ENGINE ASSEMBLY INSTALLATION

CAUTION / NOTICE / HINT

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

PROCEDURE

INSTALL ENGINE HANGER

REMOVE ENGINE FROM ENGINE STAND

Remove the engine assembly from the engine stand.

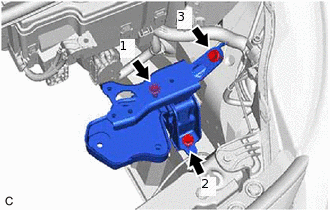

INSTALL ENGINE MOUNTING INSULATOR LH

Tip:

Tip:Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

Temporarily install the engine mounting insulator LH with the 3 bolts.

Fully tighten the 3 bolts in the order shown in the illustration.

52 N*m

530 kgf*cm

38 ft.*lbf

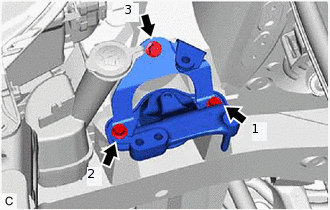

INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

Tip:

Tip:Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

Temporarily install the engine mounting insulator sub-assembly RH with the 3 bolts.

Fully tighten the 3 bolts in the order shown in the illustration.

30 N*m

306 kgf*cm

22 ft.*lbf

INSTALL CLUTCH DISC ASSEMBLY

INSTALL CLUTCH COVER ASSEMBLY

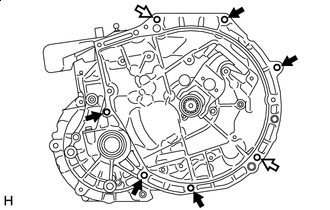

INSTALL ENGINE ASSEMBLY

-

Bolt

Nut

Align the input shaft with the clutch disc assembly and install the engine assembly to the manual transaxle.

Install the 5 bolts and 2 nuts.

Bolt

55 N*m

561 kgf*cm

41 ft.*lbf

Nut

55 N*m

561 kgf*cm

41 ft.*lbf

Note:Insert knock pins into the knock pin holes securely so that the end face of the transaxle fits close against the engine before tightening the bolts.

-

INSTALL STARTER ASSEMBLY

INSTALL ENGINE WIRE

Install the engine wire to the engine assembly.

INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

Set the engine assembly with transaxle on an engine lifter.

Note:Using height adjustment attachments and plate lift attachments, place the engine assembly with transaxle horizontally.

Operate the engine lifter and lift the engine assembly with transaxle to the position where the engine mounting insulator sub-assembly RH and engine mounting insulator LH can be installed.

CAUTION:Do not raise the engine assembly with transaxle more than necessary. If the engine assembly with transaxle is raised excessively, the vehicle may also be lifted up.

Note:Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

While raising the engine assembly with transaxle into the vehicle, do not allow it to contact the vehicle.

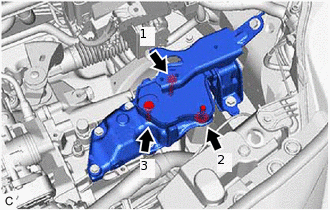

-

Temporarily install the engine mounting insulator LH with the 3 bolts.

Fully tighten the 3 bolts in the order shown in the illustration.

52 N*m

530 kgf*cm

38 ft.*lbf

Install the engine mounting insulator sub-assembly RH with the 3 nuts.

30 N*m

306 kgf*cm

22 ft.*lbf

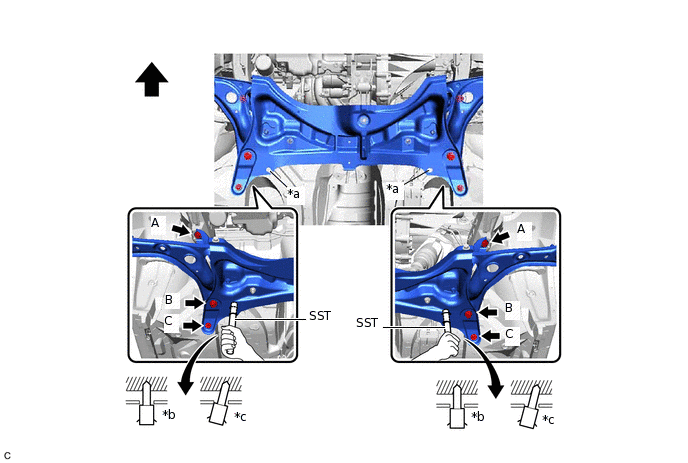

By inserting SST into the datum holes in the front suspension crossmember RH and LH alternately, tighten the bolts (A), (B) and (C) on both sides to the specified torque in several steps.

*a

Datum Hole

*b

Correct

*c

Incorrect

-

-

Front of the Vehicle

-

-

09670-00011

Bolt (A)

85 N*m

867 kgf*cm

63 ft.*lbf

Bolt (B)

134 N*m

1366 kgf*cm

99 ft.*lbf

Bolt (C)

48 N*m

489 kgf*cm

35 ft.*lbf

Note:Insert SST into the datum hole vertically.

If impossible to insert SST vertically, loosen all bolts and then insert SST again.

Lower the engine lifter.

REMOVE ENGINE HANGER

INSTALL FRONT EXHAUST PIPE ASSEMBLY

INSTALL FRONT DRIVE SHAFT ASSEMBLY

INSTALL NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

INSTALL NO. 2 STEERING INTERMEDIATE SHAFT ASSEMBLY

INSTALL STEERING COLUMN HOLE COVER PLATE

CONNECT CLUTCH RELEASE CABLE ASSEMBLY

INSPECT AND ADJUST CLUTCH PEDAL HEIGHT

for LHD:Click here

for RHD:Click here

CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

INSTALL INTAKE MANIFOLD

CONNECT ENGINE WIRE

Connect the No. 3 engine wire to the vehicle body with bolt.

8.4 N*m

86 kgf*cm

74 in.*lbf

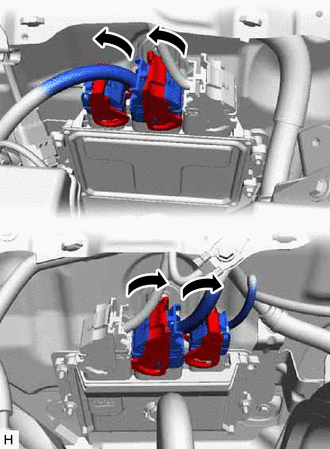

Engage the 2 claws and connect the wire harness to the No. 1 engine room relay block.

Install the nut.

8.4 N*m

86 kgf*cm

74 in.*lbf

Connect the 2 connectors to the No. 1 engine room relay block.

Install the No. 1 engine room relay block cover.

-

Connect the ECM connector and lower the lever.

Note:When connecting the ECM connector, make sure that dirt, water or other foreign matter does not contact the connecting parts of the ECM connector.

Be sure to securely connect the ECM connector.

INSTALL RADIATOR RESERVE TANK ASSEMBLY

Connect the No. 5 water by-pass hose from the No. 1 water by-pass pipe.

Connect the No. 5 water by-pass hose from the radiator reserve tank assembly.

Connect the water by-pass hose from the radiator reserve tank assembly.

-

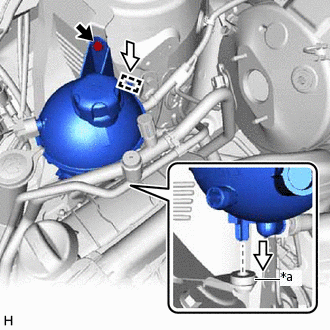

*a

Grommet

Install the radiator reserve tank assembly and engage the guide and grommet as shown in the illustration.

Install the bolt to secure the radiator reserve tank assembly.

7.5 N*m

76 kgf*cm

66 in.*lbf

CONNECT NO. 1 RADIATOR HOSE

CONNECT INLET HEATER WATER HOSE

CONNECT OUTLET HEATER WATER HOSE

INSTALL WITH MAGNET CLUTCH COMPRESSOR (w/ Air Conditioning System)

Temporarily install the compressor assembly with pulley with the 3 bolts.

Fully tighten the 3 bolts.

25 N*m

255 kgf*cm

18 ft.*lbf

Connect the connector.

INSTALL GENERATOR ASSEMBLY

INSTALL FAN AND GENERATOR V BELT

INSPECT FAN AND GENERATOR V BELT

INSTALL BATTERY CLAMP SUB-ASSEMBLY

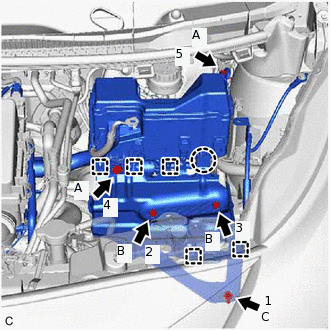

-

Engage the claw and install the battery clamp sub-assembly to the No. 1 engine room relay block.

Install the battery clamp sub-assembly with the 5 bolts in the order shown in the illustration.

Bolt (A)

8.4 N*m

86 kgf*cm

74 in.*lbf

Bolt (B)

7.4 N*m

75 kgf*cm

65 in.*lbf

Bolt (C)

17.2 N*m

175 kgf*cm

13 ft.*lbf

Engage the 5 wire harness clamps and connect the wire harness to the battery clamp sub-assembly.

-

INSTALL BATTERY

Install the battery to the battery clamp sub-assembly.

Install the No.2 battery clamp to the battery clamp sub-assembly with the bolt.

15.1 N*m

154 kgf*cm

11 ft.*lbf

Engage the 2 claws to connect the engine room main wire to the engine wire.

Install the engine room main wire with engine wire to the positive (+) battery terminal with the nut.

7.6 N*m

77 kgf*cm

67 in.*lbf

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

INSTALL OUTER COWL TOP PANEL

for LHD:Click here

for RHD:Click here

INSTALL FRONT AIR SHUTTER SEAL RH

for LHD:Click here

for RHD:Click here

INSTALL FRONT NO. 1 VENTILATOR SEAL

for LHD:Click here

for RHD:Click here

INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Connect the cable to the negative (-) battery terminal.

5.4 N*m

55 kgf*cm

48 in.*lbf

Note:When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

ADD ENGINE OIL

ADD ENGINE COOLANT

ADD MANUAL TRANSAXLE OIL

CHECK ENGINE OIL LEVEL

INSPECT AND ADJUST CLUTCH PEDAL SUB-ASSEMBLY

for LHD:Click here

for RHD:Click here

INSPECT FOR FUEL LEAK

INSPECT FOR COOLANT LEAK

INSPECT FOR OIL LEAK

INSPECT FOR EXHAUST GAS LEAK

INSTALL FRONT WHEELS

ADJUST FRONT WHEEL ALIGNMENT

CHECK SPEED SENSOR SIGNAL

w/o VSC:Click here

w/ VSC:Click here