CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM, Diagnostic DTC:P0705

| DTC Code | DTC Name |

|---|---|

| P0705 | Transmission Range Sensor Circuit Malfunction (PRNDL Input) |

DESCRIPTION

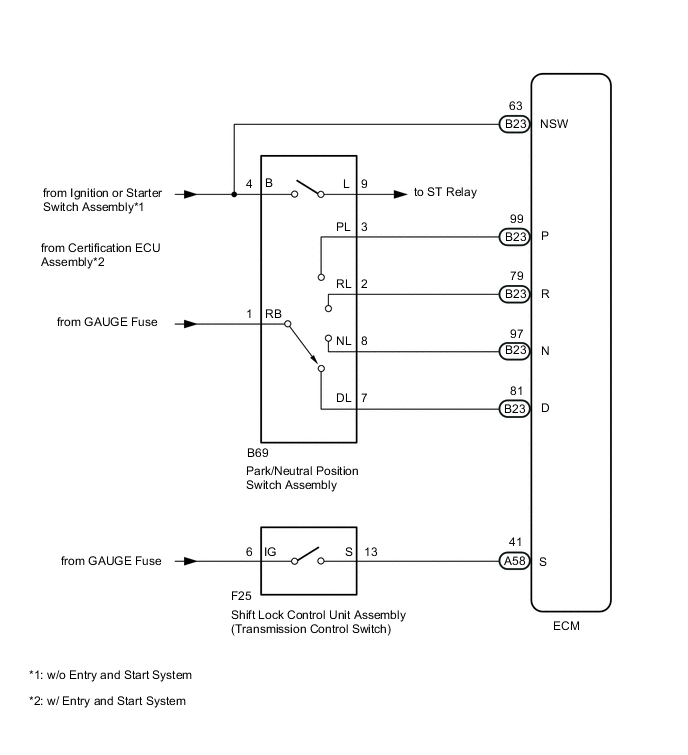

The park/neutral position switch assembly and shift lock control unit assembly (transmission control switch) detect the shift lever position and send signals to the ECM.

| DTC No. | DTC Detection Condition

|

Trouble Area |

|---|---|---|

| P0705 |

|

|

|

||

|

MONITOR DESCRIPTION

For security, the park/neutral position switch assembly detects the gearshift position so that engine can be started only when the shift lever is in P or N.

When the park/neutral position switch assembly and shift lock control unit assembly (transmission control switch) send more than one signal at a time from switch positions P, R, N, D or M, the ECM interprets this as a fault in the switch. The ECM will turn on the MIL and store the DTC.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

Note

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

-

READ VALUE USING GTS (NEUTRAL POSITION SW SIGNAL AND SHIFT SW STATUS)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Primary.

-

In accordance with the display on the GTS, read the Data List.

Engine and ECT Tester Display Measurement Item/Range Normal Condition Diagnostic Note Neutral Position SW Signal Park/neutral position switch status/

OFF or ON

-

OFF: Shift lever not in P or N

-

ON: Shift lever in P or N

When shift lever position displayed on GTS differs from actual position, adjustment of park/neutral position switch or shift cable may be incorrect. Shift SW Status (P Range) Park/neutral position switch status/

OFF or ON

-

OFF: Shift lever not in P

-

ON: Shift lever in P

Shift SW Status (R Range) Park/neutral position switch status/

OFF or ON

-

OFF: Shift lever not in R

-

ON: Shift lever in R

Shift SW Status (N Range) Park/neutral position switch status/

OFF or ON

-

OFF: Shift lever not in N

-

ON: Shift lever in N

Shift SW Status (D Range) Park/neutral position switch status/

OFF or ON

-

OFF: Shift lever not in D or M

-

ON: Shift lever in D or M

Result Result Proceed to Data displayed is within Normal Condition range A Data displayed is not within Normal Condition range B -

B

CHECK HARNESS AND CONNECTOR (BATTERY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY) Click here

A

-

-

READ VALUE USING GTS (SPORTS MODE SELECTION SW)

-

Enter the following menus: Powertrain / Engine and ECT / Data List / AT.

-

In accordance with the display on the GTS, read the Data List.

Engine and ECT Tester Display Measurement Item/Range Normal Condition Diagnostic Note Sports Mode Selection SW Sport mode select switch status/

OFF or ON

-

OFF: Shift lever not in M, "+" or "-"

-

ON: Shift lever in M, "+" or "-"

- Result Result Proceed to Data displayed is within Normal Condition range A Data displayed is not within Normal Condition range B -

A

CHECK INTERMITTENT PROBLEMS Click here

B

-

-

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH)

-

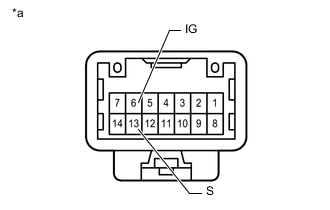

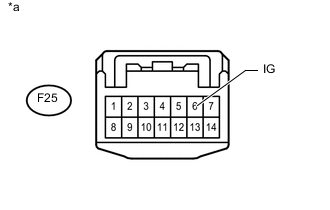

Text in Illustration *a Component without harness connected

(Transmission Control Unit Assembly

(Transmission Control Switch))

Disconnect the transmission control switch connector of the shift lock control unit assembly.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 6 (IG) - 13 (S) Shift lever in M, "+" or "-" Below 1 Ω Shift lever not in M, "+" or "-" 10 kΩ or higher

NG

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (IG POWER SUPPLY)

-

Turn the ignition switch to ON.

-

Text in Illustration *a Front view of wire harness connector

(Transmission Control Unit Assembly

(Transmission Control Switch))

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition F25-6 (IG) - Body ground Ignition switch ON 11 to 14 V Ignition switch off Below 1 V

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - ECM)

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open) Tester Connection Condition Specified Condition F25-13 (S) - A58-41 (S) Always Below 1 Ω Standard Resistance (Check for short) Tester Connection Condition Specified Condition F25-13 (S) or A58-41 (S) - Body ground and other terminals Always 10 kΩ or higher -

Connect the ECM connector.

-

Connect the transmission control switch connector of the shift lock control unit assembly.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

-

-

PERFORM INITIALIZATION

Note

-

Performing reset memory/initialization will clear the learned value of the deceleration sensor (deceleration sensor zero point calibration) and the CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, deceleration sensor zero point calibration, and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

-

Continuously variable transaxle assembly

-

ECM

-

Brake actuator assembly (Skid control ECU)

-

Oil pressure sensor

-

Deceleration sensor

-

-

After reset memory, always perform deceleration sensor (deceleration sensor zero point) calibration first, and then the CVT oil pressure calibration.

-

Always perform the zero point calibration with the vehicle on level ground.

-

Do not shake or vibrate the vehicle during the zero point calibration.

-

Using the GTS, perform the reset memory, deceleration sensor zero point calibration and CVT oil pressure calibration Click here.

-

Check for DTCs again Click here.

NEXT

END

-

-

CHECK HARNESS AND CONNECTOR (BATTERY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY)

-

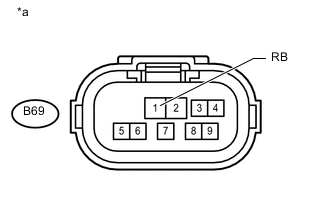

Text in Illustration *a Front view of wire harness connector

(to Park/Neutral Position Switch Assembly)

Disconnect the park/neutral position switch assembly connector.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition B69-1 (RB) - Body ground Ignition switch ON 11 to 14 V Ignition switch off Below 1 V -

Turn the ignition switch off.

-

Connect the park/neutral position switch assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

-

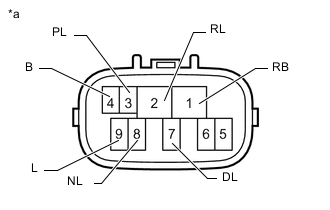

Text in Illustration *a Component without harness connected

(Park/Neutral Position Switch Assembly)

Disconnect the park/neutral position assembly switch connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 4 (B) - 9 (L) Shift lever in P or N Below 1 Ω Shift lever not in P or N 10 kΩ or higher 1 (RB) - 3 (PL) Shift lever in P Below 1 Ω Shift lever not in P 10 kΩ or higher 1 (RB) - 2 (RL) Shift lever in R Below 1 Ω Shift lever not in R 10 kΩ or higher 1 (RB) - 8 (NL) Shift lever in N Below 1 Ω Shift lever not in N 10 kΩ or higher 1 (RB) - 7 (DL) Shift lever in D or M Below 1 Ω Shift lever not in D or M 10 kΩ or higher -

Connect the park/neutral position switch assembly connector.

NG

REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH - ECM)

-

Disconnect the park/neutral position assembly switch connector.

-

Disconnect the ECM connectors.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open) Tester Connection Condition Specified Condition B69-3 (PL) - B23-99 (P) Always Below 1 Ω B69-2 (RL) - B23-79 (R) Always Below 1 Ω B69-8 (NL) - B23-97 (N) Always Below 1 Ω B69-7 (DL) - B23-81 (D) Always Below 1 Ω B69-4 (B) - B23-63 (NSW) Always Below 1 Ω Standard Resistance (Check for short) Tester Connection Condition Specified Condition B69-4 (B) or B23-63 (NSW) - Body ground and other terminals Always 10 kΩ or higher B69-2 (RL) or B23-79 (R) - Body ground and other terminals Always 10 kΩ or higher B69-7 (DL) or B23-81 (D) - Body ground and other terminals Always 10 kΩ or higher B69-8 (NL) or B23-97 (N) - Body ground and other terminals Always 10 kΩ or higher B69-3 (PL) or B23-99 (P) - Body ground and other terminals Always 10 kΩ or higher -

Connect the ECM connectors.

-

Connect the park/neutral position switch assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

-

-

PERFORM INITIALIZATION

Note

-

Performing reset memory/initialization will clear the learned value of the deceleration sensor (deceleration sensor zero point calibration) and the CVT oil pressure (CVT oil pressure calibration). Make sure to perform reset memory, deceleration sensor zero point calibration, and CVT oil pressure calibration when replacing any of the parts shown in the following table:

Replaced Part

-

Continuously variable transaxle assembly

-

ECM

-

Brake actuator assembly (Skid control ECU)

-

Oil pressure sensor

-

Deceleration sensor

-

-

After reset memory, always perform deceleration sensor (deceleration sensor zero point) calibration first, and then the CVT oil pressure calibration.

-

Always perform the zero point calibration with the vehicle on level ground.

-

Do not shake or vibrate the vehicle during the zero point calibration.

-

Using the GTS, perform the reset memory, deceleration sensor zero point calibration and CVT oil pressure calibration Click here.

-

Check for DTCs again Click here.

NEXT

END

-