BRAKE BOOSTER(for RHD) INSTALLATION

PROCEDURE

-

INSTALL BRAKE BOOSTER GASKET

-

Install a new brake booster gasket to the brake booster with master cylinder assembly.

-

-

INSTALL BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY

-

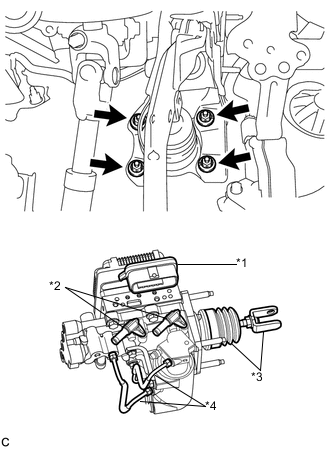

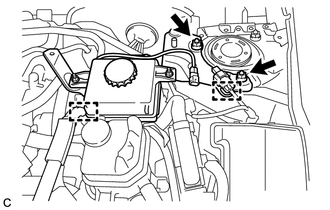

Text in Illustration *1 Connector Portion *2 Union *3 Push Rod Clevis and Boot *4 Front No. 2 Brake Tube Install the brake booster with master cylinder assembly with the 4 nuts.

- Torque:

- 13 N*m { 130 kgf*cm, 9 ft.*lbf }

Note

-

Do not kink or damage the brake lines.

-

Do not carry the brake booster with master cylinder assembly by the portion shown in bold in the illustration.

-

Be careful not to allow brake fluid to enter the connector of ECU.

-

If installing a new brake booster with master cylinder assembly, do not remove the hole plugs before connecting the brake lines because the brake booster with master cylinder is filled with brake fluid.

-

Engage the grommet of the brake line.

-

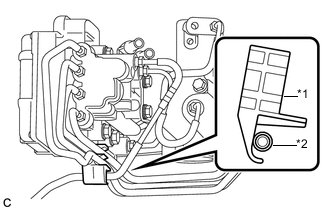

Text in Illustration *1 Clamp *2 Brake Line Set the brake line to the clamp as shown in the illustration.

Note

Securely install the brake line so that it contacts the clamp as shown in the illustration.

-

Using a union nut wrench, connect the brake line to the front flexible hose RH.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

-

Do not kink or damage the brake lines.

-

Use the formula to calculate special torque values for situations where the union nut wrench is combined with a torque wrench Click here.

-

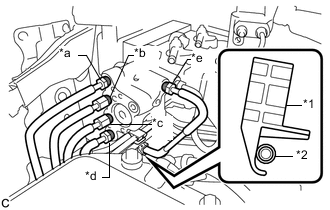

Text in Illustration *1 Clamp *2 Brake Line *a to Front Wheel Cylinder LH *b to Rear Wheel Cylinder RH *c to Brake Booster Pump Assembly *d to Rear Wheel Cylinder LH *e to Front Wheel Cylinder RH Using a union nut wrench, connect each brake line to the brake booster with master cylinder assembly as shown in the illustration.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

-

Do not kink or damage the brake lines.

-

Securely install the brake line so that it contacts the clamp as shown in the illustration.

-

Use the formula to calculate special torque values for situations where the union nut wrench is combined with a torque wrench Click here.

-

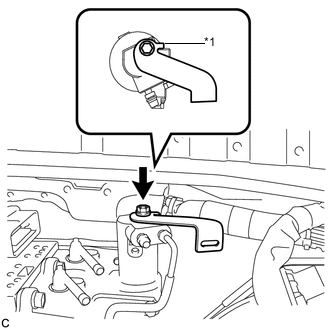

Text in Illustration *1 Stopper Install the wire harness clamp bracket to the brake booster with master cylinder assembly with the bolt.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

Note

Securely install the wire harness clamp bracket so that its stopper contacts the brake booster with master cylinder assembly as shown in the illustration.

-

Connect the connector.

Note

-

Make sure that the connector can be connected smoothly. Do not allow water, oil or dirt to enter.

-

Make sure that the connector lock is locked securely.

-

-

Engage the clamp.

-

-

CONNECT RESERVOIR TUBE ASSEMBLY

-

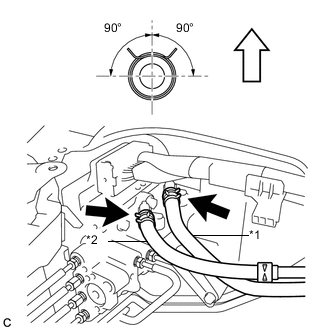

Text in Illustration *1 No. 1 Reservoir Hose *2 No. 2 Reservoir Hose

Top of Vehicle Connect the No. 1 reservoir hose and No. 2 reservoir hose with the clips.

Note

-

Make sure to match the identification marks on the hoses and brake booster with master cylinder assembly.

Identification Mark Color Connection Color No. 1 Reservoir Hose White White (Unpainted) No. 2 Reservoir Hose Green Green -

When connecting the reservoir hose, face the identification mark to the top of the vehicle.

-

Make sure to install the hose to the proper location.

-

Install the clip within the range as shown in the illustration.

-

-

-

SEPARATE BRAKE MASTER CYLINDER RESERVOIR WITH BRACKET

-

Disengage the 2 clamps.

-

Remove the 2 nuts and separate the brake master cylinder reservoir with bracket.

-

-

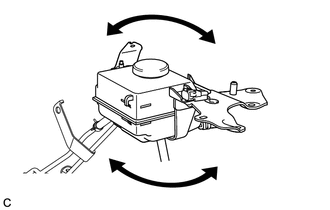

BLEED RESERVOIR TUBE ASSEMBLY

-

Add brake fluid into the reservoir.

-

Lift up the brake master cylinder reservoir assembly as far as possible and rock it back and forth to bleed air from the reservoir tube assembly.

Note

-

Do not damage the hose.

-

Do not spill the brake fluid.

-

Continue this procedure until only a minor amount of air remains in the brake actuator tube.

-

-

-

INSTALL BRAKE MASTER CYLINDER RESERVOIR WITH BRACKET

-

Install the brake master cylinder reservoir with bracket with the 2 nuts.

- Torque:

- 50 N*m { 510 kgf*cm, 37 ft.*lbf }

-

Engage the 2 clamps.

-

-

INSTALL RESERVOIR TUBE ASSEMBLY

-

Install the reservoir tube assembly with the 2 bolts and nut.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

-

-

INSTALL PUSH ROD PIN

-

INSTALL BRAKE PEDAL RETURN SPRING

-

FILL RESERVOIR WITH BRAKE FLUID

-

CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

-

for 2ZR-FXE: Click here

-

for 5ZR-FXE: Click here

-

-

BLEED BRAKE SYSTEM

-

INSPECT AND ADJUST BRAKE PEDAL

-

OBTAIN ZERO POINT OF YAW RATE AND ACCELERATION SENSOR

Tech Tips

After the brake booster with master cylinder assembly is replaced, obtain the zero point of the yaw rate and acceleration sensor Click here.

-

INSTALL NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

-

INSTALL SUSPENSION TOWER DAMPER (w/ Suspension Tower Damper)

-

INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

-

Install the outer cowl top panel sub-assembly with the 9 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

w/ Wiper Deicer:

Engage the 3 clamps to install the wire harness.

-

Engage the clamp to install the wire harness.

-

-

INSTALL COWL BODY MOUNTING REINFORCEMENT RH

-

Install the cowl body mounting reinforcement RH with the 2 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

INSTALL NO. 2 HEATER AIR DUCT SPLASH SHIELD SEAL

-

Engage the claw and guide to install the No. 2 heater air duct splash shield seal.

-

-

INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

-

Engage the 2 claws to install the No. 1 heater air duct splash shield seal.

-

-

INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY