CAN COMMUNICATION SYSTEM(for LHD with Central Gateway ECU) HOW TO PROCEED WITH TROUBLESHOOTING

| DTC Code | DTC Name |

|---|---|

| HOW TO PROCEED WITH TROUBLESHOOTING |

CAUTION / NOTICE / HINT

-

PRECAUTIONS WHEN TROUBLESHOOTING

Note

-

Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

-

If the CAN communication system is malfunctioning, check the contact pressure of the terminals in connectors, as insufficient terminal contact pressure may be the cause.

-

Refer to Diagnosis System for the DTCs for the CAN communication system.

-

Refer to troubleshooting of each system if DTCs regarding the CAN communication system are not output.

-

Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

-

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

-

CAN communication DTCs are output for CAN main bus and CAN branch malfunctions as well as for internal malfunctions or power source malfunctions of ECUs or sensors for systems using CAN communication. Therefore, when DTCs for internal malfunctions or power source malfunctions of corresponding systems are output at the same time as CAN communication DTCs, troubleshoot according to the internal malfunction and power source malfunction DTCs.

-

An open in a branch for ECUs or sensors that are connected to the CAN main bus can be checked by performing a CAN bus check using the GTS. (This inspection is possible when all the main bus lines are normal.)

-

If there was a communication error, the probable ECU or sensor for which communication stopped can be determined using the combination of communication DTCs (DTCs that start with U) that are output.

-

If a sub bus has a communication error, the gateway function equipped ECU (sub bus monitor ECU) detects it and stores DTCs related to the error.

Tech Tips

On the GTS, gateway function equipped ECUs display DTCs for ECUs connected to the sub bus.

-

When an open circuit is detected, before disconnecting related connectors for inspection, push in on the connector body to check that the connector is not loose or disconnected.

-

When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

-

PROCEDURE

-

VEHICLE BROUGHT TO WORKSHOP

Tech Tips

-

If the ignition switch can be turned ON (the power source mode can be changed to ON) when the vehicle is brought in for repair, check for DTCs and check the illumination condition of the indicators in the combination meter assembly and the basic operation of the vehicle (such as steering operation) promptly.

-

Do not turn the ignition switch off until the inspection of the vehicle is finished, as some fail-safe functions are canceled when the ignition switch is turned off.

-

If the ignition switch cannot be turned ON (the power source mode cannot be changed to ON) when the vehicle is brought in, measure the voltage of the battery. If the voltage is below 11 V, recharge or replace the battery before performing troubleshooting.

-

If the ignition switch cannot be turned to ON even though the battery voltage is normal, repair this malfunction before performing troubleshooting.

Result Proceed to NEXT

NEXT

-

-

CUSTOMER PROBLEM ANALYSIS

Tech Tips

-

When troubleshooting, confirm that the problem symptoms have been accurately identified. Preconceptions should be discarded in order to make an accurate judgment. To clearly understand what the problem symptoms are, it is extremely important to ask the customer about the problem and the conditions at the time the malfunction occurred.

-

Ask the customer if the vehicle is/was equipped with additional devices such as a theft deterrent device or monitor. (If equipped, explain the customer that the additional devices will be removed before performing troubleshooting as the malfunction cannot be checked properly)

-

It is useful to confirm the symptoms and the conditions in which the vehicle was operating at the time when a malfunction occurred. This helps to narrow down the malfunctioning part.

Tech Tips

-

What was affected (system, part or meter warning indicators)

-

What happened (details of the malfunction)

-

When (occurrence date and time, frequency and if it recurs or not)

-

Under what kind of situation did the problem occur (driving and operating condition at the occurrence and weather)

-

Road type or condition (city, suburb, paved road, unpaved road, highway, etc.)

-

Return conditions (what made the vehicle return to normal, for example, the ignition switch was turned off)

Points to be confirmed Symptom

-

Electric power steering

-

Normal

-

A little heavier than usual

-

There was no assist

-

Air conditioning

-

Whether the air conditioning system operated

-

Whether the blower fan operated

-

Multi-information display items

-

Whether the update of multi-information display items stopped

-

Whether the numeric part of drivable distance was not displayed

-

Auto lock and unlock operation

-

Whether the speed linked auto-lock function operated while driving

-

Whether the unlock function operated when the shift lever was moved to P

-

Wireless door lock function and entry function

-

Whether the lock/unlock function operated

-

Whether the illumination was turned on when the key was brought into a detection area

-

Operation of other systems of concern

Meter warning lights

-

Illumination of warning lights and the order in which they illuminated

-

Check engine (MIL)

-

ABS

-

SRS

-

EPS

-

SLIP

-

Master

-

Brake

-

PCS

-

Automatic high beam

-

Tire pressure

-

Others

-

Needle movement

-

Speedometer

-

Tachometer

-

Coolant temperature gauge

-

Content displayed on the multi-information display

Result Proceed to NEXT -

NEXT

-

-

CHECK GTS OPERATION

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Check that the GTS and ECUs can communicate with the ignition switch ON.

Tech Tips

-

If communication is not possible, the GTS screen will indicate an error.

-

If communication between the GTS and ECUs is not possible, either the GTS or vehicle has a malfunction.

-

When communication between the GTS and the vehicle is not possible, but communication is possible when the GTS is connected to another vehicle, the vehicle has the malfunction. Inspect the CANH and CANL main lines of the DLC3 and the ECU power source circuits (in this case perform steps 23 to 25 first). In addition, check that the BAT terminal of the DLC3 receives battery voltage (11 V or more).

-

If communication between the GTS and ECUs is still not possible even when the GTS is connected to another vehicle, the GTS has a malfunction. Perform the self tests described in the GTS operator's manual. (The GTS may be malfunctioning or its battery may be discharged)

Result Result Proceed to OK (Communication between the GTS and the vehicle is possible) A OK (Communication between the GTS and the vehicle is not possible but communication is possible when connected to another vehicle) B NG (Communication is not possible between the GTS and the vehicle, nor between the GTS and another vehicle) C -

B

CHECK V BUS MAIN LINE Click here

C

Refer to GTS operator's manual

A

-

-

CHECK DTC (CENTRAL GATEWAY ECU)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Central Gateway / Trouble Codes.

Body Electrical > Central Gateway > Trouble CodesOK DTC B1003 is not output. Result Proceed to OK NG

NG

REPLACE CENTRAL GATEWAY ECU Click here

OK

-

-

CHECK DTC

-

Using the GTS, perform Health Check to read current and history DTCs and record them.

Note

-

CAN communication DTCs are output when there is an open or short in any of the communication lines. Any problems with the power source of a corresponding ECU or sensor, or problems in the ECU or sensor itself also cause these DTCs to be output.

-

If a CAN communication line connector is disconnected with the ignition switch ON, the ECUs of the corresponding system and related systems store a DTC.

Tech Tips

-

If an open in a CAN main bus line, a short between the CAN bus lines (CANH and CANL) or a +B or ground short in a CAN bus occurs, DTCs of almost all ECUs and sensors on the CAN bus may be output (or a message indicating a communication error may be displayed on the GTS screen). In this case, check the resistance of the CAN bus (steps 8 to 16) first.

-

If an open occurs in just one of the lines of a CAN branch, DTCs which are not related to malfunctioning parts may be output (DTCs may be displayed randomly), or a message indicating a communication error may be displayed on the GTS.

-

-

Read the freeze frame data using the GTS and record it.

Result Proceed to NEXT

NEXT

-

-

CHECK COMMUNICATION MALFUNCTION DTCs (CONNECTION STATUS CHECK USING GTS)

-

Select "Communication Malfunction Check" from the screen on the GTS.

-

Record all the DTCs stored for ECUs and sensors.

Result Proceed to NEXT

NEXT

-

-

CHECK CAN BUS CHECK (CONNECTION STATUS CHECK USING GTS)

-

Based on the vehicle equipment and specifications, confirm the systems that use CAN communication.

-

Select "CAN Bus Check" from the screen on the GTS.

-

Observe the screen for approximately 2 minutes to check the ECUs and sensors displayed on the screen.

Result Proceed to NEXT

NEXT

-

-

CHECK CENTRAL GATEWAY ECU BRANCH LINE AND BUS 2 MAIN LINE (CA4H - CA4L)

Note

Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

Tech Tips

Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

-

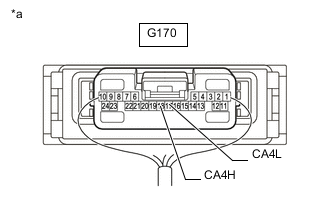

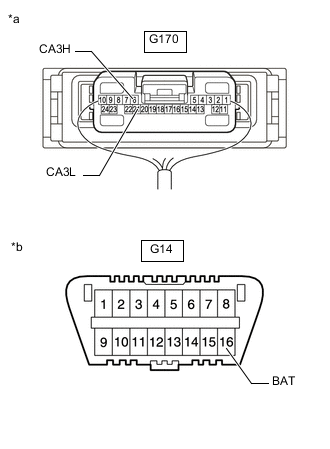

*a Component with harness connected

(Central Gateway ECU)

Disconnect the cable from the negative (-) battery terminal.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-18 (CA4H) - G170-17 (CA4L) Cable disconnected from negative (-) battery terminal 54 to 69 Ω Result Result Proceed to OK A NG (70 Ω or higher) B NG (Below 54 Ω) C

B

GO TO OPEN IN BUS 2 MAIN BUS LINE Click here

C

GO TO CHECK BUS 2 LINES FOR SHORT CIRCUIT Click here

A

-

-

CHECK FOR SHORT TO GND IN BUS 2 (CA4H, CA4L - CG)

-

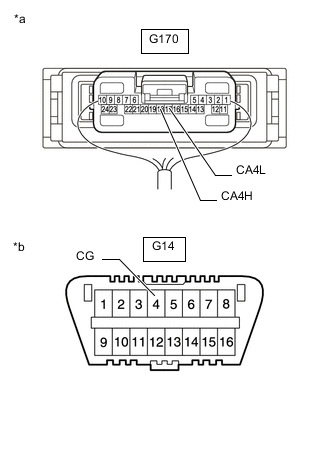

*a Component with harness connected

(Central Gateway ECU)

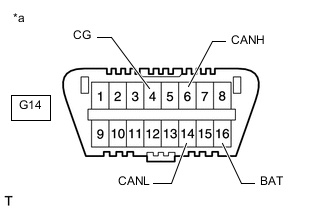

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-18 (CA4H) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher G170-17 (CA4L) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 2 LINE FOR SHORT TO GND Click here

OK

-

-

CHECK FOR SHORT TO +B IN BUS 2 (CA4H, CA4L - BAT)

-

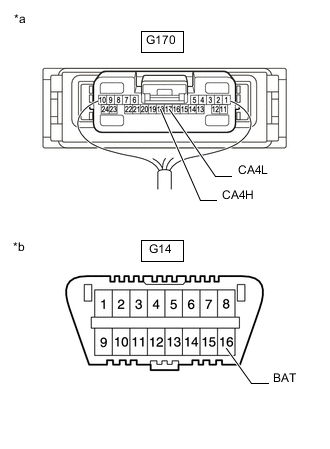

*a Component with harness connected

(Central Gateway ECU)

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-18 (CA4H) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher G170-17 (CA4L) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 2 LINE FOR SHORT TO +B Click here

OK

-

-

CHECK FOR BUS 5 MAIN LINE (CA5H - CA5L)

Note

Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

Tech Tips

Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

-

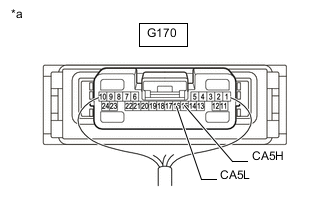

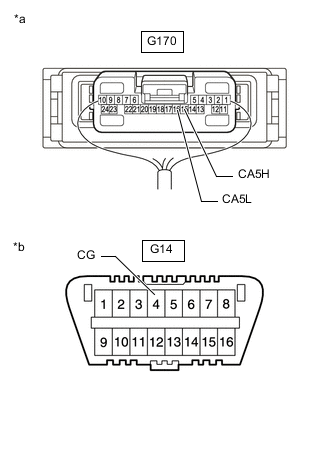

*a Component with harness connected

(Central Gateway ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-15 (CA5H) - G170-16 (CA5L) Cable disconnected from negative (-) battery terminal 54 to 69 Ω Result Result Proceed to OK A NG (70 Ω or higher) B NG (Below 54 Ω) C

B

GO TO OPEN IN BUS 5 MAIN BUS LINE Click here

C

GO TO CHECK BUS 5 LINES FOR SHORT CIRCUIT Click here

A

-

-

CHECK FOR SHORT TO GND IN BUS 5 (CA5H, CA5L - CG)

-

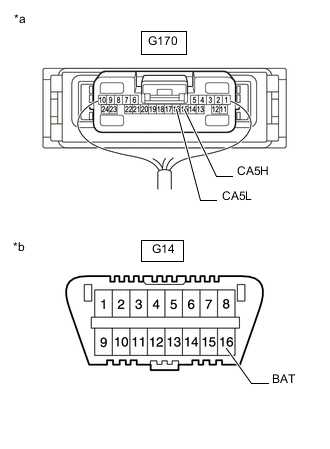

*a Component with harness connected

(Central Gateway ECU)

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-15 (CA5H) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher G170-16 (CA5L) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 5 LINE FOR SHORT TO GND Click here

OK

-

-

CHECK FOR SHORT TO +B IN BUS 5 (CA5H, CA5L - BAT)

-

*a Component with harness connected

(Central Gateway ECU)

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-15 (CA5H) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher G170-16 (CA5L) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 5 LINE FOR SHORT TO +B Click here

OK

-

-

CHECK FOR BUS 3 MAIN LINE (CA3H - CA3L)

Note

Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

Tech Tips

Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

-

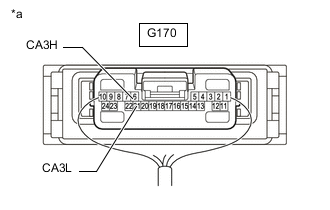

*a Component with harness connected

(Central Gateway ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-6 (CA3H) - G170-21 (CA3L) Cable disconnected from negative (-) battery terminal 54 to 69 Ω Result Result Proceed to OK A NG (70 Ω or higher) B NG (Below 54 Ω) C

B

GO TO OPEN IN BUS 3 MAIN BUS LINE Click here

C

GO TO CHECK BUS 3 LINES FOR SHORT CIRCUIT Click here

A

-

-

CHECK FOR SHORT TO GND IN BUS 3 (CA3H, CA3L - CG)

-

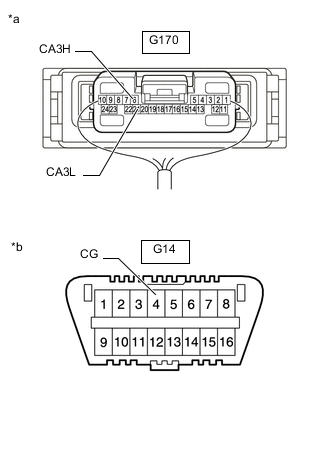

*a Component with harness connected

(Central Gateway ECU)

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-6 (CA3H) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher G170-21 (CA3L) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 3 LINE FOR SHORT TO GND Click here

OK

-

-

CHECK FOR SHORT TO +B IN BUS 3 (CA3H, CA3L - BAT)

-

*a Component with harness connected

(Central Gateway ECU)

*b Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G170-6 (CA3H) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher G170-21 (CA3L) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher Result Proceed to OK NG

NG

GO TO CHECK BUS 3 LINE FOR SHORT TO +B Click here

OK

-

-

CHECK RESULT OF CAN BUS CHECK (CONNECTION STATUS CHECK USING GTS)

-

Inspect or repair the probable malfunctioning part based on the check result of step 7 (the step in which CAN bus check was performed).

CAN Bus CheckResult of CAN Bus Check (Connection Status Check Using GTS) Result Proceed to All ECUs and sensors connected to the CAN communication system are displayed on the screen.

(CAN bus circuit is currently normal)

A

-

All ECUs except the main body ECU (multiplex network body ECU) connected to sub bus 1 are not displayed on the screen.

-

The main body ECU (multiplex network body ECU) outputs DTC U1002.

(Open or short in sub bus 1 main lines)

B

-

All ECUs except the driving support ECU assembly connected to local bus are not displayed on the screen.

-

The driving support ECU assembly outputs DTC U1002.

(Open or short in local bus main lines)

C All ECUs except the central gateway ECU connected to bus 2 are not displayed on the screen.

(Open in central gateway ECU branch lines or central gateway ECU malfunction)

D One of the ECUs or sensors connected to the bus 2, bus 3 or bus 5 is not displayed on the screen.

(Open in ECU or sensor branch lines, or communication interrupted)

E One of the ECUs or sensors connected to sub bus 1 is not displayed on the screen.*1

(Open in ECU or sensor branch lines, or communication interrupted)

F One of the ECUs or sensors connected to local bus is not displayed on the screen.*2

(Open in ECU or sensor branch lines, or communication interrupted)

In addition to ECUs and sensors which are connected to the bus 2 but are not displayed on the screen, there are ECUs or sensors for which the detection status changes (changes between detected and not detected) during the inspection.

(Open in one side of ECU or sensor branch lines)

G In addition to ECUs and sensors which are connected to the bus 3 but are not displayed on the screen, there are ECUs or sensors for which the detection status changes (changes between detected and not detected) during the inspection.

(Open in one side of ECU or sensor branch lines)

H In addition to ECUs and sensors which are connected to the bus 5 but are not displayed on the screen, there are ECUs or sensors for which the detection status changes (changes between detected and not detected) during the inspection.

(Open in one side of ECU or sensor branch lines)

I Note

-

*1: In this case, as the main body ECU (multiplex network body ECU) output communication DTCs (DTCs that start with U), the problem area can be determined from those DTCs.

-

*2: In this case, as the driving support ECU assembly output communication DTCs (DTCs that start with U), the problem area can be determined from those DTCs.

-

Non-installed ECUs or sensors will not be displayed. Do not mistake them for being in communication stop mode.

-

It may be possible to select buses that do not have ECUs or sensors from the bus selection pulldown menu on the GTS. This is not a malfunction. (This occurs when optional devices are not on a sub bus that is monitored by a gateway function equipped ECU)

Tech Tips

-

Regarding CAN Bus Check, refer to How to Interpret CAN Bus Check Screen.

-

If the detection status of ECUs changes during the inspection, one of the branch lines of a connected ECU or sensor may be open. (Signals from the ECU or sensor that has an open in one of its branch lines create electrical noise, affecting response to the GTS and whether or not the ECUs and sensors are displayed)

-

Regarding the ECUs connected to sub bus 1, the main body ECU (multiplex network body ECU) displays communicating ECUs on the GTS. If the communication between the main body ECU (multiplex network body ECU) and an ECU stops for 10 seconds or more, the ECU will no longer be displayed on the GTS.

-

Regarding the ECUs connected to local bus, the driving support ECU assembly displays communicating ECUs on the GTS. If the communication between the driving support ECU assembly and an ECU stops for 10 seconds or more, the ECU will no longer be displayed on the GTS.

-

Regarding the communication stop mode for ECUs connected to sub bus 1 and local bus, refer to the inspection procedure for the DTCs that indicate a communication stop.

-

B

GO TO U1002 Click here

C

GO TO U1002 Click here

D

GO TO CENTRAL GATEWAY ECU COMMUNICATION STOP MODE Click here

E

GO TO COMMUNICATION STOP MODE TABLE Click here

F

GO TO DIAGNOSTIC TROUBLE CODE CHART Click here

G

GO TO OPEN IN ONE SIDE OF BUS 2 BRANCH LINE Click here

H

GO TO OPEN IN ONE SIDE OF BUS 3 BRANCH LINE Click here

I

GO TO OPEN IN ONE SIDE OF BUS 5 BRANCH LINE Click here

A

-

-

CHECK RESULT OF CHECK COMMUNICATION MALFUNCTION CHECK (SELECT THE MALFUNCTIONING BUS)

-

Inspect or repair the probable malfunctioning part based on the check result of step 6 (the step in which checking for communication malfunction DTCs was performed).

Check Result of Communication Malfunction Check (Select Malfunctioning Bus) Inspection Result Proceed to The sub bus monitor ECU has not output communication DTCs but ECUs connected to the bus 2, bus 3 or bus 5 have stored communication DTCs.

(A malfunction occurred in the bus 2, bus 3 or bus 5)

A The main body ECU (multiplex network body ECU) outputs DTC U1002.

(A malfunction occurred in sub bus 1)

B The driving support ECU assembly outputs DTC U1002.

(A malfunction occurred in local bus)

C

-

The main body ECU (multiplex network body ECU) outputs DTCs other than DTC U1002.

(A malfunction occurred in an ECU branch line connected to sub bus 1)

-

The driving support ECU assembly outputs DTCs other than DTC U1002.

(A malfunction occurred in an ECU branch line connected to local bus)

D Tech Tips

-

The term ''sub bus monitor ECU'' refers to a gateway function equipped ECU that is able to monitor a bus and store DTCs.

-

When checking for communication DTCs, refer to How to Interpret Communication DTCs (DTCs that start with U).

-

Because a sub bus monitor ECU monitors signals from all ECUs that are connected to its sub bus, a sub bus monitor ECU can detect ECUs with a communication stop more accurately. In this case, perform troubleshooting by referring to the DTC combination table for the sub bus.

-

If communication DTCs are stored, and all ECUs and sensors connected to the CAN communication system are displayed on the CAN Bus Check screen of the GTS, a past malfunction that is currently not occurring is suspected.

-

When a CAN branch of the bus 2, bus 3 or bus 5 is malfunctioning, because the ECUs and sensors related to it detect the malfunction, the problem area can be determined using the combination of DTCs that are output.

-

When sub bus 1 is malfunctioning, the main body ECU (multiplex network body ECU) detects a communication stop for connected ECUs and a network communication error, and stores DTCs.

-

When local bus is malfunctioning, the driving support ECU assembly detects a communication stop for connected ECUs and a network communication error, and stores DTCs.

-

When both the sub bus monitor ECU and the ECUs connected to the bus 2, bus 3 or bus 5 store communication DTCs, check and repair the corresponding sub bus first.

-

B

GO TO U1002 Click here

C

GO TO U1002 Click here

D

GO TO DIAGNOSTIC TROUBLE CODE CHART Click here

A

-

-

DTC COMBINATION TABLE

-

Confirm the problem according to the combination of output DTCs regarding the CAN communication system.

Result Result Proceed to Combination of DTCs is not in DTC Combination Table. A Combination of DTCs is in DTC Combination Table. B Tech Tips

CAN communication system history DTCs may indicate the problem if CAN communication system DTCs are output and all ECUs and sensors connected to the CAN communication system are displayed on CAN Bus Check of the GTS.

B

GO TO COMMUNICATION STOP MODE TABLE Click here

A

-

-

IDENTIFICATION OF PROBLEM (PAST MALFUNCTION IN MAIN BUS OF BUS 2, BUS 3 OR BUS 5)

-

Connect the cable to the negative (-) battery terminal.

-

Clear the DTCs using the GTS.

-

Perform the tests in Symptom Simulation to check the wire harnesses and connectors including those for main bus lines.

-

Based on the results of the check, inspect the parts that output DTCs to determine the malfunctioning part.

Tech Tips

If DTCs are output, do not turn the ignition switch off.

Result Proceed to NEXT

NEXT

-

-

REPAIR OR REPLACEMENT

Result Proceed to NEXT

NEXT

-

CONFIRMATION TEST

Result Proceed to NEXT

NEXT

END

-

CHECK V BUS MAIN LINE

Note

Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

Tech Tips

Operating the ignition switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

-

Disconnect the cable from the negative (-) battery terminal.

-

*a Front view of DLC3 Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition G14-6 (CANH) - G14-14 (CANL) Cable disconnected from negative (-) battery terminal 54 to 66 Ω G14-6 (CANH) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher G14-14 (CANL) - G14-4 (CG) Cable disconnected from negative (-) battery terminal 200 Ω or higher G14-6 (CANH) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher G14-14 (CANL) - G14-16 (BAT) Cable disconnected from negative (-) battery terminal 6 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE CAN MAIN BUS LINE OR CONNECTOR (CENTRAL GATEWAY ECU - DLC3)

OK

-

-

CHECK DTC (CENTRAL GATEWAY ECU)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Central Gateway / Trouble Codes.

Body Electrical > Central Gateway > Trouble CodesOK DTC B1003 is not output. Result Proceed to OK NG

NG

REPLACE CENTRAL GATEWAY ECU

OK

-

-

READ VALUE USING GTS

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Body Electrical / Central Gateway / Data List.

-

According to the display on the GTS, read the Data List.

Body Electrical > Central Gateway > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note IG2 SW Ignition switch OFF or ON OFF: Ignition switch off

ON: Ignition switch ON

"OFF" is also displayed for this item when the ignition switch is ACC. IG1 SW Ignition switch OFF or ON OFF: Ignition switch off

ON: Ignition switch ON

"OFF" is also displayed for this item when the ignition switch is ACC. ACC SW Ignition switch OFF or ON OFF: Ignition switch off

ON: Ignition switch ACC

"ON" is also displayed for this item when the ignition switch is ON. +B Voltage Battery voltage Over 8 V or Under 8 V Over 8 V: Battery voltage 8 V or higher

Under 8 V: Battery voltage below 8 V

-

Body Electrical > Central Gateway > Data ListTester Display IG2 SW IG1 SW ACC SW +B Voltage OK The display is as specified in the normal condition column. Result Proceed to OK NG

OK

REPLACE CENTRAL GATEWAY ECU Click here

NG

GO TO CENTRAL GATEWAY ECU COMMUNICATION STOP MODE Click here

-