BRAKE MASTER CYLINDER(for LHD) INSTALLATION

PROCEDURE

INSTALL BRAKE MASTER CYLINDER SUB-ASSEMBLY

Note:When installing a new brake master cylinder sub-assembly, remove the protectors from the master cylinder piston and outlet ports.

-

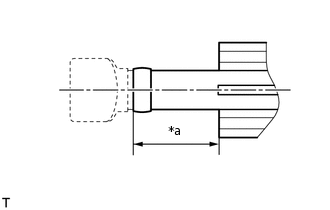

*a

More than 22 mm (0.866 in.)

for Manual Transaxle:

When installing a new brake master cylinder reservoir assembly or a new brake master cylinder sub-assembly, cut off the clutch tube tip of the brake master cylinder reservoir assembly as shown in the illustration.

CAUTION:Be careful not to cut your finger on the cut surface.

Note:Do not allow any foreign matter to enter the brake master cylinder reservoir assembly.

Make sure that fluid supply is not affected by cutting the tube.

Install a new brake master cylinder O-ring to the brake master cylinder sub-assembly.

Install the brake master cylinder sub-assembly to the brake booster assembly with the 2 nuts.

20 N*m

204 kgf*cm

15 ft.*lbf

Note:Do not hold the brake master cylinder sub-assembly by the master cylinder piston. Hold the brake master cylinder sub-assembly by its body or its reservoir when carrying it.

Do not pull out the master cylinder piston.

Do not strike or pinch the master cylinder piston and do not cause any damage to the master cylinder piston by any other means.

When installing the brake master cylinder sub-assembly to the brake booster assembly, or when removing the brake master cylinder sub-assembly from the brake booster assembly, make sure that the brake master cylinder sub-assembly is kept horizontal or with its tip facing downward (the master cylinder piston is facing upward) to prevent the master cylinder piston from falling out.

Do not allow any foreign matter to contaminate the master cylinder piston. If any foreign matter gets on the master cylinder piston, remove it by using a piece of cloth and then apply an even layer of lithium soap base glycol grease around the circumference (sliding part) of the master cylinder piston.

Do not kink or damage the brake lines.

Do not allow the brake lines to twist or interfere with other parts or the vehicle body during tightening.

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

-

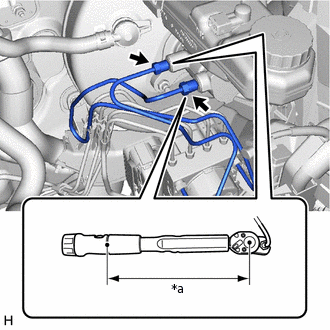

*a

Torque Wrench Fulcrum Length

Using a union nut wrench, connect the 2 brake lines to the brake master cylinder sub-assembly.

Specified tightening torque (w/o VSC)

15.2 N*m

155 kgf*cm

11 ft.*lbf

Specified tightening torque (w/ VSC)

19.5 N*m

199 kgf*cm

14 ft.*lbf

Note:Do not kink or damage the brake lines.

Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

Tip:Calculate the torque wrench reading when changing the fulcrum length of the torque wrench.

When using a union nut wrench (fulcrum length of 22 mm (0.866 in.)) + torque wrench (fulcrum length of 162 mm (6.38 in.)):

w/o VSC: 13.38 N*m (136 kgf*cm, 10 ft.*lbf)

When using a union nut wrench (fulcrum length of 20 mm (0.787 in.)) + torque wrench (fulcrum length of 162 mm (6.38 in.)):

w/ VSC: 17.36 N*m (177 kgf*cm, 13 ft.*lbf)

Connect the reservoir level switch connector and engage the 3 clamps.

-

CONNECT CLUTCH RESERVOIR TUBE (for Manual Transaxle)

Connect the clutch reservoir tube to the brake master cylinder sub-assembly and slide the clip to secure it.

BLEED BRAKE SYSTEM

BLEED CLUTCH LINE (for Manual Transaxle)

INSTALL FUEL FILTER SUPPORT (for 1WW, 1ND-TV)

INSTALL GLOW PLUG RELAY ASSEMBLY (for 1WW, 1ND-TV)

CONNECT WIRE HARNESS (for 1ND-TV)

CONNECT WIRE HARNESS (for 1WW)

INSTALL FUEL FILTER ASSEMBLY (for 1WW, 1ND-TV)

for 1WW (w/ Fuel Heater Relay):Click here

for 1WW (w/o Fuel Heater Relay):Click here

for 1ND-TV:Click here

INSTALL NO. 1 FUEL FILTER PROTECTOR (for 1WW)

for 1WW (w/ Fuel Heater Relay):Click here

for 1WW (w/o Fuel Heater Relay):Click here

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 1NR-FE)

INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1NR-FE)

INSTALL NO. 1 ENGINE COVER (for 1NR-FE)

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 1ZR-FE)

INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1ZR-FE)

INSTALL NO. 2 CYLINDER HEAD COVER (for 1ZR-FE)

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 1ZR-FAE)

INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1ZR-FAE)

INSTALL NO. 2 CYLINDER HEAD COVER (for 1ZR-FAE)

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 2ZR-FE)

INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 2ZR-FE)

INSTALL NO. 2 CYLINDER HEAD COVER (for 2ZR-FE)

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 1ND-TV)

w/o Glow Plug Controller:Click here

w/ Glow Plug Controller:Click here

INSTALL AIR CLEANER CAP SUB-ASSEMBLY (for 1ND-TV)

w/o Glow Plug Controller:Click here

w/ Glow Plug Controller:Click here

INSTALL NO. 1 ENGINE COVER (for 1ND-TV with No. 1 Engine Cover)

w/o Glow Plug Controller:Click here

w/ Glow Plug Controller:Click here

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 8NR-FTS)

INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE (for 8NR-FTS)

INSTALL AIR CLEANER CASE SUB-ASSEMBLY (for 1WW)

INSTALL AIR CLEANER CAP SUB-ASSEMBLY WITH AIR CLEANER HOSE ASSEMBLY (for 1WW)

INSTALL NO. 1 ENGINE COVER (for 1WW)

INSTALL OUTER COWL TOP PANEL (for Sedan)

Install the outer cowl top panel with the 11 bolts.

12 N*m

122 kgf*cm

9 ft.*lbf

w/ Windshield Deicer System:

Engage the 3 clamps to install the wire harness.

Connect the connector.

INSTALL NO. 2 HEATER AIR DUCT SPLASH SHIELD SEAL (for Sedan)

Engage the clamp to install the No. 2 heater air duct splash shield seal.

INSTALL WATER GUARD PLATE LH (for Sedan)

Engage the clamp to install the water guard plate LH.

INSTALL OUTER COWL TOP PANEL (for Hatchback, Wagon)

Install the outer cowl top panel with the 11 bolts.

12 N*m

122 kgf*cm

9 ft.*lbf

INSTALL NO. 2 HEATER AIR DUCT SPLASH SHIELD SEAL (for Hatchback, Wagon)

Engage the clamp to install the No. 2 heater air duct splash shield seal.

INSTALL WATER GUARD PLATE LH (for Hatchback, Wagon)

Engage the clamp to install the water guard plate LH.

INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

BLEED AIR FROM FUEL SYSTEM (for 1ND-TV)

CHECK FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK (for 1WW)

INSPECT FOR FUEL LEAK (for 1ND-TV)

w/o Glow Plug Controller:Click here

w/ Glow Plug Controller:Click here