SMART ENTRY AND START SYSTEM (for Start Function), Diagnostic DTC:B2286, P0335

| DTC Code | DTC Name |

|---|---|

| B2286 | Runnable Signal Malfunction |

| P0335 | Crankshaft Position Sensor Circuit Malfunction (NE Signal) |

DESCRIPTION

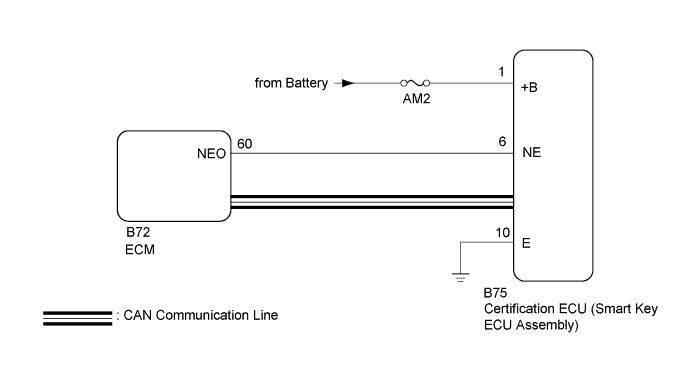

These DTCs are stored when the engine speed signal sent by the ECM via direct line and the engine speed signal sent via CAN communication do not match.

Tech Tips

When the cable is disconnected and reconnected to the negative (-) battery terminal, the power source mode returns to the state it was in before the cable was disconnected.

| DTC Code | DTC Detection Condition | Trouble Area | DTC Output Confirmation Operation |

|---|---|---|---|

| B2286 | The engine speed signal sent by the ECM via direct line and the engine speed signal sent via CAN communication (1-trip detection logic*) do not match. |

|

Disconnect the cable from the negative (-) battery terminal, wait 30 seconds and reconnect the cable to the negative (-) battery terminal. Wait 20 seconds or more with the engine switch off, and then start the engine and maintain an engine speed of 1000 rpm or more for 20 seconds or more. |

| P0335 | The engine speed signal sent by the ECM via direct line and the engine speed signal sent via CAN communication (1-trip detection logic*) do not match. |

|

Allow the engine to idle for 10 seconds or more. |

-

*: Only detected while a malfunction is present and the engine switch is on (IG)

| Vehicle Condition when Malfunction Detected | Fail-safe Function when Malfunction Detected |

|---|---|

|

|

| DTC | Data List Item | Active Test Item |

|---|---|---|

| B2286 P0335 |

Power Source Control

Starting Control |

- |

WIRING DIAGRAM

INSPECTION PROCEDURE

Note

-

When using the GTS with the vehicle engine switch off, connect the GTS to the vehicle and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the GTS and the vehicle begins. Then select the Model Code "KEY REGIST" under manual mode and enter the following menus: Body Electrical / Entry & Start(CAN). While using the GTS, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the GTS and the vehicle.

-

The smart entry and start system (for Start Function) uses a multiplex communication system (LIN communication system) and the CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting Click here. Troubleshoot the smart entry and start system (for Start Function) after confirming that the communication systems are functioning properly.

-

Before replacing the certification ECU (smart key ECU assembly) or ECM, refer to the smart entry and start system (for Start Function) precaution Click here.

-

Inspect the fuses of circuits related to this system before performing the following inspection procedure.

-

After performing repairs, perform the operation that fulfills the DTC output confirmation operation, and then confirm that no DTCs are output again.

PROCEDURE

-

READ VALUE USING GTS (ENGINE CONDITION, ENGINE SPEED)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Power Source Control or Starting Control / Data List.

-

According to the display on the GTS, read the Data List.

Power Source Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Engine Condition Engine state/Stop or Run Stop: Engine stopped

Run: Engine running

- Starting Control Tester Display Measurement Item/Range Normal Condition Diagnostic Note Engine Speed Engine speed/0 to 16383 r/min Fluctuates in accordance with engine speed - OK The Data List item changes in accordance with the engine condition.

NG

GO TO ECD SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (POWER SOURCE) Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR IN CIRCUIT CONNECTED TO POWER SOURCE

OK

-

CHECK HARNESS AND CONNECTOR (GROUND) Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ECM)

-

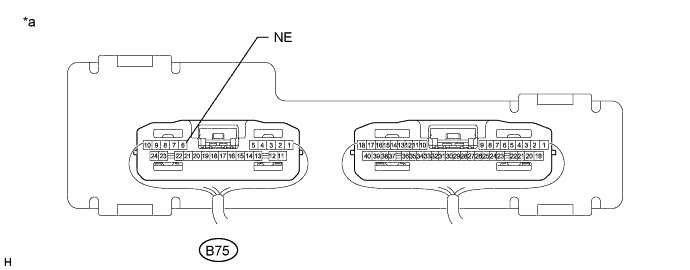

Disconnect the B75 certification ECU (smart key ECU assembly) connector.

-

Disconnect the B72 the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition B75-6 (NE) - B72-60 (NEO) Always Below 1 Ω B75-6 (NE) or B72-60 (NEO) - Body ground 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

-

Reconnect the B75 certification ECU (smart key ECU assembly) connector.

-

Reconnect the B72 ECM connector.

-

Check the engine speed input signal waveform at the terminal of the certification ECU.

Text in Illustration *a Component with harness connected

(Certification ECU (Smart Key ECU Assembly))

- - Standard Frequency Tester Connection Condition Specified Condition B75-6 (NE) - Body ground Engine stopped No pulse generated Engine running Pulse generated

NG

GO TO ECD SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) Click here

OK

REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

-