ELECTRONIC SHIFT LEVER SYSTEM, Diagnostic DTC:C2300

| DTC Code | DTC Name |

|---|---|

| C2300 | Actuator System Malfunction |

DESCRIPTION

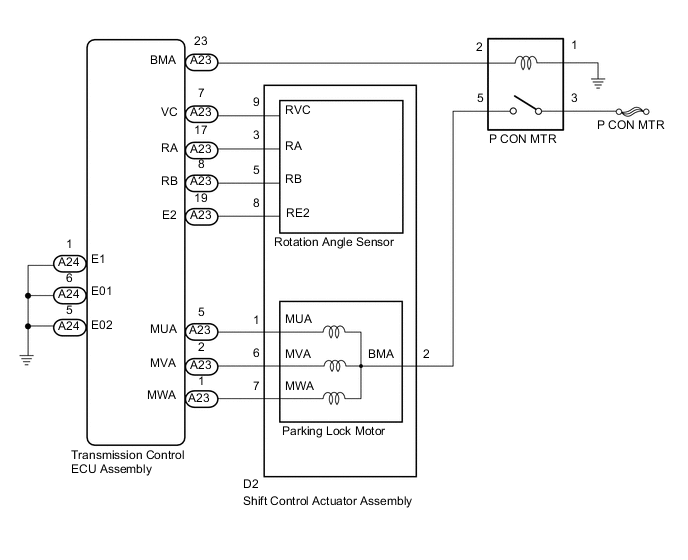

The shift control actuator assembly consists of a parking lock motor and rotation angle sensor. The transmission control ECU assembly receives a P position switch signal from the hybrid vehicle control ECU and activates the parking lock motor by controlling current, causing the parking lock mechanism to switch. The transmission control ECU assembly also detects the rotor rotation angle through the rotation angle sensor to control timing of current application to the coils.

The transmission control ECU assembly stores this DTC when it detects a malfunction in the actuator system or abnormal operation of the shift control actuator assembly caused by a power system malfunction, such as when the auxiliary battery has become discharged.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| C2300 | Decrease in the power source voltage (+B), open or short in the P CONMTR relay, shift control actuator assembly (parking lock motor or rotation angle sensor) or wire harness, or an internal malfunction of the shift control actuator assembly (parking lock motor or rotation angle sensor). |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

-

Do not remove/install the auxiliary battery or disconnect the cable from the negative (-) auxiliary battery terminal before instructed.

-

It may not be possible to clear the following DTCs using the GTS: DTC C2300 (Actuator System Malfunction), C2301 (Shift Changing Time Malfunction), C2303 (Short in Power Source Relay Circuit), C2304 (Open or Short Circuit in U Phase), C2305 (Open or Short Circuit in V Phase), C2306 (Open or Short Circuit in W Phase), C2307 (Power Supply) and C2309 (Open in B+ Circuit). In such cases, disconnect the P CON MAIN fuse and wait for at least 60 seconds to clear the DTCs after the repair.

-

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work Click here.

PROCEDURE

-

CHECK FREEZE FRAME DATA

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Read the freeze frame data "Current flag record" of DTC C2300.

Result Result Proceed to OFF A ON B -

Turn the power switch off.

B

REPLACE TRANSMISSION CONTROL ECU ASSEMBLY Click here

A

-

-

CHECK DTC OUTPUT (TRANSMISSION CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Check if DTCs are output.

Result Result Proceed to None of the DTCs in the table below are output. A One of the DTCs in the table below is output. B DTC No. Relevant Diagnosis C2304 Open or Short Circuit in U Phase C2305 Open or Short Circuit in V Phase C2306 Open or Short Circuit in W Phase -

Turn the power switch off.

B

GO TO DTC CHART (ELECTRONIC SHIFT LEVER SYSTEM) Click here

A

-

-

CHECK FREEZE FRAME DATA

-

Connect the GTS to the DLC3.

-

Release the brake pedal and turn the power switch on (IG).

Tech Tips

Do not turn the power switch on (READY).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Read the freeze frame data of DTC C2300.

Result Result Proceed to IG (+B) voltage is 9 V or more A IG (+B) voltage is less than 9 V B -

Turn the power switch off.

B

CLEAR DTC Click here

A

-

-

CLEAR DTC

-

Turn the power switch on (IG).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Read and record the DTCs and freeze frame data.

-

Turn the power switch off.

-

Disconnect the P CON MAIN fuse and wait for at least 60 seconds.

-

Check for DTCs again to see if the DTCs are cleared.

NEXT

-

-

CHARGE AUXILIARY BATTERY

-

Charge the auxiliary battery.

NEXT

-

-

CHECK DTC OUTPUT (SIMULATION TEST)

-

Connect the GTS to the DLC3.

-

Release the brake pedal and turn the power switch on (IG).

Tech Tips

Do not turn the power switch on (READY).

-

Depress the brake pedal and move the shift lever to select neutral (N).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Check if DTCs are output.

Result Result Proceed to DTC C2300 is output. A DTC C2300 is not output. B -

Turn the power switch off.

B

END (AUXILIARY BATTERY WAS INSUFFICIENTLY CHARGED)

A

-

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL ECU ASSEMBLY - SHIFT CONTROL ACTUATOR ASSEMBLY)

-

Disconnect the A23 transmission control ECU assembly connector.

-

Disconnect the D2 shift control actuator assembly connector.

-

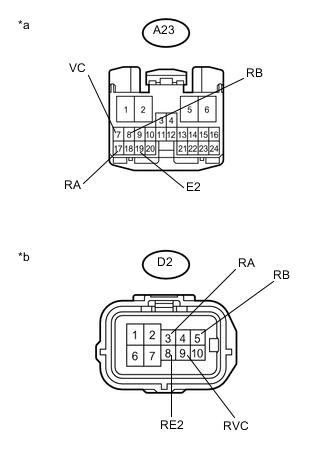

Text in Illustration *a Front view of wire harness connector

(to Transmission Control ECU Assembly)

*b Front view of wire harness connector

(to Shift Control Actuator Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Condition Specified Condition A23-7 (VC) - D2-9 (RVC) Power switch off Below 1 Ω A23-17 (RA) - D2-3 (RA) Power switch off Below 1 Ω A23-8 (RB) - D2-5 (RB) Power switch off Below 1 Ω A23-19 (E2) - D2-8 (RE2) Power switch off Below 1 Ω Standard Resistance (Check for Short) Tester Connection Condition Specified Condition A23-7 (VC) or D2-9 (RVC) - Body ground and other terminals Power switch off 10 kΩ or higher A23-17 (RA) or D2-3 (RA) - Body ground and other terminals Power switch off 10 kΩ or higher A23-8 (RB) or D2-5 (RB) - Body ground and other terminals Power switch off 10 kΩ or higher A23-19 (E2) or D2-8 (RE2) - Body ground and other terminals Power switch off 10 kΩ or higher -

Connect the D2 shift control actuator assembly connector.

-

Connect the A23 transmission control ECU assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK SHIFT CONTROL ACTUATOR ASSEMBLY (ROTATION ANGLE SENSOR)

-

Disconnect the A23 transmission control ECU assembly connector.

-

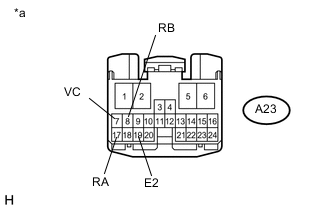

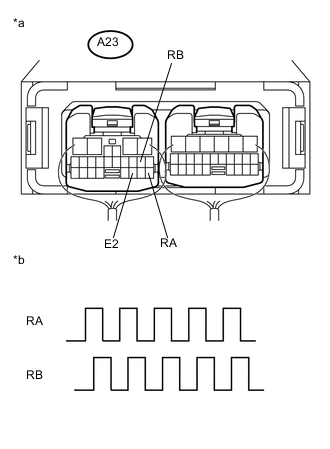

Text in Illustration *a Front view of wire harness connector

(to Transmission Control ECU Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A23-7 (VC) - A23-17 (RA) Power switch off 10 kΩ or higher A23-7 (VC) - A23-8 (RB) Power switch off 10 kΩ or higher A23-7 (VC) - A23-19 (E2) Power switch off 520 to 600 Ω A23-17 (RA) - A23-8 (RB) Power switch off 10 kΩ or higher A23-17 (RA) - A23-19 (E2) Power switch off 10 kΩ or higher A23-8 (RB) - A23-19 (E2) Power switch off 10 kΩ or higher -

Connect the A23 transmission control ECU assembly connector.

NG

REPLACE SHIFT CONTROL ACTUATOR ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL ECU ASSEMBLY - BODY GROUND)

-

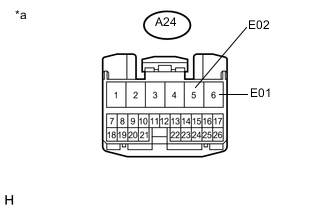

Disconnect the A24 transmission control ECU assembly connector.

-

Text in Illustration *a Front view of wire harness connector

(to Transmission Control ECU Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Condition Specified Condition A24-6 (E01) - Body ground Power switch off Below 1 Ω A24-5 (E02) - Body ground Power switch off Below 1 Ω -

Connect the A24 transmission control ECU assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK SHIFT CONTROL ACTUATOR ASSEMBLY

-

Apply that the parking brake.

-

Disconnect the D2 shift control actuator assembly connector.

-

Remove the 3 shift control actuator bolts Click here.

-

Slightly pull the shift control actuator assembly away from the hybrid vehicle transaxle.

-

Reconnect the D2 shift control actuator assembly connector.

-

Make sure the brake pedal is not depressed and turn the power switch on (ACC).

Note

The shift control actuator assembly may operate if the power switch is turned on (IG) or on (READY). Do not turn the power switch on (IG) or on (READY) during this inspection to prevent the shift control actuator assembly from operating while in contact with the splines.

-

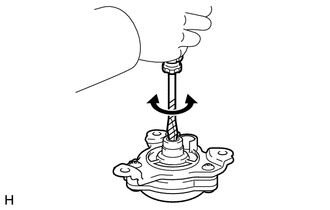

Using a screwdriver with its tip wrapped with protective tape or a piece of cloth, rotate the shaft.

Note

-

Make sure to use a screwdriver with its tip wrapped with protective tape or a piece of cloth to prevent the splines of the actuator from being damaged.

-

The shift control actuator assembly cannot be disassembled.

-

Confirm that the shaft of the shift control actuator assembly rotates smoothly.

OK The shaft of the shift control actuator assembly rotates smoothly. -

Measure the voltage according to the value(s) in the table below.

Tech Tips

As the measured voltage may not appear as a pulse waveform if the shaft is rotated quickly, make sure to rotate the shaft slowly.

Standard Voltage Tester Connection Condition Specified Condition A23-17 (RA) - A23-19 (E2) Power switch on (ACC), shaft being rotated 0 to 1.5 V ←→ 4 to 5.5 V A23-8 (RB) - A23-19 (E2) Power switch on (ACC), shaft being rotated 0 to 1.5 V ←→ 4 to 5.5 V Text in Illustration *a Component with harness connected

(Transmission Control ECU Assembly)

*b Output Waveform while Shaft of Shift Control Actuator Assembly being Rotated (Example)

-

-

Turn the power switch off.

NG

REPLACE SHIFT CONTROL ACTUATOR ASSEMBLY Click here

OK

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY

-

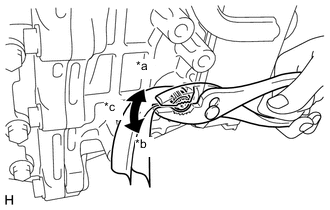

Text in Illustration *a Lock *b Unlock *c Rotate approximately 20° Wrap the shaft with a piece of cloth and turn it using pliers.

OK The shaft rotates smoothly in the lock and unlock directions. Note

During this inspection, make sure to use a piece of cloth to prevent the shaft splines from being damaged.

Tech Tips

-

When normal, the shaft cannot be rotated by hand without a tool.

-

When normal, the shaft can be in the lock and unlock direction by applying a force of 4.0 to 7.0 N*m (41 to 71 kgf*cm, 36 to 61 in.*lbf).

-

-

Set the shaft in the lock position after the inspection.

OK

REPLACE TRANSMISSION CONTROL ECU ASSEMBLY Click here

NG

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

-

-

CLEAR DTC

-

Turn the power switch on (IG).

-

Enter the following menus: Body Electrical / Transmission Control / Trouble Codes.

-

Read and record the DTCs and freeze frame data.

-

Turn the power switch off.

-

Disconnect the P CON MAIN fuse and wait for at least 60 seconds.

-

Check for DTCs again to see if the DTCs are cleared.

NEXT

-

-

INSPECT AUXILIARY BATTERY

-

Inspect the auxiliary battery Click here.

Result Result Proceed to Charge or replace the auxiliary battery. A The auxiliary battery voltage is normal. B

B

CHARGE AUXILIARY BATTERY Click here

A

-

-

CHARGE OR REPLACE AUXILIARY BATTERY

-

Charge or replace the auxiliary battery Click here.

NEXT

CHECK DTC OUTPUT (SIMULATION TEST) Click here

-