BRAKE PEDAL STROKE SENSOR INSTALLATION

Tech Tips

-

Use the same procedure for the RHD and LHD vehicles.

-

The procedure listed below is for the LHD vehicles.

Note

While the battery is connected, even if the engine switch is off, the brake control system activates when the brake pedal is depressed or the door courtesy switch turns on. Therefore during servicing of the brake system components, do not operate the brake pedal and open/close the doors while the battery is connected.

-

INSTALL BRAKE PEDAL STROKE SENSOR ASSEMBLY

-

When installing a new brake pedal stroke sensor assembly:

Note

Do not break the sensor lever set pin before installing the brake pedal stroke sensor with the bolts.

-

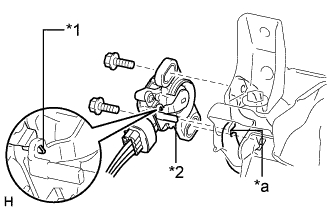

Text in Illustration *1 Pin *2 Lever *a Groove Connect the sensor connector.

-

Install a new sensor with the 2 bolts.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

Note

-

Engage the sensor lever with the brake pedal groove.

-

Check that there is no foreign matter attached to the contact surface of the sensor.

-

Check that the tip of the sensor lever is protruding from the brake pedal groove.

-

Firmly depress the brake pedal and break the sensor lever set pin.

-

Remove the broken lever set pin.

-

-

When reusing the brake pedal stroke sensor assembly:

-

Connect the sensor connector.

-

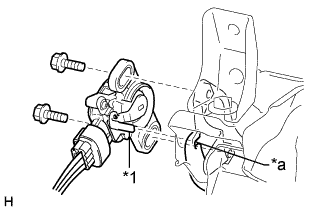

Text in Illustration *1 Lever *a Groove Temporarily install the sensor with the 2 bolts.

Note

-

Engage the sensor lever with the brake pedal groove.

-

Check that there is no foreign matter attached to the contact surface of the sensor.

-

-

Connect the cable to the negative battery terminal.

-

Connect the intelligent tester to the DLC3.

-

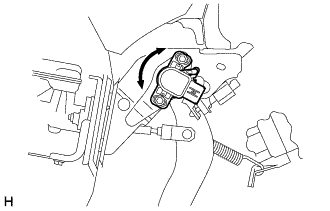

Turn the engine switch on (IG). Reading the value of the stroke sensor 1 shown on the data monitor, turn the sensor slowly to the right and left to adjust the output voltage to the standard voltage.

Standard voltage 0.8 to 1.2 V -

Tighten the 2 bolts.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

Note

Do not depress the brake pedal after turning the engine switch on (IG).

-

-

-

INSTALL NO. 1 INSTRUMENT PANEL SAFETY PAD SUB-ASSEMBLY

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

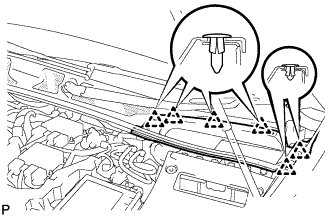

INSTALL COWL TOP VENTILATOR LOUVER

-

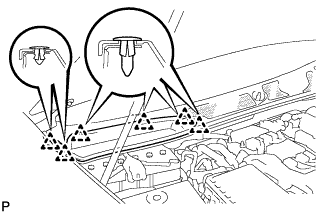

for LHD:

Install the 6 clips and cowl top ventilator louver RH.

Note

If the cowl top ventilator louver RH is not properly installed, water may leak into the engine room and cause malfunctions. Therefore, make sure the cowl top ventilator louver RH is installed properly.

-

for RHD:

Install the 6 clips and cowl top ventilator louver LH.

Note

If the cowl top ventilator louver LH is not properly installed, water may leak into the engine room and cause malfunctions. Therefore, make sure the cowl top ventilator louver LH is installed properly.

-

-

CHECK SRS WARNING LIGHT

-

CHECK AND CLEAR DTC

-

PERFORM LINEAR VALVE OFFSET LEARNING