ECD SYSTEM(w/o EGR System) Engine Difficult to Start or Stalling

DESCRIPTION

-

Faults and Symptoms of Common Rail Diesel Components

-

Engine Control

Mass Air Flow Meter Sub-assembly Main fault Decrease in performance (foreign matter is stuck) Symptoms Lack of power, black smoke Data List MAF Tech Tips

The maximum injection volume is controlled according to the output from the mass air flow meter sub-assembly.

Intake System Symptom and Corresponding Main Fault

-

Lack of power (no black smoke) due to air cleaner filter element blockage or crushed or leaking air duct

-

Black smoke (no lack of power) due to leakage between the turbocharger and intake manifold

Data List MAP Turbocharger System Main fault

-

Air leak in the turbocharged air passage

-

ECM not operating well

-

Turbocharger (turbine, bearing)

Symptoms Lack of power (when vehicle is starting, under heavy load)

(Black smoke is not emitted when racing while vehicle is stopped)

Data List MAP

-

With the ignition switch ON or during idling, MAP = atmospheric pressure (standard atmospheric pressure = 101 kPa). When the engine speed is about 1500 rpm or more, the turbocharger starts to take effect and MAP becomes higher than atmospheric pressure.

-

Atmospheric pressure decreases by 1 kPa each time elevation increases by 100 m, and is also affected by the current weather conditions.

Exhaust System Main fault Blockage Symptoms Lack of power (high engine speed, under heavy load) Glow System Main fault Glow system malfunction Symptoms Difficult to start, rough idle, knocking, white smoke (when cold) Diagnostic Point

-

Measure the resistance of the glow plug

-

Check the glow plug indicator light

Battery Main fault Battery is depleted Symptoms Difficult to start (cannot crank, crank speed is low), horn is quiet Data List Battery Voltage

-

When cranking, battery voltage is below 5 V.

Engine - 1 Main fault Damaged, seized up Symptoms Cannot crank, crank speed is low, strange noise Engine - 2 Main fault Loss of compression Symptoms Rough idle (lack of power always) Data List Engine Speed of Cyl

-

When cranking during the "Check the Cylinder Compression" Active Test, if there is a high speed cylinder, approx. 100 rpm more than the other cylinders, that cylinder may lose compression.

Injection Feedback Val

-

When an Injector Feedback Val is more than 3 mm3/st, there may be a malfunction in the corresponding cylinder.

Start System Main fault Starter system malfunction Symptoms Difficult to start Data List Starter Signal

-

Ignition switch (STA) output:

ON: Starter assembly is operating

OFF: Starter assembly is not operating

-

-

Diesel Injection

Fuel Supply Pump Assembly Main fault - Symptoms Difficult to start, engine stalling, rough idle, lack of power Data List Common Rail Pressure, Target Common Rail Pressure

-

Common Rail Pressure is within 5000 kPa of Target Common Rail Pressure during idling with the engine warmed up (engine coolant temperature is higher than 75°C (167°F)).

-

If the fuel pressure is 20000 kPa below the target pressure, then a lack of power will be felt.

-

If the fuel pressure is below 25000 kPa, then idling will be rough.

Tech Tips

The fuel pressure changes at engine start, but is approx. 25000 kPa at engine start after the engine is warmed up.

Diagnostic Trouble Code Even if Common Rail Pressure is below Target Common Rail Pressure, a DTC will not be stored. Fuel Filter Element Assembly Main fault Blockage Symptoms Difficult to start, engine stalling, rough idle, lack of power Data List Common Rail Pressure, Target Common Rail Pressure

-

Common Rail Pressure is within 5000 kPa of Target Common Rail Pressure during idling with the engine warmed up (engine coolant temperature is higher than 75°C (167°F)).

-

If the fuel pressure is 20000 kPa below the target pressure, then a lack of power will be felt.

-

If the fuel pressure is below 25000 kPa, then idling will be rough.

Tech Tips

The fuel pressure changes at engine start, but is approx. 25000 kPa at engine start after the engine is warmed up.

Diagnostic Trouble Code Even if Common Rail Pressure is below Target Common Rail Pressure, a DTC will not be stored. Injector Assembly Main fault Blockage Symptoms Rough idle, lack of power, black smoke, white smoke, knocking Data List Injection Feedback Val

-

When an Injector Feedback Val is more than 3 mm3/st, there may be a malfunction in the corresponding cylinder. This value can be read after idling for 1 minute.

Pressure Discharge Valve Main fault Does not completely close Symptoms Difficult to start, engine stall, rough idle, lack of power Fuel Pressure Sensor Main fault Open circuit, decrease in performance (foreign matter is stuck) Symptoms Difficult to start, rough idle, engine stall, lack of power Data List Common Rail Pressure, Target Common Rail Pressure

-

Slowly raise the engine speed from idling to 3000 rpm with the vehicle stopped and check that Common Rail Pressure follows Target Common Rail Pressure. If the fuel pressure sensor malfunctions, the actual fuel pressure may deviate from the target fuel pressure (either Common Rail Pressure decreases to a value less than Target Common Rail Pressure).

Diagnostic Trouble Code When the fuel pressure sensor has a fault, some DTCs may be stored. Irregular Fuel Main fault - Symptoms Difficult to start, rough idle (especially when cold) -

-

Diesel Throttle

Diesel Throttle System Main fault Stuck, does not move smoothly Symptoms

-

Stuck closed: Lack of power, difficult to start, rough idle, engine stall, black smoke. These may occur when stuck almost fully closed.

-

Stuck open: Turbocharger sound increases. When the engine is stopped, engine vibrations may occur.

Data List Actual Throttle Position

-

0%: Fully closed

-

100%: Fully open

-

When the ignition switch ON (the engine is stopped), the diesel throttle is fully open. When idling, the diesel throttle is at the halfway point. When the ignition switch is turned from ON to off, the throttle is fully closed temporarily.

-

-

-

Data List Related to Starting Trouble

-

MAP

-

MAF

-

Intake Air

-

Coolant Temp

-

Battery Voltage

-

Starter Signal

-

Engine Speed of Cyl #1 to #4

(Output only when the "Check the Cylinder Compression" Active Test is performed)

-

Target Common Rail Pressure

-

Common Rail Pressure

-

Injection Feedback Val #1 to #4

-

Injection Volume

-

Actual Throttle Position

-

CAUTION / NOTICE / HINT

-

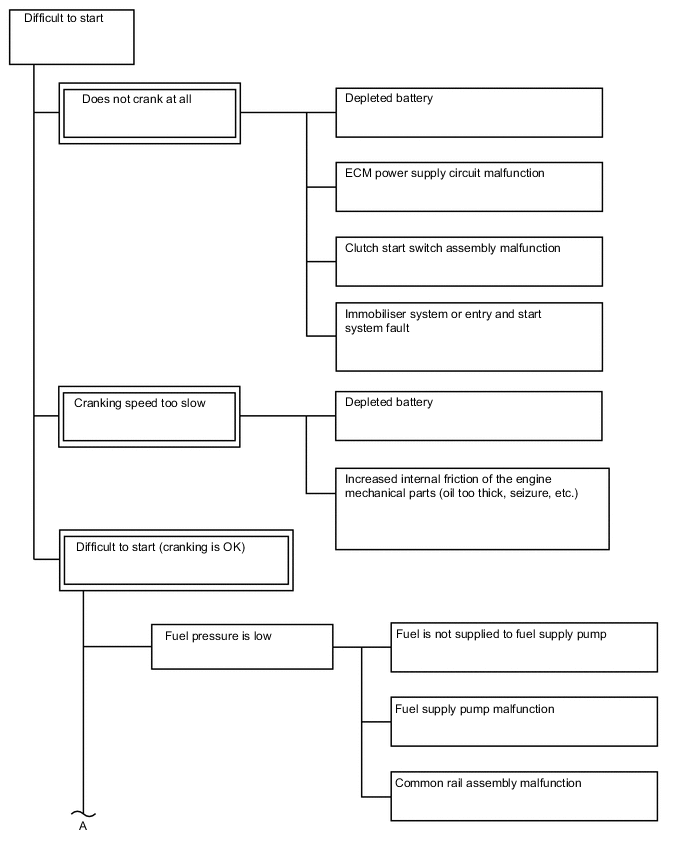

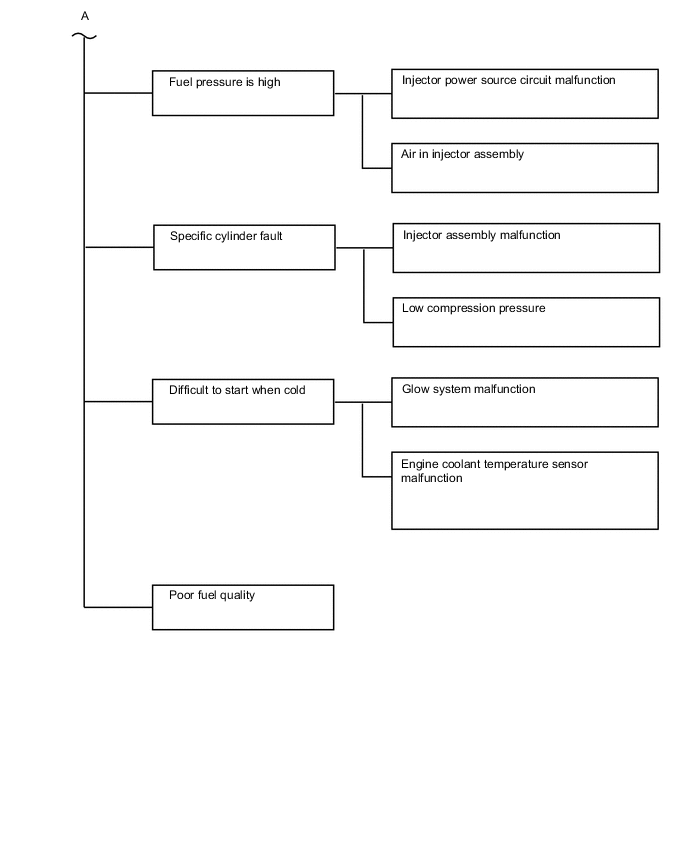

Explanation of Symptom

Starting Trouble For good starting it is essential to have:

-

Sufficient cranking speed.

-

Properly operating engine preheating system.

-

Good quality fuel.

The fuel is ignited by the heat which is generated by compression pressure.

With problems such as a depleted battery, the crankshaft speed can become low, or if the engine compression is poor due to leakage, the compression pressure will not rise and there will be difficulty starting.

When the engine is cold, even if there is compression heat, it will escape from the combustion chamber. For this reason, when the engine is started when it is cold, the glow plugs heat the compressed air.

Also, after starting the engine, by charging the glow plugs for a fixed time set according to the engine coolant temperature, diesel knocking and white smoke are prevented. The quantity of fuel injected is determined by the fuel pressure and also the amount of time the injector assembly is open.

-

-

Trouble Area Chart According to Problem Cause

Note

-

After replacing the ECM, the new ECM needs registration (Click here ) and initialization Click here.

-

After replacing an injector assembly, the ECM needs registration Click here.

Tech Tips

Specified values in the following troubleshooting flowchart are for reference only. Variations in the Data List values may occur depending on the measuring conditions or the vehicle age. Do not assume the vehicle is normal when the Data List outputs standard values. There may be concealed factors of the malfunction.

-

PROCEDURE

-

CHECK ENGINE CRANKING CONDITION

-

Check the engine cranking condition.

Result Result Proceed to Cranking is OK. A Low cranking speed.

Tech Tips

When cranking speed is low, especially when the temperature is low, check if the engine oil grade matches the recommendation.

B Does not crank at all. C

B

CHECK BATTERY CONDITION Click here

C

READ OUTPUT DTC (RELATED TO ENGINE) Click here

A

-

-

READ ALL OUTPUT DTCS

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: System Select / Health Check.

-

Check the DTCs.

Result Result Proceed to No DTC is output A Engine related DTCs are output B Tech Tips

If only DTC P1604 is output, proceed to step 3.

B

GO TO RELATED DTC Click here

A

-

-

TAKE SNAPSHOT DURING STARTING AND IDLING (PROCEDURE 3)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Diesel Starting.

-

Take a snapshot when idling with no load after the engine is warmed up and when starting trouble is occurring.

Tech Tips

-

A snapshot can be used to compare vehicle data from the time of the malfunction to normal data and is very useful for troubleshooting.

-

When there is trouble starting with a cold engine, take the snapshot when the engine is cold. Then warm up the engine (engine coolant temperature is 75°C (167°F) or higher) and after idling the vehicle for 1 minute (A/C off, electrical load off), take a snapshot of the data for 15 seconds while idling.

-

Take a snapshot when the problem is occurring, such as when the engine is cold. However, if the problem does not reoccur, it is acceptable to only take a snapshot after the engine is warmed up and when the engine is started.

Result Proceed to NEXT -

NEXT

-

-

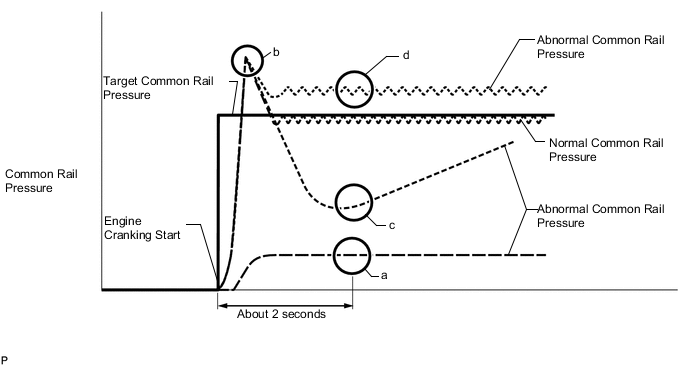

CHECK SNAPSHOT (COMMON RAIL PRESSURE)

-

Check Common Rail Pressure in the snapshot taken in procedure 3 when the engine was started.

Result Result Proceed to At the point in the illustration labeled "a", Common Rail Pressure is less than 10000 kPa from the value of Common Rail Pressure when cranking started A At the point in the illustration labeled "c", Common Rail Pressure is below Target Common Rail Pressure by 15000 kPa or more B Common Rail Pressure increases to a value that is higher than Target Common Rail Pressure immediately after cranking, and, at the point in the illustration labeled "d", Common Rail Pressure is higher than Target Common Rail Pressure C Except above D Tech Tips

-

Even if Common Rail Pressure is temporarily higher than Target Common Rail Pressure, as shown at the point in the illustration labeled "b", the fuel supply pump assembly is normal.

-

Fuel pressure is about 25000 to 35000 kPa when the engine is cranking and the engine coolant temperature is 0°C (32°F) or higher.

-

Common Rail Pressure increases rapidly during cranking.

-

B

READ VALUE USING GTS (COMMON RAIL PRESSURE) Click here

C

INSPECT INJECTOR POWER SOURCE CIRCUIT Click here

D

CHECK DATA LIST (INJECTOR FEEDBACK VAL #1 TO #4 AND INJECTION VOLUME) Click here

A

-

-

CHECK IF FUEL IS BEING SUPPLIED TO FUEL SUPPLY PUMP ASSEMBLY

-

Disconnect the inlet hose from the fuel supply pump assembly.

-

Operate the priming pump and check that fuel is being supplied to the fuel supply pump assembly.

OK Fuel is properly supplied to the fuel supply pump when the priming pump is operated. Tech Tips

-

When there is a lack of fuel, fuel pressure drops.

-

Inspect for fuel filter element assembly clogging (check that the fuel filter element assembly is not clogged).

-

-

Reconnect the inlet hose.

Result Proceed to OK NG

NG

CHECK AND REPAIR OR REPLACE CLOGGED FUEL PIPE (INCLUDING FROZEN FUEL) (FUEL TANK - FUEL SUPPLY PUMP ASSEMBLY) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (PRE-STROKE CONTROL VALVE - ECM)

-

Disconnect the pre-stroke control valve connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition X1-1 (+B) - C58-3 (PCV+) Always Below 1 Ω X1-2 (PCV) - C58-4 (PCV-) Always Below 1 Ω X1-1 (+B) or C58-3 (PCV+) - Body ground and other terminals Always 10 kΩ or higher X1-2 (PCV) or C58-4 (PCV-) - Body ground and other terminals Always 10 kΩ or higher -

Reconnect the pre-stroke control valve connector.

-

Reconnect the ECM connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

REPLACE FUEL SUPPLY PUMP ASSEMBLY (PRE-STROKE CONTROL VALVE)

-

Replace the fuel supply pump assembly.

Result Proceed to NEXT

NEXT

-

-

BLEED AIR FROM FUEL SYSTEM

-

Bleed the air from the fuel system.

Result Proceed to NEXT

NEXT

-

-

READ VALUE USING GTS (COMMON RAIL PRESSURE)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Common Rail Pressure.

Powertrain > Engine and ECT > Data ListTester Display Common Rail Pressure -

Start the engine.

-

Read the values while cranking and idling the engine.

Result Result Proceed to The engine cannot be started or the engine can be started but Common Rail Pressure is below 20000 kPa 2 seconds after the starter signal changes from OFF to ON B Except above A

A

END

B

-

-

INSPECT INJECTOR ASSEMBLY (INSPECTION FOR VALVE CLOSING PROBLEM)

-

Remove the glow plug for all the cylinders.

-

Visually check if there is fuel on the glow plugs.

Tech Tips

-

If there is fuel on a glow plug, fuel may be leaking from an injector assembly.

-

After replacing an injector assembly, make sure that the common rail pressure (fuel pressure) is within 5000 kPa of the target fuel pressure while cranking the engine.

-

If there is fuel on a glow plug, fuel may have mixed with the engine oil. Check the engine oil amount and whether the engine oil smells of diesel fuel. If the oil level is above the full line or the engine oil smells of diesel fuel, replace the engine oil.

-

-

Install the glow plug.

Result Proceed to NEXT

NEXT

GO TO STEP 23 Click here

-

-

CHECK AND REPAIR OR REPLACE CLOGGED FUEL PIPE (INCLUDING FROZEN FUEL) (FUEL TANK - FUEL SUPPLY PUMP ASSEMBLY)

-

Check and repair or replace the clogged fuel pipe.

Result Proceed to NEXT

NEXT

-

-

BLEED AIR FROM FUEL SYSTEM

-

Bleed the air from the fuel system.

Result Proceed to NEXT

NEXT

GO TO STEP 27 Click here

-

-

READ VALUE USING GTS (COMMON RAIL PRESSURE)

-

Check Common Rail Pressure in the snapshot taken in procedure 3 when the engine was warmed up.

Result Result Proceed to Difference between Common Rail Pressure and Target Common Rail Pressure is 5000 kPa (51.0 kgf/cm2, 725 psi) or more

A Except above B

B

GO TO STEP 15 Click here

A

-

-

REPLACE FUEL SUPPLY PUMP ASSEMBLY (PRE-STROKE CONTROL VALVE)

-

Replace the fuel supply pump assembly.

Result Proceed to NEXT

NEXT

-

-

REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS

-

Replace the injector assemblies of all cylinders.

Note

-

When replacing the injector assembly for a cylinder, always be sure to use a new No. 1 injection pipe sub-assembly and a new No. 2 injection pipe sub-assembly.

-

Follow the procedure in the repair manual and temporarily install the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and No. 1 nozzle leakage pipe assembly, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

-

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

-

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

-

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe sub-assembly may become incomplete, resulting in a fuel leak.

Result Proceed to NEXT -

NEXT

GO TO STEP 24 Click here

-

-

INSPECT INJECTOR POWER SOURCE CIRCUIT

-

Perform troubleshooting for DTC P062D during a startability malfunction, even if DTC P062D is not output.

When troubleshooting the injector power source circuit, check the following locations, as one may contain the cause of the malfunction

-

EDU relay

-

Injector assembly circuit

-

ECM

Tech Tips

-

When the engine cannot be started due to a malfunction in the injector power source circuit, once the DTCs are cleared, P062D cannot be stored even when the problem symptoms are reproduced and a startability malfunction occurs.

Since P062D cannot be stored when starting the engine, fuel injection cannot be performed even though fuel injection signals are output from the ECM. Therefore, using the GTS during a startability malfunction to check the data shows that an excessive amount of fuel is supplied to the common rail assembly by the fuel supply pump assembly, and as a result, the Common Rail Pressure is higher than the Target Common Rail Pressure.

-

Perform the following procedure when a malfunction cannot be found during the troubleshooting procedure for P062D and the Common Rail Pressure when starting the engine is higher than the Target Common Rail Pressure.

-

Perform the troubleshooting procedure for DTC P062D and proceed to the diagnostic flow situations where the engine does not start.

Result Result Proceed to Injector power source circuit is normal A Injector power source circuit is abnormal B -

B

REPAIR OR REPLACE MALFUNCTIONING PARTS

A

-

-

INSPECT INJECTOR ASSEMBLY

-

Disconnect the injector assembly connectors.

-

Measure the resistance of the injector assembly.

OK No open circuit malfunction. -

Reconnect the injector assembly connectors.

Result Proceed to OK NG

OK

GO TO STEP 37 Click here

NG

-

-

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER

-

Replace the injector assembly of malfunctioning cylinder.

Note

-

When replacing the injector assembly for a cylinder, always be sure to use a new No. 1 injection pipe sub-assembly and a new No. 2 injection pipe sub-assembly.

-

Follow the procedure in the repair manual and temporarily install the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and No. 1 nozzle leakage pipe assembly, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

-

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

-

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

-

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe sub-assembly may become incomplete, resulting in a fuel leak.

Result Proceed to NEXT -

NEXT

GO TO STEP 24 Click here

-

-

CHECK DATA LIST (INJECTOR FEEDBACK VAL #1 TO #4 AND INJECTION VOLUME)

-

Check Injection Feedback Val # in the snapshot taken in procedure 3 when the engine was idling.

Result Result Proceed to Injection Feedback Val #1 to #4 are 3 mm3/st or less.

Injection Volume is more than 10 mm3/st.

A* Injection Feedback Val for at least one cylinder is more than +3 mm3/st

Tech Tips

There may be a malfunction in the corresponding cylinder.

B Except above C Tech Tips

-

*: When this case occurs, usually symptoms may be noticeable, such as difficulty starting, lack of power.

-

The shift lever should be in neutral and the A/C switch and all accessory switches should be off.

-

B

PERFORM ACTIVE TEST USING GTS (CHECK THE CYLINDER COMPRESSION) Click here

C

CHECK TEMPERATURE WHEN STARTING TROUBLE OCCURS Click here

A*

-

-

REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS

-

Replace the injector assemblies of all cylinders.

Note

-

When replacing the injector assembly for a cylinder, always be sure to use a new No. 1 injection pipe sub-assembly and a new No. 2 injection pipe sub-assembly.

-

Follow the procedure in the repair manual and temporarily install the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and No. 1 nozzle leakage pipe assembly, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

-

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

-

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

-

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe sub-assembly may become incomplete, resulting in a fuel leak.

Result Proceed to NEXT -

NEXT

GO TO STEP 24 Click here

-

-

PERFORM ACTIVE TEST USING GTS (CHECK THE CYLINDER COMPRESSION)

Tech Tips

Use this Active Test to help determine whether a cylinder has compression loss or not.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Check the Cylinder Compression / Data List / Compression / Engine Speed of Cyl #1 to #4.

Powertrain > Engine and ECT > Active TestActive Test Display Check the Cylinder Compression Data List Display Engine Speed of Cyl #1 Engine Speed of Cyl #2 Engine Speed of Cyl #3 Engine Speed of Cyl #4 -

Check the engine speed during the Active Test.

Result Result Proceed to Except below A The values of Engine Speed Cyl #1 to #4 are within 10 rpm of each other. B Tech Tips

When cranking, if the speed of a cylinder is approximately 100 rpm more than the other cylinders, there is probably a complete loss of compression in that cylinder.

B

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER Click here

A

-

-

CHECK CYLINDER COMPRESSION PRESSURE OF MALFUNCTIONING CYLINDER

Tech Tips

Measure the compression of the cylinder that had a high speed during the "Check the Cylinder Compression" Active Test.

-

Check the cylinder compression pressure.

Result Proceed to OK NG

NG

CHECK ENGINE TO DETERMINE CAUSE OF LOW COMPRESSION

OK

-

-

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER

Tech Tips

It can be determined that the injector assembly is faulty as the corresponding cylinder is malfunctioning, but has no compression loss.

-

Replace the injector assembly of malfunctioning cylinder.

Note

-

When replacing the injector assembly for a cylinder, always be sure to use a new No. 1 injection pipe sub-assembly and a new No. 2 injection pipe sub-assembly.

-

Follow the procedure in the repair manual and temporarily install the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and No. 1 nozzle leakage pipe assembly, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

-

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

-

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

-

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe sub-assembly may become incomplete, resulting in a fuel leak.

Result Proceed to NEXT -

NEXT

-

-

CLEAN FUEL FILTER CASE AND REPLACE FUEL FILTER ELEMENT ASSEMBLY

-

Clean the fuel filter case and replace the fuel filter element assembly.

Tech Tips

Be sure to clean the inside of the fuel filter case as the injector assemblies may not operate properly if the fuel filter is installed with foreign matter remaining inside the fuel filter case.

Result Proceed to NEXT

NEXT

-

-

BLEED AIR FROM FUEL SYSTEM

-

Bleed the air from the fuel system.

Result Proceed to NEXT

NEXT

-

-

REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING

-

Register the injector compensation codes.

Powertrain > Engine and ECT > UtilityTester Display Injector Compensation -

Perform the injector pilot quantity learning.

Powertrain > Engine and ECT > UtilityTester Display Pilot Quantity Learning Result Proceed to NEXT

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

Result Proceed to NEXT

NEXT

END

-

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER

-

Replace the injector assembly of malfunctioning cylinder.

Note

-

When replacing the injector assembly for a cylinder, always be sure to use a new No. 1 injection pipe sub-assembly and a new No. 2 injection pipe sub-assembly.

-

Follow the procedure in the repair manual and temporarily install the No. 1 injection pipe sub-assembly, No. 2 injection pipe sub-assembly and No. 1 nozzle leakage pipe assembly, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

-

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

-

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

-

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe sub-assembly may become incomplete, resulting in a fuel leak.

Result Proceed to NEXT -

NEXT

GO TO STEP 24 Click here

-

-

CHECK TEMPERATURE WHEN STARTING TROUBLE OCCURS

-

Check the temperature when starting trouble occurs.

Result Result Proceed to Difficult to start only for cold engine. A Difficult to start both for cold and warmed up engine. B

B

GO TO STEP 32 Click here

A

-

-

READ VALUE USING GTS (COOLANT TEMP)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Diesel starting / Coolant Temp.

Powertrain > Engine and ECT > Data ListTester Display Coolant Temp -

Read the value displayed on the GTS.

OK Coolant Temp is not high when the engine is cold, and not low after the engine is warmed up Result Proceed to OK NG

NG

INSPECT ENGINE COOLANT TEMPERATURE SENSOR Click here

OK

-

-

INSPECT GLOW PLUG (RESISTANCE)

-

Inspect the glow plug.

Result Proceed to OK NG

NG

REPLACE GLOW PLUG Click here

OK

-

-

CHECK FUEL QUALITY

-

Check that only diesel fuel is being used.

-

Check that the fuel does not contain any impurities.

Result Proceed to NEXT

NEXT

GO TO STEP 37 Click here

-

-

READ OUTPUT DTC (RELATED TO ENGINE)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the DTCs.

Powertrain > Engine and ECT > Trouble CodesResult Result Proceed to No DTC is output A Engine related DTCs are output B

B

GO TO RELATED DTC Click here

A

-

-

CHECK COMMUNICATION BETWEEN GTS AND ECM

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Check if the normal starting screen appears (check whether communication with the ECM is possible).

Tech Tips

Use a GTS that is able to communicate with other vehicles.

OK Communication is possible (vehicle can be recognized). Result Proceed to OK NG

NG

CHECK VC OUTPUT CIRCUIT Click here

OK

-

-

READ VALUE USING GTS (STARTER SIGNAL AND CLUTCH SWITCH OR NEUTRAL POSITION SW SIGNAL)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary / Starter Signal and Neutral Position SW Signal*1 or Clutch Switch*2.

Powertrain > Engine > Data ListTester Display Starter Signal Neutral Position SW Signal Clutch Switch -

Read the value displayed on the GTS.

OK GTS Display Condition Specified Condition Starter Signal Cranking ON Neutral Position SW Signal*1 Shift lever in neutral ON Clutch Switch*2 Clutch pedal fully despressed ON Tech Tips

-

*1: for automatic transmission

-

*2: for manual transmission

Result Result Proceed to OK A NG (for Manual transmission) B NG (for Automatic transmission) C -

B

INSPECT CLUTCH START SWITCH Click here

C

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY for AC60E Click here for AC60F Click here

A

-

-

CHECK STARTING SYSTEM

-

Inspect the starting system.

Tech Tips

Be sure to inspect the following areas:

-

Battery

-

Starter relay

-

Starter assembly

-

Entry and start system

-

Immobiliser system

Result Proceed to NEXT -

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

Result Proceed to NEXT

NEXT

END