FRONT WHEEL ALIGNMENT ADJUSTMENT

CAUTION / NOTICE / HINT

Note

If a wheel alignment has been performed, or if suspension or underbody components have been removed/installed or replaced, be sure to perform the following initialization procedure in order for the system to function normally:

-

Perform yaw rate and acceleration sensor and roll rate and vertical acceleration sensor zero point calibration.

PROCEDURE

-

INSPECT TIRES

-

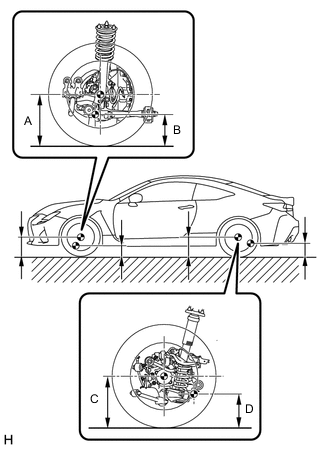

MEASURE VEHICLE HEIGHT

Note

-

Before inspecting the wheel alignment, adjust the vehicle height to the specified value.

-

Be sure to perform measurement on a level surface.

-

If it is necessary to go under the vehicle for measurement, confirm that the parking brake is applied and the vehicle is secured with chocks.

-

Inspect while the vehicle is unloaded.

-

The standard value shown here is a value that is used for performing a wheel alignment and does not indicate the height of an actual vehicle.

-

Bounce the vehicle up and down at the corners to stabilize the suspension.

-

Measure the vehicle height.

-

A: Ground clearance of front wheel center

Measurement Points:

-

B: Ground clearance of front lower suspension arm bushing set bolt center

-

C: Ground clearance of rear wheel center

-

D: Ground clearance of rear No. 2 suspension arm set bolt center

Vehicle Height (Unloaded Vehicle) Front A - B Rear C - D 129.7 mm (5.11 in.) 125 mm (4.92 in.) -

-

-

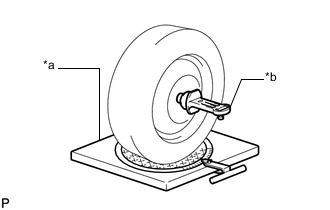

INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION

Note

Inspect while the vehicle is unloaded.

-

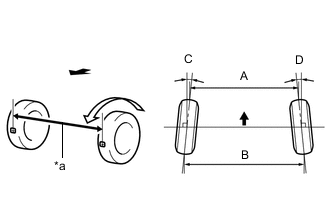

*a Turning Radius Gauge *b Camber-caster-kingpin Gauge Install a camber-caster-kingpin gauge and place the front wheels on the center of a turning radius gauge.

-

Inspect the camber, caster and steering axis inclination.

Camber (Unloaded Vehicle) Camber Inclination Right-left Difference -0°28' +/- 0°45' (-0.47° +/- 0.75°) 0°45' (0.75°) or less Caster (Unloaded Vehicle) Caster Inclination 7°38' +/- 0°45' (7.63° +/- 0.75°) Steering Axis Inclination (Unloaded Vehicle) Steering Axis Inclination Reference 9°48' +/- 0°45' (9.80° +/- 0.75°)

-

-

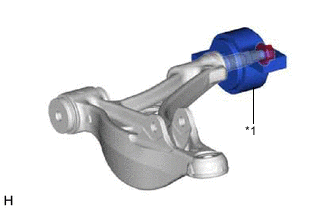

ADJUST CASTER

-

*1 Lower No. 2 Arm Bracket Sub-assembly According to the caster measurement, select a lower No. 2 arm bracket sub-assembly.

Lower No. 2 Arm Bracket Sub-assembly Part No. Installation Position Offset Angle 48075-24010 RH 0 (Standard) 48075-24080 RH +21' (+0.35°) 48075-24090 RH -21' (-0.35°) 48076-24010 LH 0 (Standard) 48076-24050 LH +21' (+0.35°) 48076-24060 LH -21' (-0.35°) Tech Tips

-

Perform adjustments so that the value is as close as possible to the median of the specified range.

-

Refer to the instructions for Removal and Installation of the front lower suspension arm assembly.

-

-

-

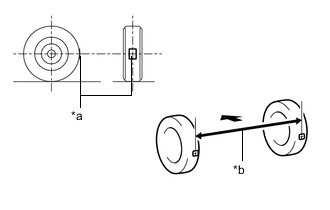

INSPECT TOE-IN

Note

Inspect while the vehicle is unloaded.

-

Bounce the vehicle up and down at the corners to stabilize the suspension.

-

Release the parking brake and move the shift lever to N.

-

Push the vehicle straight ahead approximately 5 m (16.4 ft.). (Step C)

-

*a Tread Center Mark *b Dimension B

Front of the Vehicle Put tread center marks on the rearmost points of the front wheels and measure the distance between the marks (dimension B).

-

Slowly push the vehicle straight ahead to cause the front wheels to rotate 180°. Use the front tire valve as a reference point.

Tech Tips

Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from step C again.

-

*a Dimension A

Front of the Vehicle Measure the distance between the tread center marks on the front of the wheels (dimension A).

Toe-in (Unloaded Vehicle) Specified Condition C + D: 0°00' +/- 0°10' (0° +/- 0.17°) B - A: 0 +/- 2.0 mm (0 +/- 0.0787 in.) Tech Tips

Measure "B - A" only when "C + D" cannot be measured.

If the toe-in is not within the specified range, adjust it at the steering rack ends.

-

-

ADJUST TOE-IN

-

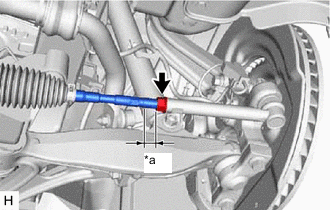

*a Thread Length Make sure that the thread length of the right and left steering rack ends are approximately the same.

Standard Difference 1.5 mm (0.0591 in.) or less -

Remove the steering rack boot clips.

-

Loosen the tie rod assembly lock nuts.

-

Adjust the steering rack ends if the difference in thread length between the right and left steering rack ends is not within the specified range.

-

If the toe-in measurement is greater than the specified range (too much toe-out), shorten the longer steering rack end so that the length difference is within the specified range.

-

If the toe-in measurement is less than the specified range (too much toe-in), extend the shorter steering rack end so that the length difference is within the specified range.

-

Measure the toe-in.

-

-

Turn the right and left steering rack ends by an equal amount to adjust the toe-in.

Toe-in (Unloaded Vehicle) Specified Condition C + D: 0°00' +/- 0°10' (0° +/- 0.17°) B - A: 0 +/- 2.0 mm (0 +/- 0.0787 in.) Tech Tips

Perform adjustments so that the value is as close as possible to the median of the specified range.

-

Make sure that the thread length of the right and left steering rack ends are the same.

-

Tighten the tie rod assembly lock nuts.

- Torque:

- 55.9 N*m { 570 kgf*cm, 41 ft.*lbf }

-

Place the steering rack boots on the seats and install the steering rack boot clips.

Tech Tips

-

Make sure that the steering rack boots are not twisted.

-

Make sure that the steering rack boot clips are facing towards the front of the vehicle.

-

-

-

INSPECT WHEEL ANGLE

-

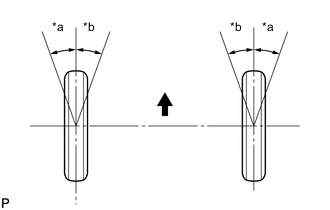

*a Inside *b Outside

Front of the Vehicle Put tread center marks on the rearmost points of a turning radius gauge.

-

Turn the steering wheel fully to the left and right and measure the turning angle.

Note

Inspect while the vehicle is unloaded.

Wheel Turning Angle (Unloaded Vehicle) Inside Wheel Outside Wheel 39°11' +/- 2°00' (39.18° +/- 2°) 34°02' (34.03°)

-

If the right and left inside wheel angles differ from the specified value, check and adjust the right and left steering rack end lengths.

-

-

-

INSPECT FRONT SUSPENSION

-

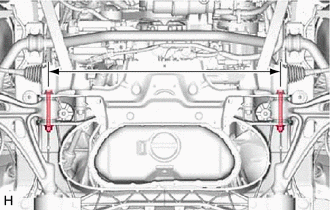

Inspect the front suspension crossmember sub-assembly.

-

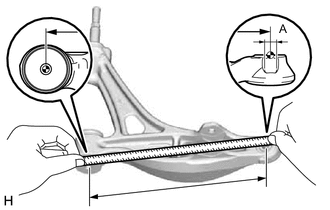

Measure the dimension between the center of the 2 installation bolts of the front lower suspension arm assembly.

Standard 692.5 to 699.5 mm (2.28 to 2.29 ft.) If the result is not as specified, replace the front suspension crossmember sub-assembly.

Tech Tips

Refer to the instructions for removal and installation of the front suspension crossmember sub-assembly.

-

-

Inspect the front lower suspension arm assembly.

-

Remove the front lower suspension arm assembly.

Tech Tips

Refer to the instructions for removal of the front lower suspension arm assembly.

-

Measure the dimension between the center of the front lower suspension arm assembly bush and the center of position A.

Standard 383.7 to 385.1 mm (1.259 to 1.263 ft.)

-

-

Inspect the front upper suspension arm assembly.

-

Remove the front upper suspension arm assembly.

Tech Tips

Refer to the instructions for removal of the front upper suspension arm assembly.

-

Measure the dimension between the center of the front upper suspension arm assembly bush and the center of the ball joint stud.

Standard 232.7 to 233.3 mm (9.17 to 9.18 in.)

-

-

-

ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

-

PERFORM YAW RATE AND ACCELERATION SENSOR AND ROLL RATE AND VERTICAL ACCELERATION SENSOR ZERO POINT CALIBRATION