HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS HOW TO PROCEED WITH TROUBLESHOOTING

-

OPERATION FLOW

Tech Tips

Perform troubleshooting in accordance with the procedure below. The following is an outline of basic troubleshooting procedure. Confirm the troubleshooting procedure for the circuit you are working on before beginning troubleshooting.

-

VEHICLE BROUGHT TO WORKSHOP

NEXT

-

CUSTOMER PROBLEM ANALYSIS

-

Ask the customer about the conditions and environment when the problem occurred.

NEXT

-

-

INSPECT BATTERY VOLTAGE

Standard voltage 11 to 14 V If the voltage is below 11 V, recharge or replace the battery before proceeding to the next step.

NEXT

-

SYMPTOM CONFIRMATION AND DTC (AND FREEZE FRAME DATA) CHECK

-

Visually check the wire harnesses, connectors and fuses for open and short circuits.

-

Warm up the engine to the normal operating temperature.

-

Confirm the problem symptoms and conditions, and check for DTCs.

Result Result Proceed to DTC is output A DTC is not output B

B

Go to step 6

A

-

-

DTC CHART

-

Find the output DTC in the DTC chart. Look at the Trouble Area column for a list of potentially malfunctioning circuits and/or parts.

NEXT

Go to step 7

-

-

PROBLEM SYMPTOMS CHART

-

Find the problem symptoms in the problem symptoms table. Look at the Suspected Area column for a list of potentially malfunctioning circuits and/or parts.

NEXT

-

-

CIRCUIT INSPECTION OR PARTS INSPECTION

-

Identify the malfunctioning circuit or part.

NEXT

-

-

ADJUST, REPAIR OR REPLACE

-

Adjust, repair or replace the malfunctioning circuit or parts.

NEXT

-

-

CONFIRMATION TEST

-

After the adjustment, repairs or replacement of components, confirm that the malfunction no longer exists. If the malfunction does not recur, perform a confirmation test under the same conditions and in the same environment as when the malfunction first occurred.

NEXT

END

-

-

-

CUSTOMER PROBLEM ANALYSIS

Tech Tips

-

When troubleshooting, confirm that the problem symptoms have been accurately identified. Preconceptions should be discarded in order to make an accurate judgment. To clearly understand what the problem symptoms are, it is extremely important to ask the customer about the problem and the conditions at the time the malfunction occurred.

-

Gather as much information as possible for reference. Past problems that seem unrelated may also help in some cases.

-

The following 5 items are important points for problem analysis:

What Vehicle model, system name When Date, time, occurrence frequency Where Road conditions Under what conditions? Driving conditions, weather conditions How did it happen? Problem symptoms

-

-

SYMPTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE

Tech Tips

The diagnostic system in this vehicle has various functions.

-

The first function is the Diagnostic Trouble Code (DTC) check. A DTC is a code stored in the ECU memory whenever a malfunction in the signal circuits to the ECU occurs. In a DTC check, a previous malfunction's DTC can be checked by a technician during troubleshooting.

-

Another function is the Input Signal Check, which checks if the signals from various switches are sent to the ECU correctly.

By using these functions, the problem areas can be narrowed down and troubleshooting can be more effective. Diagnostic functions are incorporated in the following systems of this vehicle.

System DTC Check

(Normal Mode)

DTC Check

(Check Mode)

Freeze Frame Data Sensor Check / Test Mode (Input Signal Check) Data List Active Test Customize Parameter SFI System (for 2GR-FSE) ○ ○ ○ - ○ ○ - SFI System (for 4GR-FSE) ○ ○ ○ - ○ ○ - Cruise Control System ○ - - - ○ ○ - Dynamic Laser Cruise Control System ○ - - - ○ ○ - Lane-keeping Assist System ○ - - - ○ ○ - Automatic Transmission System (A760E) ○ ○ ○ - ○ ○ - Automatic Transmission System (A760H) ○ ○ ○ - ○ ○ - Automatic Transmission System (A960E) ○ ○ ○ - ○ ○ - Four Wheel Drive Control System ○ - ○ - ○ ○ - Adaptive Variable Suspension System ○ - - ○ ○ ○ - Tire Pressure Warning System ○ - - ○ ○ ○ - Vehicle Stability Control System ○ - ○ ○ ○ ○ - Electric Parking Brake System ○ - ○ - ○ ○ - Power Steering System ○ - ○ - ○ - - Variable Gear Ratio Steering System ○ - ○ ○ ○ - - Power Tilt and Power Telescopic Steering Column System ○ - ○ - ○ ○ ○ Steering Lock System ○ - - - ○ - - Heated Steering Wheel System - - - - - - - Dynamic Rear Steering System ○ - ○ ○ ○ - - Audio and Visual System ○ - ○ - ○ - - Navigation System ○ - ○ - ○ - - LEXUS Parking Assist-sensor System ○ - - - ○ ○ - Parking Assist System ○ - - - ○ - - Blind Spot Monitor System ○ - ○ - ○ - - Garage Door Opener System - - - - - - - G-BOOK System (w/ Telematics Transceiver) ○ - - - - - - G-BOOK System (w/o Telematics Transceiver) - - - - - - - Charging System (for 2GR-FSE) - - - - - - - LIN Communication System ○ - - - ○ - - CAN Communication System ○ - - - - - - Power Door Lock Control System ○ - - - ○ ○ ○ Wireless Door Lock Control System ○ - - - ○ ○ ○ Entry and Start System (for Entry Function) ○ - - - ○ ○ ○ Entry and Start System Start (for Start Function) ○ - - - ○ ○ ○ Engine Immobiliser System ○ - - - ○ ○ - Theft Deterrent System ○ - - - ○ ○ ○ Lighting System (INT) - - - - ○ ○ ○ Meter / Gauge System ○ - ○ - ○ ○ ○ Clock System - - - - - - - Airbag System ○ ○ - - ○ - - Pre-crash Safety System ○ - - - ○ ○ - Front Power Seat Control System (for LHD) ○ - - - ○ ○ ○ Front Power Seat Control System (for RHD) ○ - - - ○ ○ ○ Seat Heater System ○ - - - - - ○ Climate Control Seat System - - - - - - - Seat Belt Warning System - - - - ○ ○ ○ Air Conditioning System ○ - - - ○ ○ ○ Rear Sunshade System - - - - ○ ○ ○ Power Window Control System ○ - - - ○ ○ ○ Windshield Deicer System - - - - - ○ - Window Defogger System - - - - - ○ - Sliding Roof System ○ - - - ○ ○ ○ Luggage Compartment Door Opener System - - - - ○ ○ - Luggage Door Closer System ○ - - - ○ - - Fuel Lid Opener System - - - - - - - Power Trunk Lid System ○ - - - ○ ○ ○ Wiper and Washer System - - - - - - - Lighting System (EXT) ○ - ○ - ○ ○ ○ Horn System - - - - - - -

-

In the DTC check, it is very important to determine whether the problem indicated by the DTC either: 1) still occurs, or 2) occurred in the past but has returned to normal. In addition, the DTC should be compared to the problem symptom to see if they are related. For this reason, DTCs should be checked before and after confirmation of symptoms (i.e., whether or not problem symptoms exist) to determine current system conditions, as shown in the flowchart below.

-

Never skip the DTC check. Failing to check for DTCs, depending on the case, may result in unnecessary troubleshooting for systems operating normally or lead to repairs not related to the problem. Follow the procedure listed in the flowchart in the correct order.

-

The following flowchart shows how to proceed with troubleshooting using the DTC check. Directions from the flowchart will indicate how to proceed either to DTC troubleshooting or to the troubleshooting of each problem symptom.

-

DTC CHECK

NEXT

-

MAKE A NOTE OF DTC DISPLAYED AND THEN CLEAR DTCs

NEXT

-

SYMPTOM CONFIRMATION

Result Result Proceed to No symptoms exist A Symptoms exist B

B

Go to step 5

A

-

SIMULATION TEST USING SYMPTOM SIMULATION METHODS

NEXT

-

DTC CHECK

Result Result Proceed to DTC is not output A DTC is output B

B

TROUBLESHOOT FOR PROBLEM INDICATED BY DTC

A

-

SYMPTOM CONFIRMATION

Result Result Proceed to Symptoms exist A No symptoms exist B If a DTC was displayed in the initial DTC check, the problem may have occurred in a wire harness or connector in that circuit in the past. Check the wire harness and connectors.

B

END

A

TROUBLESHOOT FOR EACH PROBLEM SYMPTOM

If problem symptoms are present, but no DTCs were stored again after they were cleared, then the problem causing the symptom may be occurring for something that does not store DTCs (the DTC that was displayed in the initial DTC check may have been from a past problem or a secondary problem).

-

-

SYMPTOM SIMULATION

Tech Tips

The most difficult case in troubleshooting is when no problem symptoms occur. In such a case, a thorough problem analysis must be carried out. A simulation of the same or similar conditions and environment in which the problem occurred in the customer's vehicle should be carried out. No matter how much skill or experience a technician has, troubleshooting without confirming the problem symptoms will lead to important repairs being overlooked and mistakes or delays.

-

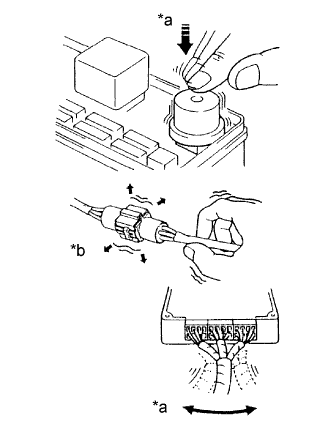

Text in Illustration *a Vibrate Slightly *b Shake Slightly VIBRATION METHOD: When a malfunction seems to occur as a result of vibration.

-

PARTS OR SENSORS

Apply slight vibration with a finger to the part or sensor suspected to be the cause of the problem, and check whether the malfunction occurs.

Note

Applying strong vibration to relays may open the relays.

-

CONNECTORS

Slightly shake the connector vertically and horizontally.

-

WIRE HARNESS

Slightly shake the wire harness vertically and horizontally.

Tech Tips

The connector joint and fulcrum of the vibration are the major areas that should be checked thoroughly.

-

-

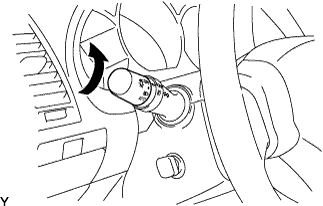

HEAT METHOD: When a malfunction seems to occur when the area in question is heated.

-

Heat the component that is the possible cause of the malfunction with a hair dryer or similar device. Check if the malfunction occurs.

Note

-

Do not heat components to more than 60°C (140°F). Exceeding this temperature may damage the components.

-

Do not apply heat directly to parts in an ECU.

-

-

-

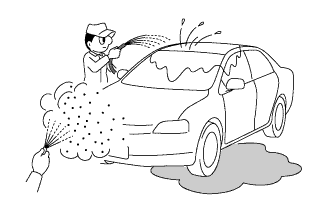

WATER SPRINKLING METHOD: When a malfunction seems to occur on a rainy day or in high-humidity.

-

Sprinkle water onto the vehicle and check if the malfunction occurs.

Note

-

Never sprinkle water directly into the engine compartment. Indirectly change the temperature and humidity by spraying water onto the front of the radiator.

-

Never apply water directly onto the electronic components.

Tech Tips

If the vehicle has or had a water leak problem, the leak may have damaged the ECU or connections. Look for evidence of corrosion or short circuits. Proceed with caution during water tests.

-

-

-

HIGH ELECTRICAL LOAD METHOD: When a malfunction seems to occur when the electrical load is high.

-

Turn on the heater blower, headlights, rear window defogger and all other electrical loads. Check if the malfunction recurs.

-

-

-

DIAGNOSTIC TROUBLE CODE CHART

Look for output Diagnostic Trouble Codes (DTCs) (from the DTC checks) in the appropriate section's Diagnostic Trouble Code chart. Use the chart to determine the trouble area and the proper inspection procedure. A description of each of the chart's columns is shown in the table below.

Item Description DTC Code Indicates the diagnostic trouble code. Detection Item Indicates the system or details of the problem. Trouble Area Indicates the suspected areas of the problem. See page Indicates the page where the inspection procedure for each circuit is to be found, or gives instruction for checking and repairs. -

PROBLEM SYMPTOMS TABLE

When no DTC is output but the problem still occurs, use the Problem Symptoms Table. The suspected areas (circuits or parts) for each problem symptom are shown in the table. The suspected areas are listed in order of probability. A description of each of the table columns is shown in the following table.

Tech Tips

In some cases, the problem is not detected by the diagnostic system even though a problem symptom occurs. It is possible that the problem occurs outside the detection range of the diagnostic system, or that the problem occurs in a completely different system.

Item Description Symptom - Suspected Area Indicates the circuit or part which needs to be checked. See page Indicates the page where the inspection procedure is located. -

INSPECTION

A description of the main points for inspection of suspected areas is shown in the following table.

Item Description Description The major role and operation of the circuit or system and its component parts are explained. DTC Code, DTC Detection Condition and Trouble Area Indicates the diagnostic trouble codes, DTC detection conditions and suspected areas for a problem. Wiring Diagram This is a wiring diagram for the circuit or system.

This diagram can be used together with the Electrical Wiring Diagram to thoroughly understand the circuit.

Wire colors are indicated by alphabetical codes. B = Black, L = Blue, R = Red, BR = Brown, LG = Light Green, V = Violet, G = Green, O = Orange, W = White, GR = Gray, P = Pink, Y = Yellow, SB = Sky Blue

The first letter indicates the basic wire color and the second letter indicates the color of the stripe.

Inspection Procedure This shows the procedure not only to determine whether the circuit is normal or abnormal, but also to determine whether the problem is located in the sensors, actuators, wire harness or ECU. Illustration of the ECU connector during the check The illustration shows whether the connector being checked is connected or disconnected.

The connections for an electrical tester are indicated by (+) or (-) after the terminal name.

For inspections between a connector and body ground, information about the ground is not shown in the illustration.