SFI SYSTEM(w/o Canister Pump Module) Active Control Engine Mount System

DESCRIPTION

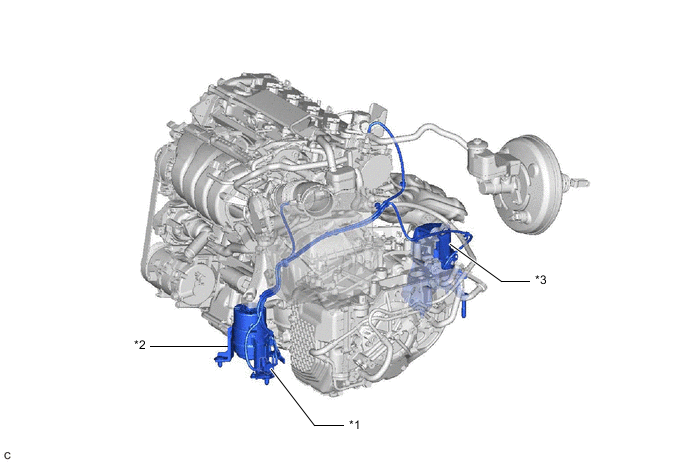

- LOCATION

*1 Vacuum Switching Valve (for Active Control Engine Mount System) *2 Front Engine Mounting Insulator *3 Rear Engine Mounting Insulator - -

The active control engine mount system decreases engine vibration at a low engine speed using the vacuum switching valve (for active control engine mount system). The vacuum switching valve (for active control engine mount system) is controlled by a pulse signal transmitted to the vacuum switching valve (for active control engine mount system) from the ECM. The frequency of this pulse signal is matched to the engine speed to decrease engine vibration.

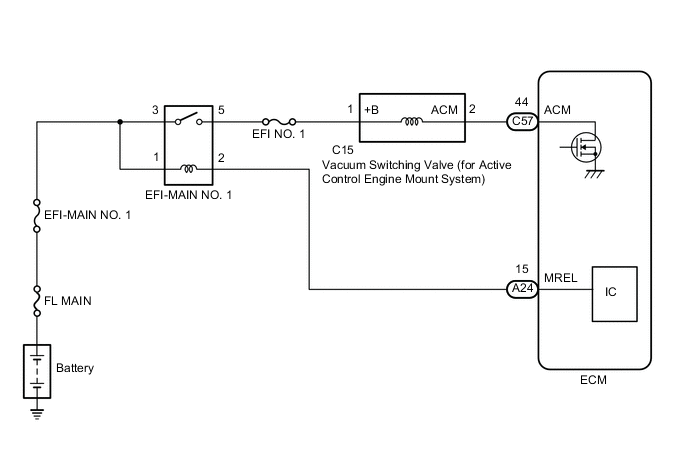

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

-

PERFORM ACTIVE TEST USING GTS (ACTIVATE THE ACM INHIBIT)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Active Test / Activate the ACM Inhibit.

Powertrain > Engine > Active TestTester Display Activate the ACM Inhibit -

According to the display on the GTS, perform the Active Test to operate the vacuum switching valve (for active control engine mount system) and for check the operating sound of the vacuum switching valve (for active control engine mount system).

OK Operating sounds can be heard. Result Proceed to OK NG

NG

CHECK TERMINAL VOLTAGE (POWER SOURCE OF VACUUM SWITCHING VALVE (FOR ACTIVE CONTROL ENGINE MOUNT SYSTEM)) Click here

OK

-

-

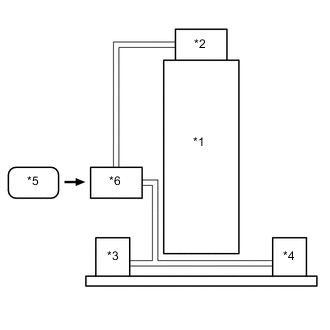

CHECK VACUUM HOSES

*1 Engine *2 Vacuum Pump Assembly *3 Front Engine Mounting Insulator *4 Rear Engine Mounting Insulator *5 ECM *6 Vacuum Switching Valve (for Active Control Engine Mount System)

-

Check the air and vacuum hoses for looseness, disconnection and blockage.

OK No looseness, disconnection or blockage. Result Proceed to OK NG

NG

REPAIR OR REPLACE VACUUM HOSES

OK

-

-

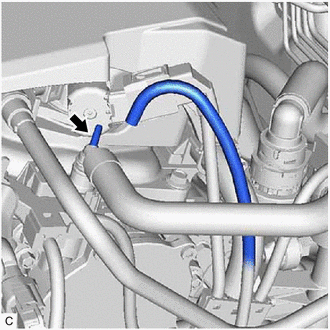

CHECK VACUUM

-

Disconnect the vacuum hose from the vacuum pump assembly.

-

Start the engine.

-

Check that the disconnected port located on the vacuum pump assembly applies suction to your finger.

OK Vacuum exists. Result Proceed to OK NG

NG

REPLACE VACUUM PUMP ASSEMBLY Click here

OK

-

-

INSPECT FRONT ENGINE MOUNTING INSULATOR

-

Inspect the front engine mounting insulator.

Result Proceed to OK NG

NG

REPLACE FRONT ENGINE MOUNTING INSULATOR Click here

OK

-

-

INSPECT REAR ENGINE MOUNTING INSULATOR

-

Inspect the rear engine mounting insulator.

Result Proceed to OK NG

OK

SYSTEM NORMAL

NG

REPLACE REAR ENGINE MOUNTING INSULATOR Click here

-

-

CHECK TERMINAL VOLTAGE (POWER SOURCE OF VACUUM SWITCHING VALVE (FOR ACTIVE CONTROL ENGINE MOUNT SYSTEM))

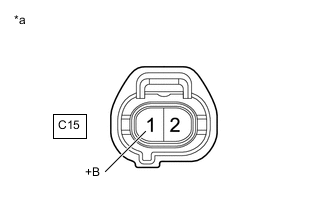

*a Front view of wire harness connector

(to Vacuum Switching Valve (for Active Control Engine Mount System))

-

Disconnect the vacuum switching valve (for active control engine mount system) connector.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition C15-1 (+B) - Body ground Ignition switch ON 11 to 14 V Result Proceed to OK NG

NG

GO TO ECM POWER SOURCE CIRCUIT Click here

OK

-

-

INSPECT VACUUM SWITCHING VALVE (FOR ACTIVE CONTROL ENGINE MOUNT SYSTEM)

-

Inspect the vacuum switching valve (for active control engine mount system).

Result Proceed to OK NG

NG

REPLACE VACUUM SWITCHING VALVE (FOR ACTIVE CONTROL ENGINE MOUNT SYSTEM) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (VACUUM SWITCHING VALVE (FOR ACTIVE CONTROL ENGINE MOUNT SYSTEM) - ECM)

-

Disconnect the vacuum switching valve (for active control engine mount system) connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition C15-2 (ACM) - C57-44 (ACM) Always Below 1 Ω C15-2 (ACM) or C57-44 (ACM) - Body ground and other terminals Always 10 kΩ or higher Result Proceed to OK NG

OK

REPLACE ECM Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-