ДВИГАТЕЛЬ В СБОРЕ СНЯТИЕ

CAUTION:

As the engine assembly with transmission is extremely heavy, the engine lifter may suddenly drop if the instructions listed in the repair manual are not followed. Therefore, always follow the instructions listed in the repair manual when performing this procedure.

-

DISCHARGE FUEL SYSTEM PRESSURE

-

PRECAUTION

Note

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the battery terminal. Therefore, make sure to read the disconnecting the cable from the battery terminal notice before proceeding with work Click here.

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

REMOVE NO. 1 ENGINE UNDER COVER

-

DRAIN ENGINE COOLANT

CAUTION:

Do not remove the radiator reservoir cap sub-assembly while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Tech Tips

Collect the engine coolant in a container and dispose of it according to the local regulations.

-

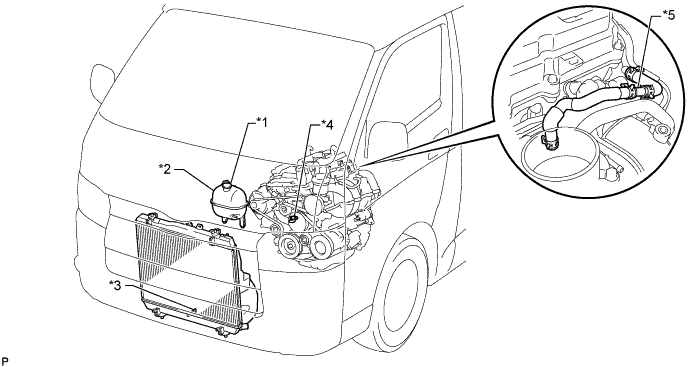

Loosen the radiator drain cock plug and drain the engine coolant.

Text in Illustration *1 Radiator Reservoir Cap Sub-assembly *2 Radiator Reservoir Assembly *3 Radiator Drain Cock Plug *4 Cylinder Block Water Drain Cock Plug *5 2-Way - - -

Remove the radiator reservoir cap sub-assembly.

-

Loosen the cylinder block water drain cock plug and drain the engine coolant from the engine.

-

-

DRAIN ENGINE OIL

-

Remove the oil filler cap.

-

Remove the oil pan drain plug and gasket, and then drain the engine oil into a container.

Note

Collect the oil in a disposable oil container.

-

Clean the oil pan drain plug and install it with a new gasket.

- Torque:

- 38 N*m { 382 kgf*cm, 28 ft.*lbf }

-

-

REMOVE FRONT SEAT ASSEMBLY RH

-

REMOVE FRONT DOOR SCUFF PLATE RH

-

REMOVE ENGINE SERVICE HOLE SUB COVER SUB-ASSEMBLY

-

Заверните коврик, выверните 5 болтов и снимите дополнительную крышку технологического отверстия двигателя.

-

-

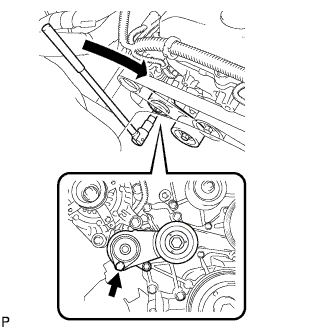

REMOVE FAN AND GENERATOR V BELT

-

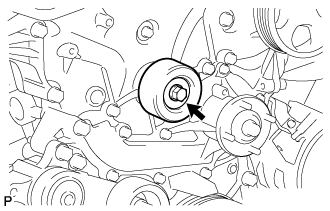

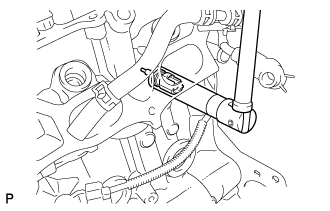

С помощью шестигранника, указанного на рисунке стрелкой, сдвиньте шкив натяжителя вниз, уменьшив тем самым натяжение поликлинового ремня вентилятора и генератора. Затем снимите поликлиновой ремень вентилятора и генератора.

Note

При снятии поликлинового ремня вентилятора и генератора не используйте болт опорного ролика.

Tech Tips

После снятия поликлинового ремня вентилятора и генератора переместите натяжитель вверх, насколько это возможно.

-

-

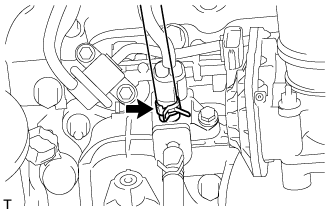

DISCONNECT NO. 4 RADIATOR HOSE

-

Slide the clamp and disconnect the No. 4 radiator hose from the engine.

-

-

DISCONNECT NO. 2 RADIATOR HOSE

-

Slide the clamp and disconnect the No. 2 radiator hose from the No. 1 radiator pipe.

-

-

DISCONNECT INLET HEATER WATER HOSE A

-

Slide the clamp and disconnect the inlet heater water hose A from the heater unit.

-

-

DISCONNECT OUTLET HEATER WATER HOSE B

-

Slide the clamp and disconnect the outlet heater water hose B from the heater unit.

-

-

DISCONNECT FUEL VAPOR FEED HOSE ASSEMBLY

-

Slide the clamp and disconnect the fuel vapor feed hose from the purge VSV.

-

-

DISCONNECT UNION TO CONNECTOR TUBE HOSE

-

Slide the clamp and disconnect the union to connector tube hose from the intake manifold.

-

-

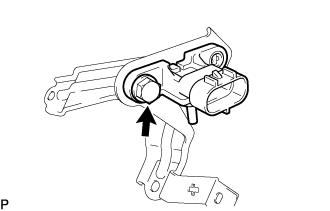

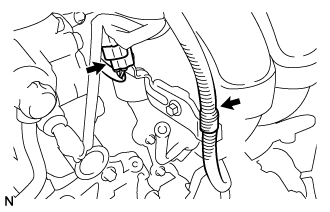

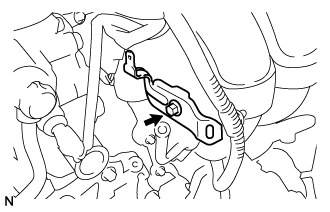

REMOVE AIR PRESSURE SENSOR

-

Disconnect the air pressure sensor connector.

-

Disconnect the vacuum hose.

-

Detach the wire harness clamp.

-

Remove the 2 bolts and air pressure sensor together with the bracket.

-

Remove the bolt and air pressure sensor.

-

-

REMOVE INTAKE AIR CONNECTOR

-

Сдвиньте хомут и отсоедините шланг системы принудительной вентиляции картера № 2 от крышки головки блока цилиндров в сборе.

-

Отсоедините вакуумный шланг от патрубка подачи воздуха.

-

Ослабьте 2 хомута шланга.

-

Выверните 2 болта и снимите соединитель впуска воздуха.

-

-

DISCONNECT NO. 5 AIR HOSE

-

Slide the clamp and disconnect the No. 5 air hose from the air switching valve assembly.

-

-

DISCONNECT NO. 1 FUEL HOSE

-

Disconnect the No. 1 fuel hose from the fuel pressure pulsation damper assembly Click here.

-

-

DISCONNECT NO. 2 FUEL HOSE

-

Disconnect the No. 2 fuel hose from the fuel delivery pipe sub-assembly Click here.

-

-

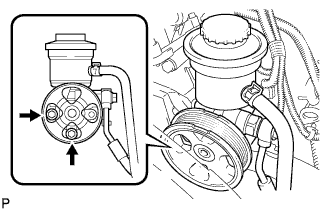

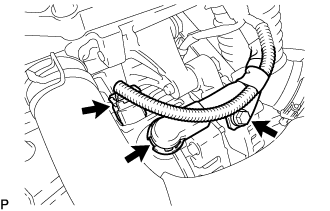

DISCONNECT VANE PUMP ASSEMBLY

-

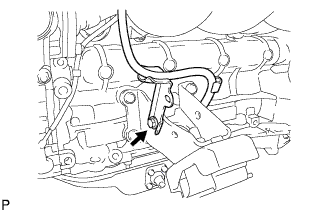

Disconnect the oil pressure switch connector.

-

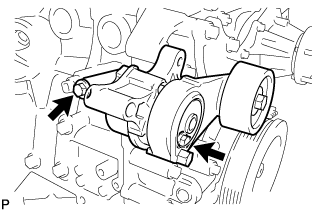

Remove the 2 bolts and disconnect the vane pump assembly from the engine.

-

Support the vane pump assembly securely.

-

-

REMOVE ENGINE OIL LEVEL DIPSTICK

-

REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

-

Remove the bolt and engine oil level dipstick guide.

-

-

DISCONNECT COMPRESSOR AND MAGNETIC CLUTCH

-

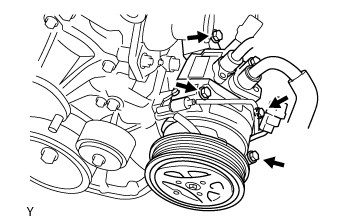

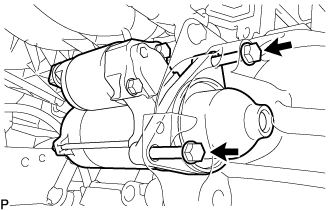

Disconnect the compressor and magnetic clutch connector.

-

Remove the 4 bolts and disconnect the compressor and magnetic clutch from the engine.

Tech Tips

Disconnect the compressor and magnetic clutch with the No. 1 cooler refrigerant suction hose and No. 1 cooler refrigerant discharge hose stuck by suspended from the rope.

-

Support the compressor and magnetic clutch securely.

-

-

DISCONNECT ENGINE WIRE

-

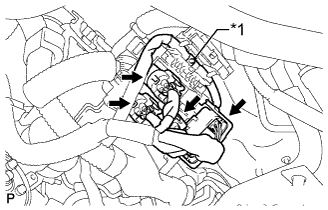

Disconnect the wire harness support of the ECM.

-

Disconnect the connectors of the ECM.

-

Disconnect the clamps of the engine wire and ground cable.

-

Disconnect the starter connector Click here.

-

Disconnect the generator connector Click here.

-

Text in Illustration *1 Nut Remove the nut and disconnect the 4 connectors from the engine room junction block.

-

-

REMOVE FRONT EXHAUST PIPE ASSEMBLY

-

REMOVE PROPELLER SHAFT ASSEMBLY

-

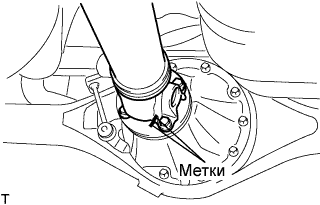

Нанесите метки на оба фланца.

-

Снимите 4 гайки с болтами и шайбами.

Tech Tips

Если фланцевое соединение разделяется с трудом, временно затяните только одну гайку и, равномерно распределяя удары, с помощью молотки и латунного стержня, отделите карданный вал от соединительного фланца дифференциала.

-

Снимите карданный вал в сборе.

-

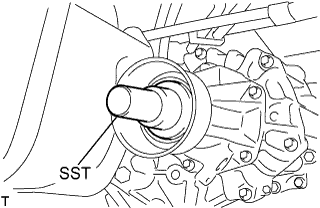

Установите SST в трансмиссию для предотвращения утечки масла.

Note

Будьте осторожны, чтобы не повредить сальник.

-

При работе с автоматической трансмиссией используйте следующий SST

- SST

- 09325-40010

-

При работе с механической трансмиссией используйте следующий SST

- SST

- 09325-20010

-

-

-

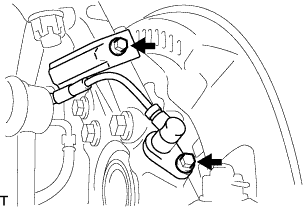

REMOVE FRONT SPEED SENSOR LH

-

Выверните 2 болта и отсоедините датчик частоты вращения от поворотного кулака.

Note

-

Будьте осторожны, чтобы не повредить датчик частоты вращения.

-

Не допускайте налипания на датчик частоты вращения посторонних частиц.

-

-

-

REMOVE FRONT SPEED SENSOR RH

Tech Tips

Use the same procedure described for the LH side.

-

REMOVE FRONT DISC BRAKE CALIPER ASSEMBLY LH

-

Выверните 2 болта и снимите суппорт тормоза в сборе.

Note

Суппорт тормоза не должен повисать на гибком шланге, поэтому его следует закрепить проводом или каким-либо аналогичным средством.

-

-

REMOVE FRONT DISC BRAKE CALIPER ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

SEPARATE FRONT SUSPENSION SUB-ASSEMBLY UPPER LH

-

Снимите шплинт и ослабьте гайку.

- SST

- 09628-62011

Note

Гайку не отворачивайте.

-

Используя SST, отсоедините поворотный кулак от верхнего рычага подвески и отверните гайку.

Note

-

Закрепите поворотный кулак проводом, чтобы к гибкому шлангу не прикладывалось чрезмерное усилие.

-

Старайтесь не повредить пыльник шарового шарнира.

-

-

-

SEPARATE FRONT SUSPENSION SUB-ASSEMBLY UPPER RH

Tech Tips

Use the same procedure described for the LH side.

-

SEPARATE FRONT SHOCK ABSORBER ASSEMBLY LH

-

Выверните болт и отсоедините передний амортизатор от нижнего рычага передней подвески.

-

-

SEPARATE FRONT SHOCK ABSORBER ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

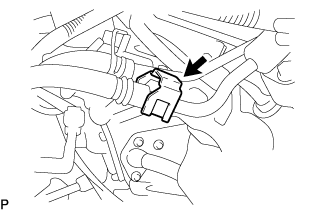

DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

-

Установите рычаг переключения передач в положение N.

-

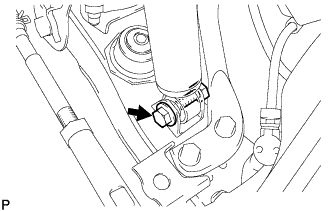

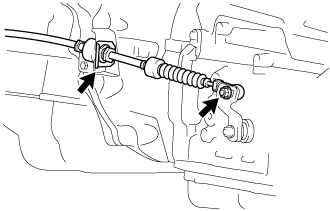

Отверните гайку и отсоедините трос механизма переключения передач от левого рычага приводного вала трансмиссии.

-

Снимите фиксатор и отсоедините трос механизма переключения передач в сборе от кронштейна троса.

-

-

DISCONNECT OIL COOLER HOSE

-

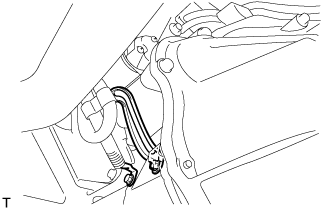

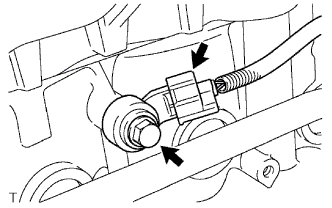

Slide the 2 clamps and disconnect the inlet oil cooler hose and outlet oil cooler hose from the oil cooler tube.

-

-

SEPARATE STEERING TORQUE SHAFT ASSEMBLY

-

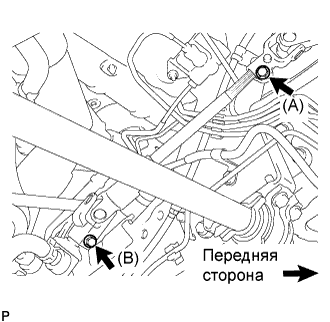

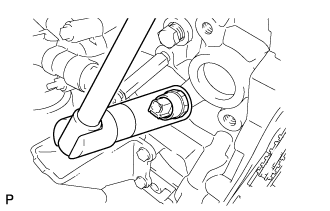

Ослабьте болт (A), выверните болт (B), а затем сдвиньте крутящий вал рулевого управления в сборе.

Tech Tips

-

Не выворачивайте болт (A) полностью.

-

Не отсоединяйте крутящий вал рулевого управления в сборе от тяги рулевого управления с усилителем в сборе.

-

-

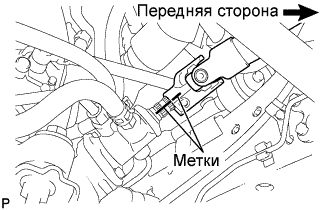

Нанесите метки на крутящий вал рулевого управления в сборе и тягу рулевого управления с усилителем в сборе.

-

Отсоедините крутящий вал рулевого управления в сборе от тяги рулевого управления с усилителем в сборе.

-

-

REMOVE ENGINE ASSEMBLY WITH TRANSMISSION

-

Using the engine lifter, hold the engine assembly and separate the rear engine mount.

Note

-

Place wooden blocks or plate lift attachments so that the engine is level.

-

With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

-

Never install attachments to the oil pan of the engine assembly or transmission as doing so may deform the oil pan.

-

-

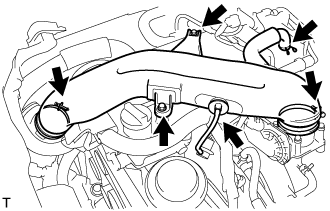

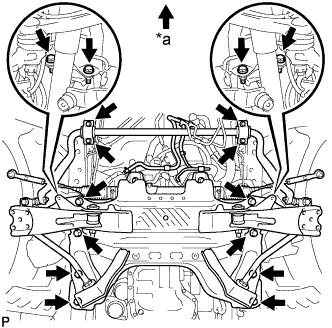

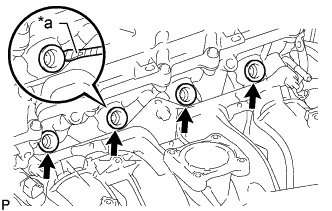

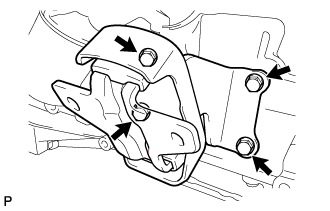

Text in Illustration *a Front Side Remove the stabilizer brackets and 16 bolts of the front suspension crossmember sub-assembly.

-

Operate the engine lifter, and then slowly remove the engine from the vehicle.

Note

-

Make sure the engine is clear of all wiring and hoses.

-

While lowering the engine from the vehicle, do not allow it to contact the vehicle.

-

-

Attach an engine sling device and hang the engine with a chain block.

Note

Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

-

-

INSTALL ENGINE HANGER

-

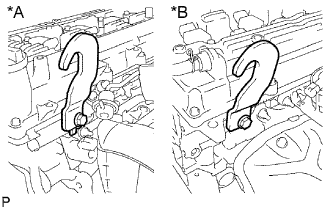

Text in Illustration *A LH Side *B RH Side Install the 2 engine hangers with the 2 bolts.

- Torque:

- 42 N*m { 428 kgf*cm, 31 ft.*lbf }

Note

Use new 2 bolts for the 2 engine hangers.

Tech Tips

Engine Hangers 12281-75050 Bolt 91672-81025

-

-

REMOVE STARTER ASSEMBLY

-

Detach the wire harness clamp from the wire harness bracket.

-

Remove the bolt and wire harness bracket.

-

Remove the bolt and disconnect the wire harness.

-

Disconnect the starter connector.

-

Remove the terminal cap.

-

Remove the nut and disconnect the wire harness.

-

Remove the 2 bolts and starter assembly.

-

-

REMOVE AUTOMATIC TRANSMISSION ASSEMBLY

-

FIX ENGINE ASSEMBLY

-

Using wooden blocks or plate lift attachments, set the engine on a flat surface.

Note

-

Place wooden blocks or plate lift attachments so that the engine is level.

-

Never install attachments to the oil pan of the engine assembly or transmission as doing so may deform the oil pan.

-

Perform this step while supporting the engine assembly using a sling device and chain block.

-

-

-

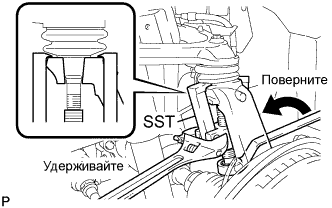

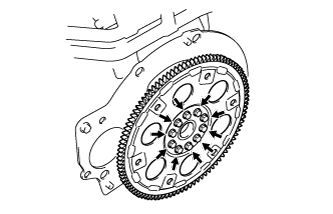

REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

-

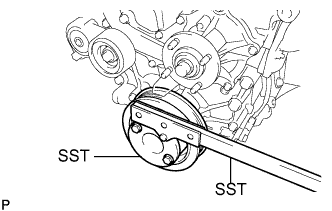

Using SST, hold the crankshaft.

- SST

- 09213-54015 ( 91651-60855 )

- 09330-00021

-

Remove the 10 bolts, rear drive plate spacer, drive plate and ring gear sub-assembly and front drive plate spacer.

-

-

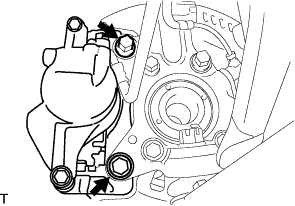

REMOVE REAR END PLATE

-

Remove the bolt and disconnect the No. 1 water by-pass pipe from rear end plate.

-

Remove the bolt and rear end plate.

-

-

REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

-

Hold the engine with the engine sling device and chain block.

-

Remove the 4 bolts from the engine mounting insulator.

-

Remove the engine assembly by operating the engine sling device and chain block.

-

-

REMOVE ENGINE WIRE

-

Remove the engine wire from the engine assembly.

-

-

INSTALL ENGINE TO ENGINE STAND

Note

-

Pay attention to the angle of the sling device as the engine assembly or engine hangers may be damaged or deformed if the angle is incorrect.

-

With the exception of installing the engine assembly to an engine stand or removing the engine assembly from an engine stand, do not perform any work on the engine while it is suspended, as doing so is dangerous.

-

Install the engine to an engine stand with the bolts.

-

Remove the 2 bolts and 2 engine hangers.

-

-

REMOVE PCV PIPE

-

Remove the bolt and PCV pipe.

-

-

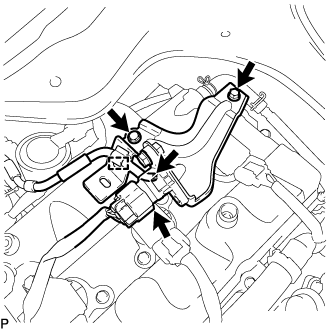

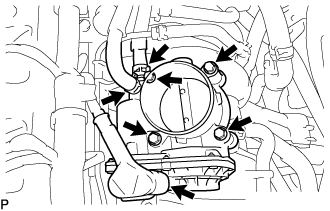

REMOVE THROTTLE BODY ASSEMBLY

-

Отсоедините разъем двигателя дроссельной заслонки.

-

Сдвиньте хомут и отсоедините перепускной шланг охлаждающей жидкости от корпуса дроссельной заслонки в сборе.

-

Сдвиньте хомут и отсоедините перепускной шланг охлаждающей жидкости № 2 от корпуса дроссельной заслонки в сборе.

-

Выверните 4 болта и снимите корпус дроссельной заслонки в сборе.

-

Снимите прокладку с впускного коллектора.

-

-

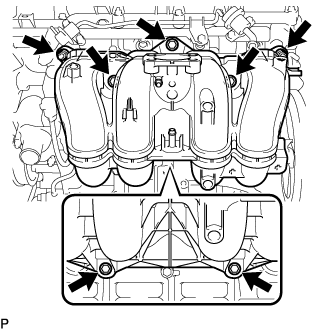

REMOVE INTAKE MANIFOLD

-

Disconnect the vacuum switching valve connector.

-

Slide the clamp and disconnect the purge line hose from the vacuum switching valve.

-

Detach the 2 wire harness clamps from the wire harness bracket.

-

Slide the clamp and disconnect the No. 3 PCV hose from the intake manifold.

-

Slide the clamp and disconnect the vacuum hose from the intake manifold.

-

Remove the bolt and wire harness bracket from the intake manifold.

-

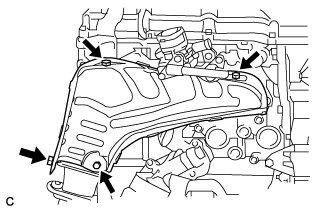

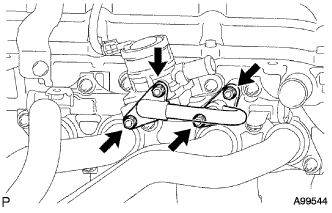

Remove the 5 bolts, 2 nuts and intake manifold.

-

Remove the gasket from the intake manifold.

-

Remove the intake manifold insulator from the intake manifold.

-

-

REMOVE IGNITION COIL ASSEMBLY

-

Remove the 4 bolts and 4 ignition coil assemblies.

-

-

REMOVE SPARK PLUG

-

Using a 16 mm spark plug wrench, remove the 4 spark plugs.

-

-

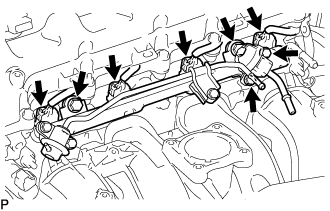

REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

Note

Be careful not to drop the fuel injector assemblies when removing the fuel delivery pipe sub-assembly.

-

Disconnect the vacuum hose from the fuel pressure regulator assembly.

-

Slide the clamp and disconnect the No. 2 fuel hose from the fuel pressure regulator assembly.

-

Disconnect the 4 fuel injector connectors.

-

Remove the 2 bolts, fuel pressure pulsation damper assembly and O-ring.

-

Remove the 2 bolts and fuel delivery pipe sub-assembly together with the 4 fuel injector assemblies.

Note

Be careful not to drop the fuel injector assemblies when removing the fuel delivery pipe sub-assembly.

-

Remove the 2 No. 1 delivery pipe spacers from the cylinder head sub-assembly.

-

Remove the 4 injector vibration insulators.

-

Text in Illustration *a Protective Tape Using a screwdriver, pry out the 4 injector spacers and 4 O-rings from the cylinder head sub-assembly.

Tech Tips

Tape the screwdriver tip before use.

-

-

REMOVE FUEL INJECTOR ASSEMBLY

-

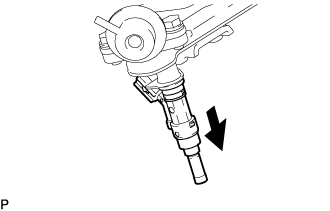

Pull out the 4 fuel injector assemblies from the fuel delivery pipe sub-assembly.

Text in Illustration

Pull Out -

Remove the O-rings from the fuel injector assemblies.

-

-

REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

-

Remove the 4 bolts and No. 1 exhaust manifold heat insulator.

-

-

REMOVE NO. 4 INTAKE PIPE

-

Remove the 4 nuts and No. 4 intake pipe.

-

Remove the 2 gaskets.

-

-

REMOVE AIR SWITCHING VALVE ASSEMBLY

-

Disconnect the air switching valve connector.

-

Remove the 2 nuts and air switching valve assembly.

-

-

REMOVE EXHAUST MANIFOLD

-

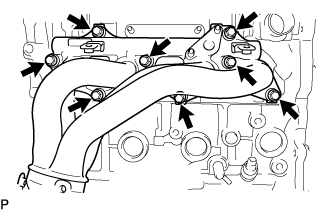

Remove the 8 nuts, exhaust manifold and gasket.

-

-

REMOVE FAN PULLEY

-

Remove the 4 nuts, fan pulley and fan spacer.

-

-

REMOVE NO. 1 WATER BY-PASS PIPE

-

Remove the bolt, 2 nuts, No. 1 water by-pass pipe and gasket.

-

-

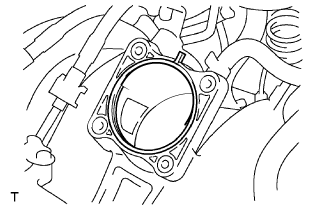

REMOVE WATER INLET

-

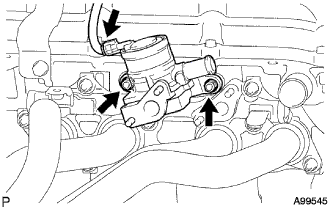

Remove the 2 nuts and bolt and disconnect the water inlet.

-

Remove the gasket.

-

-

REMOVE THERMOSTAT

-

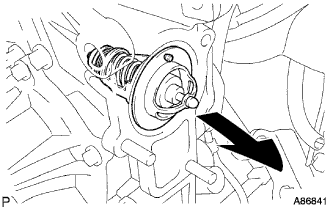

Remove the thermostat and gasket.

-

-

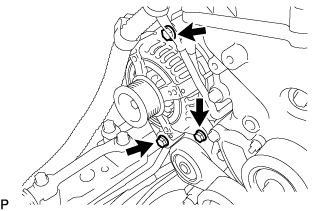

REMOVE GENERATOR ASSEMBLY

-

Disconnect the generator connector.

-

Remove the terminal cap.

-

Remove the nut and disconnect the wire harness from terminal B.

-

Remove the bolt and disconnect the wire harness clamp.

-

Remove the 3 bolts and generator assembly.

-

-

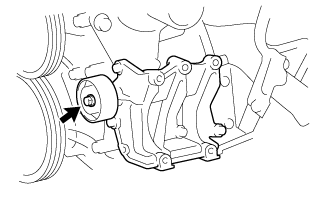

REMOVE IDLE PULLEY ASSEMBLY

-

Loosen the bolt, and then remove the idle pulley assembly.

Tech Tips

The bolt in the illustration cannot be removed from the idle pulley assembly.

-

-

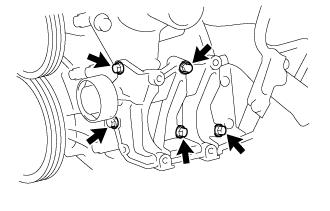

REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

-

Remove the 5 bolts and No. 1 compressor mounting bracket.

-

-

REMOVE NO. 1 IDLER PULLEY SUB-ASSEMBLY

-

Remove the bolt, collar and No. 1 idler pulley sub-assembly.

-

-

REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

-

Remove the 2 bolts and V-ribbed belt tensioner assembly.

-

-

REMOVE ENGINE OIL PRESSURE SWITCH ASSEMBLY

-

Using a 24 mm deep socket wrench, remove the engine oil pressure switch assembly.

-

-

REMOVE KNOCK CONTROL SENSOR

-

Disconnect the knock control sensor connector.

-

Remove the bolt and knock control sensor.

-

-

REMOVE ENGINE COOLANT TEMPERATURE SENSOR

-

Disconnect the engine coolant temperature sensor connector.

-

Using a 19 mm deep socket wrench, remove the engine coolant temperature sensor and gasket.

-

-

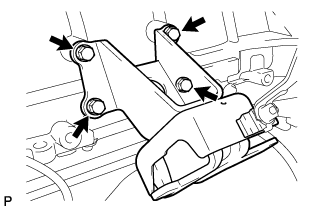

REMOVE FRONT NO. 1 ENGINE MOUNTING BRACKET RH

Tech Tips

Perform this procedure only when replacement of the front No. 1 engine mounting bracket RH is necessary.

-

Remove the 4 bolts and front No. 1 engine mounting bracket RH.

-

-

REMOVE FRONT NO. 1 ENGINE MOUNTING BRACKET LH

Tech Tips

Perform this procedure only when replacement of the front No. 1 engine mounting bracket LH is necessary.

-

Remove the 4 bolts and front No. 1 engine mounting bracket LH.

-

-

REMOVE ENGINE OIL LEVEL SENSOR

-

Remove the 4 bolts and engine oil level sensor.

-