AUTOMATIC TRANSAXLE UNIT REASSEMBLY

CAUTION / NOTICE / HINT

Tech Tips

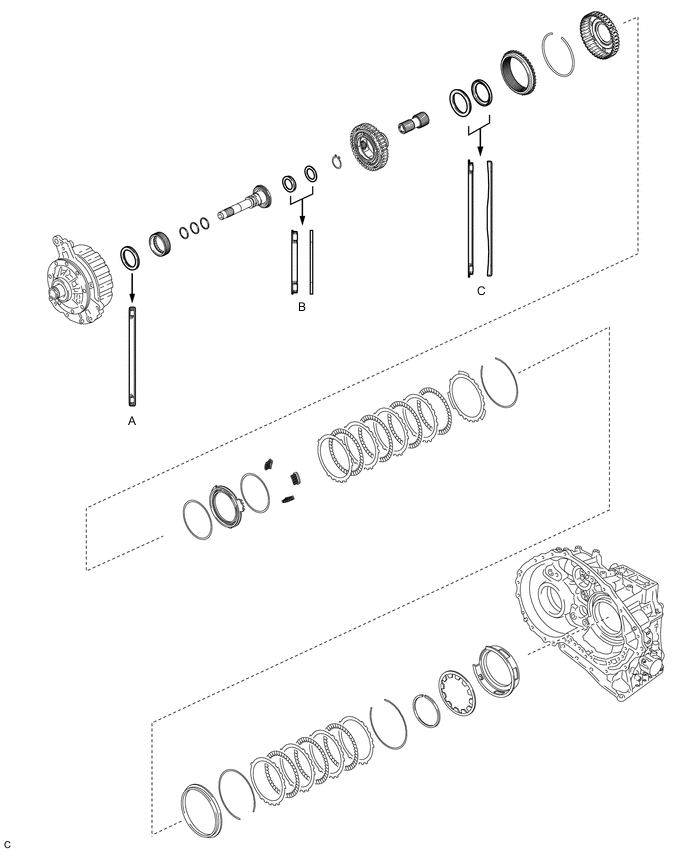

Check each bearing position and installation direction.

| Mark | Front Race Diameter Inside / Outside mm (in.) |

Thrust Bearing Diameter Inside / Outside mm (in.) |

Rear Race Diameter Inside / Outside mm (in.) |

|---|---|---|---|

| A | - | 57.7 (2.27) / 75.2 (2.96) | - |

| B | - | 29.1 (1.15) / 48 (1.89) | 30.7 (1.21) / 48.3 (1.90) |

| C | - | 62.6 (2.46) / 82.4 (3.24) | 65.9 (2.59) / 80.3 (3.16) |

| D | 59.4 (2.34) / 77 (3.03) | 53.1 (2.09) / 79 (3.11) | - |

| E | - | 56.1 (2.21) / 80.9 (3.19) | - |

| F | - | 61.2 (2.41) / 79 (3.11) | - |

| G | - | 28 (1.10) / 47.1 (1.85) | 26.1 (1.03) / 44 (1.73) |

| H | 52.2 (2.06) / 70.4 (2.77) | 48.9 (1.93) / 72.0 (2.83) | - |

PROCEDURE

-

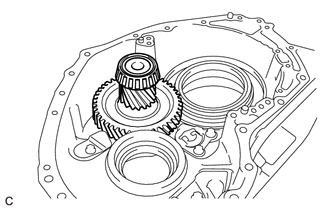

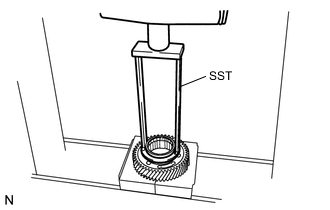

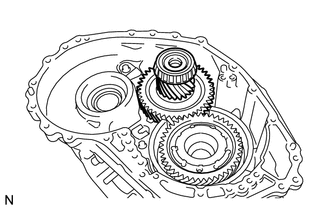

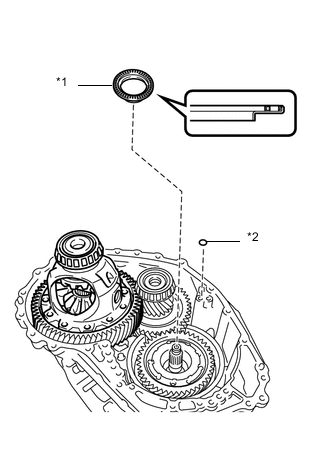

INSTALL COUNTER DRIVE GEAR BEARING

Tech Tips

Perform this procedure only when replacement of the counter drive gear bearing or transaxle case sub-assembly is necessary.

-

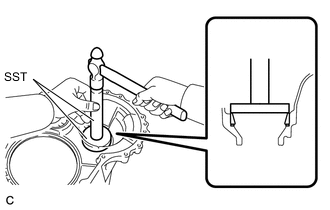

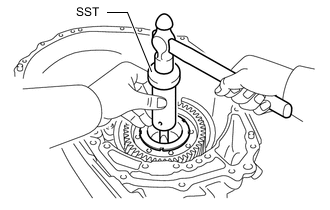

Using SST and a press, install a new counter drive gear bearing (outer race) and snap ring to the transaxle case sub-assembly.

- SST

- 09950-60020 ( 09951-01030 )

- 09950-70010 ( 09951-07100 )

-

-

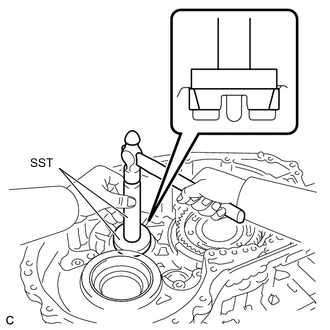

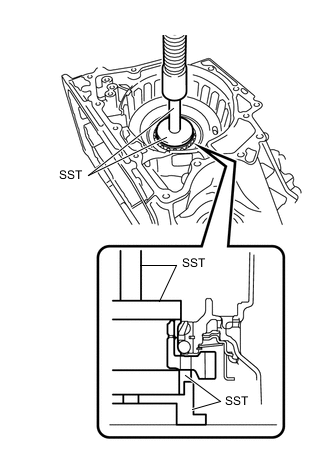

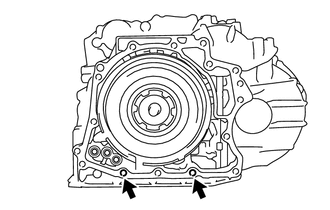

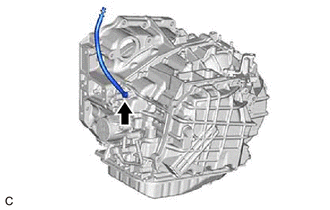

INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING (OUTER RACE)

-

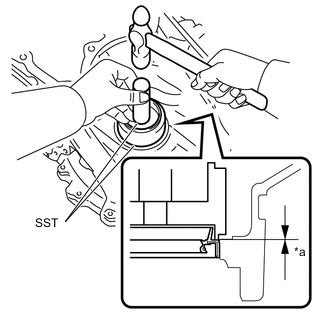

Using SST and a hammer, install a new front differential case rear tapered roller bearing (outer race) to the transaxle case sub-assembly.

- SST

- 09950-60020 ( 09951-00790 )

- 09950-70010 ( 09951-07150 )

Note

Make sure to install the front differential case rear tapered roller bearing (outer race) so that there is no clearance between the front differential case rear tapered roller bearing (outer race) and transaxle case sub-assembly.

-

-

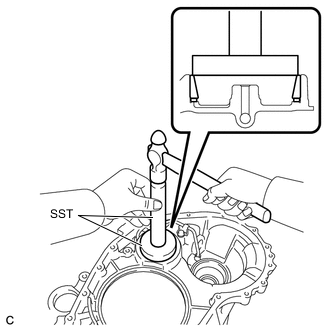

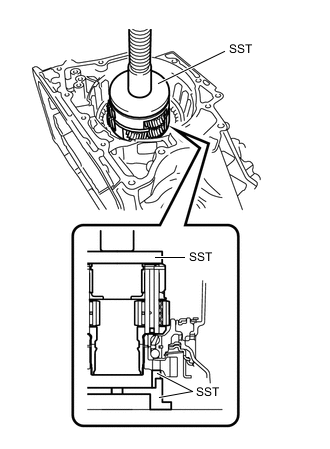

INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING (OUTER RACE)

-

Install the shim to the transaxle housing.

-

Using SST and a hammer, install a new front differential case front tapered roller bearing (outer race) to the transaxle housing.

- SST

- 09950-60010 ( 09951-00480 )

- 09950-70010 ( 09951-07150 )

Note

Make sure to install the front differential case front tapered roller bearing (outer race) so that there is no clearance between the front differential case front tapered roller bearing (outer race), shim and transaxle housing.

-

-

INSTALL FRONT DIFFERENTIAL CASE REAR TAPERED ROLLER BEARING (INNER RACE)

-

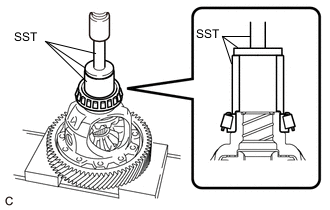

Using SST and a press, install a new front differential case rear tapered roller bearing (inner race) to the front differential case.

- SST

- 09726-36010

- 09950-70010 ( 09951-07100 )

Note

-

Do not damage the front differential case rear tapered roller bearing (inner race) cage when installing the front differential case rear tapered roller bearing (inner race).

-

Make sure to install the front differential case rear tapered roller bearing (inner race) so that there is no clearance between the front differential case rear tapered roller bearing (inner race) and front differential case.

-

-

INSTALL FRONT DIFFERENTIAL CASE FRONT TAPERED ROLLER BEARING (INNER RACE)

-

Using SST and a press, install a new front differential case front tapered roller bearing (inner race) to the front differential case.

- SST

- 09523-36010

- 09950-60010 ( 09951-00540 )

- 09950-70010 ( 09951-07100 )

Note

-

Do not damage the front differential case front tapered roller bearing (inner race) cage when installing the front differential case front tapered roller bearing (inner race).

-

Make sure to install the front differential case front tapered roller bearing (inner race) so that there is no clearance between the front differential case front tapered roller bearing (inner race) and front differential case.

-

-

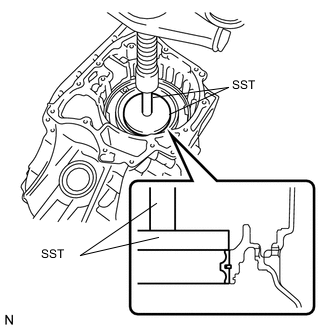

ADJUST DIFFERENTIAL SIDE BEARING PRELOAD

-

Remove any remaining seal packing from the contact surfaces of the transaxle housing and transaxle case sub-assembly.

-

Install the front differential case to the transaxle case sub-assembly.

-

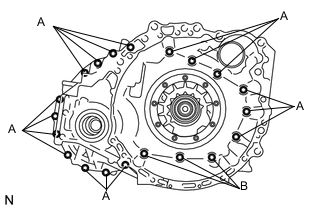

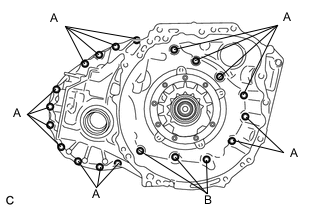

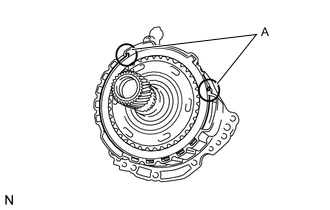

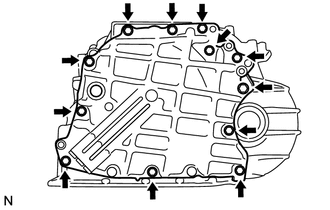

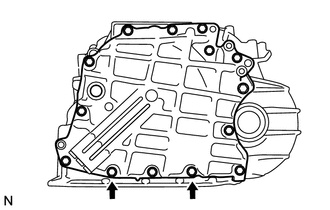

Install the transaxle housing to the transaxle case sub-assembly with the 20 bolts.

- Torque:

- Bolt (A)

- 30.6 N*m { 312 kgf*cm, 23 ft.*lbf }

- Bolt (B)

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

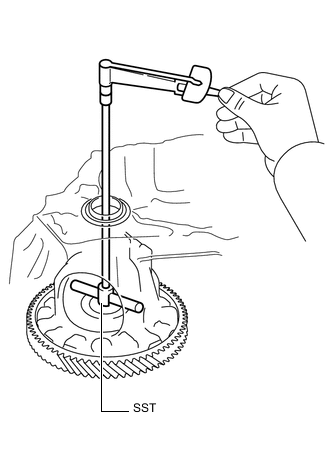

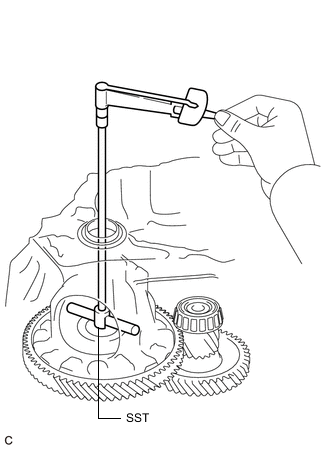

Using SST, turn the front differential case right and left 2 or 3 times to settle the bearings.

- SST

- 09564-33010

-

Using SST and a torque wrench, measure the turning torque of the differential side bearings while rotating SST at 10 rpm.

- SST

- 09564-33010

Turning Torque 0.8 to 1.4 N*m (9 to 14 kgf*cm, 8 to 12 in.*lbf) If the turning torque is not within the specified range, refer to the table below to select a shim for the front differential case front tapered roller bearing (outer race) so that the turning torque is within the specified range.

Shim Thickness Part No. Thickness (mm (in.)) 90564-79054 2.000 (0.0787) 90564-79055 2.025 (0.0797) 90564-79056 2.050 (0.0807) 90564-79057 2.075 (0.0817) 90564-79058 2.100 (0.0827) 90564-79059 2.125 (0.0837) 90564-79060 2.150 (0.0846) 90564-79061 2.175 (0.0856) 90564-79062 2.200 (0.0866) 90564-79063 2.225 (0.0876) 90564-79064 2.250 (0.0886) 90564-79065 2.275 (0.0896) 90564-79066 2.300 (0.0906) 90564-79067 2.325 (0.0915) 90564-79068 2.350 (0.0925) 90564-79069 2.375 (0.0935) 90564-79070 2.400 (0.0945) 90564-79071 2.425 (0.0955) 90564-79072 2.450 (0.0965) 90564-79073 2.475 (0.0974) 90564-79074 2.500 (0.0984) 90564-79075 2.525 (0.0994) 90564-79076 2.550 (0.100) 90564-79077 2.575 (0.101) 90564-79078 2.600 (0.102) 90564-79079 2.625 (0.103) 90564-79080 2.650 (0.104) 90564-79081 2.675 (0.105) 90564-79082 2.700 (0.106) 90564-79083 2.725 (0.107) 90564-79084 2.750 (0.108) 90564-79085 2.775 (0.109) 90564-79086 2.800 (0.110) 90564-79087 2.825 (0.111) 90564-79088 2.850 (0.112) 90564-79089 2.875 (0.113) -

Remove the 20 bolts and transaxle housing from the transaxle case sub-assembly.

-

Remove the front differential case from the transaxle case sub-assembly.

-

-

INSTALL COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING (OUTER RACE)

-

Using SST and a hammer, install a new counter driven gear rear tapered roller bearing (outer race) to the transaxle case sub-assembly.

- SST

- 09950-60010 ( 09951-00650 )

- 09950-70010 ( 09951-07100 )

Note

Make sure to install the counter driven gear rear tapered roller bearing (outer race) so that there is no clearance between the counter driven gear rear tapered roller bearing (outer race) and transaxle case sub-assembly. If there is any clearance, the turning torque of the counter driven gear cannot be measured correctly.

-

-

INSTALL COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING (OUTER RACE)

-

Install the shim to the transaxle housing.

-

Using SST, install a new counter driven gear front tapered roller bearing (outer race) to the transaxle housing.

- SST

- 09950-60020 ( 09951-00810 )

- 09950-70010 ( 09951-07100 )

Note

Make sure to install the counter driven gear front tapered roller bearing (outer race) so that there is no clearance between the counter driven gear front tapered roller bearing (outer race), shim and transaxle housing. If there is any clearance, the turning torque of the counter driven gear cannot be measured correctly.

-

-

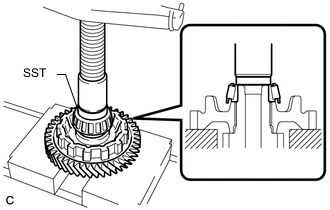

INSTALL COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING (INNER RACE)

-

Using SST and a press, install a new counter driven gear rear tapered roller bearing (inner race) to the counter driven gear.

- SST

- 09950-60010 ( 09951-00420 )

Note

Make sure to install the counter driven gear rear tapered roller bearing (inner race) so that there is no clearance between the counter driven gear rear tapered roller bearing (inner race) and counter driven gear. If there is any clearance, the turning torque of the counter driven gear cannot be measured correctly.

-

-

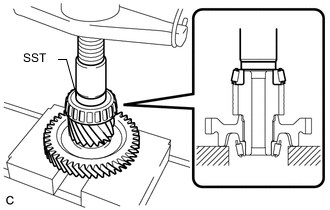

INSTALL COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING (INNER RACE)

-

Using SST and a press, install a new counter driven gear front tapered roller bearing (inner race) to the counter driven gear.

- SST

- 09950-60010 ( 09951-00530 )

Note

Make sure to install the counter driven gear front tapered roller bearing (inner race) so that there is no clearance between the counter driven gear front tapered roller bearing (inner race) and counter driven gear. If there is any clearance, the turning torque of the counter driven gear cannot be measured correctly.

-

-

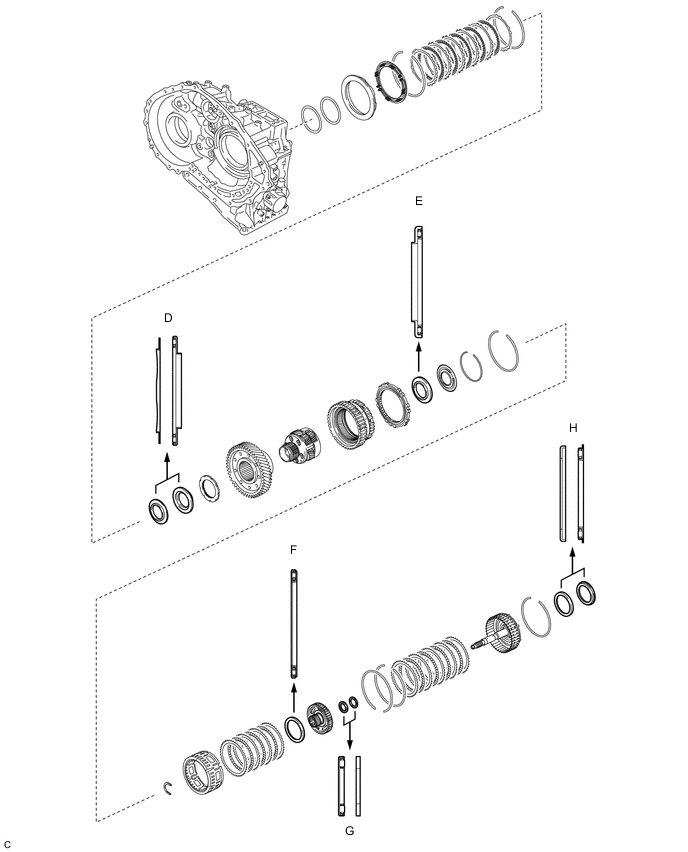

ADJUST COUNTER DRIVEN GEAR PRELOAD

-

Remove any remaining seal packing from the contact surfaces of the transaxle housing and transaxle case sub-assembly.

-

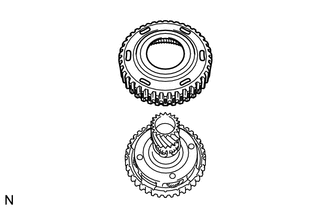

Install the counter driven gear to the transaxle case sub-assembly.

-

Install the front differential case to the transaxle case sub-assembly.

-

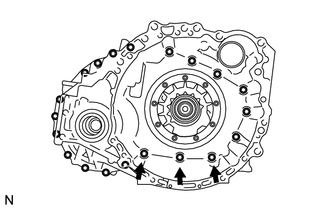

Install the transaxle housing to the transaxle case sub-assembly with the 20 bolts.

- Torque:

- Bolt (A)

- 30.6 N*m { 312 kgf*cm, 23 ft.*lbf }

- Bolt (B)

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

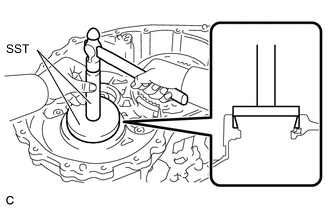

Using SST and a torque wrench, measure the turning torque of the counter driven gear while rotating SST at 10 rpm.

- SST

- 09564-33010

Turning Torque Differential Side Bearing Preload + 2.7 to 5.1 N*m (28 to 52 kgf*cm, 24 to 45 in.*lbf) If the turning torque is not within the specified range, refer to the table below to select a shim for the counter driven gear front tapered roller bearing (outer race) so that the turning torque is within the specified range.

Shim Thickness Part No. Thickness (mm (in.)) 90564-71014 2.000 (0.0787) 90564-71015 2.025 (0.0797) 90564-71016 2.050 (0.0807) 90564-71017 2.075 (0.0817) 90564-71018 2.100 (0.0827) 90564-71019 2.125 (0.0837) 90564-71020 2.150 (0.0846) 90564-71021 2.175 (0.0856) 90564-71022 2.200 (0.0866) 90564-71023 2.225 (0.0876) 90564-71024 2.250 (0.0886) 90564-71025 2.275 (0.0896) 90564-71026 2.300 (0.0906) 90564-71027 2.325 (0.0915) 90564-71028 2.350 (0.0925) 90564-71029 2.375 (0.0935) 90564-71030 2.400 (0.0945) 90564-71031 2.425 (0.0955) 90564-71032 2.450 (0.0965) 90564-71033 2.475 (0.0974) 90564-71034 2.500 (0.0984) 90564-71035 2.525 (0.0994) 90564-71036 2.550 (0.100) 90564-71037 2.575 (0.101) 90564-71038 2.600 (0.102) 90564-71039 2.625 (0.103) 90564-71040 2.650 (0.104) 90564-71041 2.675 (0.105) 90564-71042 2.700 (0.106) 90564-71043 2.725 (0.107) 90564-71044 2.750 (0.108) 90564-71045 2.775 (0.109) 90564-71046 2.800 (0.110) 90564-71047 2.825 (0.111) 90564-71048 2.850 (0.112) 90564-71049 2.875 (0.113) 90564-71050 2.900 (0.114) 90564-71051 2.925 (0.115) 90564-71052 2.950 (0.116) 90564-71053 2.975 (0.117) 90564-71054 3.000 (0.118) -

Remove the 20 bolts and transaxle housing from the transaxle case sub-assembly.

-

Remove the front differential case from the transaxle case sub-assembly.

-

Remove the counter driven gear from the transaxle case sub-assembly.

-

-

INSTALL MANUAL VALVE LEVER SHAFT OIL SEAL

-

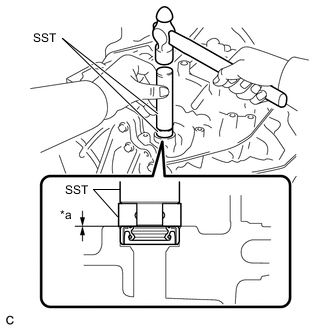

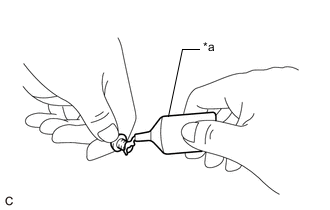

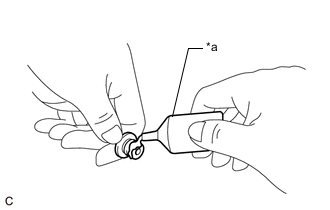

*a Depth Coat the lip of a new manual valve lever shaft oil seal with a small amount of MP grease.

-

Using SST and a hammer, install the manual valve lever shaft oil seal to the transaxle case sub-assembly.

- SST

- 09950-60010 ( 09951-00230 )

- 09950-70010 ( 09951-07100 )

Standard Depth -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) Note

Be sure to install the manual valve lever shaft oil seal in the correct direction.

-

-

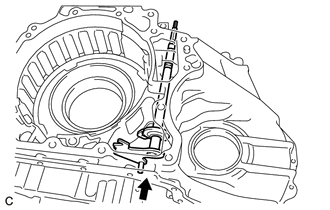

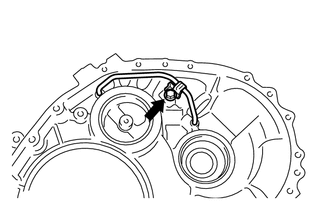

INSTALL MANUAL VALVE LEVER SHAFT SUB-ASSEMBLY

-

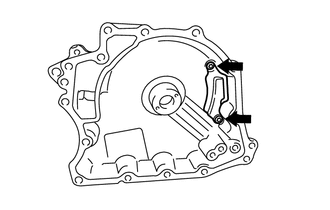

Install the manual valve lever shaft sub-assembly to the transaxle case sub-assembly.

Note

Do not damage the manual valve lever shaft oil seal when installing the manual valve lever shaft sub-assembly to the transaxle case sub-assembly.

-

Using needle-nose pliers, install the manual valve lever shaft retainer spring to the manual valve lever shaft sub-assembly.

-

-

INSTALL PARKING LOCK ROD SUB-ASSEMBLY

-

Align the protrusions on the parking lock rod sub-assembly with the notches on the manual valve lever shaft sub-assembly and install the parking lock rod sub-assembly.

-

-

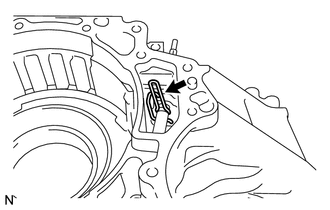

INSTALL MANUAL DETENT SPRING SUB-ASSEMBLY

-

Install the manual detent spring sub-assembly and manual detent spring cover to the transaxle case sub-assembly with the bolt.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

Note

Make sure to install the manual detent spring sub-assembly first and then the manual detent spring cover.

-

-

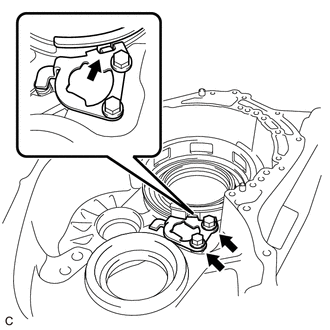

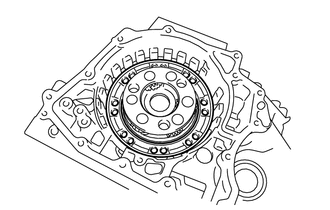

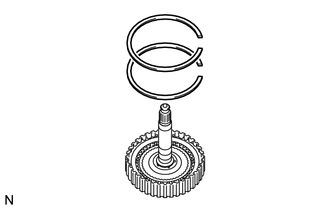

INSTALL NO. 3 BRAKE PISTON

-

Coat the lips of the No. 3 brake piston with ATF.

-

Temporarily install the No. 3 brake piston to the transaxle case sub-assembly.

-

Temporarily install the pawl stopper plate to the transaxle case sub-assembly with the 2 bolts.

Note

After installing, make sure that the protrusions on the No. 3 brake piston and grooves on the pawl stopper plate are aligned.

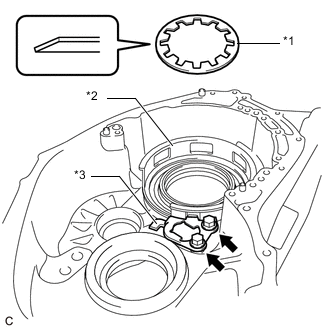

-

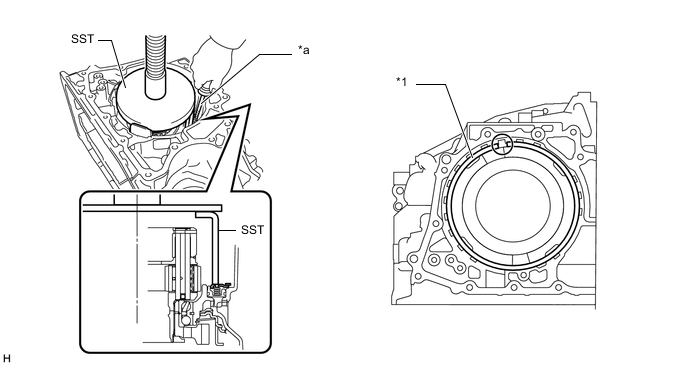

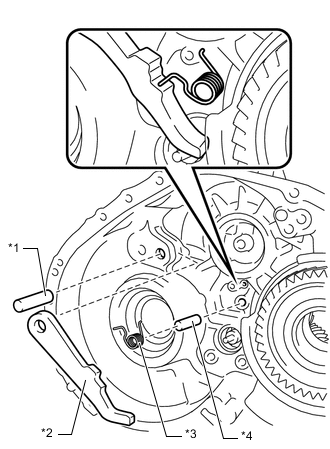

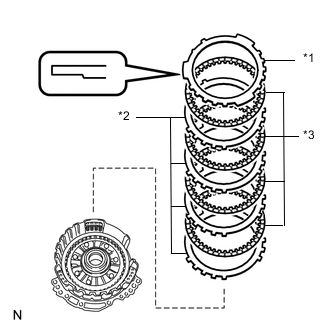

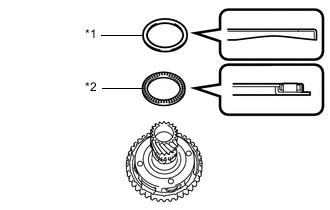

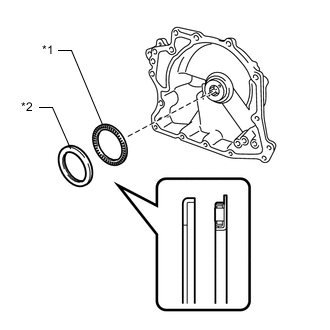

*1 Brake Piston Return Spring *2 No. 3 Brake Piston *3 Pawl Stopper Plate Press the No. 3 brake piston into the transaxle case sub-assembly.

Note

Make sure that the lips of the No. 3 brake piston are not twisted or caught on the transaxle case sub-assembly.

Tech Tips

Use the installation surface of the brake piston return spring to press the No. 3 brake piston into the transaxle case sub-assembly.

-

Install the brake piston return spring to the transaxle case sub-assembly.

Note

Install the brake piston return spring as shown in the illustration.

-

Remove the 2 bolts and pawl stopper plate from the transaxle case sub-assembly.

-

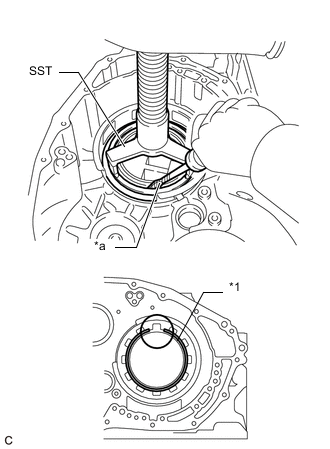

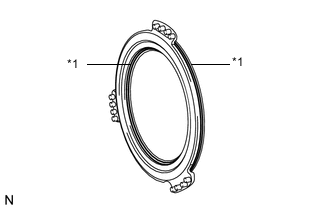

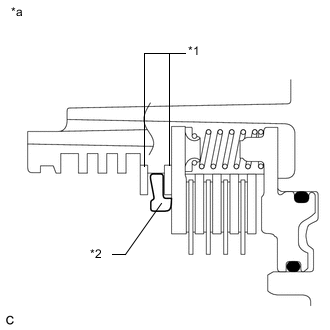

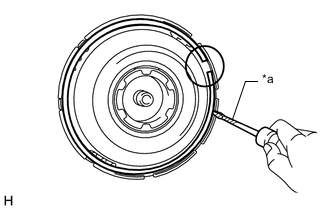

*1 Snap Ring *a Protective Tape Place SST on the brake piston return spring and compress the brake piston return spring with a press.

- SST

- 09387-00070

Note

Stop the press when the brake piston return spring is flush with the snap ring groove. This prevents the brake piston return spring from being deformed.

-

Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the transaxle case sub-assembly as shown in the illustration.

Note

-

Confirm that the snap ring is correctly located in the groove of the transaxle case sub-assembly.

-

Be sure to orient the snap ring so that the edges do not protrude into one of the cutouts on the brake piston return spring as shown in the illustration.

-

-

-

INSTALL COUNTER DRIVE GEAR

Note

Perform this procedure only when the counter drive gear bearing or transaxle case sub-assembly is replaced.

-

Using SST and a press, install a new counter drive gear bearing (bearing inner race (front side)) to the counter drive gear.

- SST

- 09387-00020

Note

Make sure to install the counter drive gear bearing (bearing inner race (front side)) so that there is no clearance between the counter drive gear bearing (bearing inner race (front side)) and counter drive gear.

-

Install 2 new counter drive gear bearings (balls and cage) to the counter drive gear bearing (outer race).

-

Using SST and a press, install the counter drive gear with counter drive gear bearing (bearing inner race (front side)) and a new counter drive gear bearing (bearing inner race (rear side)) to the transaxle case sub-assembly.

- SST

- 09223-15030

- 09527-17011

- 09950-70010 ( 09951-07100 )

- 09950-60020 ( 09951-00810 )

-

-

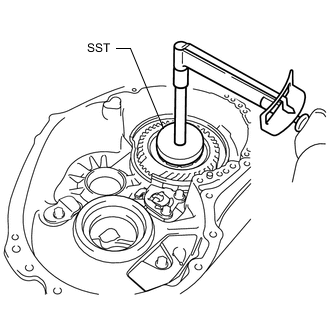

INSTALL FRONT PLANETARY GEAR ASSEMBLY

-

Using SST and a press, install the front planetary gear assembly to the transaxle case sub-assembly.

- SST

- 09223-15030

- 09527-17011

- 09951-01100

-

-

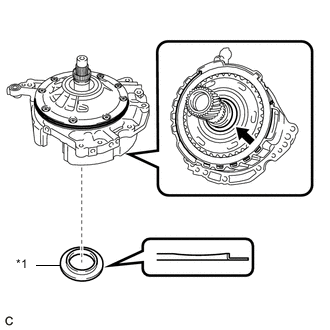

INSTALL NO. 2 BRAKE PISTON

-

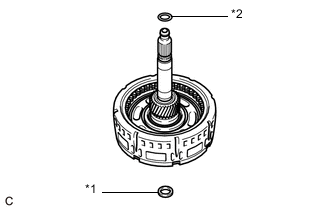

*1 O-ring Coat 2 new O-rings with ATF and install them to the No. 2 brake piston.

Note

Ensure that the 2 O-rings are not twisted.

-

Install the No. 2 brake piston to the transaxle case sub-assembly.

Note

Be careful not to damage the 2 O-rings.

-

-

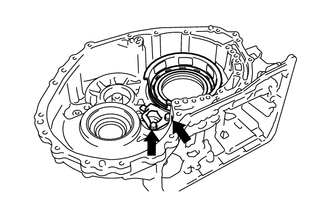

INSTALL 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

-

Install the 1st and reverse brake return spring sub-assembly to the transaxle case sub-assembly.

-

Place SST on the 1st and reverse brake return spring sub-assembly and compress the 1st and reverse brake return spring sub-assembly with a press.

*1 Snap Ring - - *a Protective Tape - - - SST

- 09387-00060

Note

Stop the press when the 1st and reverse brake return spring sub-assembly is flush with the snap ring groove. This prevents the 1st and reverse brake return spring sub-assembly from being deformed.

-

Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the transaxle case sub-assembly as shown in the illustration.

Note

-

Confirm that the snap ring is correctly located in the groove of the transaxle case sub-assembly.

-

Be sure to orient the snap ring so that the edges do not protrude into one of the cutouts on the transaxle case sub-assembly as shown in the illustration.

-

Be sure to install the snap ring so that the ends of the snap ring are within the area shown in the illustration.

-

-

-

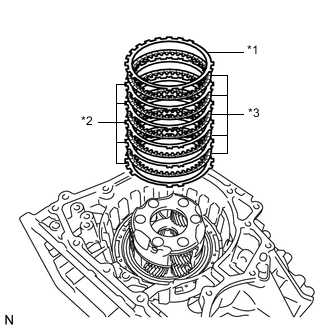

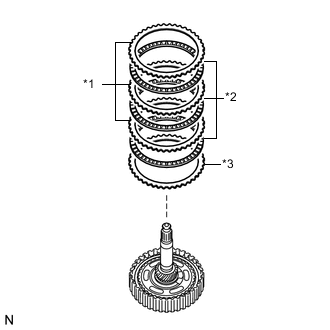

INSTALL NO. 2 BRAKE DISC

-

*1 No. 2 Brake Flange *2 No. 2 Brake Plate *3 No. 2 Brake Disc Install the 5 No. 2 brake discs, 5 No. 2 brake plates and No. 2 brake flange to the transaxle case sub-assembly.

Note

Make sure that the No. 2 brake discs, No. 2 brake plates and No. 2 brake flange are installed in the correct order.

-

*1 Snap Ring *a Protective Tape Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the transaxle case sub-assembly.

Note

-

Confirm that the snap ring is correctly located in the groove of the transaxle case sub-assembly.

-

Be sure to orient the snap ring so that the edges do not protrude into one of the cutouts on the transaxle case sub-assembly as shown in the illustration.

-

Be sure to install the snap ring so that the ends of the snap ring are within the area shown in the illustration.

-

-

-

INSPECT CLEARANCE OF NO. 2 BRAKE PISTON

-

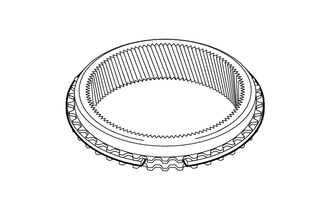

INSTALL PLANETARY RING GEAR FLANGE

-

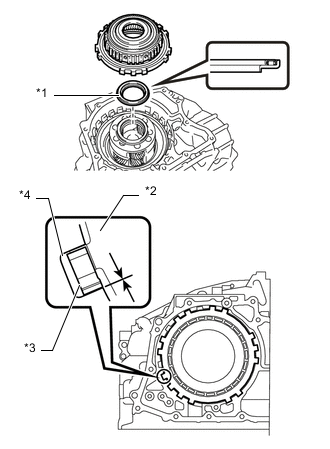

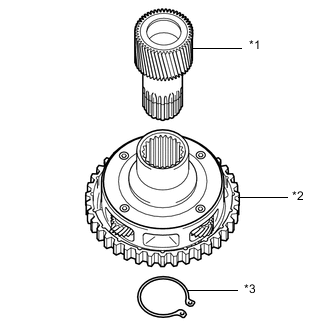

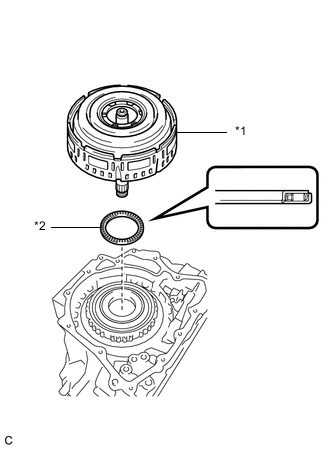

*1 Snap Ring *2 Planetary Ring Gear Flange *3 Planetary Ring Gear Install the planetary ring gear flange to the planetary ring gear.

-

Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the planetary ring gear.

Note

Confirm that the snap ring is correctly located in the groove of the planetary ring gear.

-

-

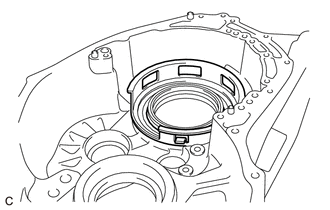

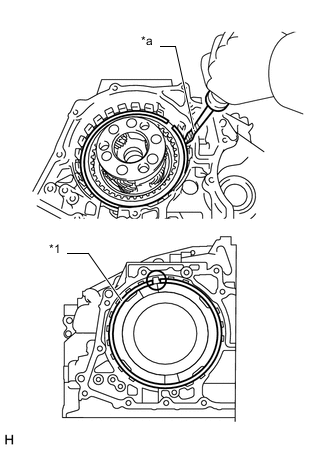

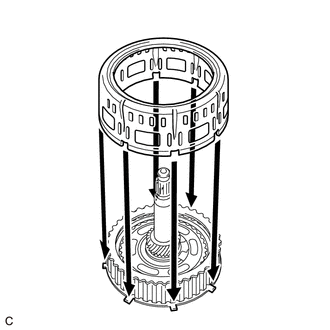

INSTALL ONE-WAY CLUTCH ASSEMBLY

-

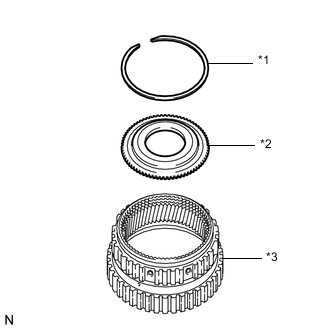

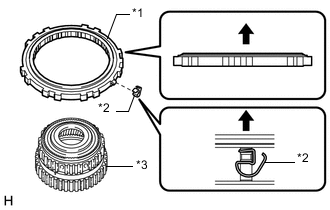

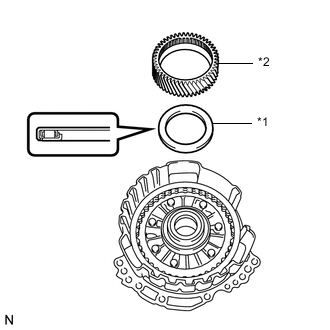

*1 One-way Clutch Assembly *2 Outer Race Retainer *3 Planetary Ring Gear

Rear Side Install the outer race retainer to the one-way clutch assembly.

-

Install the one-way clutch assembly to the planetary ring gear.

Note

Make sure that the one-way clutch assembly is installed in the correct direction as shown in the illustration.

-

*1 Thrust Needle Roller Bearing *2 One-way Clutch Assembly *3 Outer Race Retainer *4 Transaxle Case Sub-assembly Coat the thrust needle roller bearing with ATF and install it to the front planetary gear assembly.

Thrust Needle Roller Bearing Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 56.1 (2.21) 80.9 (3.19) Note

Be sure to install the thrust needle roller bearing so that the temper colored side of the race is visible.

-

Install the one-way clutch assembly with planetary ring gear to the transaxle case sub-assembly.

Note

-

Make sure that there is no clearance between the outer race retainer and the claw on the one-way clutch assembly. If there is any clearance, the spring of the retainer will be deformed.

-

Ensure that there is no clearance between the one-way clutch assembly and transaxle case sub-assembly.

-

-

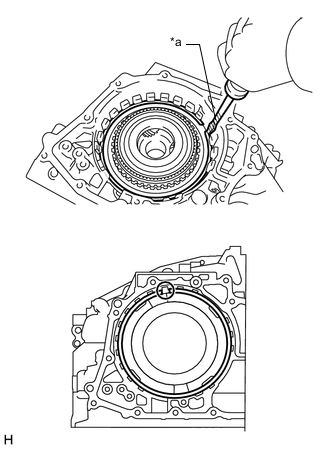

*a Protective Tape Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the transaxle case sub-assembly.

Note

-

Confirm that the snap ring is correctly located in the groove of the transaxle case sub-assembly.

-

Be sure to orient the snap ring so that the edges do not protrude into one of the cutouts on the transaxle case sub-assembly as shown in the illustration.

-

-

-

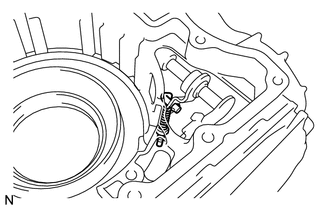

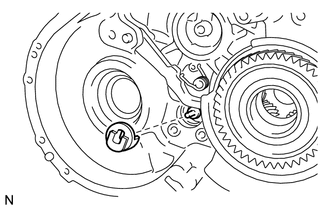

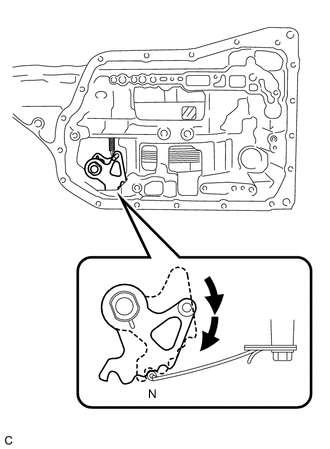

INSTALL PARKING LOCK PAWL

-

*1 Parking Lock Pawl Shaft *2 Parking Lock Pawl *3 Spring *4 Parking Lock Pawl Pin Install the parking lock pawl to the transaxle case sub-assembly with the parking lock pawl shaft.

-

Install the parking lock pawl pin to the transaxle case sub-assembly.

-

Install the spring to the parking lock pawl pin.

Note

Make sure that one end of the spring is secured in the hole of the transaxle case sub-assembly and the other end is positioned on the parking lock pawl as shown in the illustration.

-

-

INSTALL PARKING LOCK SLEEVE

-

Install the parking lock sleeve to the transaxle case sub-assembly.

-

-

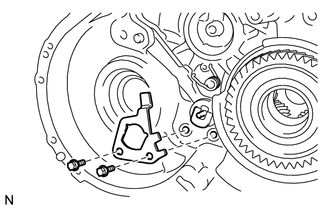

INSTALL PAWL STOPPER PLATE

-

Install the pawl stopper plate to the transaxle case sub-assembly with the 2 bolts.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

-

INSTALL PAWL SHAFT CLAMP

-

Install the pawl shaft clamp to the transaxle case sub-assembly with the bolt.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

-

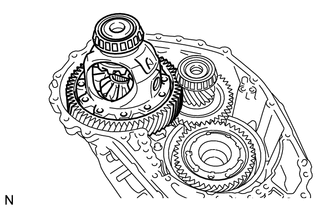

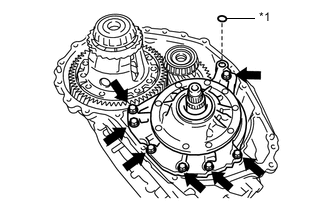

INSTALL COUNTER DRIVEN GEAR

-

Install the counter driven gear to the transaxle case sub-assembly.

-

-

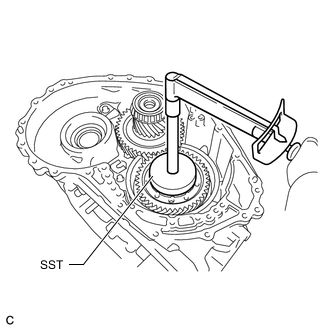

INSTALL COUNTER DRIVE GEAR NUT

-

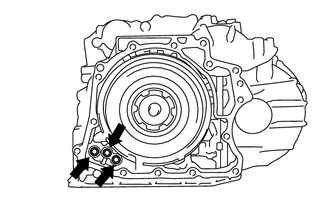

Turn the manual valve lever shaft sub-assembly 2 notches counterclockwise to set it to the P position as shown in the illustration.

-

Using SST, install a new counter drive gear nut to the front planetary gear assembly.

- SST

- 09387-00130

- Torque:

- 120 N*m { 1224 kgf*cm, 89 ft.*lbf }

-

Turn the manual valve lever shaft sub-assembly 2 notches clockwise to set it to the N position as shown in the illustration.

-

Remove the counter driven gear from the transaxle case sub-assembly.

-

Using SST and a torque wrench, measure the turning torque of the bearing while rotating SST at 60 rpm.

- SST

- 09387-00130

Turning Torque 0.1 to 0.2 N*m (1 to 2 kgf*cm, 0.9 to 1.7 in.*lbf) If the measured value is not within the specified range, gradually tighten the counter drive gear nut until the turning falls within the specified range.

Maximum Torque 180 N*m (1835 kgf*cm, 133 ft.*lbf) -

Using SST and a hammer, stake the front planetary gear assembly.

- SST

- 09930-00010

-

Install the counter driven gear to the transaxle case sub-assembly.

-

-

INSTALL FRONT DIFFERENTIAL CASE

-

Install the front differential case to the transaxle case sub-assembly.

-

-

INSTALL NO. 1 BRAKE PISTON

-

*1 O-ring Coat 2 new O-rings with ATF and install them to the No. 1 brake piston.

Note

Ensure that the 2 O-rings are not twisted.

-

Install the No. 1 brake piston to the front oil pump assembly.

Note

Be careful not to damage the 2 O-rings.

-

-

INSTALL 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

-

Install the 3 2nd brake piston return spring sub-assemblies to the front oil pump assembly.

Note

Make sure that the 3 2nd brake piston return spring sub-assemblies are installed to the protrusions on the front oil pump assembly.

-

-

INSTALL NO. 1 BRAKE DISC

-

*1 No. 1 Brake Flange *2 No. 1 Brake Plate *3 No. 1 Brake Disc Install the 4 No. 1 brake discs, 4 No. 1 brake plates and No. 1 brake flange to the front oil pump assembly.

Note

-

Make sure that the No. 1 brake discs, No. 1 brake plates and No. 1 brake flange are installed in the correct order.

-

Be sure to install the No. 1 brake flange in the correct direction.

-

-

*a Protective Tape Place SST on the No. 1 brake flange and compress the No. 1 brake flange with a press.

- SST

- 09387-00070

- 09495-65040

Note

Stop the press when the 2nd brake piston return spring sub-assemblies are flush with the snap ring groove. This prevents the 2nd brake piston return spring sub-assemblies from being deformed.

-

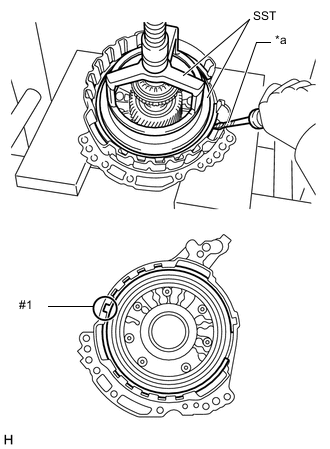

Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the front oil pump assembly as shown in the illustration.

Note

-

Confirm that the snap ring is correctly located in the groove of the front oil pump assembly.

-

Make sure to align the protruding part of the snap ring with the cutout (#1) of the front oil pump assembly shown in the illustration to install the snap ring.

-

-

Install the brake snap ring stopper to the front oil pump assembly.

Note

Be sure to install the brake snap ring stopper in the correct direction.

-

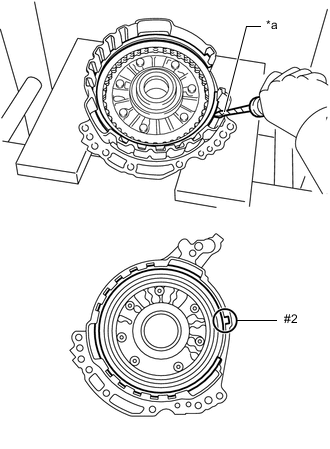

*a Protective Tape Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the front oil pump assembly as shown in the illustration.

Note

-

Confirm that the snap ring is correctly located in the groove of the front oil pump assembly.

-

Make sure to align the protruding part of the snap ring with the cutout (#2) of the front oil pump assembly shown in the illustration to install the snap ring.

-

-

*1 Snap Ring *2 Brake Snap Ring Stopper *a Correctly installed Check that the brake snap ring stopper can be turned by hand.

Note

If the brake snap ring stopper cannot be turned by hand, the brake snap ring stopper may have been installed upside down, or a snap ring may not have been completely located in the groove on the front oil pump assembly. Remove and reinstall the snap ring and brake snap ring stopper.

-

-

INSPECT CLEARANCE OF NO. 1 BRAKE PISTON

-

INSTALL UNDERDRIVE PLANETARY SUN GEAR

-

*1 Thrust Needle Roller Bearing *2 Underdrive Planetary Sun Gear Coat the thrust needle roller bearing with ATF and install it to the front oil pump assembly.

Thrust Needle Roller Bearing Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 57.7 (2.27) 75.2 (2.96) Note

Be sure to install the thrust needle roller bearing in the correct direction.

-

Install the underdrive planetary sun gear to the front oil pump assembly.

-

-

INSTALL INPUT SHAFT SUB-ASSEMBLY

-

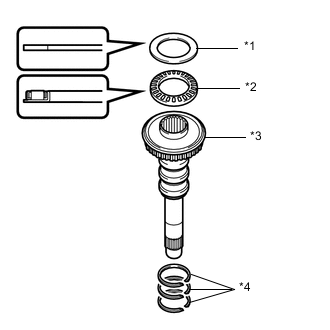

*1 Thrust Bearing Race *2 Thrust Needle Roller Bearing *3 Input Shaft Sub-assembly *4 Input Shaft Oil Seal Ring Coat 3 new input shaft oil seal rings with ATF and install them to the input shaft sub-assembly.

Note

Do not expand the gap of the input shaft oil seal rings excessively.

-

Coat the thrust needle roller bearing and thrust bearing race with ATF, and install them to the input shaft sub-assembly.

Thrust Needle Roller Bearing and Thrust Bearing Race Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 29.1 (1.15) 48 (1.89) Thrust bearing race 30.7 (1.21) 48.3 (1.90) Note

Be sure to install the thrust needle roller bearing in the correct direction.

-

Install the input shaft sub-assembly to the front oil pump assembly.

-

-

INSTALL PLANETARY SUN GEAR SUB-ASSEMBLY

-

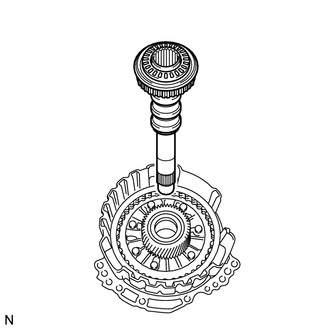

*1 Planetary Sun Gear Sub-assembly *2 Underdrive Planetary Gear Assembly *3 Snap Ring Using a snap ring expander, install the snap ring to the underdrive planetary gear assembly.

-

Using a snap ring expander, install the planetary sun gear sub-assembly to the underdrive planetary gear assembly with the snap ring expanded.

-

-

INSTALL UNDERDRIVE PLANETARY RING GEAR

Tech Tips

Perform this procedure only when replacement of the underdrive planetary ring gear or No. 3 brake hub is necessary.

-

Install the snap ring to the underdrive planetary ring gear.

-

*a Protective Tape While compressing the snap ring with a screwdriver with its tip wrapped with protective tape, install the underdrive planetary ring gear to the No. 3 brake hub.

Note

Confirm that the snap ring is correctly located in the groove of the No. 3 brake hub.

-

-

INSTALL NO. 3 BRAKE HUB

-

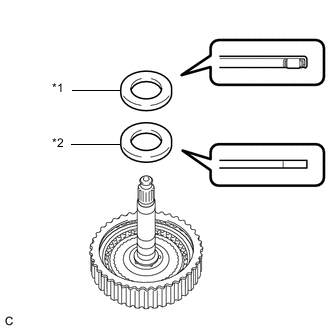

*1 Thrust Bearing Race *2 Thrust Needle Roller Bearing Coat the thrust needle roller bearing and thrust bearing race with ATF and install them to the underdrive planetary gear assembly.

Thrust Needle Roller Bearing and Thrust Bearing Race Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 62.6 (2.46) 82.4 (3.24) Thrust bearing race 65.9 (2.59) 80.3 (3.16) Note

Be sure to install the thrust needle roller bearing so that the temper colored side of the race is visible.

-

Install the No. 3 brake hub to the underdrive planetary gear assembly.

-

-

INSTALL UNDERDRIVE PLANETARY GEAR ASSEMBLY

-

Install the underdrive planetary gear assembly to the front oil pump assembly.

-

-

INSTALL NO. 3 BRAKE DISC

-

*1 No. 3 Brake Flange *2 No. 3 Brake Plate *3 No. 3 Brake Disc Install the 2 No. 3 brake flanges, 3 No. 3 brake discs and 2 No. 3 brake plates to the front oil pump assembly.

Note

Make sure that the No. 3 brake discs, No. 3 brake plates and No. 3 brake flanges are installed in the correct order.

-

Using a screwdriver with its tip wrapped with protective tape, install the snap ring to the front oil pump assembly.

Note

-

Confirm that the snap ring is correctly located in the groove of the front oil pump assembly.

-

Make sure that the snap ring ends are positioned as shown in the illustration (A).

-

-

-

INSPECT CLEARANCE OF NO. 3 BRAKE PISTON

-

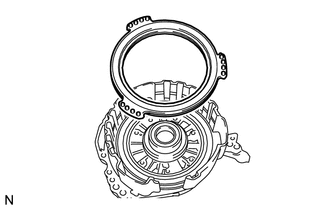

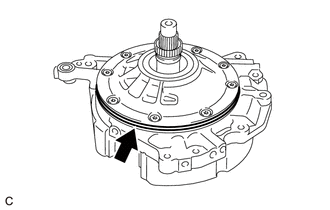

INSTALL FRONT OIL PUMP ASSEMBLY

-

*1 Thrust Needle Roller Bearing *2 O-ring Coat a new O-ring with ATF and install it to the transaxle case sub-assembly.

-

Coat the thrust needle roller bearing with ATF.

-

Install the thrust needle roller bearing to the counter drive gear nut.

Thrust Needle Roller Bearing Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 53.1 (2.09) 79 (3.11) Note

Be sure to install the thrust needle roller bearing in the correct direction.

-

Coat the thrust bearing race with MP grease.

-

*1 Thrust Bearing Race Install the thrust bearing race to the underdrive planetary gear assembly.

Thrust Bearing Race Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust bearing race 59.4 (2.34) 77 (3.03) -

Coat a new front oil pump body O-ring with ATF and install it to the front oil pump assembly.

Note

Make sure that the front oil pump body O-ring is installed correctly with the identification line facing outward and check that it is not twisted, protruding or damaged.

-

*1 Gasket Install the front oil pump assembly to the transaxle case sub-assembly with the 7 bolts.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

Coat a new gasket with ATF and install it to the front oil pump assembly.

-

-

INSTALL DIFFERENTIAL GEAR LUBE APPLY TUBE

-

Install the differential gear lube apply tube to the transaxle housing.

Note

Insert the differential gear lube apply tube to the transaxle housing until it makes contact with the stopper.

-

Install the clamp to the differential gear lube apply tube with the bolt.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

Note

There should be clearance between the differential gear lube apply tube and clamp.

-

-

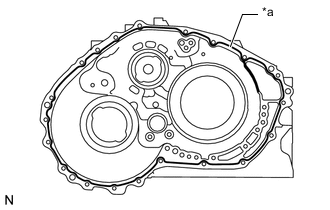

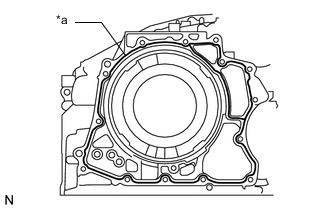

INSTALL TRANSAXLE HOUSING

-

Clean and degrease the 3 bolts and installation holes in the transaxle case sub-assembly.

-

Remove any remaining seal packing from the contact surfaces of the transaxle housing and transaxle case sub-assembly.

Note

Make sure that there is no ATF on the contact surfaces.

-

*a FIPG Apply FIPG to the transaxle case sub-assembly.

FIPG Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Note

-

Apply FIPG in a continuous line (width 1.2 mm (0.0472 in.)) along the sealing surface of the transaxle case sub-assembly.

-

After applying FIPG, install the transaxle housing to the transaxle case sub-assembly within 3 minutes and tighten the bolts within 20 minutes.

-

-

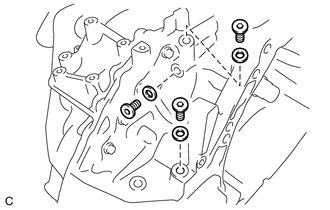

Install the transaxle housing to the transaxle case sub-assembly with the 17 bolts.

- Torque:

- 30.6 N*m { 312 kgf*cm, 23 ft.*lbf }

-

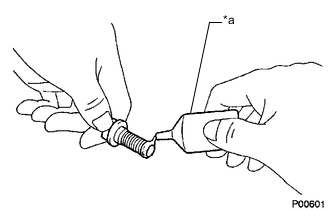

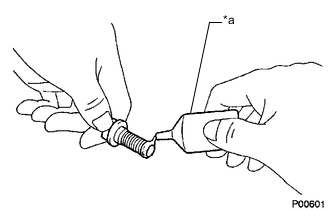

*a Adhesive Apply adhesive to 2 or 3 threads on the ends of the 3 bolts.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent Note

Make sure to install the 3 bolts immediately after applying adhesive to prevent foreign matter from attaching to them.

-

Install the 3 bolts.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

-

INSTALL NO. 1 CLUTCH DISC

-

*1 No. 1 Clutch Flange *2 No. 1 Clutch Plate *3 No. 1 Clutch Disc Install the No. 1 clutch flange, 4 No. 1 clutch discs and 4 No. 1 clutch plates to the direct multiple disc clutch assembly.

Note

Make sure that the No. 1 clutch flange, No. 1 clutch discs and No. 1 clutch plates are installed in the correct order.

-

Using a screwdriver with its tip wrapped with protective tape, install the 2 snap rings to the direct multiple disc clutch assembly.

Note

-

Confirm that the snap rings are correctly located in the groove of the direct multiple disc clutch assembly.

-

Be careful not to damage the direct multiple disc clutch assembly.

-

-

-

INSPECT CLEARANCE OF NO. 1 CLUTCH DISC

-

INSTALL REAR PLANETARY SUN GEAR ASSEMBLY

-

*1 Thrust Needle Roller Bearing *2 Thrust Bearing Race Coat the thrust needle roller bearing and thrust bearing race with ATF and install them to the direct multiple disc clutch assembly.

Thrust Needle Roller Bearing and Thrust Bearing Race Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 28 (1.10) 47.1 (1.85) Thrust bearing race 26.1 (1.03) 44 (1.73) Note

Be sure to install the thrust needle roller bearing so that the temper colored side of the race is visible.

-

*1 Rear Planetary Sun Gear Assembly Install the rear planetary sun gear assembly to the direct multiple disc clutch assembly.

-

Using a brass bar and a hammer, install the snap ring to the direct multiple disc clutch assembly.

Tech Tips

Use a piece of cloth to keep the snap ring from flying off.

-

-

INSTALL NO. 2 CLUTCH DISC

-

*1 No. 2 Clutch Plate *2 No. 2 Clutch Disc *3 No. 2 Clutch Flange Install the No. 2 clutch flange, 3 No. 2 clutch discs and 3 No. 2 clutch plates to the direct multiple disc clutch assembly.

Note

Make sure that the No. 2 clutch flange, No. 2 clutch discs and No. 2 clutch plates are installed in the correct order.

-

-

INSTALL DIRECT MULTIPLE DISC CLUTCH SNAP RING

-

Install the No. 2 direct clutch piston to the direct multiple disc clutch assembly.

Note

Be sure to engage the claws on the direct multiple disc clutch assembly in the grooves on the No. 2 direct clutch piston.

-

*a Protective Tape Using a screwdriver with its tip wrapped with protective tape, install the direct multiple disc clutch snap ring to the direct multiple disc clutch assembly.

Note

-

Position the opening of the direct multiple disc clutch snap ring as shown in the illustration.

-

Confirm that the direct multiple disc clutch snap ring is correctly located in the groove of the direct multiple disc clutch assembly.

-

-

-

INSPECT CLEARANCE OF NO. 2 CLUTCH DISC

-

INSTALL DIRECT MULTIPLE DISC CLUTCH ASSEMBLY

-

*1 Intermediate Shaft Oil Seal *2 O-ring Coat a new O-ring with ATF and install it to the direct multiple disc clutch assembly.

Note

Ensure that the O-ring is not twisted.

-

Coat a new intermediate shaft oil seal with ATF and install it to the direct multiple disc clutch assembly.

-

*1 Direct Multiple Disc Clutch Assembly *2 Thrust Needle Roller Bearing Coat the thrust needle roller bearing with ATF and install it to the transaxle case sub-assembly.

Thrust Needle Roller Bearing Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 61.2 (2.41) 79 (3.11) -

Install the direct multiple disc clutch assembly to the transaxle case sub-assembly.

-

-

INSPECT INTERMEDIATE SHAFT END PLAY

-

INSTALL REAR TRANSAXLE COVER SUB-ASSEMBLY

-

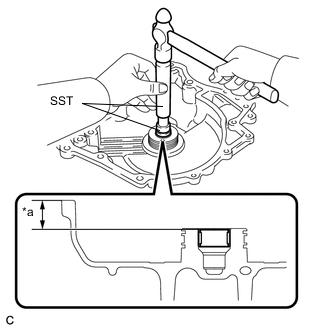

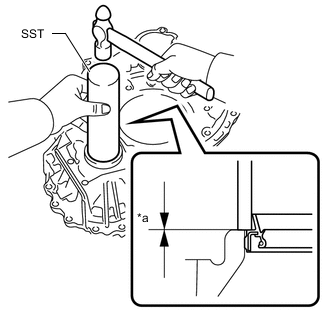

*a Depth Using SST and a hammer, install a new needle roller bearing to the rear transaxle cover sub-assembly.

- SST

- 09950-60010 ( 09951-00220 )

- 09950-70010 ( 09951-07100 )

Standard Depth 21.5 to 21.9 mm (0.846 to 0.862 in.) -

Clean and degrease the 2 "TORX" screws and installation holes in the rear transaxle cover sub-assembly.

-

*a Adhesive Apply adhesive to the 2 "TORX" screws.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent Note

Make sure to install the 2 "TORX" screws immediately after applying adhesive to prevent foreign matter from attaching to them.

-

Using a T30 "TORX" socket wrench, install the rear transaxle cover plate to the rear transaxle cover sub-assembly with the 2 "TORX" screws.

- Torque:

- 7.5 N*m { 76 kgf*cm, 66 in.*lbf }

-

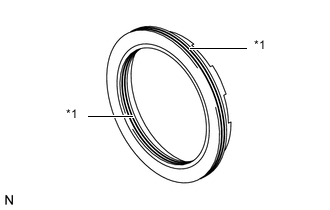

*1 Oil Seal Ring Coat 2 new oil seal rings with ATF and install them to the rear transaxle cover sub-assembly.

Note

Confirm that the 2 oil seal rings are correctly located in the grooves of the rear transaxle cover sub-assembly.

-

*1 Thrust Needle Roller Bearing *2 Thrust Bearing Race Coat the thrust needle roller bearing and thrust bearing race with MP grease and install them to the rear transaxle cover sub-assembly.

Thrust Needle Roller Bearing and Thrust Bearing Race Diameter - Inside (mm (in.)) Outside (mm (in.)) Thrust needle roller bearing 48.9 (1.93) 72.0 (2.83) Thrust bearing race 52.2 (2.06) 70.4 (2.77) Note

Be sure to install the thrust needle roller bearing and thrust bearing race in the correct direction.

-

Coat 3 new O-rings with ATF and install them to the transaxle case sub-assembly.

-

Clean and degrease the 2 bolts and installation holes in the transaxle case sub-assembly.

-

Remove any remaining seal packing from the contact surfaces of the rear transaxle cover sub-assembly and transaxle case sub-assembly.

Note

Make sure that there is no ATF on the contact surfaces.

-

*a FIPG Apply FIPG to the transaxle case sub-assembly.

FIPG Toyota Genuine Seal Packing 1281, Three Bond 1281 or equivalent Note

Apply FIPG in a continuous line (width 1.2 mm (0.0472 in.)) along the sealing surface of the transaxle case sub-assembly.

-

Install the rear transaxle cover sub-assembly to the transaxle case sub-assembly with the 12 bolts.

- Torque:

- 22.7 N*m { 231 kgf*cm, 17 ft.*lbf }

-

*a Adhesive Apply adhesive to 2 or 3 threads on the ends of the 2 bolts.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent Note

Make sure to install the 2 bolts immediately after applying adhesive to prevent foreign matter from attaching to them.

-

Install the 2 bolts.

- Torque:

- 16.9 N*m { 172 kgf*cm, 12 ft.*lbf }

-

-

INSTALL REAR TRANSAXLE COVER PLUG

-

Coat 3 new O-rings with ATF and install them to the 3 rear transaxle cover plugs.

Note

Ensure that the 3 O-rings are not twisted.

-

Install the 3 rear transaxle cover plugs to the rear transaxle cover sub-assembly.

- Torque:

- 7.4 N*m { 75 kgf*cm, 65 in.*lbf }

-

-

INSTALL REFILL PLUG

-

Install a new gasket to the refill plug.

-

Install the refill plug to the rear transaxle cover sub-assembly.

- Torque:

- 49 N*m { 500 kgf*cm, 36 ft.*lbf }

-

-

INSPECT INPUT SHAFT SUB-ASSEMBLY END PLAY

-

INSTALL TRANSAXLE CASE GASKET

-

INSTALL NO. 1 CHECK VALVE SUB-ASSEMBLY

-

INSTALL TRANSMISSION VALVE BODY ASSEMBLY

-

INSTALL VALVE BODY OIL STRAINER ASSEMBLY

-

INSTALL TRANSMISSION OIL CLEANER MAGNET

-

INSTALL AUTOMATIC TRANSAXLE OIL PAN GASKET

-

INSTALL AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

-

INSTALL NO. 1 TRANSMISSION OIL FILLER TUBE

-

Using a 6 mm hexagon socket wrench, install the No. 1 transmission oil filler tube to the automatic transaxle oil pan sub-assembly.

- Torque:

- 1.7 N*m { 17 kgf*cm, 15 in.*lbf }

-

-

INSTALL OVERFLOW PLUG

-

Using a 6 mm hexagon socket wrench, install the overflow plug and a new gasket to the automatic transaxle oil pan sub-assembly.

- Torque:

- 40 N*m { 408 kgf*cm, 30 ft.*lbf }

-

-

INSTALL FRONT DRIVE SHAFT OIL SEAL LH

-

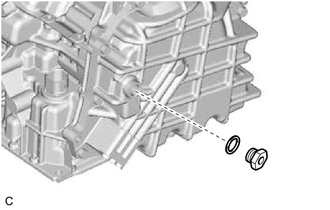

Coat the lip of a new front drive shaft oil seal LH with MP grease.

-

*a Depth Using SST and a hammer, install the front drive shaft oil seal LH to the transaxle case sub-assembly.

- SST

- 09316-10010

- 09950-70010 ( 09951-07100 )

Standard Depth -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) Note

-

Make sure that the front drive shaft oil seal LH is installed in the correct direction.

-

Do not damage the front drive shaft oil seal LH lip.

-

-

INSTALL FRONT DRIVE SHAFT OIL SEAL RH

-

Coat the lip of a new front drive shaft oil seal RH with MP grease.

-

*a Depth Using SST and a hammer, install the front drive shaft oil seal RH to the transaxle housing.

- SST

- 09316-60011 ( 09316-00011 )

Standard Depth -0.5 to 0.5 mm (-0.0197 to 0.0197 in.) Note

-

Make sure that the front drive shaft oil seal RH is installed in the correct direction.

-

Do not damage the front drive shaft oil seal RH lip.

-

-

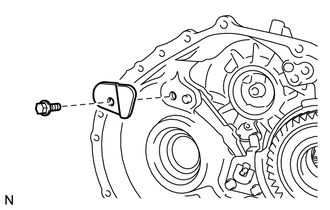

INSTALL NO. 2 TRANSAXLE CASE PLUG

-

Clean and degrease the 3 No. 2 transaxle case plugs and installation holes in the transaxle housing.

-

Install 3 new gaskets to the 3 No. 2 transaxle case plugs.

-

*a Adhesive Apply adhesive to 2 or 3 threads on the ends of the 3 No. 2 transaxle case plugs.

Adhesive Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent Note

Make sure to install the 3 No. 2 transaxle case plugs immediately after applying adhesive to prevent foreign matter from attaching to them.

-

Using a 6 mm hexagon socket wrench, install the 3 No. 2 transaxle case plugs to the transaxle housing.

- Torque:

- 17 N*m { 173 kgf*cm, 13 ft.*lbf }

-

-

INSTALL NO. 1 TRANSAXLE CASE PLUG

-

Coat 3 new O-rings with ATF and install them to the 3 No. 1 transaxle case plugs.

Note

Ensure that the 3 O-rings are not twisted.

-

Install the 3 No. 1 transaxle case plugs to the transaxle case sub-assembly.

- Torque:

- 7.4 N*m { 75 kgf*cm, 65 in.*lbf }

-

-

INSTALL OIL COOLER TUBE ELBOW

-

*a 0 to 15° *b Torque Wrench Fulcrum Length Coat a new O-ring with ATF and install it to the oil cooler tube elbow.

-

Using SST, install the oil cooler tube elbow to the transaxle case sub-assembly.

- SST

- 09922-10010

- Torque:

- Specified tightening torque

- 27 N*m { 275 kgf*cm, 20 ft.*lbf }

Tech Tips

-

Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

-

When using SST (fulcrum length of 137 mm (5.39 in.)) + torque wrench (fulcrum length of 180 mm (7.09 in.)):

15.3 N*m (156 kgf*cm, 11 ft.*lbf)

-

-

INSTALL OIL COOLER UNION SUB-ASSEMBLY

-

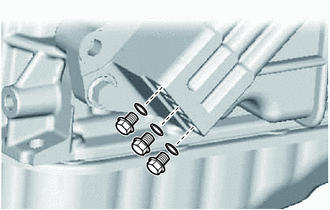

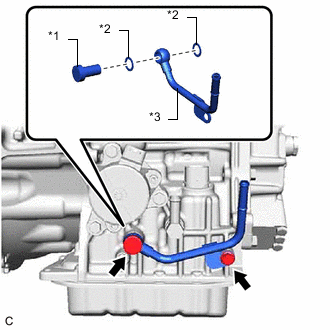

*1 Union Bolt *2 Gasket *3 Oil Cooler Union Sub-assembly Temporarily install the oil cooler union sub-assembly to the transaxle case sub-assembly with the bolt.

-

Install the oil cooler union sub-assembly and 2 new gaskets to the transaxle case sub-assembly with the union bolt as shown in the illustration.

- Torque:

- 27.5 N*m { 280 kgf*cm, 20 ft.*lbf }

-

Tighten the bolt.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

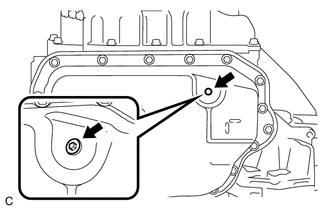

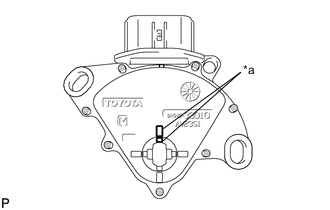

INSTALL PARK/NEUTRAL POSITION SWITCH ASSEMBLY

-

*a Protrusion Align the protrusions of the park/neutral position switch assembly as shown in the illustration.

-

Install the park/neutral position switch assembly to the transaxle case sub-assembly with the 2 bolts.

- Torque:

- 5.4 N*m { 55 kgf*cm, 48 in.*lbf }

Note

-

Before installing the park/neutral position switch assembly, remove any dirt or rust on the manual valve lever shaft sub-assembly. Be sure to install the park/neutral position switch assembly straight along the manual valve lever shaft sub-assembly while being careful not to deform the plate spring that supports the manual valve lever shaft sub-assembly. If the plate spring is deformed, the park/neutral position switch assembly cannot be reinstalled correctly.

-

After installing the park/neutral position switch assembly, confirm that the 2 protrusions on the park/neutral position switch assembly are aligned.

-

-

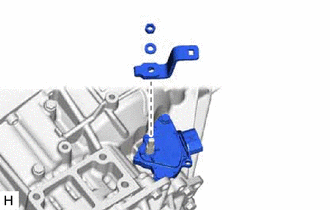

INSTALL TRANSMISSION CONTROL SHAFT LEVER

-

Install the transmission control shaft lever to the manual valve lever shaft sub-assembly with the washer and nut.

- Torque:

- 12.7 N*m { 130 kgf*cm, 9 ft.*lbf }

-

-

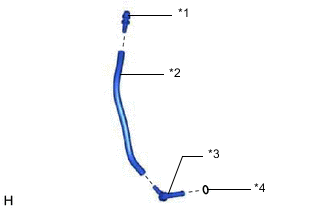

INSTALL BREATHER PLUG HOSE

-

*1 No. 1 Breather Plug *2 Breather Plug Hose *3 No. 2 Breather Plug *4 O-ring Coat a new O-ring with ATF and install it to the No. 2 breather plug.

Note

Ensure that the O-ring is not twisted.

-

Install the No. 2 breather plug to the breather plug hose.

-

Install the No. 1 breather plug to the breather plug hose.

-

Install the transmission breather hose sub-assembly to the transaxle case sub-assembly.

Note

Make sure that the stopper of the No. 2 breather plug is in contact with the side of the boss on the transaxle case sub-assembly.

-