- Click here

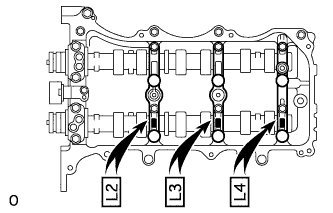

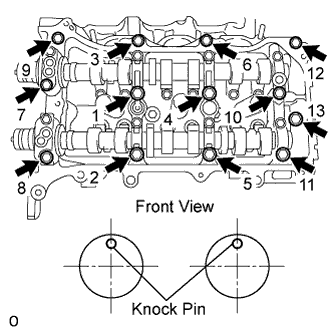

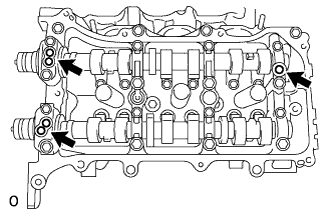

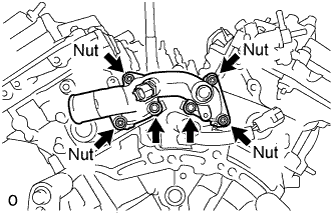

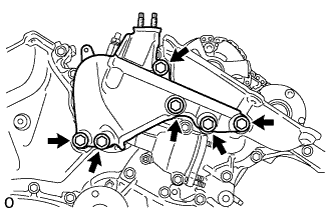

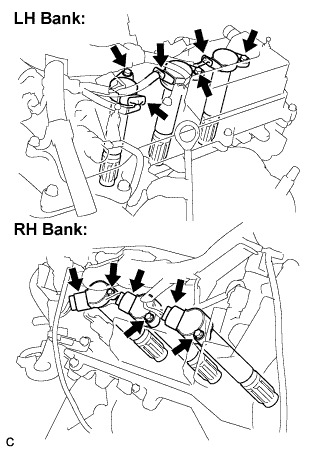

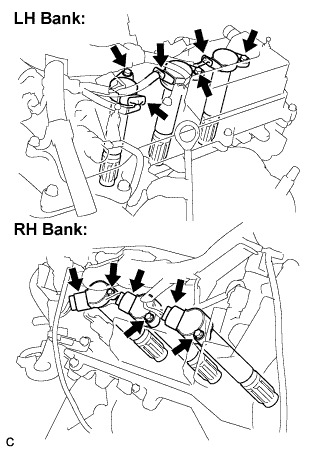

INSTALL CAMSHAFT BEARING CAP

-

Apply engine oil to the camshaft journals, camshaft housing sub-assembly LH and camshaft bearing caps.

-

Install the No. 3 camshaft and No. 4 camshaft to the camshaft housing sub-assembly LH.

-

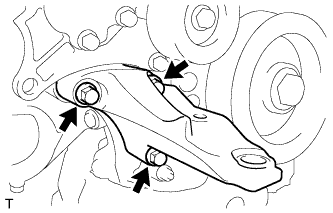

Make sure of the marks and numbers on the camshaft bearing caps and place them in each proper position and direction.

-

Temporarily tighten the 8 bolts in the order shown in the illustration.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

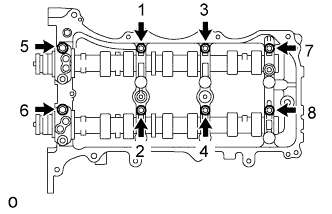

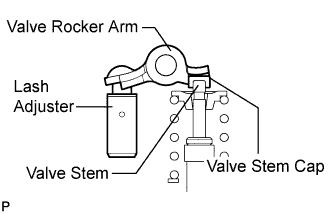

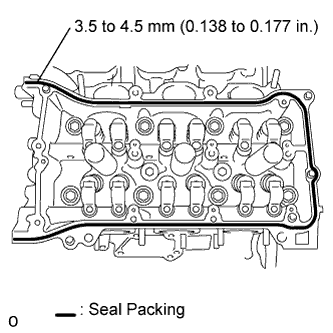

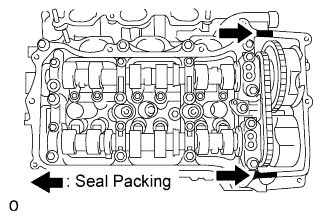

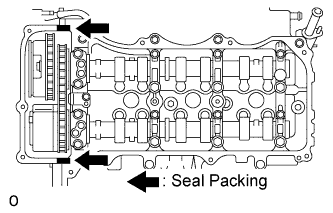

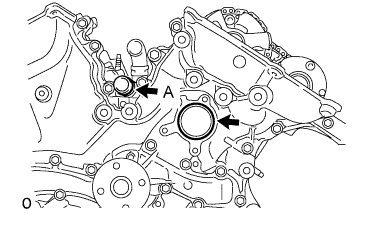

INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH

-

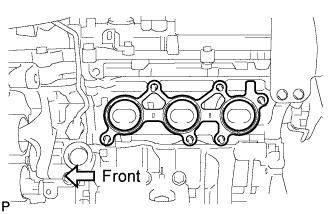

Make sure that the valve rocker arm is installed as shown in the illustration.

-

Apply seal packing in a continuous line as shown in the illustration.

Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal diameter 3.5 to 4.5 mm (0.138 to 0.177 in.) Note:

-

Remove any oil from the contact surface.

-

Install the camshaft housing sub-assembly LH within 3 minutes.

-

Do not start the engine for at least 2 hours after installing.

-

-

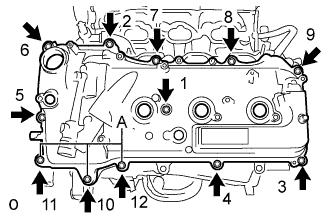

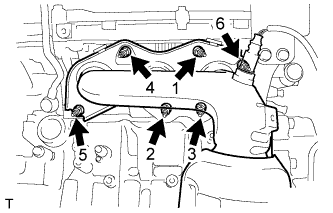

Install the camshaft housing sub-assembly LH and tighten the 13 bolts in the order shown in the illustration.

28 N*m 286 kgf*cm 21 ft.*lbf Note:

-

When installing the camshaft housing sub-assembly LH, it is necessary to correctly position the camshafts as shown in the illustration. Failure to correctly position these parts may result in damage due to contact between the pistons and valves. If a camshaft is rotated with a piston at TDC, valve contact will occur.

-

If any of the bolts are loosened during installation, remove the camshaft housing sub-assembly LH, clean the installation surfaces, and reapply seal packing.

-

If the camshaft housing sub-assembly LH is removed because any of the bolts are loosened during installation, make sure that the previously applied seal packing does not enter any oil passages.

-

-

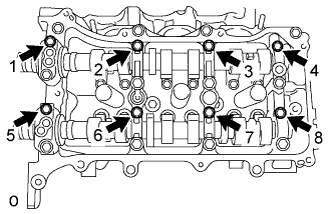

Tighten the 8 bolts in the order shown in the illustration.

16 N*m 163 kgf*cm 12 ft.*lbf

-

- Click here

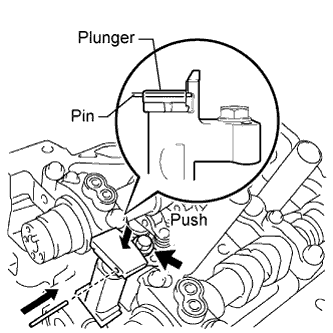

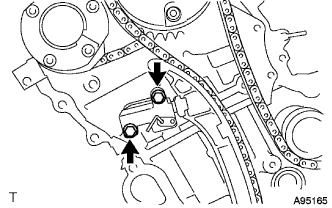

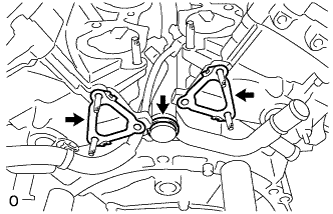

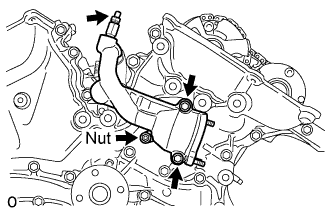

INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY

-

Install the No. 3 chain tensioner assembly with the bolt.

21 N*m 214 kgf*cm 15 ft.*lbf -

While pushing in the tensioner, insert a pin of 1.0 mm (0.039 in.) diameter into the hole to hold it.

-

- Click here

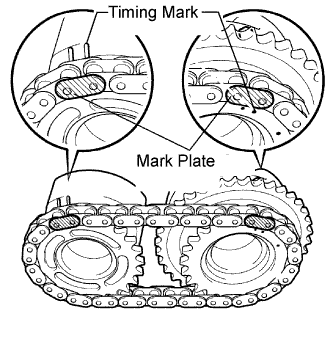

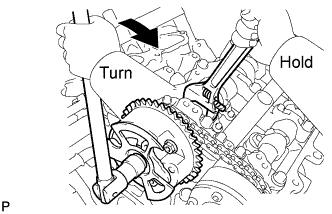

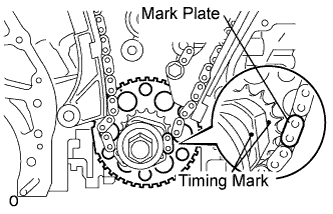

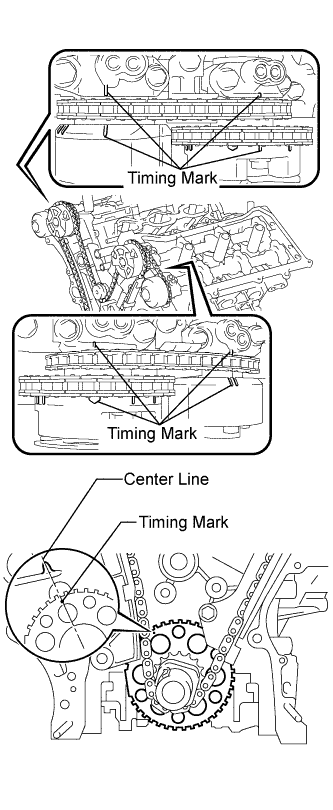

INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 2)

-

Align the mark plate (yellow) with the timing marks (2-dot mark) of the camshaft timing gear assemblies as shown in the illustration.

-

Apply a light coat of engine oil to the bolt threads and bolt-seating surface.

-

Align the knock pin of the camshaft with the pin hole of the camshaft timing gear assembly. Install the camshaft timing gear assembly and camshaft timing exhaust gear LH with the No. 2 chain sub-assembly installed.

-

Hold the hexagonal portion of the camshaft with a wrench, and tighten the 2 bolts.

100 N*m 1020 kgf*cm 74 ft.*lbf -

Remove the pin from the No. 3 chain tensioner assembly.

-

- Click here

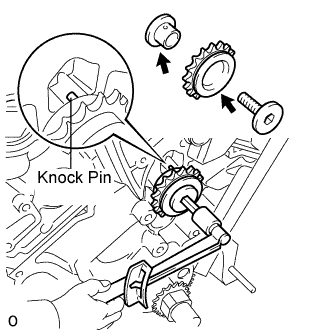

INSTALL IDLE SPROCKET ASSEMBLY

-

Apply a light coat of engine oil to the rotating surface of the No. 1 idle gear shaft.

-

Temporarily install the No. 1 idle gear shaft and idle sprocket assembly with the No. 2 idle gear shaft while aligning the knock pin of the No. 1 idle gear shaft with the knock pin groove of the cylinder block sub-assembly.

Note:Be careful of the idle gear installation position.

Tip:Check that no foreign matter is on the No. 1 or No. 2 idle gear shafts.

-

Using a 10 mm hexagon wrench, tighten the No. 2 idle gear shaft.

60 N*m 612 kgf*cm 44 ft.*lbf Tip:After installing the idle sprocket assembly, check that it turns smoothly.

-

- Click here

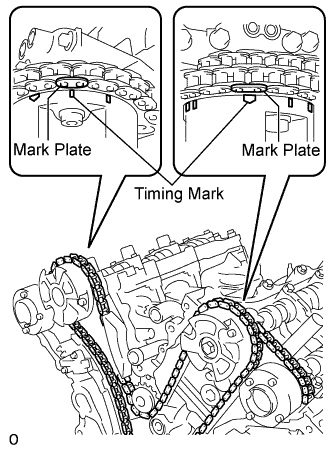

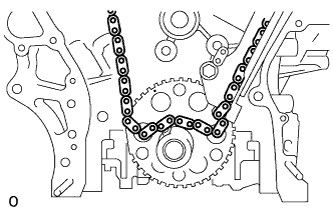

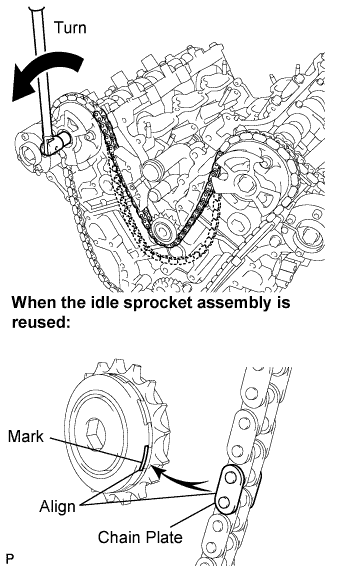

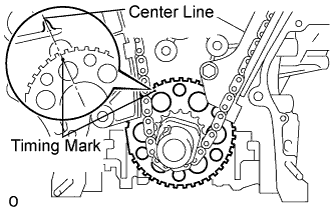

INSTALL CHAIN SUB-ASSEMBLY

-

Align the mark plates and timing marks as shown in the illustration and install the chain sub-assembly.

Tip:The camshaft mark plates are orange.

-

Do not pass the chain sub-assembly over the crankshaft, just temporarily place it on the crankshaft.

-

Turn the camshaft timing gear assembly on bank 1 counterclockwise to tighten the chain sub-assembly between the banks.

Note:When the idle sprocket assembly is reused, align the chain plate with the mark where the plate had been in order to tighten the chain sub-assembly between the banks.

-

Align the mark plate and timing marks as shown in the illustration and install the chain sub-assembly onto the crankshaft timing sprocket.

Tip:The crankshaft mark plate is yellow.

-

Temporarily tighten the pulley set bolt.

-

Turn the crankshaft clockwise to set it to the RH block bore center line (TDC/compression).

-

- Click here

INSTALL CHAIN TENSIONER SLIPPER

-

Install the chain tensioner slipper.

-

- Click here

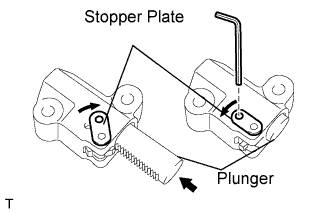

INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

-

Move the stopper plate upward to release the lock, and push the plunger deep into the No. 1 chain tensioner assembly.

-

Move the stopper plate downward to set the lock, and insert a hexagon wrench into the hole of the stopper plate.

-

Install the No. 1 chain tensioner assembly with the 2 bolts.

10 N*m 102 kgf*cm 7 ft.*lbf -

Remove the hexagon wrench from the No. 1 chain tensioner assembly. Check that each timing mark is aligned with the crankshaft at the TDC/compression.

-

Remove the pulley set bolt.

-

- Click here

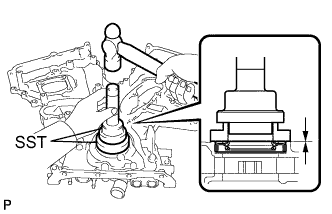

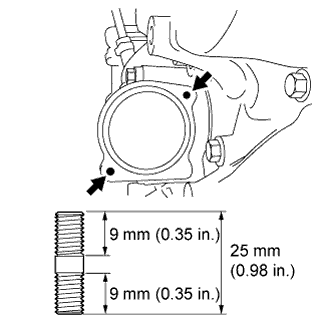

INSTALL TIMING CHAIN CASE OIL SEAL

-

Using SST, tap in a new timing chain case oil seal until its surface is flush with the timing chain cover sub-assembly edge.

09223-22010 09506-35010 Note:

-

Keep the lip free of foreign matter.

-

Do not tap in the timing chain case oil seal at an angle.

-

Make sure that the timing chain case oil seal edge does not stick out of the timing chain cover sub-assembly.

-

-

- Click here

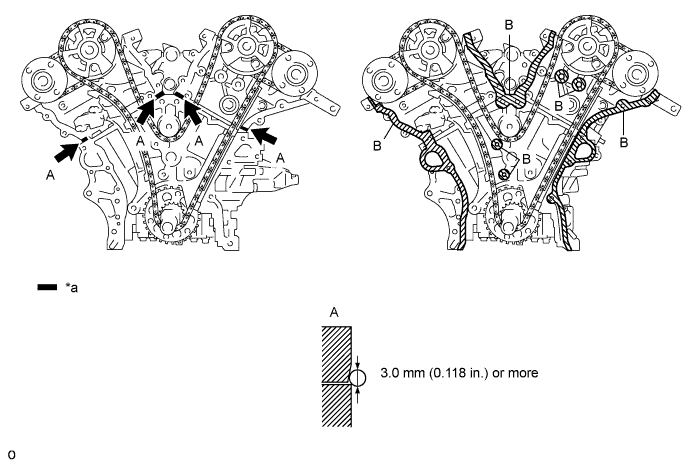

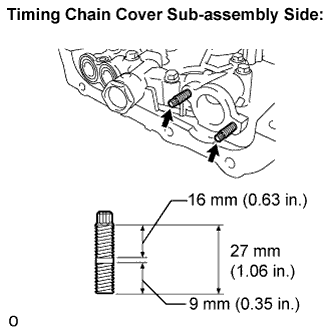

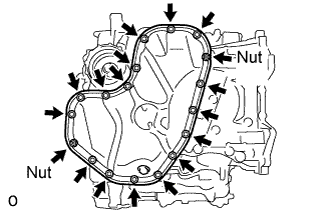

INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

-

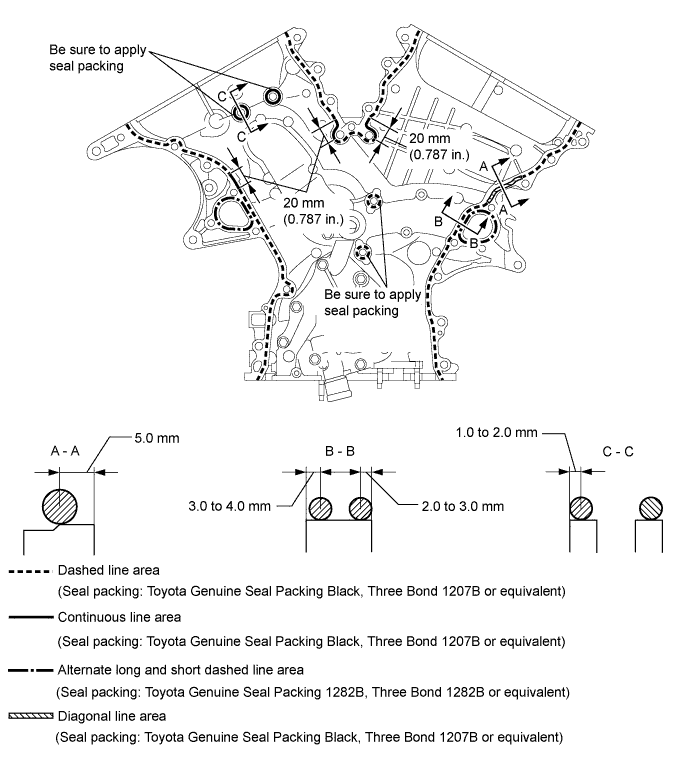

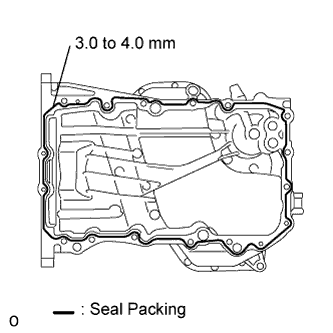

Apply seal packing in a continuous line to the engine unit as shown in the following illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal Diameter 3.0 mm (0.118 in.) or more Note:

-

Be sure to clean the contact surfaces, especially the surfaces indicated by (B) in the illustration.

-

If there is oil on the contact surfaces, wipe them with an oil-free cloth before applying seal packing.

-

Install the timing chain cover sub-assembly within 3 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

-

-

Apply seal packing in a continuous line to the timing chain cover sub-assembly as shown in the following illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent Note:

-

If there is oil on the contact surfaces, wipe them with an oil-free cloth before applying seal packing.

-

Install the timing chain cover sub-assembly within 3 minutes and tighten the bolts within 15 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

Seal Packing Application Chart Area Seal Packing Diameter Application Position from Inside Seal Line Continuous Line Area 4.5 mm (0.177 in.) or more 3.0 to 4.0 mm (0.118 to 0.157 in.) Alternate Long and Dashed Line Area 3.5 mm (0.138 in.) or more 2.0 to 3.0 mm (0.079 to 0.118 in.) Dashed Line Area 3.5 mm (0.138 in.) or more 3.0 to 4.0 mm (0.118 to 0.157 in.) Diagonal Line Area 6.0 mm (0.236 in.) or more 5.0 mm (0.197 in.) -

-

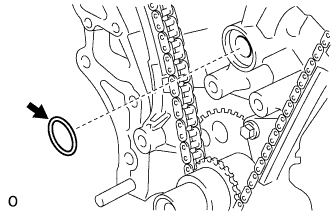

Install a new gasket.

-

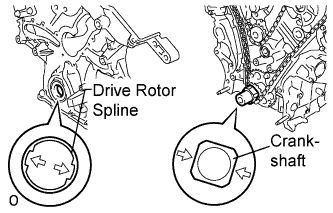

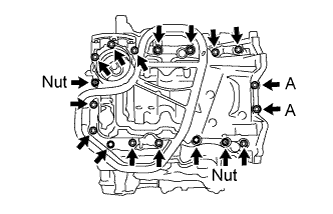

Align the oil pump's drive rotor spline and the crankshaft as shown in the illustration. Install the spline and timing chain cover sub-assembly to the crankshaft.

-

Temporarily tighten the timing chain cover sub-assembly with the 23 bolts and 2 nuts.

Bolt Length Item Length Bolt A 40 mm (1.57 in.) Bolt B 55 mm (2.17 in.) Bolt C 25 mm (0.98 in.) Note:Make sure that there is no oil on the bolt and nut threads.

-

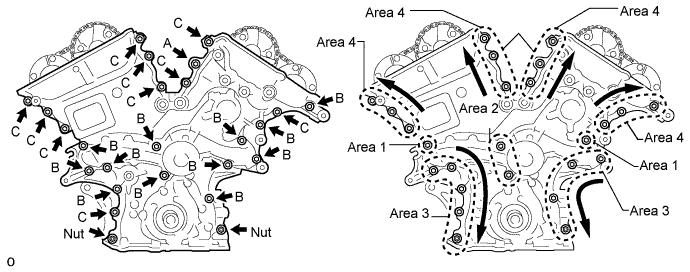

Fully tighten the bolts in this order: Area 1 and Area 2.

21 N*m 214 kgf*cm 15 ft.*lbf -

Fully tighten the bolts in Area 3.

21 N*m 214 kgf*cm 15 ft.*lbf Tip:Tighten the bolts and nuts from top to bottom as shown in the illustration.

-

Fully tighten the bolts in Area 4.

Bolt A 43 N*m 438 kgf*cm 32 ft.*lbf Except Bolt A 21 N*m 214 kgf*cm 15 ft.*lbf Tip:Tighten the bolts from bottom to top as shown in the illustration.

-

Install a new chain cover plate gasket and the chain cover plate with the 4 bolts.

9.1 N*m 93 kgf*cm 81 in.*lbf

-

- Click here

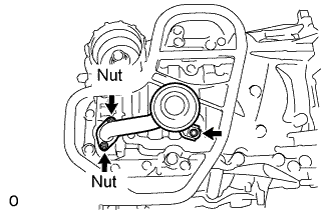

INSTALL OIL PAN SUB-ASSEMBLY

-

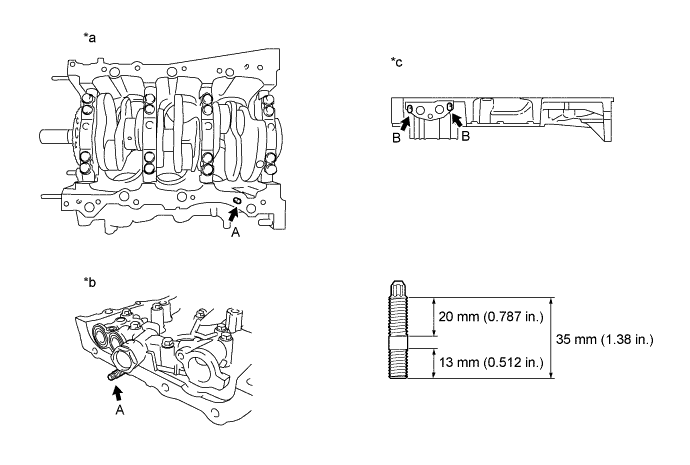

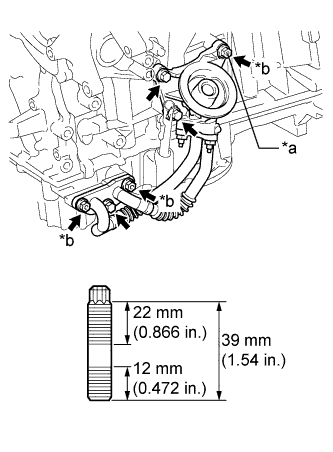

Using an E8 "TORX" socket wrench, install the 4 stud bolts.

Table 1. Text in Illustration *a Lower Cylinder Block *b Timing Chain Cover *c Oil Pan Sub-assembly LH Side - - Bolt A 10 N*m 102 kgf*cm 7 ft.*lbf Bolt B 9.0 N*m 92 kgf*cm 80 in.*lbf -

Install 2 new O-rings.

-

Apply seal packing in a continuous line as shown in the illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal Diameter 3.0 to 4.0 mm (0.118 to 0.157 in.) Note:

-

Remove any oil from the contact surface.

-

Install the oil pan sub-assembly within 3 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

-

-

Install the oil pan sub-assembly with the 16 bolts and 2 nuts.

Bolt A 10 N*m 102 kgf*cm 7 ft.*lbf Except Bolt A 21 N*m 214 kgf*cm 15 ft.*lbf

-

- Click here

INSTALL OIL STRAINER SUB-ASSEMBLY

-

Using an E6 "TORX" socket wrench, install the stud bolts as shown in the illustration.

4.0 N*m 41 kgf*cm 35 in.*lbf -

Install a new gasket and the oil strainer sub-assembly with the bolt and 2 nuts.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

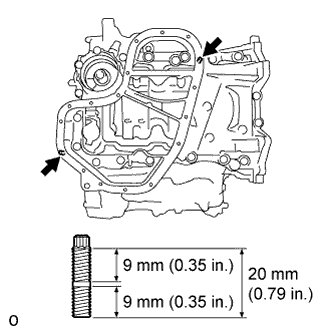

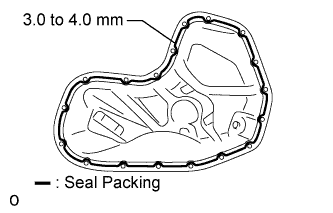

INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

-

Using an E6 "TORX" socket wrench, install the stud bolts as shown in the illustration.

4.0 N*m 41 kgf*cm 35 in.*lbf -

Apply seal packing in a continuous line as shown in the illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal Diameter 3.0 to 4.0 mm (0.118 to 0.157 in.) Note:

-

Remove any oil from the contact surface.

-

Install the No. 2 oil pan sub-assembly within 3 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

-

-

Install the No. 2 oil pan sub-assembly with the 16 bolts and 2 nuts.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

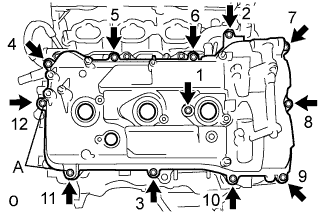

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1)

-

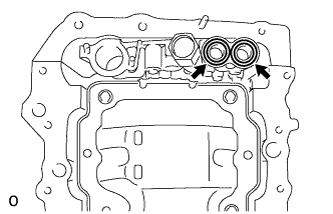

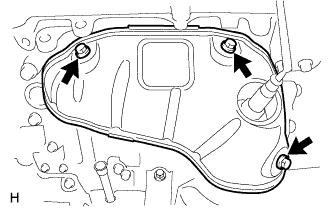

Apply seal packing as shown in the illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:

-

Remove any oil from the contact surface.

-

Install the cylinder head cover sub-assembly within 3 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

-

-

Install 3 new gaskets as shown in the illustration.

-

Install a new cylinder head cover gasket to the cylinder head cover sub-assembly.

-

Install a cylinder head cover sub-assembly with the 12 bolts and a new seal washer.

Bolt A 21 N*m 214 kgf*cm 15 ft.*lbf Except bolt A 10 N*m 102 kgf*cm 7 ft.*lbf Tip:After tightening all bolts, check the tightening torque of 1 and 11. Retighten the bolt if necessary.

-

- Click here

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 2)

-

Apply seal packing as shown in the illustration.

Seal Packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note:

-

Remove any oil from the contact surfaces.

-

Install the cylinder head cover sub-assembly within 3 minutes of applying seal packing.

-

Do not start the engine for at least 2 hours after installation.

-

-

Install 3 new gaskets as shown in the illustration.

-

Install a new cylinder head cover gasket to the cylinder head cover sub-assembly.

-

Install the cylinder head cover sub-assembly with the 12 bolts and a new seal washer.

Bolt A 21 N*m 214 kgf*cm 15 ft.*lbf Except bolt A 10 N*m 102 kgf*cm 7 ft.*lbf Tip:After tightening all bolts, check the tightening torque of 1 and 10. Retighten the bolt if necessary.

-

- Click here

INSTALL WATER OUTLET

-

Install 2 new gaskets and a new O-ring.

Tip:Apply soapy water to the O-ring.

-

Install the water outlet with the 2 bolts and 4 nuts.

Bolt 10 N*m 102 kgf*cm 7 ft.*lbf Nut 10 N*m 102 kgf*cm 7 ft.*lbf Note:Be careful that the O-ring does not get caught between the parts.

-

- Click here

INSTALL WATER INLET HOUSING

-

Install 2 new O-rings.

Tip:Apply a small amount of water or soapy water to O-ring (A) shown in the illustration before installation.

-

Install the 2 stud bolts.

4.0 N*m 41 kgf*cm 35 in.*lbf -

Install the water inlet housing with the 2 bolts and nut.

10 N*m 102 kgf*cm 7 ft.*lbf Note:Be careful that the O-ring does not get caught between the parts.

-

Connect the No. 1 water by-pass hose.

-

Apply adhesive around the drain cock assembly.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent -

Install the drain cock assembly to the water inlet housing.

30 N*m 306 kgf*cm 22 ft.*lbf -

Install the drain cock plug to the drain cock assembly.

13 N*m 130 kgf*cm 9 ft.*lbf -

Install a new gasket to the thermostat.

-

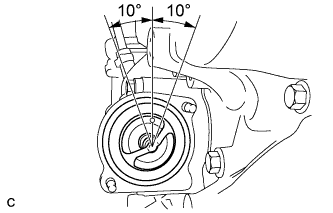

Align the thermostat jiggle valve with the upper stud bolt, and insert the thermostat in the water inlet housing.

Tip:The jiggle valve may be set within 10° of either side of the prescribed position.

-

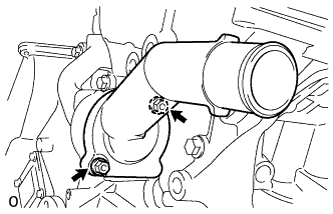

Install the water inlet with the 2 nuts.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

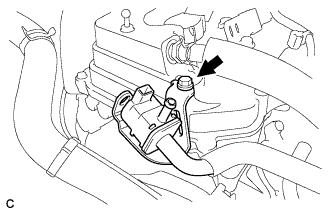

INSTALL NO. 1 OIL COOLER BRACKET

-

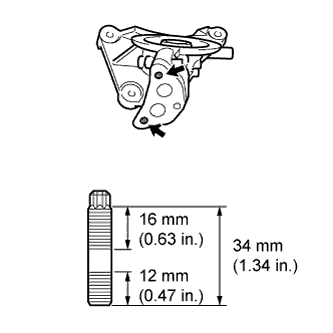

Using an E8 "TORX" socket wrench, install the 2 stud bolts as shown in the illustration.

10 N*m 102 kgf*cm 7 ft.*lbf -

Install a new gasket to the No. 1 oil cooler bracket.

-

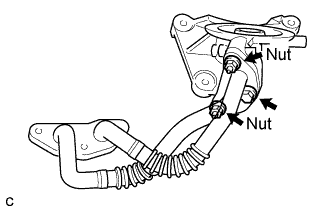

Install the oil cooler pipe with the bolt and 2 nuts.

21 N*m 214 kgf*cm 16 ft.*lbf -

Using an E7 "TORX" socket wrench, install the stud bolt as shown in the illustration.

Table 2. Text in Illustration *a Stud Bolt *b Nut -

Install a new gasket to the oil pan sub-assembly.

-

Install the No. 1 oil cooler bracket with oil cooler pipe with the 3 bolts and 3 nuts.

21 N*m 214 kgf*cm 16 ft.*lbf

-

- Click here

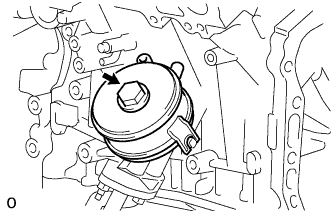

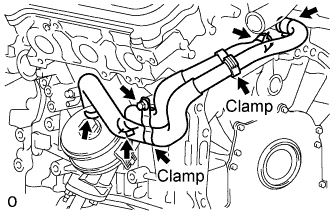

INSTALL OIL COOLER ASSEMBLY

-

Install a new O-ring.

-

Install the oil cooler assembly with the union bolt.

68 N*m 693 kgf*cm 50 ft.*lbf -

Install the 2 water by-pass hoses with the bolt, 2 clamps, and 4 clips.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

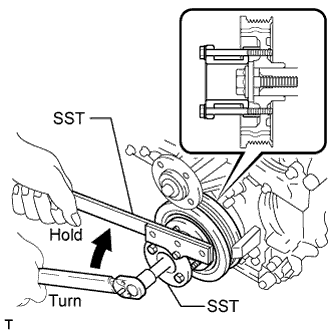

INSTALL CRANKSHAFT PULLEY

-

Align the pulley set key with the key groove of the crankshaft pulley, and slide on the crankshaft pulley.

-

Using SST, install the pulley bolt.

09213-70011 09213-70020 09330-00021 250 N*m 2550 kgf*cm 184 ft.*lbf

-

- Click here

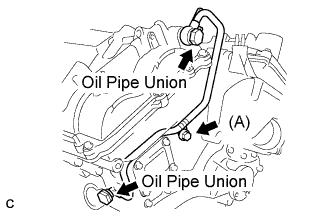

INSTALL OIL PIPE

-

Make sure that there is no foreign matter on the mesh of the oil control valve filter RH.

Note:Do not touch the mesh when installing the oil control valve filter RH.

-

Install the oil control valve filter RH to the oil pipe union. Install new gaskets and temporarily install the oil pipe (on the cylinder head cover sub-assembly side).

-

Install a new gasket and temporarily install the oil pipe (on the cylinder head sub-assembly side) with the oil pipe union.

-

Install the bolt (A) to the cylinder head sub-assembly.

10 N*m 102 kgf*cm 7 ft.*lbf -

Tighten the oil pipe union (on the cylinder head cover sub-assembly side).

65 N*m 663 kgf*cm 48 ft.*lbf -

Tighten the oil pipe union (on the cylinder head sub-assembly side).

65 N*m 663 kgf*cm 48 ft.*lbf Note:If the link that connects the gaskets is broken, remove the connecting link by using side cutters or a similar tool.

-

- Click here

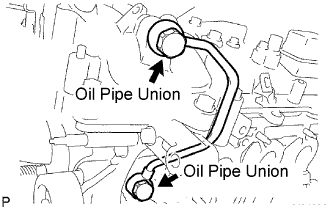

INSTALL NO. 1 OIL PIPE

-

Make sure that there is no foreign matter on the mesh of the oil control valve filter LH.

Note:Do not touch the mesh when installing the oil control valve filter LH.

-

Install the oil control valve filter LH to the oil pipe union. Install new gaskets and temporarily install the No. 1 oil pipe (on the cylinder head cover sub-assembly side).

-

Install a new gasket and temporarily install the No. 1 oil pipe (on the cylinder head sub-assembly side) with the oil pipe union.

-

Tighten the oil pipe union (on the cylinder head cover sub-assembly side).

65 N*m 663 kgf*cm 48 ft.*lbf -

Tighten the oil pipe union (on the cylinder head sub-assembly side).

65 N*m 663 kgf*cm 48 ft.*lbf Note:If the link that connects the gaskets is broken, remove the connecting link by using side cutters or a similar tool.

-

- Click here

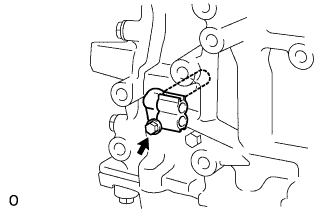

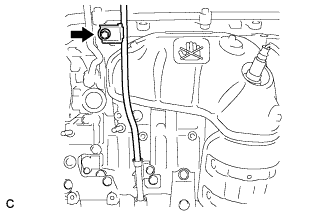

INSTALL CRANKSHAFT POSITION SENSOR

-

Install the crankshaft position sensor with the bolt.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

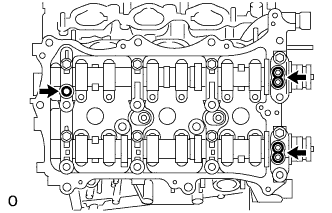

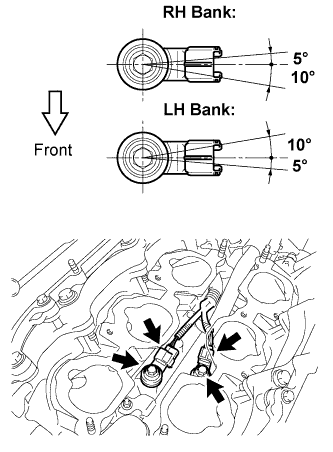

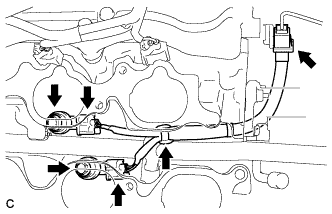

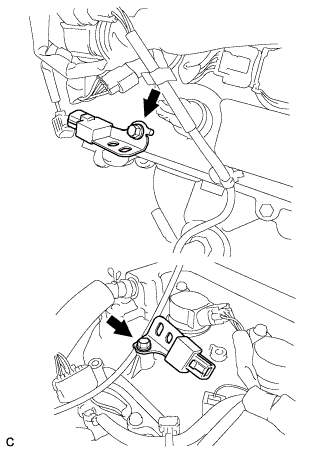

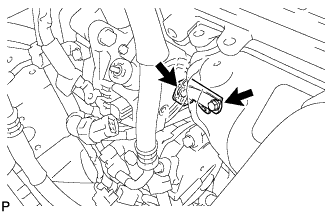

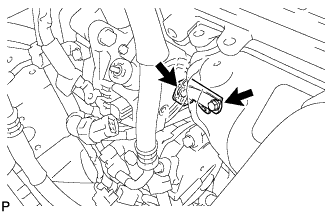

INSTALL KNOCK CONTROL SENSOR

-

Install the 2 knock control sensors with the 2 bolts as shown in the illustration.

20 N*m 204 kgf*cm 15 ft.*lbf -

Connect the 2 knock control sensor connectors.

-

- Click here

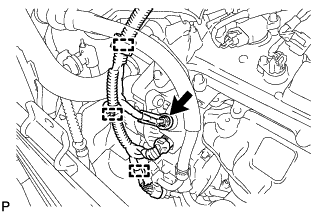

INSTALL KNOCK CONTROL SENSOR WIRE

-

Connect the 2 knock control sensor connectors and 3 clamps.

-

- Click here

INSTALL NO. 1 VACUUM SWITCHING VALVE

-

Install the bolt and No. 1 vacuum switching valve.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

INSTALL RADIO SETTING CONDENSER

-

Install the 2 bolts and 2 radio setting condensers.

10 N*m 102 kgf*cm 7 ft.*lbf

-

- Click here

INSTALL NO. 1 ENGINE FRONT MOUNTING BRACKET LH

-

Install the No. 1 front engine mounting bracket LH with the 6 bolts.

54 N*m 551 kgf*cm 40 ft.*lbf Tip:

-

Install the water inlet and mounting bracket within 15 minutes after installing the chain cover.

-

Do not start the engine for at least 2 hours after installation.

-

-

- Click here

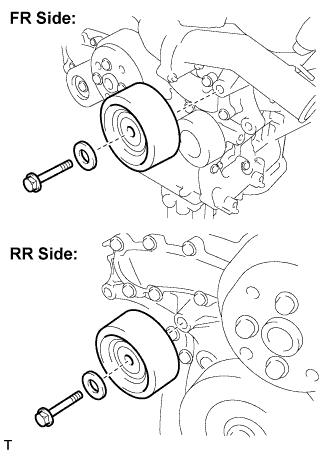

INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

-

Install the No. 2 idler pulley sub-assembly and cover plate with the bolt.

43 N*m 438 kgf*cm 32 ft.*lbf

-

- Click here

INSTALL NO. 2 TIMING GEAR COVER

-

Install the No. 2 timing gear cover with the 2 bolts.

6.0 N*m 61 kgf*cm 53 in.*lbf

-

- Click here

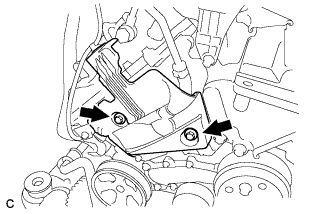

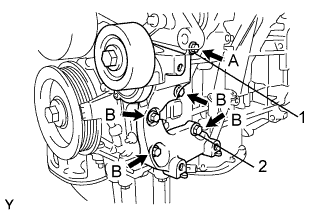

INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

-

Temporarily install the V-ribbed belt tensioner assembly with the 5 bolts.

Tip:Each bolt length is as follows:

A: 70 mm (2.76 in.)

B: 33 mm (1.30 in.)

-

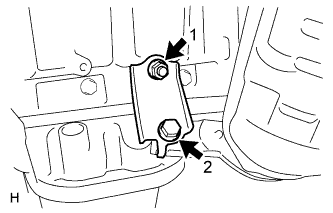

Install the V-ribbed belt tensioner assembly by tightening the bolt 1 and bolt 2 in the order shown in the illustration.

43 N*m 438 kgf*cm 32 ft.*lbf -

Tighten the other bolts.

43 N*m 438 kgf*cm 32 ft.*lbf

-

- Click here

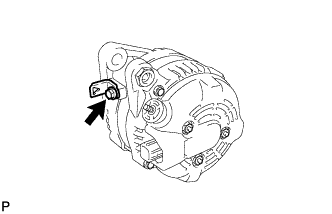

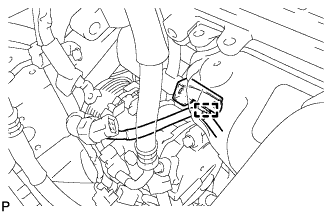

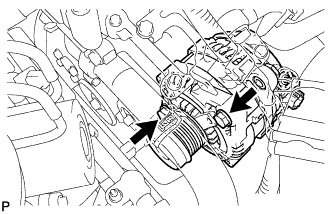

INSTALL GENERATOR ASSEMBLY

-

Install the wire harness clamp bracket with the bolt.

20 N*m 204 kgf*cm 15 ft.*lbf -

Connect the generator bracket with the wire harness clamp.

-

Install generator assembly with the 2 bolts.

43 N*m 438 kgf*cm 32 ft.*lbf -

Temporarily install the 2 bolts.

-

Fully tighten the 2bolts.

20 N*m 204 kgf*cm 15 ft.*lbf -

Connect the generator connector to the generator assembly.

-

Install the generator wire with the nut.

9.8 N*m 100 kgf*cm 87 in.*lbf -

Install the terminal cap.

-

Connect the 3 wire harness clamps.

-

Connect the magnetic clutch connector to the compressor and magnetic clutch.

-

- Click here

INSTALL TRANSVERSE ENGINE MOUNTING BRACKET

-

Install the engine mounting bracket RH with the 3 bolts.

54 N*m 551 kgf*cm 40 ft.*lbf

-

- Click here

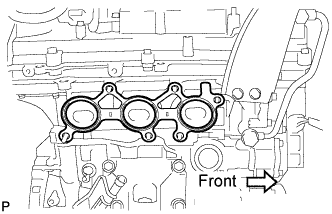

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

-

Install a new gasket as shown in the illustration.

-

Install the exhaust manifold sub-assembly LH with the 6 nuts in the order shown in the illustration.

21 N*m 214 kgf*cm 15 ft.*lbf

-

- Click here

INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

-

Remove the 3 bolts and No. 2 exhaust manifold heat insulator.

-

- Click here

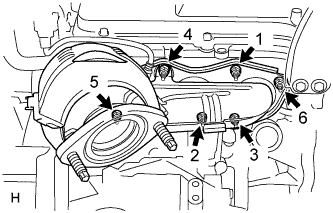

INSTALL NO. 2 MANIFOLD STAY

-

Install the No. 2 manifold stay with the bolt and nut in the order shown in the illustration.

34 N*m 347 kgf*cm 25 ft.*lbf

-

- Click here

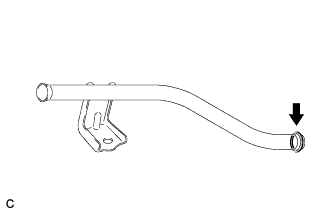

INSTALL NO. 2 ENGINE OIL LEVEL DIPSTICK GUIDE

-

Install a new O-ring to the No. 2 engine oil level dipstick guide.

-

Apply a light coat of engine oil to the O-rings.

-

Push in the No. 2 engine oil level dipstick guide end into the No. 1 engine oil level dipstick guide.

-

Install the No. 2 engine oil level dipstick guide with the bolt.

21 N*m 214 kgf*cm 15 ft.*lbf -

Install the engine oil level dipstick.

-

- Click here

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

-

Install a new gasket as shown in the illustration.

-

Install the exhaust manifold sub-assembly RH with the 6 nuts in the order shown in the illustration.

21 N*m 214 kgf*cm 15 ft.*lbf

-

- Click here

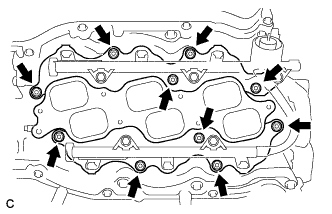

INSTALL INTAKE MANIFOLD

Note:DO NOT apply oil to the bolts listed below:

Tightening Parts Intake Manifold and Cylinder Head Sub-assembly RH Intake Manifold and Cylinder Head Sub-assembly LH

-

Set a new gasket on each cylinder head.

Note:

-

Align the port holes of the gasket and cylinder head.

-

Make sure that the gasket is installed in the correct direction.

-

-

Set the intake manifold on the cylinder heads.

-

Install and tighten the 6 bolts and 4 nuts uniformly in several steps.

21 N*m 214 kgf*cm 15 ft.*lbf

-

- Click here

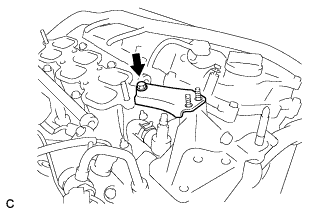

INSTALL NO. 2 ENGINE MOUNTING STAY RH

-

Install the No. 2 mounting stay RH with the bolt.

21 N*m 214 kgf*cm 15 ft.*lbf

-

- Click here

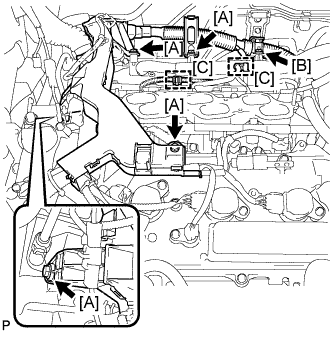

INSTALL IGNITION COIL ASSEMBLY (for LHD)

-

Install the 6 ignition coils with the 6 bolts.

10 N*m 102 kgf*cm 7 ft.*lbf -

Connect the 6 ignition coil connectors.

-

Install the 4 bolts [A].

8.3 N*m 84 kgf*cm 73 in.*lbf -

Install the nut [B].

8.3 N*m 84 kgf*cm 73 in.*lbf -

Install the 2 clamps [C].

-

- Click here

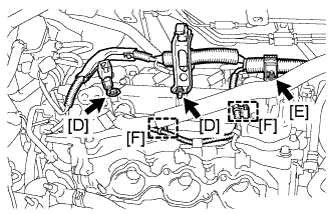

INSTALL IGNITION COIL ASSEMBLY (for RHD)

-

Install the 6 ignition coils with the 6 bolts.

10 N*m 102 kgf*cm 7 ft.*lbf -

Connect the 6 ignition coil connectors.

-

Install the 2 bolts [D].

8.3 N*m 84 kgf*cm 73 in.*lbf -

Install the nut [E].

8.3 N*m 84 kgf*cm 73 in.*lbf -

Install the 2 clamps [F].

-

- Click here

REMOVE ENGINE STAND

- Click here

INSTALL ENGINE ASSEMBLY

Tip: