MAIN BODY ECU INSTALLATION

PROCEDURE

-

INSTALL MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)

Note

-

Make sure that no foreign matter gets on the connecting surfaces.

-

Do not touch the ECU connector.

-

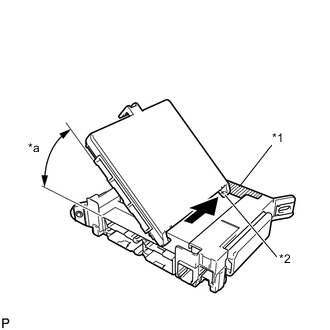

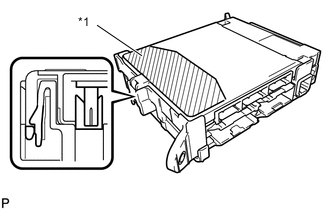

Text in Illustration *1 Housing Sidewall *2 Main Body ECU (multiplex network body ECU) Guide *a 20° Insert the main body ECU (multiplex network body ECU) up to the position where it contacts the housing sidewall of the guide as shown in the illustration.

Tech Tips

Make sure to keep the angle 20° or more as shown in the illustration.

-

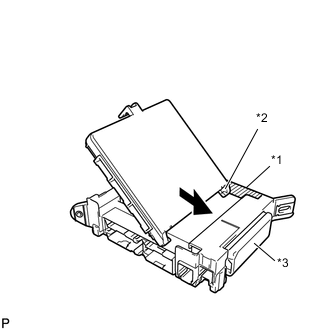

Text in Illustration *1 Housing Sidewall *2 Side A Contact Portion *3 Junction Block Fuse Slide the guide of the main body ECU (multiplex network body ECU) along the housing sidewall so that it contacts the junction block fuses as shown in the illustration.

-

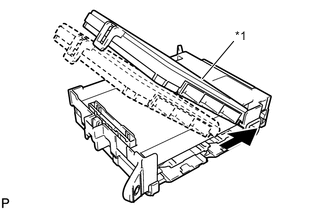

Text in Illustration *1 Side A Contact Portion Slide the the main body ECU (multiplex network body ECU) as shown in the illustration.

-

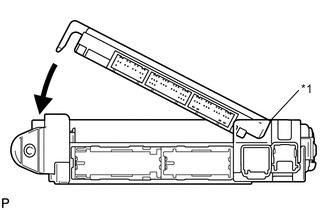

Text in Illustration *1 Side A Contact Portion While keeping the main body ECU (multiplex network body ECU) in contact with side A of the junction block (axis of rotation), rotate it downward as shown in the illustration.

-

Text in Illustration *1 Push Area Press the push area until the claw engages to install the main body ECU (multiplex network body ECU).

Note

-

Make sure to press only the push area.

-

Confirm the engagement of the main body ECU (multiplex network body ECU) and junction block by listening for the lock sound.

Tech Tips

If a lock sound cannot be heard, visually check the lock part engagement. The engagement can also be confirmed if the main body ECU (multiplex network body ECU) and junction block are flush.

-

-

-

INSTALL COWL SIDE JUNCTION BLOCK LH

-

Connect the 2 connectors.

Note

Be sure to connect each connector securely.

-

Install the instrument panel cowl side junction block LH with the bolt and nuts.

- Torque:

- nut

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- bolt

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Connect the 7 connectors.

Note

Be sure to connect each connector securely.

-

w/ VGRS:

-

Attach the 2 clamps.

-

Connect the 5 connectors.

-

-

w/o VGRS:

-

Attach the clamp.

-

Connect the connector.

-

-

-

INSTALL CLEARANCE WARNING ECU ASSEMBLY

-

INSTALL NO. 1 LOWER INSTRUMENT PANEL AIRBAG ASSEMBLY (for LHD)

-

INSTALL NO. 1 INSTRUMENT PANEL GARNISH SUB-ASSEMBLY (for LHD)

-

INSTALL NO. 1 INSTRUMENT PANEL SAFETY PAD SUB-ASSEMBLY (for LHD)

-

INSTALL GLOVE COMPARTMENT DOOR ASSEMBLY (for RHD)

-

INSTALL NO. 2 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY (for RHD)

-

INSTALL CENTER INSTRUMENT CLUSTER FINISH PANEL

-

INSTALL INSTRUMENT PANEL FINISH PANEL END LH

-

INSTALL INSTRUMENT SIDE PANEL LH

-

INSTALL FRONT DOOR OPENING TRIM COVER LH

-

INSTALL FRONT DOOR SCUFF PLATE LH

-

CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

INSTALL LUGGAGE COMPARTMENT TRIM COVER LH

-

INSTALL LUGGAGE COMPARTMENT FLOOR MAT