REPAIR INSTRUCTION PRECAUTION

-

BASIC REPAIR HINT

-

HINTS ON OPERATIONS

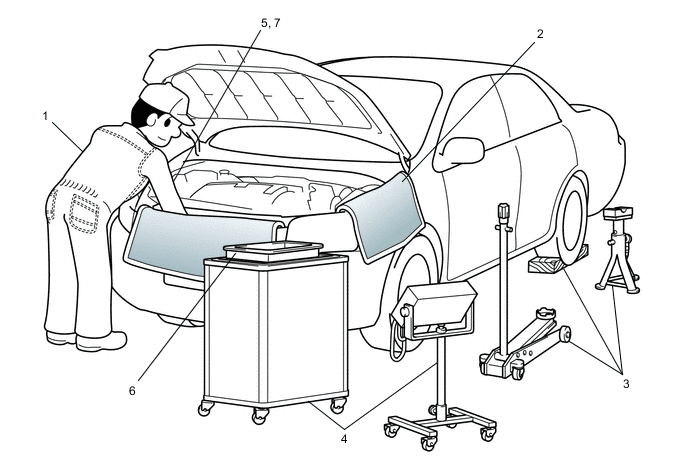

1 Attire

-

Always wear a clean uniform.

-

A hat and safety shoes must be worn.

2 Vehicle protection Prepare a grille cover, fender cover, seat cover and floor mat before starting work. 3 Safety procedures

-

When working with 2 or more persons, be sure to check the safety of one another.

-

When working with the engine running, make sure to provide ventilation for exhaust fumes in the workshop.

-

If working on high temperature, high pressure, rotating, moving or vibrating parts, wear appropriate safety equipment and take extra care not to injure yourself or others.

-

When jacking up the vehicle, be sure to support the vehicle at the specified locations with safety stands.

-

When lifting up the vehicle, use appropriate safety equipment.

4 Preparation of tools and measuring equipment Before starting work, prepare a tool stand, SST, measuring equipment, oil, and any replacement parts required. 5 Removal and installation, disassembly and assembly operations

-

Diagnose with a thorough understanding of proper procedures and of the reported problem.

-

Before removing any parts, check the general condition of the assembly and for deformation and damage.

-

If the procedure is complicated, take notes. For example, note the total number of electrical connections, bolts or hoses removed. Add matchmarks to ensure reassembly of components in the original positions. Temporarily mark hoses and their fittings if needed.

-

Clean and wash the removed parts if necessary and assemble them after a thorough check.

6 Removed parts

-

Place the removed parts in a separate box to avoid mixing them up with new parts or contaminating the new parts.

-

For non-reusable parts such as gaskets, O-rings and self-locking nuts, replace them with new ones as instructed in this manual.

-

Retain the removed parts for customer inspection, if requested.

7* Checks to perform after work is finished

-

Make sure that removed and installed parts (oil filler cap, level dipstick, floor mat, etc.) are properly installed/tightened.

-

Make sure that none of the cloths or tools that were used have been left in the engine compartment or within the vehicle.

-

Check that there are no oil leaks.

CAUTION:

*: Be sure to perform these checks properly, not performing these checks properly after finishing work can lead to a serious accident or injury.

-

-

JACKING UP AND SUPPORTING THE VEHICLE

-

Care must be taken when jacking up and supporting the vehicle. Be sure to lift and support the vehicle at the proper locations.

-

-

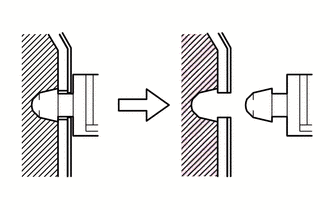

*a Seal Lock Adhesive PRECOATED PARTS

-

Precoated parts are bolts and nuts that are coated with seal lock adhesive at the factory.

-

If a precoated part is retightened, loosened or moved in any way, it must be recoated with the specified adhesive.

-

When reusing a precoated part, clean off the old adhesive and dry the part with compressed air. Then apply new seal lock adhesive appropriately to that part.

-

Some seal lock agents harden slowly. You may have to wait for the seal lock adhesive to harden.

-

-

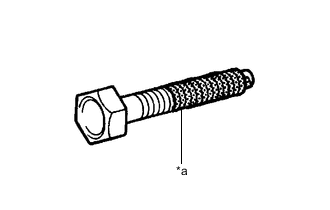

SMALL-HEAD BOLTS

-

*A Example: M6 Bolt *a Ring Mark *b Black Small-head bolts are bolts with a smaller bolt head than standard bolts with the same thread diameter and flange diameter.

-

Although the size of the bolt head is smaller than a standard bolt, the tightening torque remains unchanged as the thread diameter and flange diameter are not different. Make sure to tighten all small-head bolts to the correct torque indicated in the repair manual.

-

As the force applied to the sides of the head of a small-head bolt is higher than that of a standard bolt when the same tightening torque is used, the height of the bolt head has been increased to ensure its strength.

-

For identification purposes, small-head bolts are black and the bolt head is marked with a ring.

-

-

GASKETS

-

When necessary, use a sealer on gaskets to prevent leaks.

-

-

BOLTS, NUTS AND SCREWS

-

Carefully follow all of the specifications for tightening torque. Always use a torque wrench.

-

Make sure that no foreign matter (burrs, paint, etc.) gets trapped under the heads of the bolts and nuts when tightening them.

-

-

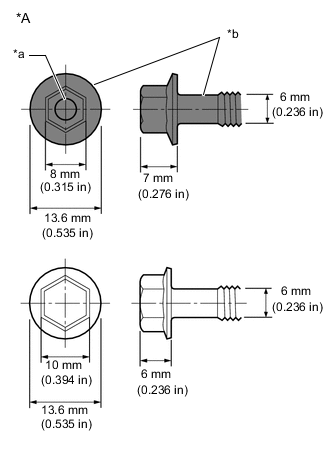

*a NG *b OK FUSES

-

When inspecting a fuse, check that the wire of the fuse is not broken.

-

If the wire of a fuse is broken, confirm that there are no shorts in its circuit.

-

When a fuse is replaced, a fuse with the same amperage rating must be used.

Illustration Symbol Part Name Abbreviation

FUSE FUSE

MEDIUM CURRENT FUSE M-FUSE

HIGH CURRENT FUSE H-FUSE

FUSIBLE LINK FL

CIRCUIT BREAKER CB

FUSIBLE LINK FL

-

-

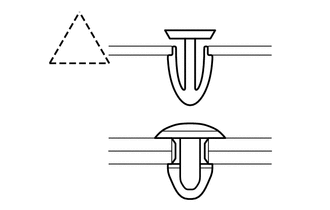

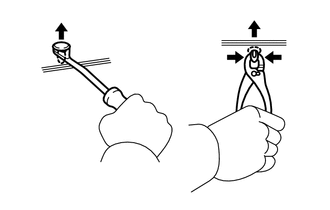

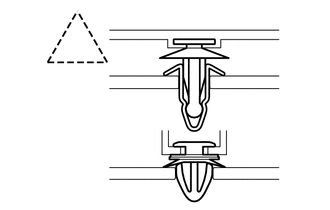

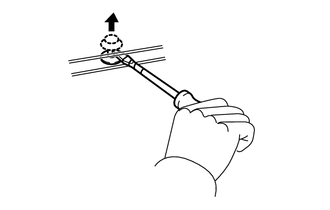

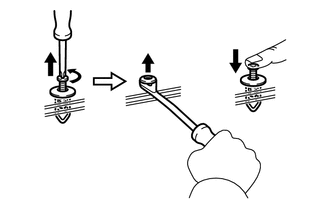

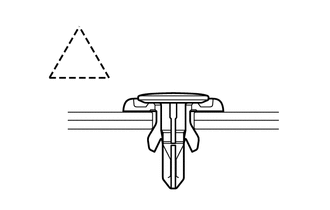

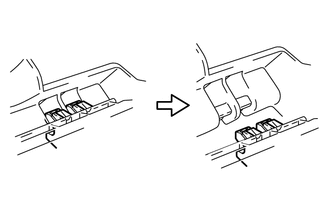

CLIPS

-

The removal and installation methods of typical clips used for vehicle body parts are shown in the table below.

Tech Tips

If clips are damaged during a procedure, always replace the damaged clips with new ones.

Shape (Example) Removal/Installation

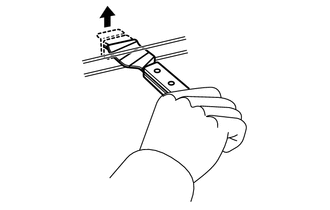

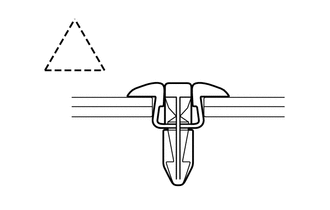

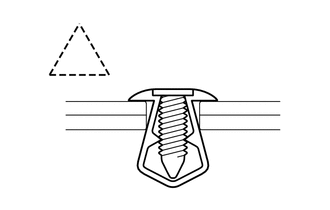

Remove the clips with a clip remover or pliers.

Remove the clips using a clip remover or a screwdriver with its tip wrapped with protective tape.

Remove the clips with a wide scraper to prevent panel damage.

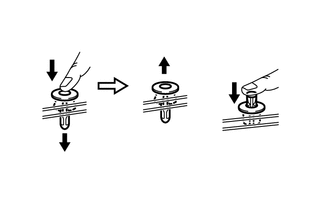

Remove the clips by pushing the center pin through and pulling out the shell.

Remove the clips by unscrewing the center pin and prying out the shell.

Remove the clips by prying out the pin using a screwdriver with its tip wrapped with protective tape and then prying out the shell.

-

-

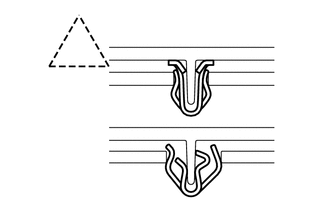

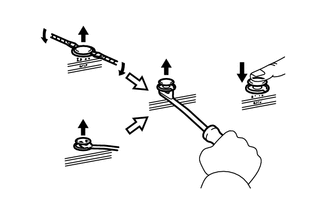

CLAWS

-

The removal and installation methods of typical claws used for vehicle body parts are shown in the table below.

Tech Tips

If claws are damaged during a procedure, always replace the cap or cover that has damaged claws with a new one.

Shape (Example) Illustration / Procedures

Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.

Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.

Disengage the claws using a screwdriver with its tip wrapped with protective tape to remove the caps or covers.

-

-

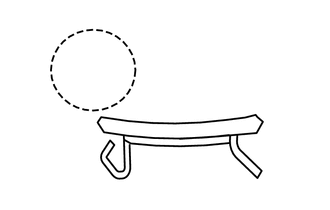

HINGES, GUIDES, CLAMPS, PINS, ETC.

-

The removal and installation methods of typical hinges, guides, clamps and pins used for vehicle body parts are shown in the table below.

Tech Tips

If clamps are damaged during a procedure, always replace the cap or cover that has damaged clamps with a new one.

Shape (Example) Removal/Installation

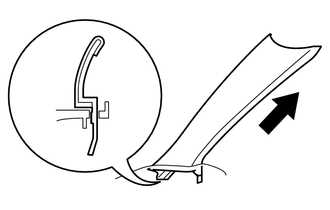

Pull away from the pins to disengage.

Disengage the pins by pulling.

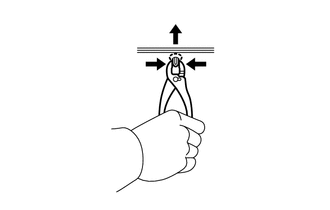

Remove the clamps with pliers.

Disengage the pins by pulling.

-

-

REMOVAL AND INSTALLATION OF VACUUM HOSES

-

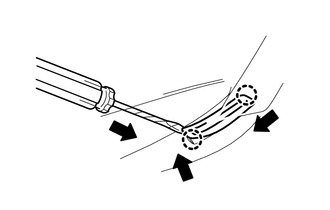

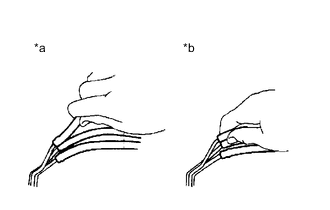

*a Incorrect *b Correct To disconnect a vacuum hose, pull and twist it from the end of the hose. Do not pull it from the middle of the hose as this may damage the hose.

-

When disconnecting vacuum hoses, use tags to identify where they should be reconnected.

-

After completing any hose related repairs, double-check that the vacuum hoses are properly connected. The label under the hood shows the proper layout.

-

When using a vacuum gauge, never force the hose onto a connector that is too large. If a hose has been stretched, air may leak. Use a step-down adapter if necessary.

-

-

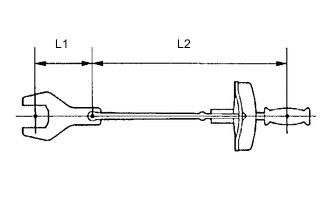

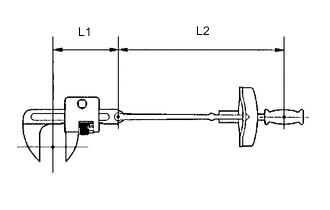

TORQUE WHEN USING TORQUE WRENCH WITH EXTENSION TOOL

-

Use the formula below to calculate special torque values for situations where SST or an extension tool is combined with a torque wrench.

T' Reading of torque wrench (N*m (kgf*cm, ft.*lbf)) T Torque (N*m (kgf*cm, ft.*lbf)) L1 Length of SST or extension tool (cm (in.)) L2 Length of torque wrench (cm (in.)) Note

If an extension tool or SST is combined with a torque wrench and used to tighten to a torque specification in this manual, the actual torque will be excessive and parts will be damaged.

-

-

-

ACTIONS TO BE TAKEN WHEN BATTERIES ARE DISCHARGED

-

Perform this procedure when the battery is fully discharged.

Tech Tips

The following problems indicate that the battery is discharged:

-

No display appears on the instrument panel when the engine switch is turned on (IG).

-

The engine does not start.

-

The headlights are dim.

-

The sound from the horn is weak.

Note

Never use a quick charger.

Tech Tips

The booster terminal cannot be used to rescue a vehicle with a discharged battery.

-

-

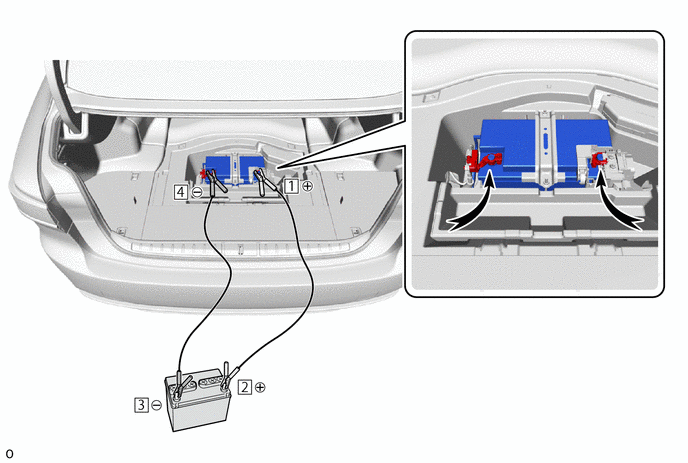

Method connecting booster cables to the battery:

-

Engage the parking brake.

-

Turn the engine switch off and remove the key from the interior detection area.

-

Remove the luggage compartment mat sub-assembly.

-

Using booster cables, connect the battery of the rescue vehicle to the battery of the stalled vehicle as shown in the illustration.

Connecting Sequence Connecting Location 1 Positive (+) battery terminal of stalled vehicle 2 Positive (+) battery terminal of rescue vehicle 3 Negative (-) battery terminal of rescue vehicle 4 Negative (-) battery terminal of stalled vehicle

-

Start the engine of the rescue vehicle and run the engine at a speed slightly higher than usual.

-

Turn the engine switch on.

Note

Once the engine starts, immediately disconnect the booster cable by performing the connection procedure in reverse. Do not leave the booster cables connected because they are not designed for recharging purposes.

-

-

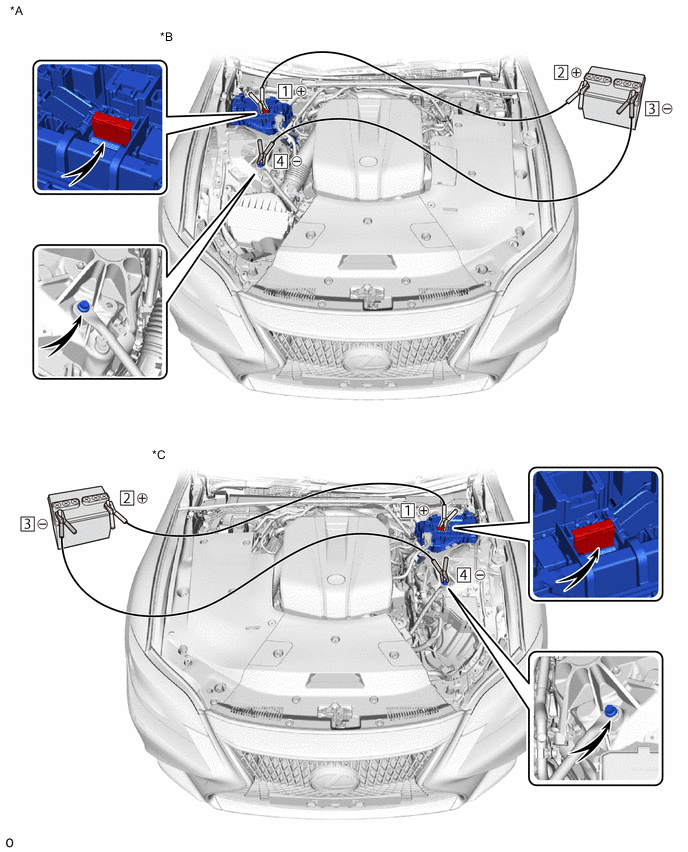

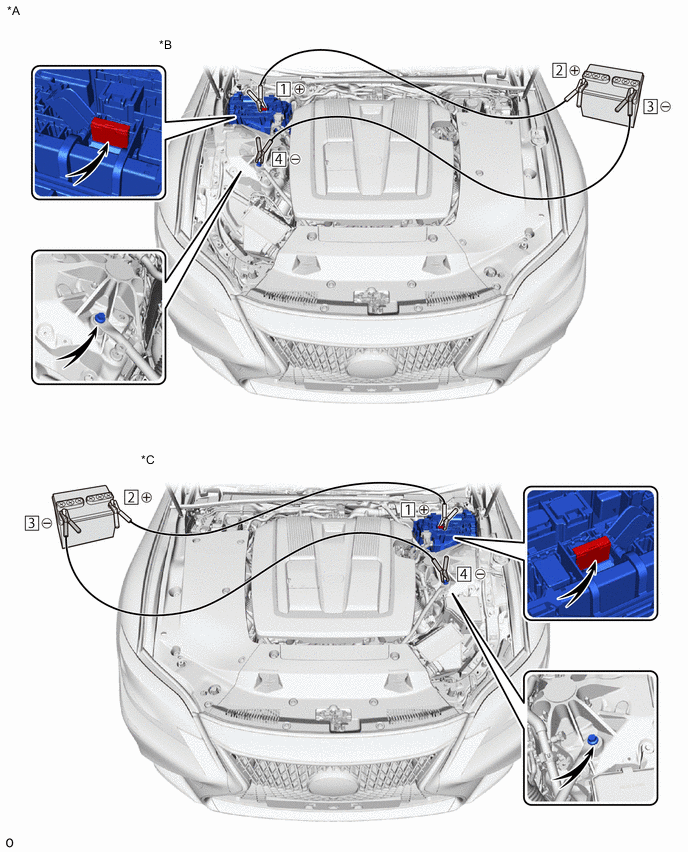

Method connecting booster cables to the positive booster terminal:

-

Engage the parking brake.

-

Turn the engine switch off and remove the key from the interior detection area.

-

for 8GR-FKS:

-

for LHD:

Remove the radiator cover plate.

-

for RHD:

Remove the upper radiator support seal.

-

-

for V35A-FTS:

-

for LHD:

Remove the radiator cover plate.

-

for RHD:

Remove the upper radiator support seal.

-

-

Remove the hood to cowl top seal and the center cowl top ventilator louver.

-

Remove the No. 1 engine room relay block cover.

-

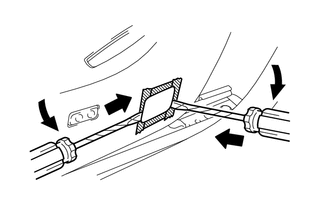

Using booster cables, connect the battery of the rescue vehicle to the battery of the stalled vehicle as shown in the illustration.

Connecting Sequence Connecting Location 1 Positive booster terminal of stalled vehicle 2 Positive (+) battery terminal of rescue vehicle 3 Negative (-) battery terminal of rescue vehicle 4 Position shown in the illustration on stalled vehicle

*A for 8GR-FKS *B for LHD *C for RHD - -

*A for V35A-FTS *B for LHD *C for RHD - - -

Start the engine of the rescue vehicle and run the engine at a speed slightly higher than usual.

-

Turn the engine switch on.

Note

Once the engine starts, immediately disconnect the booster cable by performing the connection procedure in reverse. Do not leave the booster cables connected because they are not designed for recharging purposes.

-

-

-

FOR VEHICLES EQUIPPED WITH SRS AIRBAG AND SEAT BELT PRETENSIONER

This vehicle is equipped with a Supplemental Restraint System (SRS).

CAUTION:

-

Before performing pre-disposal deployment of any SRS parts, review and closely follow all applicable environmental and hazardous material regulations. Pre-disposal deployment may be considered hazardous material treatment.

-

Failure to carry out the service operations in the correct sequence could cause the SRS to unexpectedly deploy during servicing and lead to a serious injury. Furthermore, if a mistake is made when servicing the SRS, it is possible that the SRS may fail to operate properly. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read the following section carefully.

-

GENERAL NOTICE

-

As malfunctions of the SRS are difficult to confirm, Diagnostic Trouble Codes (DTCs) become the most important source of information when troubleshooting. When troubleshooting the SRS, always check for DTCs before disconnecting the battery.

-

Work must be started at least 90 seconds after the engine switch is turned off and the cable is disconnected from the negative (-) battery terminal.

The SRS is equipped with a back-up power source. If work is started within 90 seconds of turning the engine switch off and disconnecting the cable from the negative (-) battery terminal, the SRS may deploy.

When the cable is disconnected from the negative (-) battery terminal, the clock and audio system memory will be cleared. Before starting work, make a note of the settings of each memory system. When work is finished, reset the clock and audio system as before.

CAUTION:

Never use a back-up power source (battery or other) to avoid clearing the system memory. The back-up power source may inadvertently power the SRS and cause it to deploy.

-

If the vehicle has been involved in a minor collision where the SRS does not deploy, the steering pad, front passenger airbag assembly, knee airbag assembly, seat side airbag assembly, rear seat cushion airbag assembly, curtain shield airbag assembly, seat outer belt assembly and pop up hood lifter assembly should be inspected before further use of the vehicle.

-

Never use SRS parts from another vehicle. When replacing parts, use new ones.

-

Before performing repairs, remove the airbag sensor assemblies if impacts are likely to be applied to the sensor during repairs.

-

Never disassemble and attempt to repair any of the airbag sensor assemblies or SRS parts.

-

Steering pad

-

Front passenger airbag assembly

-

Knee airbag assembly

-

Seat side airbag assembly

-

Rear seat cushion airbag assembly

-

Curtain shield airbag assembly

-

Seat outer belt assembly

-

Pop up hood lifter assembly

-

-

Replace any airbag sensor assembly or SRS parts if: 1) damage has occurred from being dropped, or 2) cracks, dents or other defects in the case, bracket or connector are present.

-

Do not directly expose the airbag sensor assemblies or SRS parts to hot air or flames.

-

Use a voltmeter/ohmmeter with high impedance (minimum = 10 kΩ) for troubleshooting electrical circuits.

-

Information labels are attached to the SRS parts. Follow the instructions on the labels.

-

After work on the SRS is completed, check the SRS warning light.

-

-

SPIRAL CABLE

-

The steering wheel must be fitted correctly to the steering column with the spiral cable at the neutral position. Otherwise, cable damage and other problems may occur. Refer to the information about correct installation of the steering wheel.

-

-

STEERING PAD

-

Always place a removed or new steering pad with the deployment surface facing upward. Placing the steering pad with the deployment surface facing downward could cause a serious accident if the airbag deploys. Also, do not place anything on top of the steering pad.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the steering pad.

-

Store the steering pad in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or steering pad by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

-

-

FRONT PASSENGER AIRBAG ASSEMBLY

-

Always place a removed or new front passenger airbag assembly with the deployment surface facing upward. Placing the airbag assembly with the airbag deployment surface facing downward could cause a serious accident if the airbag deploys.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the front passenger airbag assembly.

-

Store the front passenger airbag assembly in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or front passenger airbag assembly by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

-

-

KNEE AIRBAG ASSEMBLY

-

Always place a removed or new knee airbag assembly with the airbag deployment surface facing upward. Placing the airbag assembly with the airbag deployment surface facing downward could cause a serious accident if the airbag deploys.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the knee airbag assembly.

-

Store the knee airbag assembly in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or a knee airbag assembly by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

for Driver Side: Click here

for Front Passenger Side: Click here

-

-

SEAT SIDE AIRBAG ASSEMBLY

-

Always place a removed or new seat side airbag assembly with the airbag deployment surface facing upward.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the seat side airbag assembly.

-

Store the seat side airbag assembly in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or a seat side airbag assembly by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

for Front Side: Click here

for Rear Side (Power Seat): Click here

for Rear Side (Fixed Seat Type): Click here

-

-

REAR SEAT CUSHION AIRBAG ASSEMBLY

-

Always place a removed or new rear seat cushion airbag assembly with the airbag deployment surface facing upward.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the rear seat cushion airbag assembly.

-

Store the rear seat cushion airbag assembly in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or an rear seat cushion airbag assembly by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

-

-

CURTAIN SHIELD AIRBAG ASSEMBLY

-

Always place a removed or new curtain shield airbag assembly in a clear plastic bag, and keep it in a safe place.

CAUTION:

The plastic bag should be disposed of after use.

Note

Never disassemble a curtain shield airbag assembly.

-

Never measure the resistance of the airbag squib. This may cause the airbag to deploy, which could cause serious injury.

-

Grease or detergents of any kind should not be applied to the curtain shield airbag assembly.

-

Store the curtain shield airbag assembly in an area where the ambient temperature is below 93°C (199°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or a curtain shield airbag assembly by itself, the airbag should be deployed using SST before disposal. Deploy the airbag in a safe place away from electrical noise.

-

-

SEAT OUTER BELT ASSEMBLY (SEAT BELT PRETENSIONER)

-

Never measure the resistance of the seat outer belt assembly. This may cause the pretensioner of the seat outer belt assembly to deploy, which could cause serious injury.

-

Never disassemble the seat outer belt assembly.

-

Never install the seat outer belt assembly on another vehicle.

-

Store the seat outer belt assembly in an area where the ambient temperature is below 80°C (176°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or a seat outer belt assembly by itself, the seat outer belt assembly should be deployed before disposal. Deploy the seat outer belt assembly in a safe place away from electrical noise.

for Front Side: Click here

for Rear Side (Power Seat): Click here

for Rear Side (Fixed Seat Type): Click here

-

As the seat outer belt assembly is hot after being deployed, allow some time for it to cool down sufficiently before disposal. Never apply water to cool down the seat outer belt assembly.

-

Grease, detergents, oil or water should not be applied to the seat outer belt assembly.

-

-

POP UP HOOD LIFTER ASSEMBLY

-

Never measure the resistance of the pop up hood lifter assembly. This may cause the pop up hood lifter assembly to activate, which could cause serious injury.

-

Never disassemble the pop up hood lifter assembly.

-

Never install the pop up hood lifter assembly on another vehicle.

-

Store the pop up hood lifter assembly in an area where the ambient temperature is below 115°C (239°F), the humidity is not high and there is no electrical noise.

-

Before using an electric welder anywhere on the vehicle, disconnect the center airbag sensor assembly connectors. These connectors contain shorting springs. This feature reduces the possibility of the airbag deploying due to current entering the squib wiring.

-

When disposing of the vehicle or a pop up hood lifter assembly by itself, the pop up hood lifter assembly should be activated before disposal. Activate the pop up hood lifter assembly in a safe place away from electrical noise.

for Front Side: Click here

for Rear Side: Click here

-

If the hood release lever is pulled after the pop up hood lifter assembly is activated, the hood may rise more.

-

As the pop up hood lifter assembly is hot after being activated, allow some time for it to cool down sufficiently before disposal. Never apply water to cool down the pop up hood lifter assembly.

-

Grease, detergents, oil or water should not be applied to the pop up hood lifter assembly.

-

-

CENTER AIRBAG SENSOR ASSEMBLY

-

Never reuse a center airbag sensor assembly that has been involved in a collision where the SRS has deployed.

-

The connectors to the center airbag sensor assembly should be connected or disconnected with the sensor installed to the vehicle. If the connectors are connected or disconnected while the center airbag sensor assembly is not installed, the SRS may be deployed.

-

Work must be started at least 90 seconds after the engine switch is turned off and the cable is disconnected from the negative (-) battery terminal, even if only loosening the bolts of the center airbag sensor assembly.

-

-

WIRE HARNESS AND CONNECTOR

-

All of the connectors for this system are a standard yellow color. If an SRS wire harness has an open circuit or a connector is broken, replace it.

-

-

-

ELECTRONIC CONTROL

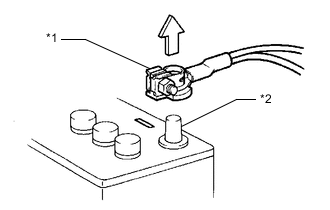

*1 Cable *2 Negative (-) battery Terminal Note

-

Certain systems need to be initialized after disconnecting and reconnecting the cable to the negative (-) battery terminal.

-

After the engine switch is turned off, the navigation system requires approximately a minute to record various types of memory and settings. As a result, after turning the engine switch off, wait a minute or more before disconnecting the cable from the negative (-) battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) battery Terminal System Name See Procedure Vehicle enrolled in telematics system (for G-BOOK) 6 minutes Vehicle not enrolled in telematics system (for G-BOOK) 1 minute

-

DISCONNECTING AND RECONNECTING CABLE TO NEGATIVE (-) BATTERY TERMINAL

-

Before performing work on electronic components, disconnect the cable from the negative (-) battery terminal to prevent damage to the electrical system or components.

-

When disconnecting the cable, turn the engine switch and headlight switch off and loosen the cable nut completely. Perform these operations without twisting or prying the cable. Then disconnect the cable.

-

Clock settings, radio settings, audio system memory, DTCs and other data will be cleared when the cable is disconnected from the negative (-) battery terminal. Write down any necessary data before disconnecting the cable.

-

-

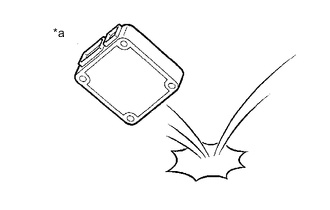

*a Incorrect HANDLING OF ELECTRONIC PARTS

-

Do not open the cover or case of the ECU unless absolutely necessary. If the IC terminals are touched, the IC may be rendered inoperative by static electricity.

-

Do not pull on the wires when disconnecting electronic connectors. Pull on the connector itself.

-

Do not drop electronic components, such as sensors or relays. If they are dropped on a hard surface, they should be replaced.

-

When cleaning the engine components with steam, protect the electronic components, air filter and emission-related components from water.

-

Never use an impact wrench to remove or install temperature switches or temperature sensors.

-

When measuring the resistance between terminals of a wire connector, insert the tester probe carefully to prevent the terminals from bending.

-

-

-

REMOVAL AND INSTALLATION OF FUEL CONTROL PARTS

-

PLACE FOR REMOVING AND INSTALLING FUEL SYSTEM PARTS

-

Work in a location with good air ventilation that does not have welders, grinders, drills, electric motors, stoves, or any other ignition sources nearby.

-

Never work in a pit or near a pit as fuel vapors will collect there.

-

-

REMOVING AND INSTALLING FUEL SYSTEM PARTS

-

Prepare a fire extinguisher before starting work.

-

To prevent static electricity, install a ground wire between the fuel changer and vehicle, and do not spray the surrounding area with water. Be careful when performing work in this area, as the floor surface will become slippery. Do not clean up gasoline spills with water, as this may cause the gasoline to spread, and possibly create a fire hazard.

-

Avoid using electric motors, work lights and other electric equipment that can cause sparks or high temperatures.

-

Avoid using iron hammers as they may create sparks.

-

Dispose of fuel-contaminated cloth separately using a fire resistant container.

-

-

-

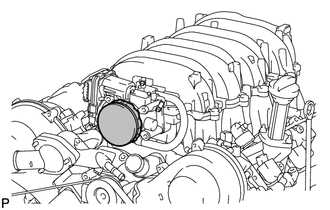

REMOVAL AND INSTALLATION OF ENGINE INTAKE PARTS

-

If any metal particles enter intake system parts, they may damage the engine.

-

When removing and installing intake system parts, cover the openings of the removed parts and engine openings. Use adhesive tape or other suitable materials.

-

When installing intake system parts, check that no metal particles have entered the engine or installed parts.

-

-

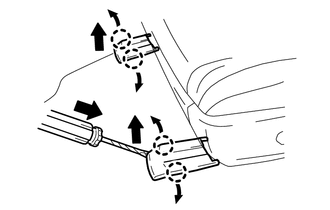

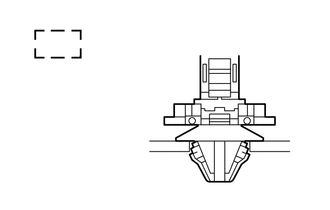

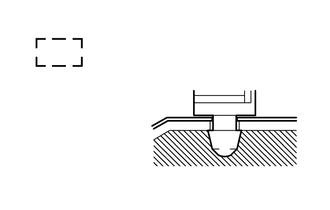

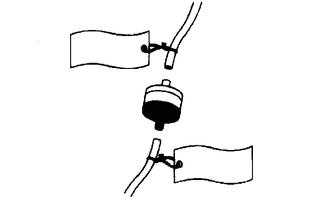

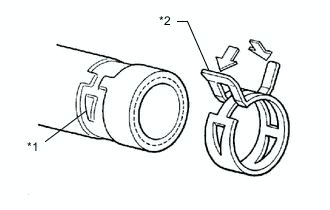

HANDLING OF HOSE CLAMPS

*1 Clamp Track *2 Spring Type Clamp

-

Before removing a hose, check the clamp position so that it can be reinstalled in the same position.

-

Replace any deformed or dented clamps with new ones.

-

When reusing a hose, attach the clamp on the clamp track portion of the hose.

-

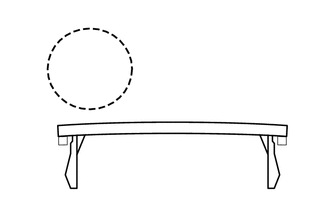

For a spring type clamp, it may be necessary to spread the tabs slightly after installation by pushing them in the direction of the arrows as shown in the illustration.

-

-

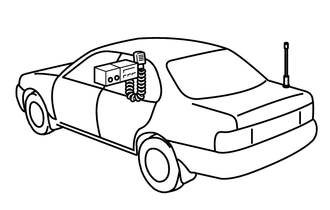

FOR VEHICLES EQUIPPED WITH MOBILE COMMUNICATION SYSTEMS

-

Install the antenna as far away from the ECU and sensors of the vehicle electronic systems as possible.

-

Install the antenna and feeder at least 20 cm (7.87 in.) away from the ECUs and sensors of the vehicle electronic systems. For details about ECU and sensor locations, refer to the section on the applicable components.

-

Keep the antenna and feeder separate from other wiring as much as possible. This will prevent signals sent from the communication equipment from affecting vehicle equipment and vice versa.

-

Check that the antenna and feeder are correctly adjusted.

-

Do not install a high-powered mobile communication system.

-

-

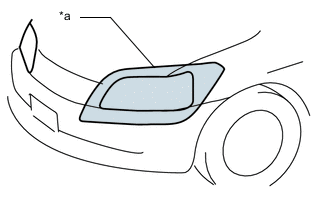

HEADLIGHT INSPECTION OR MAINTENANCE

-

*a Illumination for 3 minutes or more prohibited if covered When the headlights are illuminated, do not cover the headlights for 3 minutes or more.

Note

As the headlight outer lens is made of resin, the resulting heat created when covering the headlight for an extended period of time may deform the headlight.

-

-

FOR AIR SUSPENSION SYSTEM

-

When lifting or jacking up the vehicle, first turn off the vehicle height control.

-

-

FOR ELECTRIC PARKING BRAKE SYSTEM

-

Precautions when working on vehicle.

-

If the vehicle needs to be tilted after stopping the vehicle on a level surface, push the electric parking brake switch twice, as the braking force may be insufficient.

Tech Tips

-

The electric parking brake determines how much braking force to apply using the yaw rate sensor value for the slope of the road.

-

Push the electric parking brake twice to apply the parking brake with the maximum braking force.

-

-

-

Parking brake forced release method.

For the parking brake forced release method: Click here

-

-

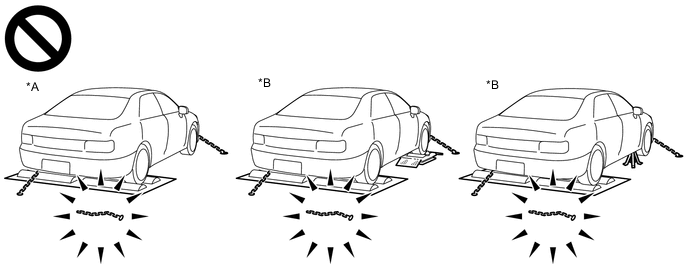

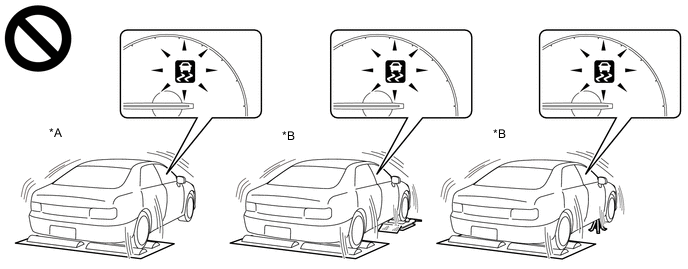

PRECAUTIONS WHEN USING DRUM TESTER

-

When testing with a 2-wheel drum tester such as a speedometer tester, combination tester for the speedometer and brakes, or chassis dynamometer, or when jacking up the front wheels and turning the wheels, perform the following procedure to enter Inspection Mode and disable the TRC and VSC systems.

-

for Electronically Controlled Brake System (w/ Vacuum Brake Booster): Click here

-

for Electronically Controlled Brake System (w/o Vacuum Brake Booster): Click here

Note

Secure the vehicle with lock chains for safety.

Tech Tips

-

If Inspection Mode is not used, the vehicle may unexpectedly move off the dynamometer because of TRC and VSC operation.

-

The VSC OFF switch (satellite switch set) must not be used to disable TRC and VSC operation when the vehicle is to be operated on a dynamometer. Pressing the VSC OFF switch (satellite switch set) does not disable TRC and VSC operation completely.

-

-

When using a drum tester, be sure to enter the VSC OFF mode to prohibit TRC and VSC control.

CAUTION:

-

Do not use the drum tester with any of the lock chains disconnected.

*A for 2WD *B for AWD -

Using the drum tester with a lock chain disconnected could cause the vehicle to begin moving unexpectedly.

-

Do not use the drum tester while the TRC or VSC is able to operate.

*A for 2WD *B for AWD -

TRC or VSC operation could cause the vehicle to begin moving unexpectedly.

-

-

NOTICES FOR VSC RELATED PROCEDURES

-

For VSC related parts, adjustments are required after removal and installation. Therefore, perform removal and installation only when necessary.

-

When performing VSC related procedures, be sure to strictly follow the preparation and completion procedures.

-

When performing removal and installation or replacement of VSC related parts, first disconnect the cable from the negative (-) battery terminal.

-

-

-

ELECTRONIC SHIFT LEVER SYSTEM

-

BASIC OPERATION

-

This vehicle is equipped with an electronic shift lever system. This system electrically communicates the driver's intended shift state to the ECUs responsible for system control. The system also uses an electrically operated transmission parking lock mechanism.

Tech Tips

-

Normally, the transmission parking lock mechanism does not operate when the battery is depleted or disconnected.

-

The shift lever position can be switched to P by the sub-battery even if the battery is depleted or disconnected.

-

If the electronic shift lever system has been damaged due to a flood, etc., the shift state will not be able to be changed to or from park (P).When the shift state cannot be changed from park (P) to any other state, transport the vehicle by using the forced parking release mechanism to release the parking brake.

for AGA0E: Click here

for AGA0F: Click here

-

There is no mechanical connection between the P position switch, shift lever and the transmission.

-

-

This system allows the driver to select the reverse (R), neutral (N), drive (D) and manual (M)* shift states using the shift lever or select the park (P) shift state by pushing the P position switch. Shift states are ECU controlled based on the actions of the driver and various conditions. Shift states can be verified using the shift position indicator in the combination meter and shift lever side shift position indicator or by using the GTS.

-

*: For enhanced engine braking.

-

-

-

-

NOTE REGARDING PROHIBITION OF FOUR-WHEEL TOWING TRACTION

Do not tow the vehicle with all 4 wheels on the ground.

Note

If the vehicle is towed with all 4 wheels touching the ground, the stop and start system may be damaged.

Tech Tips

If the vehicle must be towed with the 4 wheels on the ground, turn the engine switch off and then turn the engine switch on (IG) before towing the vehicle.

-

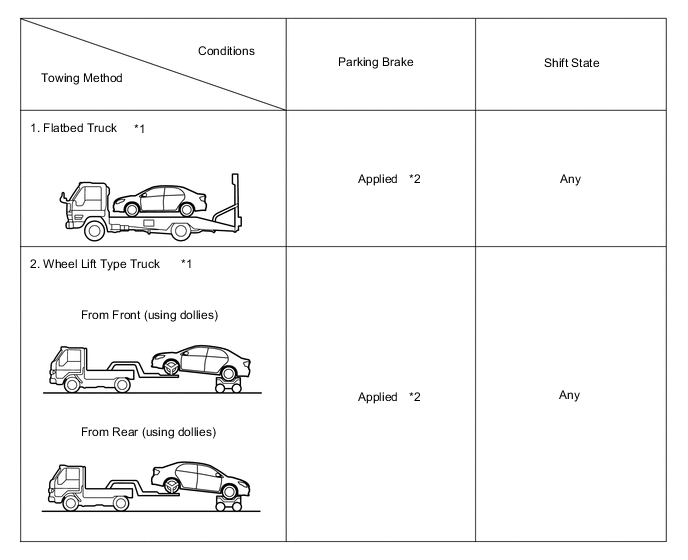

PRECAUTIONS FOR TOWING REAR WHEEL DRIVE VEHICLES

-

Use one of the following methods to tow the vehicle.

-

If the vehicle has trouble with the chassis or drivetrain, use method 1 (flatbed truck).

Note

-

Do not use any towing method other than those shown above.

-

*1: If the vehicle is tilted after parking on a level surface, the braking force may be insufficient as the electric parking brake determines how much braking force to apply by automatically detecting the slope of the road.

Tech Tips

*2: Push the electric parking brake twice to apply the parking brake with the maximum braking force.

-

-

If a tow truck is not available, in an emergency the vehicle may be temporarily towed using a cable or chain secured to the emergency towing eyelet(s). This should only be attempted on hard surfaced roads for short distances below 30 km/h (18 mph).

A driver must be in the vehicle to steer and operate the brakes. The vehicle's wheels, drivetrain, axles, steering and brakes must be in good condition.

Note

If the towing speed or distance exceeds the above limits, or the vehicle is towed in a backward direction with the wheels on the ground, the drivetrain or vehicle may be damaged.

-

Emergency towing procedure

-

Turn the engine switch on (IG).

-

Depress the brake pedal and move the shift lever to N.

-

Release the parking brake.

-

Release the brake pedal slowly.

Note

-

Use extreme caution when towing the vehicle. Avoid sudden starts or erratic driving maneuvers which place excessive stress on the emergency towing eyelet and the cables or chains.

-

Do not turn off the engine switch. Turning off the engine switch may result in engagement of the parking lock, resulting in a hazardous situation or accident.

Tech Tips

-

Neutral (N) cannot be selected if the battery is discharged or if it has been disconnected.

-

There is a possibility that neutral (N) cannot be selected when parts related to the electronic shift lever system are malfunctioning.

-

-

-

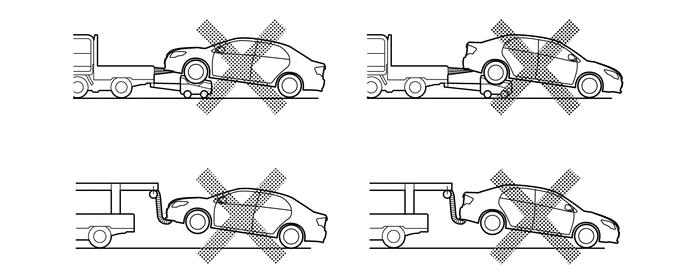

The towing methods shown below are dangerous and can damage the vehicle, so do not use them.

-

Do not tow the vehicle with only 2 wheels on the ground.

CAUTION:

If the vehicle is towed with only the front wheels on the ground, the steering may move, causing the vehicle to become unstable.

Note

If the vehicle is towed with only the rear wheels on the ground, the drivetrain may overheat and be damaged.

-

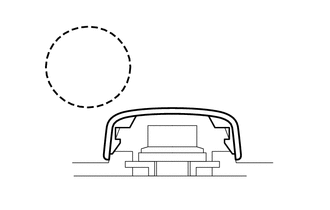

Do not use a sling-type towing method either from the front or rear.

Note

If a sling-type tow truck is used, damage may occur to the vehicle body.

-

-

-

PRECAUTIONS FOR TOWING ALL WHEEL DRIVE VEHICLES

-

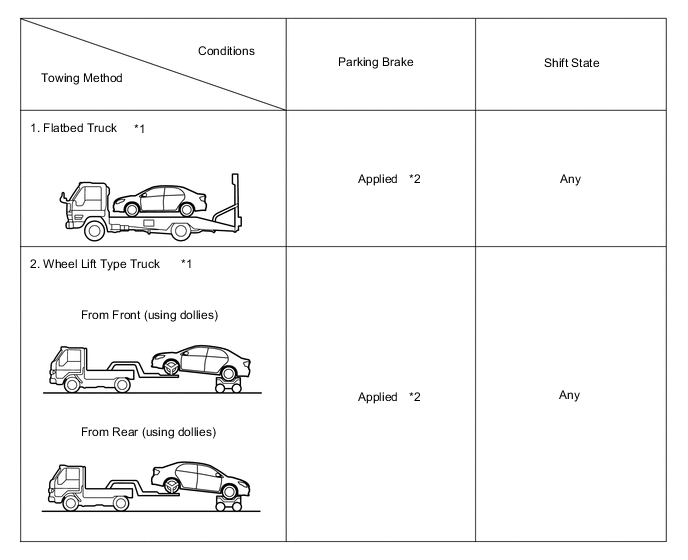

Use one of the following methods to tow the vehicle.

-

If the vehicle has trouble with the chassis or drivetrain, use method 1 (flatbed truck).

Note

-

Do not use any towing method other than those shown above.

-

*1: If the vehicle is tilted after parking on a level surface, the braking force may be insufficient as the electric parking brake determines how much braking force to apply by automatically detecting the slope of the road.

Tech Tips

*2: Push the electric parking brake twice to apply the parking brake with the maximum braking force.

-

-

If a tow truck is not available, in an emergency the vehicle may be temporarily towed using a cable or chain secured to the emergency towing eyelet(s). This should only be attempted on hard surfaced roads for short distances below 30 km/h (18 mph).

A driver must be in the vehicle to steer and operate the brakes. The vehicle's wheels, drivetrain, axles, steering and brakes must be in good condition.

Note

If the towing speed or distance exceeds the above limits, or the vehicle is towed in a backward direction with any of the wheels on the ground, the drivetrain may be damaged.

-

Emergency towing procedure

-

Turn the engine switch on (IG).

-

Depress the brake pedal and move the shift lever to N.

-

Release the parking brake.

-

Release the brake pedal slowly.

Note

-

Use extreme caution when towing the vehicle. Avoid sudden starts or erratic driving maneuvers which place excessive stress on the emergency towing eyelet and the cables or chains.

-

Do not turn off the engine switch. Turning off the engine switch may result in engagement of the steering lock, resulting in a hazardous situation or accident.

Tech Tips

-

Neutral (N) cannot be selected if the battery is discharged or if it has been disconnected.

-

There is a possibility that neutral (N) cannot be selected when parts related to the electronic shift lever system are malfunctioning.

-

-

-

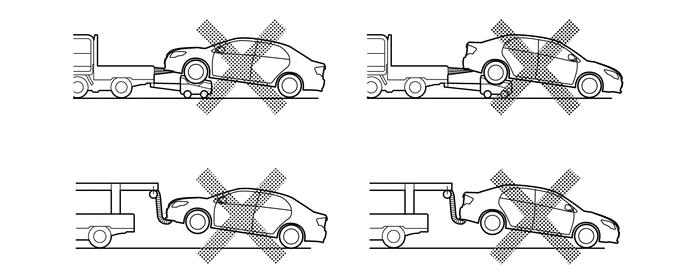

The towing methods shown below are dangerous and can damage the vehicle, so do not use them.

-

Do not tow the vehicle with only 2 wheels on the ground.

Note

If the vehicle is towed with only the 2 wheels on the ground, the drivetrain may overheat and be damaged or the wheels may come off the dollies.

-

Do not use a sling-type towing method either from the front or rear.

Note

If a sling-type tow truck is used, damage may occur to the vehicle body.

-

-

-

WARNING NOTIFICATION FUNCTION (for G-BOOK)

Note

-

Before performing inspections or repairs which may cause warning messages or DTCs to occur, such as a simulation test or road test, it is necessary to activate warning notification restraint mode so that the G-BOOK center does not recognize the warnings as real ones.

-

Warning notification restraint mode can be entered by using the GTS or operating the multi-display.

Tech Tips

The warning notification function sends a warning ON signal, received from the combination meter assembly via CAN communication, to the G-BOOK center using the G-BOOK device if a warning is displayed in the vehicle due to a vehicle malfunction.

-

Warning notification restraint mode

Tech Tips

To cancel warning notification restraint mode, turn the engine switch off and on (IG) to display the service mode screen and cancel warning notification restraint mode.

-

Warning notification restraint mode (Using the GTS)

-

Turn the engine switch off.

-

Connect the GTS to the DLC3.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Trouble Codes.

-

-

Warning notification restraint mode (Using the multi-display)

-

Enter diagnostic mode of navigation system.

-

-

-

-

ALARM NOTIFICATION FUNCTION (for G-BOOK)

-

If the theft deterrent system is activated, the G-BOOK center makes a phone call to the customer.

Note

-

When servicing the vehicle, make sure that the vehicle does not experience any conditions that could cause a telephone call to be made by a G-BOOK operator.

-

Before performing inspections or repairs which may activate the alarm notification function, be sure to inform the customer that they may receive a telephone call from a G-BOOK operator.

Tech Tips

The alarm notifications can be canceled via the multi-display assembly screen.

-

-

-

STRICT PROHIBITION OF MANUAL EMERGENCY CALL USING EMERGENCY CALL SERVICE

-

for G-BOOK:

-

Do not make an emergency call when not in emergency situations. For inspections, use the manual maintenance check.

Note

-

If the emergency call service is used to connect to the G-BOOK center when not in an emergency situation, an unnecessary workload will be generated at the G-BOOK center. This may cause a delayed response by the G-BOOK center to other emergency calls.

-

If emergency vehicles are dispatched due to an accidental operation of the emergency call switch, you may be charged or punished according to related laws.

-

-

If the emergency call switch is accidentally operated;

-

If the emergency call switch is accidentally operated, contact the G-BOOK center to tell them that the call was made by mistake.

-

An emergency call cannot be halted or finished from the vehicle. Only the G-BOOK center can halt or finish the call.

-

If the G-BOOK center cannot be informed that the call was made by mistake, the center will report to authorities, emergency facilities and dealerships in compliance with its agreements. As a result, emergency vehicles may be dispatched.

-

-

-

for ERA-GLONASS:

-

Do not make emergency calls in non-emergency situations. When performing an inspection, use the manual maintenance check.

Note

-

If the emergency call service is used to connect to the PSAP in a non-emergency situation, an unnecessary workload will be generated at the PSAP. This may cause a delayed response by the PSAP to other emergency calls.

-

If emergency vehicles are dispatched due to an accidental operation of the manual (SOS) switch, you may be charged or punished according to local law.

-

-

If the manual (SOS) switch is accidentally operated:

-

Contact the PSAP to tell them that the call was made by mistake.

-

An emergency call cannot be halted or finished from the vehicle. Only the PSAP can halt or finish an emergency call.

-

If the PSAP cannot be informed that the emergency call was made by mistake, the center will report an emergency to authorities, emergency facilities and dealerships in compliance with its agreements. As a result, emergency vehicles may be dispatched.

-

-

-

-

FOR VEHICLES EQUIPPED WITH CATALYTIC CONVERTER

CAUTION:

If a large amount of unburned gasoline or gasoline vapors flow into the converter, it may cause converter overheating and create a fire hazard. To prevent this, observe the following precautions:

-

Use only unleaded gasoline.

-

Avoid performing unnecessary spark tests.

-

Perform a spark test only when absolutely necessary. Perform this test as rapidly as possible.

-

While testing, never race the engine unless instructed.

-

-

Avoid a prolonged engine compression measurement. Engine compression measurements must be performed as rapidly as possible.

-

Do not run the engine when the fuel tank is nearly empty. This may cause the engine to misfire and create an extra load on the converter.

-

-

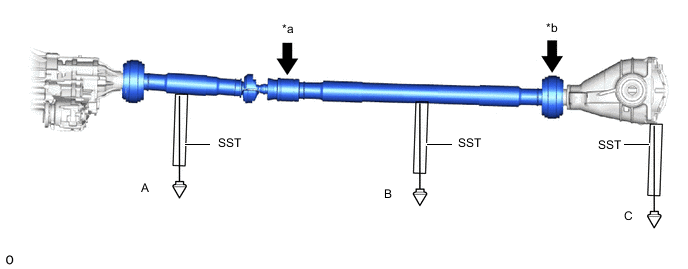

INSPECTION AND ADJUSTMENT OF JOINT ANGLE DURING REMOVAL AND INSTALLATION OF PROPELLER SHAFT

-

When performing operations which involve the removal and installation of the propeller shaft, always check the joint angle. Make adjustments if necessary.

*a No. 2 Joint Angle *b No. 3 Joint Angle

-