ECD SYSTEM(for DPF) Intake/Exhaust System

CAUTION / NOTICE / HINT

Note

-

After replacing the ECM, the new ECM needs registration (See page ) and initialization Click here.

-

After replacing the fuel supply pump assembly, the ECM needs initialization Click here.

-

After replacing an injector assembly, the ECM needs registration Click here.

PROCEDURE

-

TAKE SNAPSHOT DURING IDLING AND 4000 RPM (PROCEDURE 1)

-

Connect the intelligent tester to the DLC3.

-

Start the engine and turn the tester on.

-

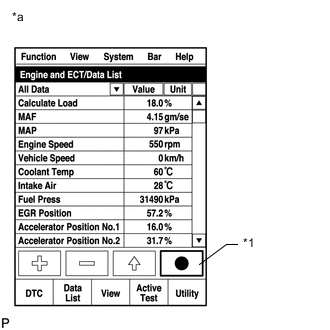

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data.

-

Text in Illustration *1 Snapshot Button *a Reference Take a snapshot of the following Data List items.

Tech Tips

-

A snapshot can be used to compare vehicle data from the time of the malfunction to normal data and is very useful for troubleshooting. The data in the list below is that of a normal vehicle, but as the data varies between individual vehicles, this data should only be used for reference.

-

Graphs like the ones shown below can be displayed by transferring the stored snapshot data from the tester to a PC (Personal Computer). Intelligent Viewer must be installed on the PC.

-

Check the Data List at idling and at 4000 rpm with no load after the engine is warmed up.

-

NEXT

-

-

READ VALUE USING INTELLIGENT TESTER (MAP AND MAF)

-

Check MAP and MAF in the snapshot taken in procedure 1 when the engine was running at 4000 rpm with no load.

Result Result Proceed to MAP is below 90 kPa*1 A MAP is 140 kPa or more and MAF is 85 gm/s or more*2 B Except above*3 C Tech Tips

The above values were measured under standard atmospheric pressure. The value are influenced by elevation, weather conditions, etc.

Standard atmospheric pressure is 101 kPa (1.0 kgf/cm2, 15 psi). For every 100 m (328 ft.) increase in elevation, pressure drops by 1 kPa (0.01 kgf/cm2, 0.1 psi). This varies by weather.

*1: There may be a problem in the turbocharger system.

*2: There may be a problem in the fuel system or intake system.

*3: There may be a problem in intake system or a problem with the EGR valve (valve stuck open or valve does not close).

B

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

C

CHECK AIR INTAKE SYSTEM Click here

A

-

-

READ VALUE USING INTELLIGENT TESTER (MAP AND ATMOSPHERE PRESSURE)

-

Connect the intelligent tester to the DLC3.

-

Start the engine and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / MAP and Atmosphere Pressure.

-

Compare MAP and Atmosphere Pressure when the ignition switch ON (do not start the engine).

Standard Difference between MAP and Atmosphere Pressure is less than 8 kPa. Tech Tips

-

If MAP and Atmosphere Pressure have the same value, both are normal. If there is a difference of 10 kPa or more, compare the values to the atmospheric pressure for that day. The sensor whose deviation is the greatest is malfunctioning.

-

Standard atmospheric pressure is 101 kPa (1.0 kgf/cm2, 15 psi). For every 100 m (328 ft.) increase in elevation, pressure drops by 1 kPa (0.01 kgf/cm2, 0.1 psi). This varies by weather.

Result Result Proceed to MAP and Atmosphere Pressure have same value A MAP is different from actual atmospheric pressure B Atmosphere Pressure is different from actual atmospheric pressure C -

B

REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR Click here

C

REPLACE ECM Click here

A

-

-

CHECK AIR INTAKE SYSTEM

-

Check for air leaks and blockages between the air cleaner case and turbocharger sub-assembly, and between the turbocharger sub-assembly and intake manifold.

Result Result Proceed to No leaks or blockages in the intake system A Leaks and/or blockages exist in the intake system B Tech Tips

-

Inspect the air intake system, especially hoses and pipes between the air cleaner and turbocharger sub-assembly.

-

Check for abnormal disconnections, pipe and hose squashing, and any damage in the intake system.

-

Using your hand, check whether the pipes and hoses in the intake system are securely connected.

-

By applying soapy water and revving up the engine, air leaks from the intake system can be checked by checking for bubbles.

-

Make sure that the hose between the manifold absolute pressure sensor and intake manifold is not loose or disconnected.

-

Check for any modifications in the intake system made by the user.

-

B

REPAIR OR REPLACE AIR INTAKE SYSTEM Click here

A

-

-

INSPECT TURBOCHARGER SUB-ASSEMBLY

-

Inspect the turbocharger sub-assembly Click here.

NG

REPLACE TURBOCHARGER SUB-ASSEMBLY Click here

OK

-

-

CHECK FOR INTERMITTENT PROBLEMS

-

Check for intermittent problems Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE MANIFOLD ABSOLUTE PRESSURE SENSOR

-

Replace the manifold absolute pressure sensor .

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPAIR OR REPLACE AIR INTAKE SYSTEM

-

Repair or replace the malfunctioning part in the air intake system.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE TURBOCHARGER SUB-ASSEMBLY

-

Replace the turbocharger sub-assembly Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

CHECK AIR INTAKE SYSTEM

-

Check for air leaks and blockages between the air cleaner case and turbocharger sub-assembly, and between the turbocharger sub-assembly and intake manifold.

Result Result Proceed to No leaks or blockages in the intake system A Leaks and/or blockages exist in the intake system B Tech Tips

-

Inspect the air intake system, especially hoses and pipes between the air cleaner and turbocharger sub-assembly.

-

Check for abnormal disconnections, pipe and hose squashing, and any damage in the intake system.

-

Using your hand, check whether the pipes and hoses in the intake system are securely connected.

-

By applying soapy water and revving up the engine, air leaks from the intake system can be checked by checking for bubbles.

-

Make sure that the hose between the manifold absolute pressure sensor and intake manifold is not loose or disconnected.

-

Check for any modifications in the intake system made by the user.

-

B

REPAIR OR REPLACE AIR INTAKE SYSTEM Click here

A

-

-

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ACTIVATE THE EGR VALVE CLOSE)

-

Connect the intelligent tester to the DLC3.

-

Start the engine and warm it up, and make sure the A/C switch and all accessory switches are off.

-

Turn the ignition switch off. Wait for 30 seconds, and then restart the engine.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

-

Read the MAF value displayed on the tester while the engine is idling.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the EGR Valve Close.

-

Read the MAF value when the EGR valve is closed using the Active Test function.

Tech Tips

-

If idling continues for 20 minutes or more, the EGR valve target opening angle becomes 0% (EGR valve fully closed). As this makes diagnosis impossible, it becomes necessary to drive the vehicle or restart the engine.

-

Before performing the diagnosis, confirm that the EGR valve target opening angle is not 0%.

Result Active Test Result Proceed to Activate the EGR Valve Close:

Off (Open) to On (Closed)

MAF value does not change B MAF value changes A Note

As the measured values may differ from those shown below due to factors such as differences in measuring environments and changes in vehicle condition due to aging, do not use these values to determine whether the vehicle is malfunctioning or not.

Tech Tips

The problem may be a temporary one, due to the entry of deposits or foreign matter. Check that there are no deposits or foreign matter in the electric EGR control valve assembly or mass air flow meter.

Reference EGR Valve Condition (Opening) Measuring Condition MAF (Reference) Open (67%)

-

Atmosphere pressure: 101 kPa

-

Intake air temperature: 30°C (86°F)

-

Engine coolant temperature: 88°C (190°F)

3 to 12 gm/s Closed (0%) 7 gm/s or more -

B

READ VALUE USING INTELLIGENT TESTER (MAF) Click here

A

-

-

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ACTIVATE THE VSV FOR EGR COOLER BYPASS)

-

Connect the intelligent tester to the DLC3.

-

Start the engine and warm it up, and make sure the A/C switch and all accessory switches are off.

-

Turn the ignition switch off and wait for 30 seconds.

-

Start the engine and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

-

Read the MAF value displayed on the tester while the engine is idling.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for EGR Cooler Bypass / Data List / EGR Cooler Bypass Position.

Tech Tips

Whether the EGR is passing through the bypass side or cooler side during the Active Test can be confirmed by checking EGR Cooler Bypass Position.

-

Using the Active Test function, switch the EGR valve bypass switching valve between "Cooler" and "Bypass" a few times, and then check whether the MAF value changes after switching the valve from "Cooler" to "Bypass".

Tech Tips

If idling continues for 20 minutes or more, the EGR valve target opening angle becomes 0% (EGR valve fully closed). As this makes diagnosis impossible, it becomes necessary to drive the vehicle or restart the engine.

Result Tester Display Result Proceed to Activate the VSV for EGR Cooler Bypass:

Cooler to Bypass

MAF value does not change A MAF value changes B Tech Tips

If the EGR cooler is clogged, the mass air flow changes.

A

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

B

REPLACE EGR COOLER Click here

-

-

REPAIR OR REPLACE AIR INTAKE SYSTEM

-

Repair or replace the malfunctioning part in the air intake system.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

READ VALUE USING INTELLIGENT TESTER (MAF)

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

-

With the ignition switch ON and engine stopped, read the value when 30 seconds has elapsed.

Standard Tester Display Switch Condition Standard MAF Ignition switch ON (do not start engine) Less than 0.3 gm/s

NG

REPLACE MASS AIR FLOW METER Click here

OK

-

-

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (ACTIVATE THE VSV FOR EGR COOLER BYPASS)

-

Connect the intelligent tester to the DLC3.

-

Start the engine and warm it up, and make sure the A/C switch and all accessory switches are off.

-

Turn the ignition switch off and wait for 30 seconds.

-

Start the engine and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / MAF.

-

Read the MAF value displayed on the tester while the engine is idling.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VSV for EGR Cooler Bypass / Data List / EGR Cooler Bypass Position.

Tech Tips

Whether the EGR is passing through the bypass side or cooler side during the Active Test can be confirmed by checking EGR Cooler Bypass Position.

-

Using the Active Test function, switch the EGR valve bypass switching valve between "Cooler" and "Bypass" a few times, and then check whether the MAF value changes after switching the valve from "Cooler" to "Bypass".

Tech Tips

If idling continues for 20 minutes or more, the EGR valve target opening angle becomes 0% (EGR valve fully closed). As this makes diagnosis impossible, it becomes necessary to drive the vehicle or restart the engine.

Result Tester Display Result Proceed to Activate the VSV for EGR Cooler Bypass:

Cooler to Bypass

MAF value does not change A MAF value changes B Tech Tips

If the EGR cooler is clogged, the mass air flow changes.

B

REPLACE EGR COOLER Click here

A

-

-

CHECK FOR DEPOSIT (ELECTRIC EGR CONTROL VALVE ASSEMBLY)

-

Remove the electric EGR control valve assembly Click here.

-

Visually check the electric EGR control valve assembly for deposits.

If there are deposits, clean the electric EGR control valve assembly.

Note

-

When cleaning the electric EGR control valve assembly, make sure the valve is completely closed.

-

When cleaning the electric EGR control valve assembly, perform initialization procedure Click here.

-

Do not forcibly open the valve, as it may be damaged or deformed.

-

When cleaning the electric EGR control valve assembly, use a piece of cloth soaked with cleaning solvent. Spraying the solvent directly onto these parts or soaking the parts in the solvent may damage the parts.

Tech Tips

-

If the EGR valve does not open properly or is stuck closed, the amount of intake air increases and combustion sounds and engine vibration may increase.

-

If the EGR valve does not close properly or is stuck open, EGR becomes excessive and combustion becomes unstable. Also, there may be a lack of power.

-

-

Reinstall the electric EGR control valve assembly Click here.

NEXT

-

-

REPLACE EGR COOLER

-

Replace the EGR cooler Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE MASS AIR FLOW METER

-

Replace the mass air flow meter Click here.

Tech Tips

If foreign matter is stuck inside the mass air flow meter, the output characteristics of the mass air flow meter may change, resulting in a malfunction.

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

NEXT

END