ENGINE ASSEMBLY REMOVAL

CAUTION / NOTICE / HINT

CAUTION:

The engine assembly with transmission is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

PROCEDURE

-

PRECAUTION

Note

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

-

REMOVE ENGINE ROOM SIDE COVER

-

REMOVE COOL AIR INTAKE DUCT SEAL

-

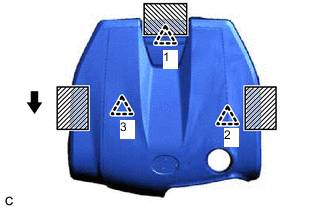

REMOVE V-BANK COVER SUB-ASSEMBLY

-

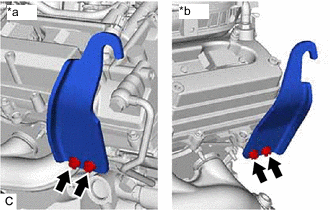

Areas to be held when lifting V-bank cover sub-assembly

Front Hold the rear area of the V-bank cover sub-assembly shown in the illustration and detach the rear clip (1).

Note

If the V-bank cover sub-assembly is lifted rearward or forward and to the right or left at the same time, the V-bank cover sub-assembly may be damaged.

-

Hold and lift both sides of the V-bank cover sub-assembly to detach the 2 front clips (2) and (3) to remove the V-bank cover sub-assembly.

-

-

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

-

DISCHARGE FUEL SYSTEM PRESSURE

-

ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

-

SECURE STEERING WHEEL

-

REMOVE FRONT WHEELS

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

-

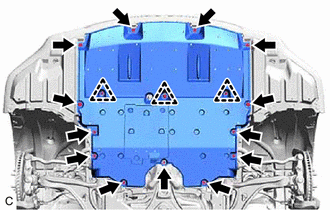

REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

-

Remove the 13 screws, 3 clips and No. 1 engine under cover assembly.

-

-

REMOVE REAR ENGINE UNDER COVER LH

-

Remove the screw and rear engine under cover LH.

-

-

REMOVE REAR ENGINE UNDER COVER RH

Tech Tips

Perform the same procedure as for the LH side.

-

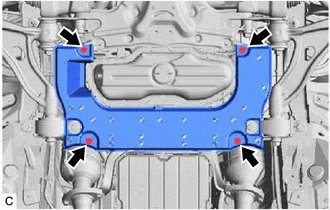

REMOVE FRONT SUSPENSION MEMBER BRACE

-

Remove the 4 bolts, turn the clip to loosen it, and remove the front suspension member brace.

Tech Tips

Do not remove the clip from the front suspension member brace.

-

-

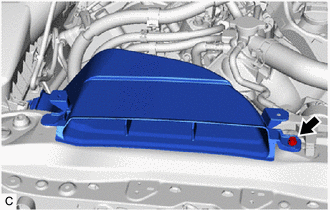

REMOVE NO. 2 ENGINE UNDER COVER (w/ No.2 Engine Under Cover)

-

Remove the 4 screws and No. 2 engine under cover.

-

-

DRAIN ENGINE OIL

-

DRAIN ENGINE COOLANT

-

DRAIN AUTOMATIC TRANSMISSION FLUID

-

REMOVE INLET NO. 1 AIR CLEANER

-

Remove the bolt and inlet No. 1 air cleaner.

-

-

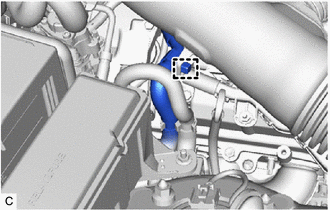

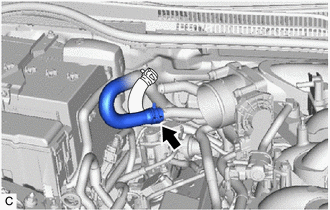

DISCONNECT NO. 2 VENTILATION HOSE

-

REMOVE AIR CLEANER CAP WITH AIR CLEANER HOSE

Tech Tips

Perform this procedure only when replacement of the air cleaner filter element sub-assembly or air cleaner case sub-assembly is necessary.

-

REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

Tech Tips

Perform this procedure only when replacement of the air cleaner filter element sub-assembly is necessary.

-

Remove the air cleaner filter element sub-assembly from the air cleaner case sub-assembly.

-

-

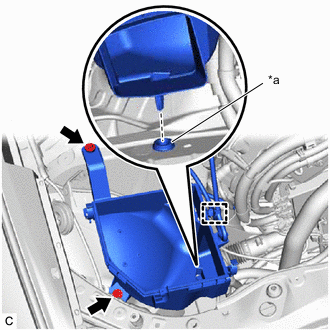

REMOVE AIR CLEANER CASE SUB-ASSEMBLY

Tech Tips

Perform this procedure only when replacement of the air cleaner case sub-assembly is necessary.

-

*a Air Cleaner Support Disconnect the wire harness clamp from the air cleaner case sub-assembly.

-

Remove the 2 bolts and air cleaner case sub-assembly.

Note

Make sure the air cleaner support remains attached to the vehicle body.

-

-

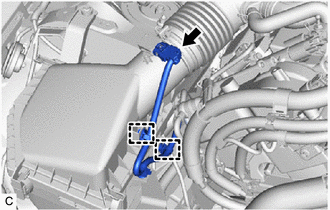

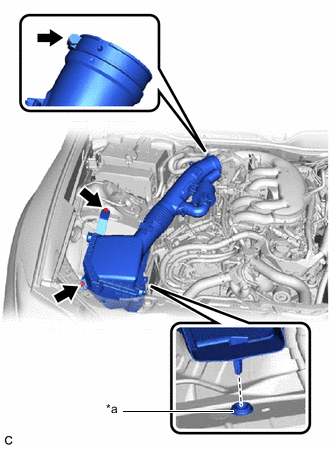

REMOVE AIR CLEANER ASSEMBLY WITH AIR CLEANER HOSE

-

Disconnect the mass air flow meter sub-assembly connector.

-

Disconnect the 2 wire harness clamps from the air cleaner assembly with air cleaner hose.

-

Disconnect the No. 2 fuel vapor feed hose clamp from the air cleaner cap with air cleaner hose.

-

Disconnect the union to check valve hose from the air cleaner cap with air cleaner hose (for RHD).

-

*a Air Cleaner Support Remove the 2 bolts.

-

Loosen the hose clamp and remove the air cleaner assembly with air cleaner hose.

Note

Make sure the air cleaner support remains attached to the vehicle body.

-

-

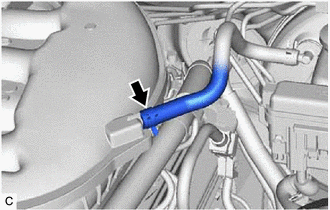

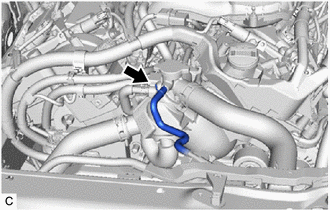

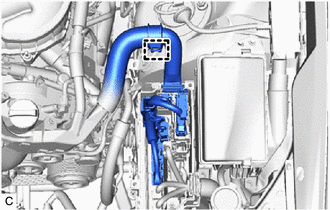

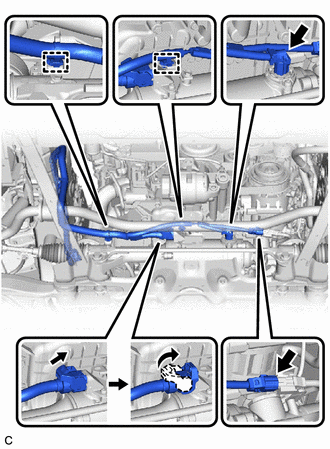

DISCONNECT UNION TO CHECK VALVE HOSE (for LHD)

-

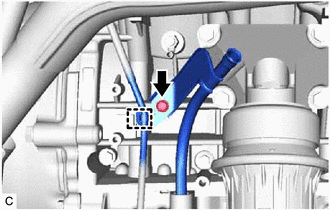

Slide the clip and disconnect the union to check valve hose from the intake air surge tank assembly.

-

-

DISCONNECT UNION TO CHECK VALVE HOSE (for RHD)

-

Slide the clip and disconnect the union to check valve hose from the intake air surge tank assembly.

-

-

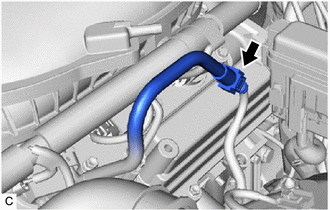

DISCONNECT NO. 2 FUEL VAPOR FEED HOSE

-

Slide the clip and disconnect the No. 2 fuel vapor feed hose from the purge valve (purge VSV).

-

-

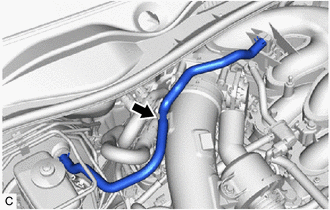

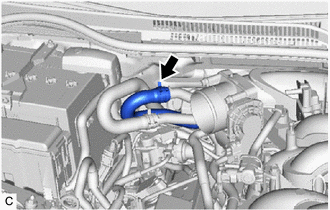

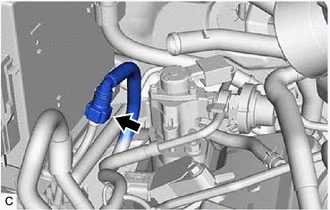

DISCONNECT RADIATOR RESERVE TANK HOSE

-

Slide the clip and disconnect the radiator reserve tank hose from the water inlet sub-assembly.

-

-

REMOVE NO. 1 RADIATOR HOSE

-

DISCONNECT NO. 2 RADIATOR HOSE

-

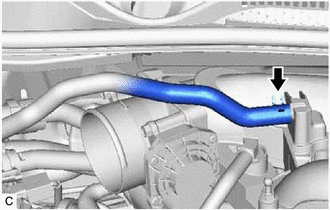

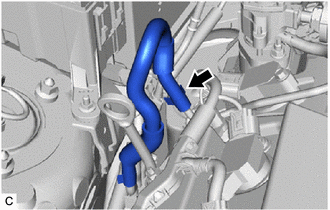

DISCONNECT INLET HEATER WATER HOSE A

-

Slide the clip and disconnect the inlet heater water hose A from the No. 3 heater water by-pass pipe.

-

-

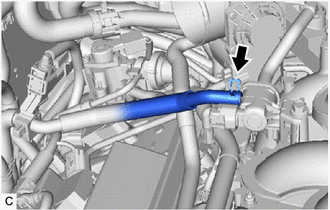

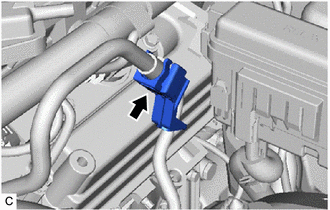

DISCONNECT OUTLET HEATER WATER HOSE A

-

Slide the clip and disconnect the outlet heater water hose A from the No. 3 heater water by-pass pipe.

-

-

DISCONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE

-

DISCONNECT SUCTION HOSE

-

REMOVE ENGINE ROOM ECU COVER

-

DISCONNECT WIRE HARNESS (for LHD)

Tech Tips

After disconnecting the wire harness, secure it with tape or equivalent to keep it out of the way.

-

Engine room LH side:

-

Disconnect the engine wire clamp.

-

Disconnect the engine wire from the engine room ECU box.

-

-

Engine room RH side:

-

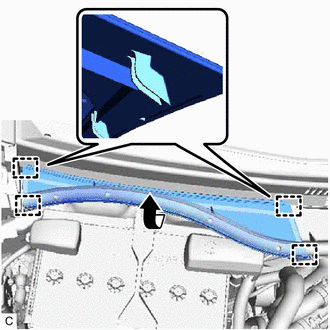

Separate the No. 1 center cowl top ventilator louver from the cowl top ventilator louver sub-assembly.

-

Disconnect the No. 2 engine wire clamp.

-

Remove the nut and disconnect the No. 2 engine wire from the positive (+) battery terminal.

-

Remove the No. 1 engine room relay block cover from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disconnect the 2 No. 4 engine wire clamps.

-

Remove the nut from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disengage the 2 claws and disconnect the No. 4 engine wire from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disconnect the No. 3 engine wire clamp.

-

Remove the bolt and disconnect the No. 3 engine wire from the vehicle body.

-

-

-

DISCONNECT WIRE HARNESS (for RHD)

Tech Tips

After disconnecting the wire harness, secure it with tape or equivalent to keep it out of the way.

-

Engine room LH side:

-

Separate the No. 1 center cowl top ventilator louver from the cowl top ventilator louver sub-assembly.

-

Disconnect the No. 2 engine wire clamp.

-

Remove the nut and disconnect the No. 2 engine wire from the positive (+) battery terminal.

-

Remove the No. 1 engine room relay block cover from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disconnect the No. 4 engine wire clamp.

-

Remove the nut from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disengage the 2 claws and disconnect the No. 4 engine wire from the No. 1 engine room relay block and No. 1 junction block assembly.

-

Disconnect the engine wire clamp.

-

Disconnect the engine wire from the engine room ECU box.

-

-

Engine room RH side:

-

Disconnect the No. 3 engine wire clamp.

-

Remove the bolt and disconnect the No. 3 engine wire from the vehicle body.

-

-

-

DISCONNECT FUEL TUBE SUB-ASSEMBLY

-

Remove the fuel pipe clamp.

-

Disconnect the fuel tube sub-assembly from the fuel pipe.

-

-

DISCONNECT NO. 3 FUEL HOSE

-

Slide the clip and disconnect the No. 3 fuel hose from the No. 1 fuel pipe sub-assembly.

-

-

DISCONNECT NO. 2 FUEL TUBE SUB-ASSEMBLY

-

Remove the fuel pipe clamp.

-

Disconnect the No. 2 fuel tube sub-assembly from the fuel pipe.

-

-

REMOVE NO. 2 ENGINE OIL LEVEL DIPSTICK GUIDE

-

REMOVE PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY

-

REMOVE NO. 1 EXHAUST PIPE SUPPORT BRACKET SUB-ASSEMBLY

-

SEPARATE STEERING SLIDING WITH SHAFT YOKE SUB-ASSEMBLY

-

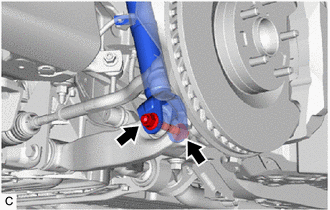

DISCONNECT FRONT SHOCK ABSORBER ASSEMBLY LH

-

Remove the bolt and nut, and disconnect the front shock absorber assembly LH from the front suspension lower arm assembly LH.

Note

Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured.

-

-

DISCONNECT FRONT SHOCK ABSORBER ASSEMBLY RH

Tech Tips

Perform the same procedure as for the LH side.

-

SEPARATE FRONT LOWER BALL JOINT ASSEMBLY LH

-

SEPARATE FRONT LOWER BALL JOINT ASSEMBLY RH

Tech Tips

Perform the same procedure as for the LH side.

-

DISCONNECT WIRE HARNESS

-

Disconnect the 2 wire harness clamps and 3 wire harness connectors from the power steering link assembly.

Tech Tips

For the connector with lock lever, pull up the lock lever to disengage the lock.

-

-

REMOVE FLOOR SHIFT GEAR SHIFTING ROD SUB-ASSEMBLY

-

REMOVE SUSPENSION TOWER DAMPER

-

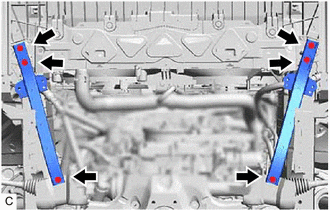

REMOVE FRONT UPPER NO. 2 SUSPENSION MEMBER

-

Remove the 6 bolts and 2 front upper No. 2 suspension members.

-

-

REMOVE FRONT LOWER SUSPENSION MEMBER PROTECTOR

-

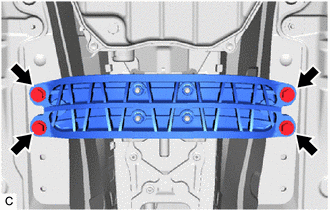

Remove the 4 bolts and front lower suspension member protector from the front suspension crossmember sub-assembly.

-

-

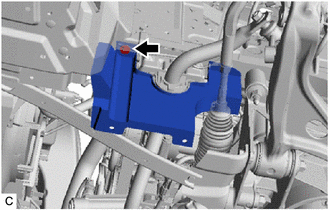

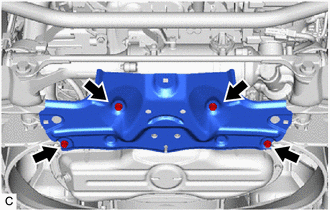

REMOVE ENGINE ASSEMBLY WITH TRANSMISSION

-

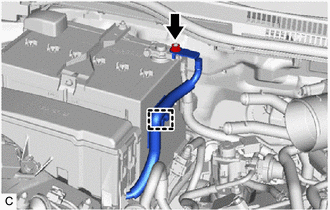

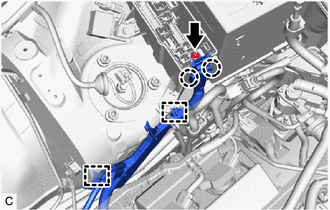

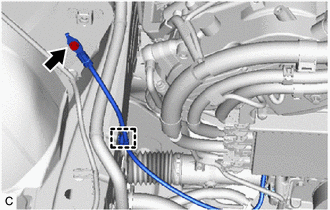

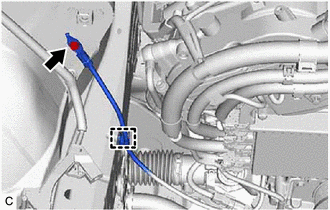

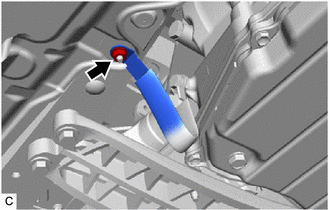

Remove the nut and disconnect the No. 2 earth wire from the vehicle body.

-

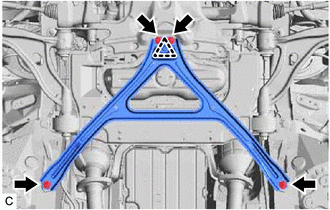

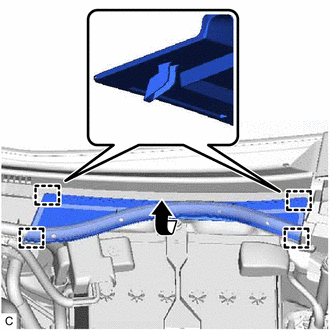

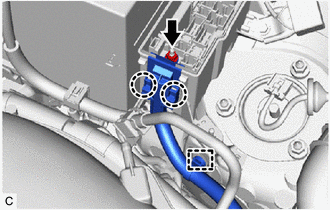

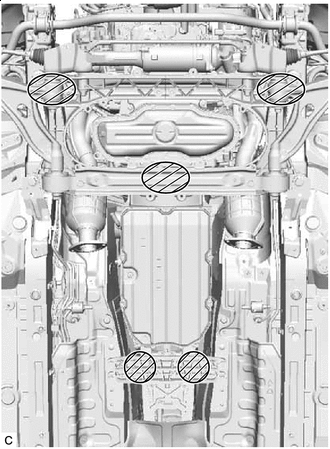

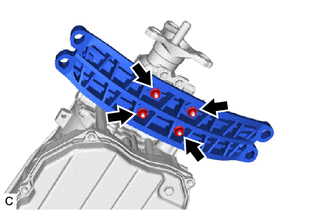

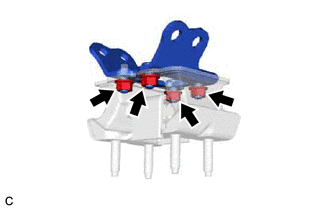

Attachment Installation Position Place height adjustment attachments and plate lift attachments in the positions shown in the illustration and set an engine lifter underneath the engine assembly with transmission.

Note

-

Using height adjustment attachments and plate lift attachments, keep the engine assembly with transmission horizontal.

-

Securely support the engine assembly to prevent it from turning upside down until it is secured to an engine stand.

-

To prevent the oil pan from deforming, do not place any attachments under the oil pan of the engine assembly with transmission.

-

Do not perform any procedure while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

-

-

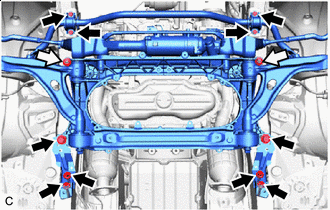

Remove the 4 bolts, and separate the rear engine mounting member from the vehicle body.

-

Bolt

Nut Remove the 4 bolts and disconnect the front No. 2 stabilizer bracket LH and front No. 2 stabilizer bracket RH.

-

Remove the 6 bolts, 2 nuts and strut bar bracket reinforcement LH, strut bar bracket reinforcement RH and front suspension crossmember sub-assembly.

-

Operate the engine lifter and remove the engine assembly with transmission from the vehicle.

Note

-

Make sure that the engine assembly with transmission is clear of all wiring, hoses and the steering sliding with shaft yoke sub-assembly.

-

After removing the engine assembly with transmission, hang the steering sliding with shaft yoke sub-assembly with rope or equivalent.

-

-

-

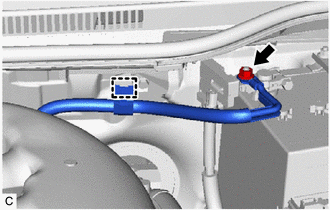

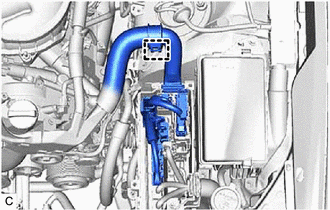

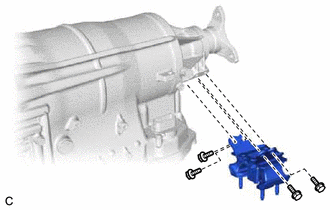

INSTALL NO. 1 ENGINE HANGER

-

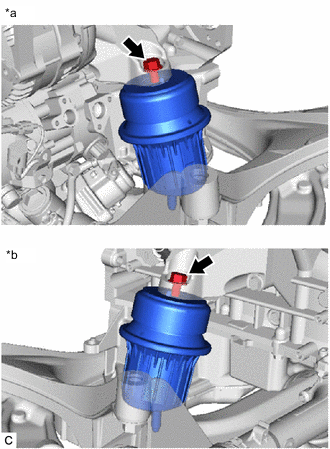

*a RH Side *b LH Side Install the 2 No. 1 engine hangers with the 4 bolts shown in the illustration.

- Torque:

- 33 N*m { 337 kgf*cm, 24 ft.*lbf }

Tech Tips

No. 1 Engine Hanger 12281-31070 Bolt 91671-F0822 -

Attach an engine sling device and hang the engine assembly with transmission with a chain block.

Note

-

Pay attention to the angle of the sling device as the engine assembly or No. 1 engine hangers may be damaged or deformed if the angle is incorrect.

-

Do not perform any procedure while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

-

-

-

REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

-

Disconnect the wire harness clamp from the engine oil level dipstick guide.

-

Remove the bolt and engine oil level dipstick guide.

-

Remove the O-ring from the engine oil level dipstick guide.

-

-

REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY LH (TWC: Front Catalyst)

-

REMOVE EXHAUST MANIFOLD SUB-ASSEMBLY RH (TWC: Front Catalyst)

-

REMOVE STARTER ASSEMBLY

-

REMOVE FLYWHEEL HOUSING SIDE COVER

-

REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

-

DISCONNECT WIRE HARNESS

-

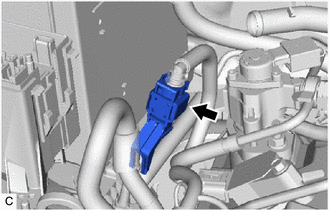

DISCONNECT WATER BY-PASS HOSE

-

REMOVE AUTOMATIC TRANSMISSION ASSEMBLY

-

REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

-

REMOVE FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

-

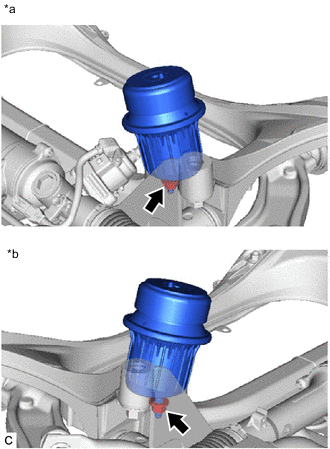

*a LH Side *b RH Side Remove the 2 bolts and front suspension crossmember sub-assembly from the engine assembly.

-

-

REMOVE FRONT ENGINE MOUNTING INSULATOR

Tech Tips

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

-

*a LH Side *b RH Side Remove the 2 nuts and 2 front engine mounting insulators from the front suspension crossmember sub-assembly.

-

-

REMOVE REAR ENGINE MOUNTING MEMBER

Tech Tips

Perform this procedure only when replacement of the rear No. 1 engine mounting insulator is necessary.

-

Remove the 4 nuts and rear engine mounting member from the rear No. 1 engine mounting insulator.

-

-

REMOVE REAR NO. 1 ENGINE MOUNTING INSULATOR

Tech Tips

Perform this procedure only when replacement of the rear No. 1 engine mounting insulator is necessary.

-

Remove the 4 bolts and No. 1 engine mounting bracket from the automatic transmission assembly.

-

Remove the 4 nuts and rear No. 1 engine mounting insulator from the No. 1 engine mounting bracket.

-

-

INSTALL ENGINE TO ENGINE STAND

-

Install the engine assembly to an engine stand.

Note

-

Pay attention to the angle of the sling device as the engine assembly or No. 1 engine hangers may be damaged or deformed if the angle is incorrect.

-

Do not perform any procedure while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

-

-

Remove the 4 bolts and 2 No. 1 engine hangers.

-

-

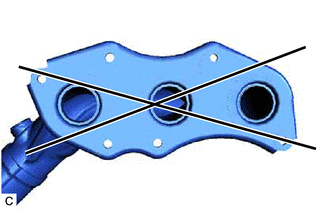

INSPECT EXHAUST MANIFOLD SUB-ASSEMBLY (TWC: Front Catalyst)

-

Using a precision straightedge and feeler gauge, measure the warpage of the surface which contacts the cylinder head sub-assembly.

Maximum Warpage 0.70 mm (0.02756 in.) Tech Tips

If the warpage is more than the maximum, replace the exhaust manifold sub-assembly.

-