SFI SYSTEM (w/ Dual VVT-i), Diagnostic DTC:P0102, P0103

| DTC Code | DTC Name |

|---|---|

| P0102 | Mass Air Flow Circuit Low |

| P0103 | Mass Air Flow Circuit High |

DESCRIPTION

The mass air flow meter is a sensor that measures the amount of air flowing through the throttle valve.

The ECM uses this information to determine the fuel injection time and to provide the appropriate air-fuel ratio.

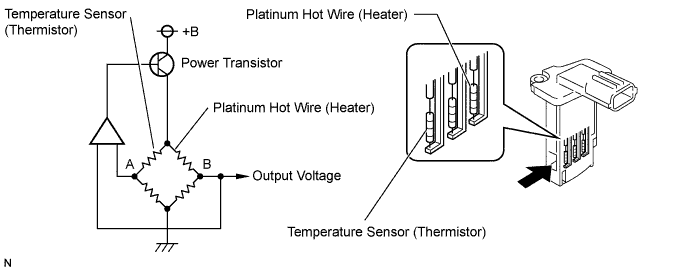

Inside the mass air flow meter, there is a heated platinum wire which is exposed to the flow of intake air.

By applying a specific electrical current to the wire, the ECM heats it to a given temperature. The flow of incoming air cools both the wire and an internal thermistor, affecting their resistance. To maintain a constant current value, the ECM varies the voltage applied to the wire and internal thermistor. The voltage level is proportional to the airflow through the sensor, and the ECM uses it to calculate the intake air volume.

The circuit is constructed so that the platinum hot wire and temperature sensor create a bridge circuit, and the power transistor is controlled so that the potentials of A and B remain equal to maintain the predetermined temperature.

Tech Tips

When either of these DTCs is stored, the ECM enters fail-safe mode. During fail-safe mode, the ignition timing is calculated by the ECM according to the engine speed and throttle valve position. The ECM continues operating in fail-safe mode until a pass condition is detected.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0102 | Mass air flow meter voltage is below 0.2 V for 3 seconds (1 trip detection logic). |

|

| P0103 | Mass air flow meter voltage is higher than 4.9 V for 3 seconds (1 trip detection logic). |

|

Tech Tips

When either of these DTCs is stored, check the air flow rate by entering the following menus: Powertrain / Engine and ECT / Data List / All Data / MAF.

| MAF (gm/sec) | Malfunction |

|---|---|

| Approximately 0.0 |

|

| 160.0 or more | Open in E2G circuit |

MONITOR DESCRIPTION

If there is a defect in the mass air flow meter or an open or short circuit, the voltage level deviates from the normal operating range. The ECM interprets this deviation as a malfunction in the mass air flow meter and stores a DTC.

Example:

When the sensor output voltage remains below 0.2 V, or higher than 4.9 V for more than 3 seconds, the ECM stores a DTC.

If the malfunction is not repaired successfully, a DTC is stored 3 seconds after the engine is next started.

MONITOR STRATEGY

| Frequency of Operation | Continuous |

CONFIRMATION DRIVING PATTERN

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

-

Turn the ignition switch off and wait for at least 30 seconds.

-

Turn the ignition switch to ON and turn the GTS on.

-

Wait 5 seconds or more.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the pending DTCs.

Tech Tips

-

If a pending DTC is output, the system is malfunctioning.

-

If a pending DTC is not output, perform the following procedure.

-

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

-

Input the DTC: P0102, P0103.

-

Check the DTC judgment result.

GTS Display Description NORMAL

-

DTC judgment completed

-

System normal

ABNORMAL

-

DTC judgment completed

-

System abnormal

INCOMPLETE

-

DTC judgment completed

-

Perform driving pattern after confirming DTC enabling conditions

N/A

-

Unable to perform DTC judgment

-

Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

Tech Tips

-

If the judgment result shows NORMAL, the system is normal.

-

If the judgment result shows ABNORMAL, the system has a malfunction.

-

If the judgment result shows INCOMPLETE or N/A, perform the Confirmation Driving Pattern and check the DTC judgment result again.

-

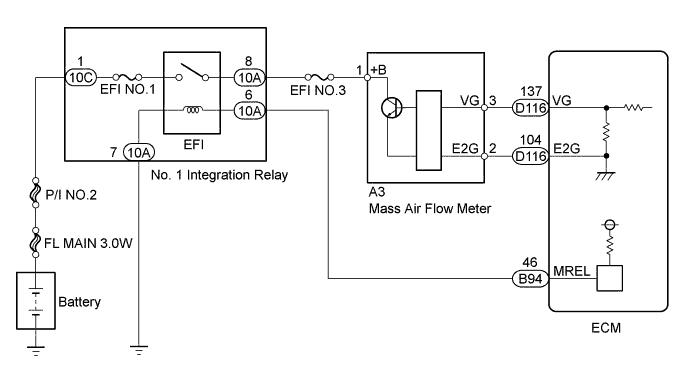

WIRING DIAGRAM

INSPECTION PROCEDURE

Note

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

Tech Tips

Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

-

READ DTC OUTPUT

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read DTCs.

Result Result Proceed to DTC P0102 is output A DTC P0103 is output B

B

CHECK HARNESS AND CONNECTOR (SENSOR GROUND) Click here

A

-

-

INSPECT MASS AIR FLOW METER (POWER SOURCE VOLTAGE)

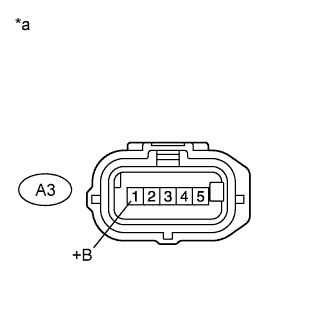

Text in Illustration *a Front view of wire harness connector

(to Mass Air Flow Meter)

-

Disconnect the mass air flow meter connector.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition A3-1 (+B) - Body ground Ignition switch ON 11 to 14 V

NG

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - NO. 1 INTEGRATION RELAY) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

-

Disconnect the mass air flow meter connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A3-3 (VG) - D116-137 (VG) Always Below 1 Ω A3-2 (E2G) - D116-104 (E2G) Always Below 1 Ω A3-3 (VG) or D116-137 (VG) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT MASS AIR FLOW METER

-

Inspect the mass air flow meter Click here.

Tech Tips

Perform "Inspection After Repair" after replacing the mass air flow meter Click here.

NG

REPLACE MASS AIR FLOW METER Click here

OK

REPLACE ECM Click here

-

-

CHECK HARNESS AND CONNECTOR (SENSOR GROUND)

-

Disconnect the mass air flow meter connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A3-2 (E2G) - Body ground Always Below 1 Ω Tech Tips

Perform "Inspection After Repair" after replacing the mass air flow meter Click here.

NG

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) Click here

OK

REPLACE MASS AIR FLOW METER Click here

-

-

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

-

Disconnect the mass air flow meter connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A3-2 (E2G) - D116-104 (E2G) Always Below 1 Ω

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

REPLACE ECM Click here

-

-

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - NO. 1 INTEGRATION RELAY)

-

Disconnect the mass air flow meter connector.

-

Remove the No. 1 integration relay from the No. 1 engine room relay block.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A3-1 (+B) - 10A-8 Always Below 1 Ω A3-1 (+B) or 10A-8 - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

CHECK ECM POWER SOURCE CIRCUIT Click here

-