ENGINE ON-VEHICLE INSPECTION

PROCEDURE

-

INSPECT ENGINE COOLANT

-

INSPECT ENGINE OIL

-

INSPECT BATTERY

-

INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

-

Remove the air cleaner cap sub-assembly.

-

Remove the air filter element sub-assembly.

-

Visually check that the air cleaner filter element sub-assembly is not excessively damaged or oily. If necessary, replace the air cleaner filter element sub-assembly.

Tech Tips

-

If there is any foreign matter or clogs in the air cleaner filter element sub-assembly, clean it with compressed air.

-

If any foreign matter or clogs remain even after cleaning the air cleaner filter element sub-assembly with compressed air, replace it.

-

-

Install the air cleaner filter element sub-assembly.

-

Install the air cleaner cap sub-assembly.

-

-

INSPECT V-RIBBED BELT

-

INSPECT ENGINE SPEED

Note

-

Turn all the electrical systems and the A/C off.

-

Inspect the engine idle speed with the cooling fan off.

-

When checking the idle speed, the transaxle should be in neutral.

-

Warm up and stop the engine.

-

When using the GTS:

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed.

Powertrain > Engine and ECT > Data ListTester Display Engine Speed -

Inspect the engine idle speed.

Standard Idle Speed 720 to 820 rpm -

Fully depress the accelerator pedal.

-

Inspect the maximum engine speed.

Maximum Speed 5150 to 5250 rpm -

Turn the ignition switch off.

-

Disconnect the GTS from the DLC3.

-

-

When not using the GTS:

-

Using SST, connect a tachometer probe to terminal 9 (TAC) of the DLC3.

- SST

- 09843-18040

Note

Be sure to connect the tachometer to the correct terminal. Connecting the wrong terminals can cause damage.

-

Turn the ignition switch to ON.

-

Start the engine.

-

Inspect the engine idle speed.

Standard Idle Speed 720 to 820 rpm -

Fully depress the accelerator pedal.

-

Inspect the maximum engine speed.

Maximum Speed 5150 to 5250 rpm -

Turn the ignition switch off.

-

Disconnect the tachometer probe from terminal 9 (TAC) of the DLC3.

-

-

-

INSPECT COMPRESSION

-

Warm up and stop the engine.

-

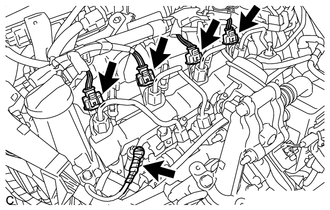

Disconnect the 4 connectors from the 4 injector assemblies.

-

Remove the 4 glow plug assemblies.

Note

In order to avoid shorting the circuit of the wire harness connected to the glow plug No. 1 connector, wind vinyl tape around the wire harness terminal portion.

-

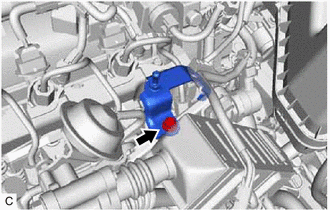

Remove the bolt and separate the No. 3 engine cover bracket.

-

Connect the cable to the negative (-) battery terminal.

-

Crank the engine to remove foreign matter before measuring the compression.

-

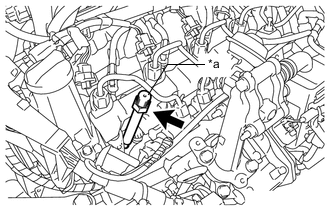

*a SST (Attachment) Install the SST (attachment) into the glow plug assembly hole.

- SST

- 09992-00026 ( 09992-00121, 09992-00160 )

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

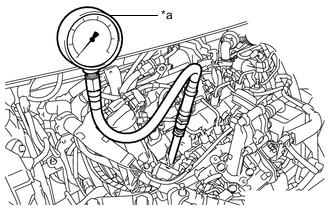

*a SST (Compression Gauge) Connect a SST (compression gauge) to the SST (attachment).

- SST

- 09992-00026 ( 09992-00211 )

-

While cranking the engine, measure the compression pressure.

Compression Pressure 2300 kPa (23.5 kgf/cm2, 334 psi) Minimum Pressure 2050 kPa (20.9 kgf/cm2, 297psi) Difference Between Each Cylinder 500 kPa (5.1 kgf/cm2, 73 psi) or less Note

-

Use a fully-charged battery so that the engine speed can be increased to 250 rpm or more.

-

Inspect the other cylinders in the same way.

-

Measure the compression pressure in as short a time as possible.

If the cylinder compression is low, pour a small amount of engine oil into the cylinder through the glow plug assembly hole, and then inspect it again.

Tech Tips

-

If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or damaged.

-

If the compression pressure stays low, a valve may be stuck or seated improperly, or there may be leaks in the cylinder head gasket.

-

-

Remove the SST (compression gauge and attachment).

-

Install the No. 3 engine cover bracket with the bolt.

- Torque:

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

Install the 4 glow plug assemblies.

-

Connect the 4 connectors to the 4 injector assemblies.

-