ТОПЛИВНАЯ ФОРСУНКА УСТАНОВКА

Tech Tips

Perform "Inspection After Repairs" after replacing the fuel injector assembly Click here.

-

INSTALL FUEL INJECTOR ASSEMBLY

Tech Tips

Perform "Inspection After Repairs" after replacing the fuel injector assembly Click here.

-

Apply a light coat of gasoline or spindle oil to new O-rings, and then install one onto each fuel injector assembly.

-

Apply a light coat of gasoline or spindle oil to the contact surfaces of the fuel delivery pipe sub-assembly and the O-ring of the fuel injector assembly.

-

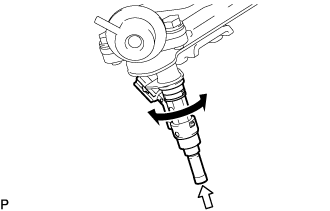

Apply a light coat of gasoline or spindle oil to the O-ring again, and then install the fuel injector assembly into the fuel delivery pipe sub-assembly by turning it right and left.

Text in Illustration

Turn

Push Note

-

Be careful not to twist the O-ring.

-

After installing the fuel injector assembly, check that it turns smoothly. If not, reinstall it with a new O-ring.

-

-

-

INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

-

Apply a light coat of gasoline or spindle oil to new O-rings and install them to the injector spacers.

Note

Make sure that the O-rings are installed between the parts correctly.

-

Install the 4 injector spacers to the cylinder head sub-assembly.

-

Install 4 new injector vibration insulators to the cylinder head sub-assembly.

-

Install the 2 No. 1 delivery pipe spacers to the cylinder head sub-assembly.

-

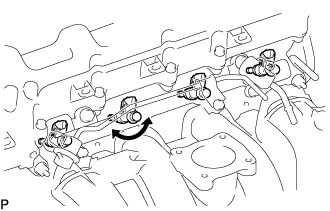

Temporarily install the fuel delivery pipe sub-assembly together with the 4 fuel injector assemblies with the 2 bolts.

Note

-

Do not drop the fuel injector assemblies when installing the fuel delivery pipe sub-assembly.

-

Make sure that the fuel injector assembly turns smoothly.

-

-

Tighten the 2 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Apply a light coat of gasoline or spindle oil to a new O-ring.

-

Install the fuel pressure pulsation damper assembly with the 2 bolts.

- Torque:

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

Connect the 4 fuel injector connectors.

-

Connect the No. 2 fuel hose to the fuel pressure regulator assembly, and slide the clamp to secure the hose.

-

Connect the vacuum hose to the fuel pressure regulator assembly.

-

-

INSTALL NO. 1 FUEL HOSE

-

Connect the No. 1 fuel hose to the fuel pressure pulsation damper assembly Click here.

-

-

INSTALL THROTTLE BODY ASSEMBLY

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

INSPECT FOR FUEL LEAK

-

Make sure that there are no fuel leaks after performing maintenance on the fuel system.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

-

Check that there are no fuel leaks from the fuel system.

If there are fuel leaks, repair or replace parts as necessary.

-

Turn the ignition switch off.

-

Disconnect the GTS from the DLC3.

-

-