seconds. Repeat this process twice.

-

Set the air pressure to 0.4 MPa (4.1 kgf/cm2, 58 psi).

-

Check that water sprays in mist form from the nozzle.

-

Keep the nozzle parallel to the cooler condenser assembly.

-

Do not allow the nozzle to contact the fins of the cooler condenser assembly.

-

Keep the nozzle moving while spraying water.

-

Do not spray the cooler compressor assembly or generator assembly excessively.

-

-

Leave the cooler condenser assembly as is for 10 minutes to let the water penetrate the dirt.

-

Clean the cooler condenser assembly again.

Note

-

Clean the fins of the cooler condenser assembly by spraying the entire area for 150 seconds. Repeat this process twice.

-

Set the air pressure to 0.4 MPa (4.1 kgf/cm2, 58 psi).

-

Check that water sprays in mist form from the nozzle.

-

Keep the nozzle parallel to the cooler condenser assembly.

-

Do not allow the nozzle to contact the fins of the cooler condenser assembly.

-

Keep the nozzle moving while spraying water.

-

Do not spray the cooler compressor assembly or generator assembly excessively.

-

-

Using an air blow gun, dry the cooler condenser assembly for 3 minutes.

-

-

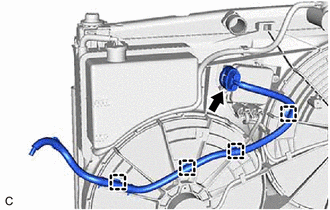

Disconnect the cooling fan ECU connector.

-

Disengage the 4 wire harness clamps.

-

Disengage the 3 claws and separate the fan shroud assembly from the radiator assembly.

-

Clean the radiator assembly.

-

Insert the washer nozzle between the radiator assembly and fan shroud and spray the radiator assembly.

Note

-

Clean the fins of the radiator assembly by spraying the entire area for 150 seconds. Repeat this process twice.

-

Set the air pressure to 0.4 MPa (4.1 kgf/cm2, 58 psi).

-

Check that water sprays in mist form from the nozzle.

-

Keep the nozzle parallel to the radiator assembly.

-

Do not allow the nozzle to contact the fins of the radiator assembly.

-

Keep the nozzle moving while spraying water.

-

-

Leave the radiator assembly as is for 10 minutes to let the water penetrate the dirt.

-

Clean the radiator assembly again.

Note

-

Clean the fins of the radiator assembly by spraying the entire area for 150 seconds. Repeat this process twice.

-

Set the air pressure to 0.4 MPa (4.1 kgf/cm2, 58 psi).

-

Check that water sprays in mist form from the nozzle.

-

Keep the nozzle parallel to the radiator assembly.

-

Do not allow the nozzle to contact the fins of the radiator assembly.

-

Keep the nozzle moving while spraying water.

-

-

Using an air blow gun, dry the radiator assembly for 3 minutes.

-

-

Check the fins of the radiator assembly for clogs again.

If the radiator assembly is clogged, clean the cooler condenser assembly and radiator assembly again.

-

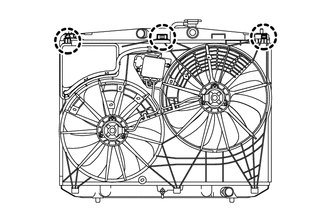

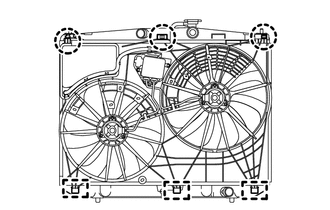

Check that the 3 guides at the bottom are engaged to the radiator assembly.

-

Engage the 3 claws to install the fan shroud assembly to the radiator assembly.

-

Engage the 4 wire harness clamps.

-

Connect the cooling fan ECU connector.

-

Remove the piece of cloth from the opening of each air duct.

-

Install the inlet air cleaner assembly.

-

Install the cool air intake duct seal.

-

Install the radiator side seal RH.

-

Install the radiator side deflector seal LH.

-