COMMON RAIL (w/ DPF) INSTALLATION

Note

-

When replacing the injectors (including shuffling the injectors between the cylinders), common rail or cylinder head, it is necessary to replace the injection pipes with new ones.

-

When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

-

After removing the injection pipes and fuel inlet pipe, clean them with a brush and compressed air.

-

INSTALL COMMON RAIL ASSEMBLY

-

Install the common rail with the 2 bolts.

- Torque:

- 38 N*m { 387 kgf*cm, 28 ft.*lbf }

-

-

INSTALL FUEL INLET PIPE SUB-ASSEMBLY

Note

-

When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket or timing gear case, it is necessary to replace the fuel inlet pipe with a new one.

-

Keep the fuel inlet pipe free of foreign matter.

-

If a No. 1 injection pipe clamp is removed from the fuel inlet pipe, replace the No. 1 injection pipe clamp with a new one.

-

Temporarily install the fuel inlet pipe with the union nuts.

-

Install the 2 No. 1 injection pipe clamps with the 2 bolts.

- Torque:

- 6.5 N*m { 66 kgf*cm, 58 in.*lbf }

-

Using a 17 mm union nut wrench, tighten the fuel inlet pipe union nut on the common rail side.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Using a 17 mm union nut wrench, tighten the fuel inlet pipe union nut on the fuel supply pump side.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

CONNECT NO. 5 WATER BY-PASS HOSE

-

INSTALL VACUUM CONTROL VALVE SET

-

Install the vacuum control valve set with the bolt.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Connect the 2 vacuum hoses and vacuum control valve connector to the No. 3 vacuum transmitting pipe sub-assembly.

-

-

INSTALL INJECTION PIPE SUB-ASSEMBLY

Note

-

When replacing an injector, it is necessary to replace the 4 injection pipes with new ones.

-

Keep the joints of the injection pipe clean.

-

Temporarily install the 4 injection pipes with the union nuts.

-

Install the 3 No. 2 injection pipe clamps with the 3 bolts.

- Torque:

- 6.5 N*m { 66 kgf*cm, 58 in.*lbf }

-

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Using a 17 mm union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

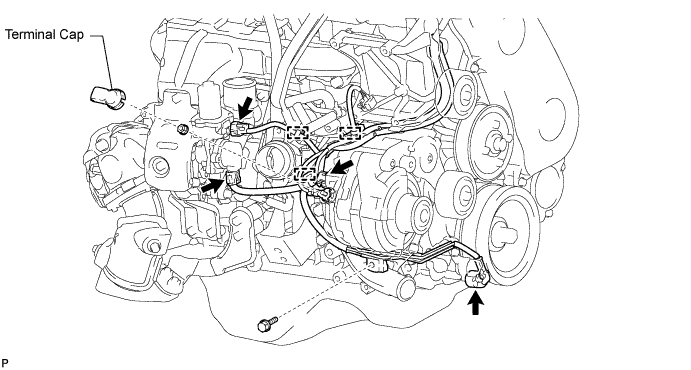

CONNECT ENGINE WIRE

-

Attach the 5 clamps.

-

Connect the 5 connectors.

-

Connect the ECM connector Click here.

-

Attach the clamp.

-

Install the bolt.

- Torque:

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

Install the generator wire to terminal B with the nut.

- Torque:

- 9.8 N*m { 100 kgf*cm, 87 in.*lbf }

-

Install the terminal cap.

-

Install the engine wire with the bolt.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

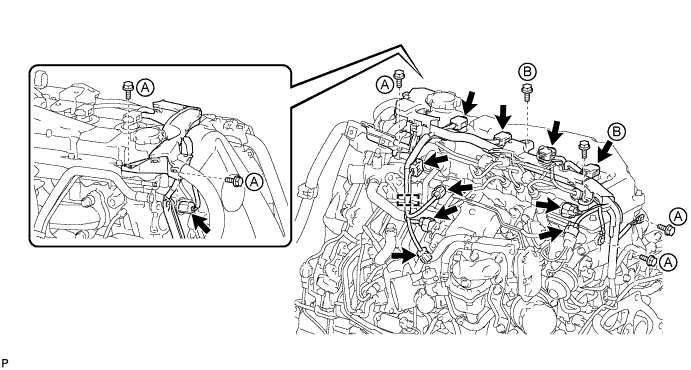

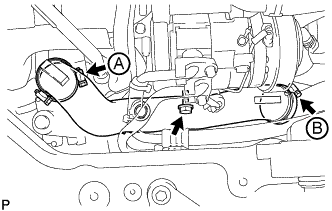

Connect the 4 connectors and attach the 3 clamps.

-

Install the engine wire with the 7 bolts.

- Torque:

- for bolt A

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

- for bolt B

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

Connect the 11 connectors.

-

Attach the clamp and connect the engine wire to the No. 1 timing belt cover.

-

Connect the glow plug connector and attach the clamp.

-

Attach the 3 clamps and connect the water by-pass hose and oil return hose.

-

-

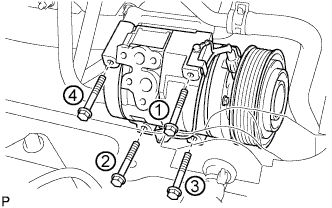

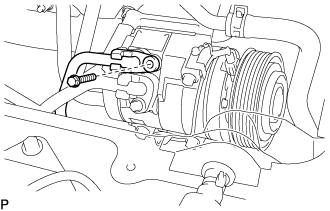

INSTALL COMPRESSOR AND MAGNETIC CLUTCH

-

Provisionally tighten the compressor and magnetic clutch with the 4 bolts.

-

Tighten the compressor and magnetic clutch with the 4 bolts.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

Note

Tighten the bolts in the order shown in the illustration to install the compressor and magnetic clutch.

-

-

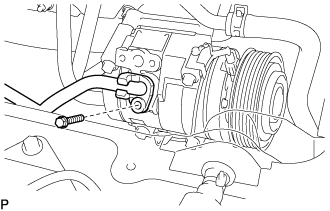

CONNECT NO. 1 COOLER REFRIGERANT SUCTION HOSE

-

Remove the attached vinyl tape from the hose.

-

Apply sufficient compressor oil (ND-OIL 8) to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil ND-OIL 8 or equivalent -

Install the O-ring onto the cooler refrigerant suction hose.

-

Install the cooler refrigerant suction hose onto the compressor and magnetic clutch with the bolt.

- Torque:

- 9.8 N*m { 100 kgf*cm, 87 in.*lbf }

-

-

CONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE

-

Remove the attached vinyl tape from the hose.

-

Apply sufficient compressor oil (ND-OIL 8) to a new O-ring and the fitting surface of the compressor and magnetic clutch.

Compressor oil ND-OIL 8 or equivalent -

Install the O-ring onto the cooler refrigerant discharge hose.

-

Install the cooler refrigerant discharge hose onto the compressor and magnetic clutch with the bolt.

- Torque:

- 9.8 N*m { 100 kgf*cm, 87 in.*lbf }

-

-

INSTALL FAN AND GENERATOR V BELT

-

Rotate the V-ribbed belt tensioner pulley clockwise, and then install the fan and generator V belt.

Note

Make sure that the fan and generator V belt is set properly on each pulley.

-

Check that the indicator mark of the V-ribbed belt tensioner Click here.

-

-

INSTALL COMPRESSOR OUTLET ELBOW

-

Install the compressor outlet elbow with the 2 hose clamps and bolt.

- Torque:

- for bolt

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

- for hose clamp A

- 6.5 N*m { 66 kgf*cm, 58 in.*lbf }

- for hose clamp B

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

-

INSTALL ENGINE SERVICE HOLE SUB COVER SUB-ASSEMBLY

-

Install the engine service hole sub cover with the 5 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

INSTALL FRONT SEAT ASSEMBLY RH

-

INSTALL FRONT DOOR SCUFF PLATE RH

-

Attach the 5 clips to install the front door scuff plate RH.

-

-

INSTALL DIESEL THROTTLE BODY ASSEMBLY

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

-

ADD ENGINE COOLANT

-

Firmly tighten the drain plugs.

-

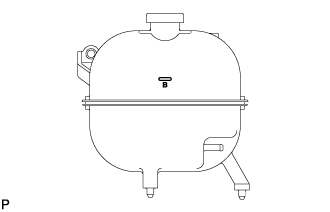

Fill the radiator reservoir assembly with engine coolant to the top of the inlet.

Standard Capacity Item Specified Condition w/o Heater 13.2 liters (13.9 US qts, 11.6 Imp. qts) w/ Front Heater 14.2 liters (15.0 US qts, 12.5 Imp. qts) w/ Front and Rear Heaters 16.2 liters (17.1 US qts, 14.3 Imp. qts) Note

Do not substitute plain water for engine coolant.

Tech Tips

-

Use of improper coolants may damage the engine cooling system.

-

Use only Toyota Super Long Life Coolant or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

-

-

Loosen the bleeder plug of the outlet housing.

-

When air is bled and the engine coolant drains out, firmly tighten the bleeder plug.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

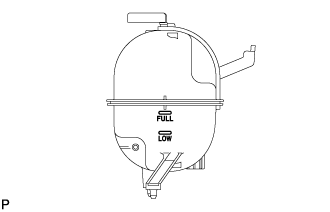

Add engine coolant up to the B line mark in the radiator reservoir assembly and install the radiator reservoir cap sub-assembly.

-

Warm up the engine until the thermostat opens.

-

While the thermostat is open, circulate the engine coolant for several minutes.

Tech Tips

The thermostat open timing can be confirmed by pressing the No. 3 radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

-

-

After the engine cools down, check that the engine coolant level is between the LOW and FULL level marks.

-

-

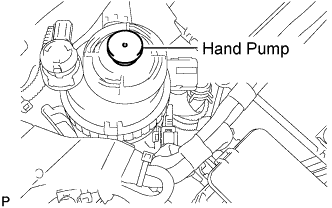

BLEED AIR FROM FUEL SYSTEM

-

Using the hand pump mounted on the fuel filter cap, bleed air from the fuel system. Continue pumping until the pump resistance increases.

Note

-

Hand pump pumping speed: Max. 2 strokes/ sec.

-

The hand pump must be pushed with a full stroke during pumping.

-

When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

-

If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

-

If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

-

If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

-

-

Check if the engine starts.

Note

-

Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

-

Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

-

Use a fully-charged battery.

-

When the engine can be started, proceed to the next step.

-

If the engine cannot be started, bleed air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

-

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs.

-

w/ DPF: Click here

-

w/o DPF: Click here

-

-

Start the engine.*1

-

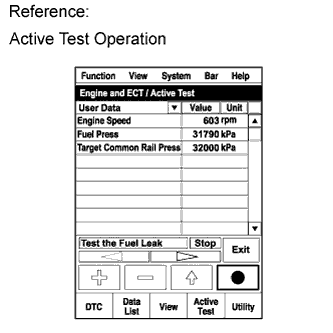

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

-

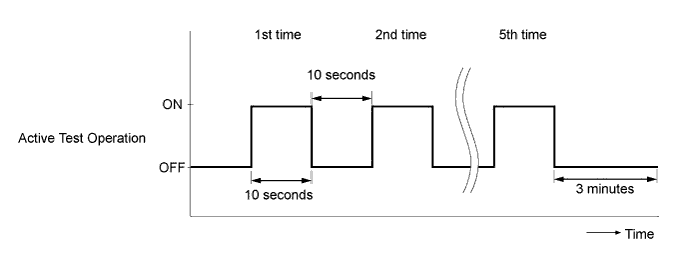

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

-

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time.

Tech Tips

When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

-

Clear the DTCs.

-

w/ DPF: Click here

-

w/o DPF: Click here

Tech Tips

It is necessary to clear the DTCs as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

-

-

Repeat steps *1 to *3.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

OK No DTCs are output.

-

-

INSPECT FOR COOLANT LEAK

CAUTION:

Do not remove the radiator cap while the engine and radiator are still hot. Hot, pressurized engine coolant and steam may be released and cause serious burns.

-

Fill the radiator with coolant and attach a radiator cap tester to the radiator.

-

Warm up the engine.

-

Using a radiator cap tester, increase the pressure inside the radiator to 137 kPa (1.4 kgf/cm2, 19.9 psi), and check that the pressure does not drop.

Tech Tips

If the pressure drops, check the hoses, radiator and water pump for leaks. If no external leaks are found, check the heater core, cylinder block and cylinder head.

-

-

INSPECT FOR FUEL LEAK

-

Perform the Active Test.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test.

-

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurize common rail interior and check for fuel leaks Stop/Start

-

Fuel pressure inside common rail increased to specified value and engine speed increased to 2000 rpm when Active Test is performed

-

Above conditions preserved while Active Test is being performed

-

-

-

-

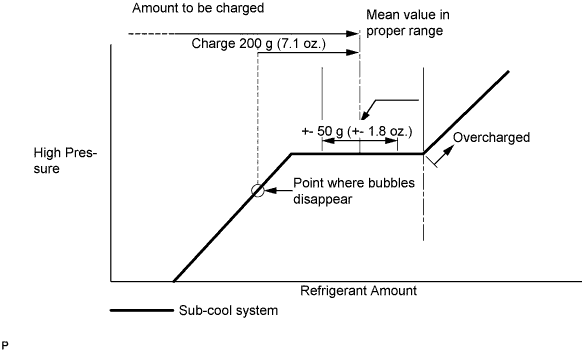

CHARGE REFRIGERANT

-

Perform vacuum purging using a vacuum pump.

-

Charge with refrigerant HFC-134a (R134a).

Standard Single A/C 520 to 580g (18.3 to 20.5 oz.) Dual A/C 670 to 730g (23.0 to 25.7 oz.) - SST

- 07110-58060 ( 07117-58090, 07117-78050, 07117-58070, 07117-58060, 07117-58080, 07117-88060, 07117-88070, 07117-88080 )

Note

-

Do not operate the cooler compressor before charging refrigerant as the cooler compressor does not work properly without any refrigerant, which causes the compressor to overheat.

-

Approximately 100 g (3.5 oz.) of refrigerant may need to be charged after bubbles disappear. The refrigerant amount should be checked by quantity, and not with the sight glass.

Tech Tips

Prepare a service can to recharge refrigerant if using the refrigerant gas collected with the freon collection/recycling device because the collective rate of the device is approximately 90%.

-

-

WARM UP ENGINE

-

Warm up the engine at less than 1,850 rpm for 2 minutes or more after charging refrigerant.

Note

Be sure to warm up the compressor when turning the A/C switch on after removing and installing the cooler refrigerant lines (including the compressor), to prevent damage to the compressor.

-

-

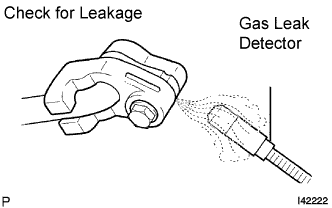

INSPECT FOR LEAKAGE OF REFRIGERANT

-

After recharging refrigerant gas, check for leakage of refrigerant gas using a halogen leak detector.

-

Carry out the test under the following conditions:

-

Stop the engine.

-

Secure good ventilation (the gas leak detector may react to volatile gases which are not refrigerant, such as evaporated gasoline and exhaust gas).

-

Repeat the test 2 or 3 times.

-

Make sure that there is some refrigerant remaining in the refrigeration system.

When the compressor is off: approx. 392 to 588 kPa (4 to 6 kgf/cm2, 57 to 85 psi)

-

-

Using a gas leak detector, check for leakage of the refrigerant line.

-

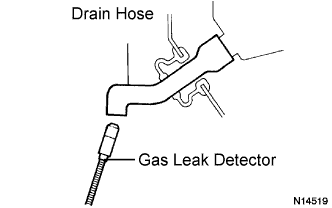

Bring the gas leak detector close to the drain hose with the detector's power off.

Tech Tips

-

After the blower motor has stopped, let the cooling unit stand for more than 15 minutes.

-

Bring the gas leak detector sensor under the drain hose.

-

When bringing the gas leak detector close to the drain hose, make sure that the gas leak detector does not react to volatile gases.

If such reaction is unavoidable, the vehicle must be lifted up.

-

-

If a gas leak is not detected on the drain hose, remove the blower motor control from the cooling unit. Insert the gas leak detector sensor into the unit and perform the test.

-

Disconnect the pressure switch connector and leave it for approximately 20 minutes. Bring the gas leak detector close to the pressure switch and perform the test.

-