SFI SYSTEM

-

OPERATION

-

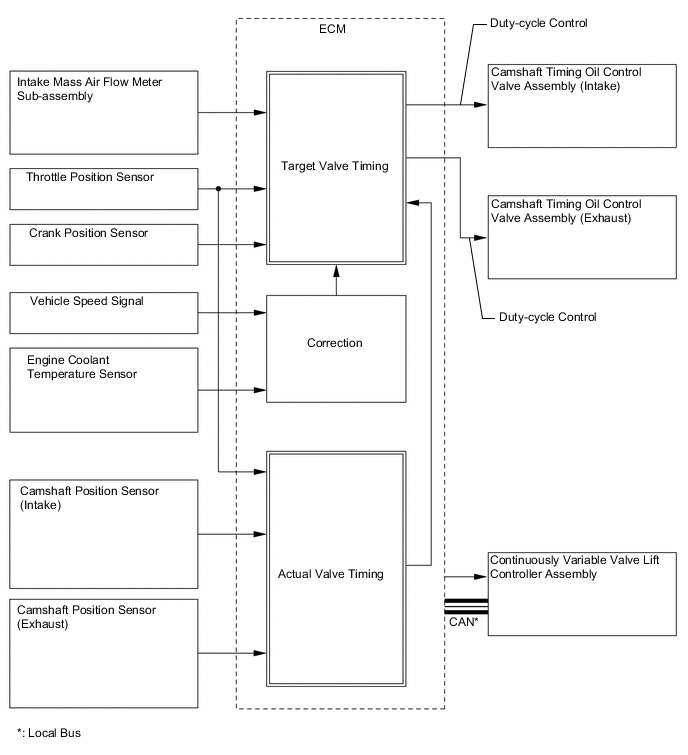

Using the engine speed, intake air mass, throttle position and engine coolant temperature, the ECM can calculate the optimal valve timing for each driving condition and can control the camshaft timing oil control valve assembly. In addition, the ECM uses signals from the camshaft position sensor and the crank position sensor to detect the actual valve timing, thus providing feedback control to achieve the target valve timing.

-

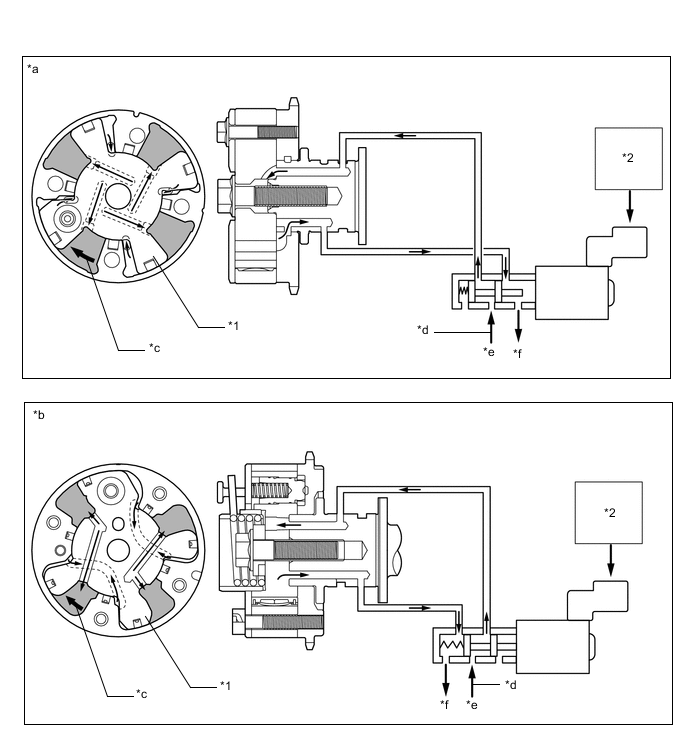

When the camshaft timing oil control valve assembly is positioned as illustrated below by the advance signals from the ECM, the resultant oil pressure is applied to the timing advance side vane chamber to rotate the camshaft in the timing advance direction:

*1 Vane *2 ECM *a Intake Side *b Exhaust Side *c Rotation Direction *d Oil Pressure *e In *f Drain -

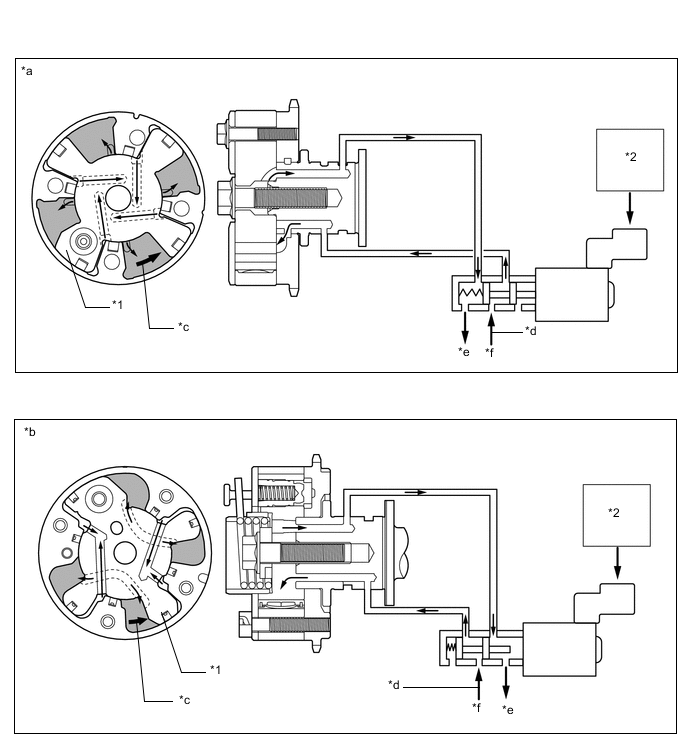

When the camshaft timing oil control valve assembly is positioned as illustrated below by the retard signals from the ECM, the resultant oil pressure is applied to the timing retard side vane chamber to rotate the camshaft in the timing retard direction:

*1 Vane *2 ECM *a Intake Side *b Exhaust Side *c Rotation Direction *d Oil Pressure *e Drain *f In -

After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve assembly in the neutral position unless the traveling state changes. This adjusts the valve timing at the desired target position and prevents the engine oil from running out.

-