EMISSION CONTROL SYSTEM(w/o Canister Pump Module) ON-VEHICLE INSPECTION

PROCEDURE

-

INSPECT FUEL CUT OPERATION

-

Increase the engine speed to approximately 3000 rpm.

-

Use a sound scope to check for injector operating sounds.

-

When the accelerator pedal is released, check that injector operating sounds stop momentarily and then resume.

Standard Item Specified Condition Fuel cut-off engine speed 2500 rpm or higher Fuel injection restart engine speed 1400 rpm If the result is not as specified, check the fuel injector assemblies, wire harness and ECM.

-

-

VISUALLY CHECK HOSES, CONNECTIONS AND GASKETS

-

Visually check that the hoses, connections and gaskets have no cracks, leaks or damage.

Note

-

Detachment or other problems with the engine oil level dipstick, oil filler cap sub-assembly, ventilation hose or other components may cause the engine to run improperly.

-

Air suction caused by disconnections, looseness or cracks in any part of the air induction system between the throttle body with motor assembly and cylinder head sub-assembly will cause engine failure or engine malfunctions.

If any defects are found, replace parts as necessary.

-

-

-

INSPECT EVAPORATIVE EMISSION CONTROL SYSTEM

-

Connect the GTS to the DLC3.

-

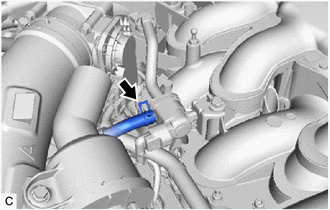

Slide the clip and disconnect the No. 2 fuel vapor feed hose from the purge valve (purge VSV).

-

Start the engine.

-

Turn the GTS on.

-

Warm up the engine.

-

Enter the following menus: Powertrain / Engine / Active Test / Activate the VSV for Evap Control.

Powertrain > Engine > Active TestTester Display Activate the VSV for Evap Control -

Check that vacuum occurs at the purge valve (purge VSV) port.

-

If vacuum does not occur, check the following items.

-

Purge valve (purge VSV)

-

Clogging in the No. 2 fuel vapor feed hose that connects the intake air surge tank assembly and purge valve (purge VSV)

-

Voltage from the ECM PRG terminal

-

-

Exit Active Test mode, connect the No. 2 fuel vapor feed hose to the purge valve (purge VSV) and slide the clip to secure it.

-

Enter the following menus: Powertrain / Engine / Data List / EVAP (Purge) VSV.

Powertrain > Engine > Data ListTester Display EVAP (Purge) VSV -

Warm up the engine and drive the vehicle.

-

Confirm that the purge valve (purge VSV) opens.

If the result is not as specified, replace the purge valve (purge VSV), wire harness or ECM.

-