REPAIR INSTRUCTION INITIALIZATION

-

PROCEDURES NECESSARY WHEN CABLE IS DISCONNECTED/RECONNECTED TO BATTERY TERMINAL

Procedures necessary when cable is disconnected/reconnected to battery terminal Necessary Procedure Procedure Details Effect or Inoperative Function when Necessary Procedure is not Performed Note Reset back door unlock position*1 After reconnecting the cable to the negative (-) battery terminal, perform an unlock operation with the door control switch. Back door unlock function If the back door is open/closed when disconnecting the cable from the battery terminal, it is necessary to reset it. Reset luggage compartment door unlock position*2 After reconnecting the cable to the negative (-) battery terminal, perform an unlock operation with the door control switch. Luggage compartment door unlock function If the luggage compartment door is open/closed when disconnecting the cable from the battery terminal, it is necessary to reset it.

-

*1: for Wagon

-

*2: for Sedan

Note

-

After the battery is reconnected, be sure to wait 10 seconds or more before attempting to start the engine. The engine may not start immediately after the battery is reconnected.

-

w/ Navigation System (for HDD):

After the ignition switch is turned off, the HDD navigation system requires approximately a minute to record various types of memory and settings. As a result, after turning the ignition switch off, wait a minute or more before disconnecting the cable from the negative (-) battery terminal.

-

-

PROCEDURES NECESSARY WHEN ECU OR OTHER PARTS ARE REPLACED

Procedures necessary when ECU or other parts are replaced Replacement Part Necessary Procedure Effect or Inoperative Function when Necessary Procedure is not Performed Note Fuel injector

-

Injector compensation code registration

-

Pilot quantity learning

Injector fuel injection compensation amount is same as before replacement, affecting injector fuel injection volume - Fuel supply pump Supply pump initialization Engine startability is affected - ECM

-

Learning values save

-

Learning values write

Engine starting - Crankshaft position sensor plate Clear crank time compensation data Injector fuel injection compensation amount is same as before replacement, affecting injector fuel injection volume - catalyst*1 Clear DPNR/DPF thermal deterioration data Even if catalytic converter is replaced with new one, catalyst record of DPNR/DPF thermal deterioration stored in ECM is same as before replacement - Air fuel ratio sensor*1 Clear A/F sensor compensation data EGR volume is affected - Automatic transaxle assembly (for U660E)

-

Transaxle compensation code input

-

Road test

-

Rest memory

Large shift shock -

-

Valve body assembly

-

Shift solenoid valve SL3 and/or 4

-

Transaxle compensation code initialize

-

Road test

-

Rest memory

Large shift shock - Shift solenoid valve SL1 and/or 2 Road test Large shift shock - TCM (If possible, read the transaxle compensation code from the previous TCM) Possible

-

Transaxle compensation code input (Into the new TCM)

-

Reset memory

-

Road test

Large shift shock - Impossible

-

Transaxle compensation code initialize

-

Reset memory

-

Road test

Large shift shock Millimeter wave radar sensor assembly Adjust millimeter wave radar sensor assembly (Dynamic radar cruise control system)

-

Dynamic radar cruise control system

-

Lane-keeping assist system

- Driving support ECU Driving support ECU initialization

-

Dynamic radar cruise control system

-

Lane-keeping assist system

-

Pre-crash safety system

- Lane recognition camera sensor assembly Adjust lane recognition camera sensor assembly Lane-keeping assist system - for 1AD-FTV

-

Clutch cover assembly

-

Clutch disc assembly

-

Clutch release with bearing cylinder assembly

-

Brake pedal stroke sensor (Clutch pedal stroke sensor).

-

Clutch pedal sub-assembly

-

Clutch master cylinder

Calibration The vehicle may not be able to start off smoothly due to a deviation in the timing of the electric parking brake release of the drive away release function. - for 2AD-FTV

-

Clutch cover assembly

-

Clutch disc assembly

-

Clutch release with bearing cylinder assembly

-

Brake pedal stroke sensor (Clutch pedal stroke sensor).

-

Clutch pedal sub-assembly

-

Clutch master cylinder

Calibration The vehicle may not be able to start off smoothly due to a deviation in the timing of the electric parking brake release of the drive away release function. - for 2AD-FHV

-

Clutch cover assembly

-

Clutch disc assembly

-

Clutch release with bearing cylinder assembly

-

Brake pedal stroke sensor (Clutch pedal stroke sensor).

-

Clutch pedal sub-assembly

-

Clutch master cylinder

Calibration The vehicle may not be able to start off smoothly due to a deviation in the timing of the electric parking brake release of the drive away release function. -

-

Electric parking brake ECU (Parking brake with bracket actuator assembly)

-

Yaw rate sensor

-

Clutch pedal

-

Brake pedal stroke sensor (Clutch pedal stroke sensor)

-

Brake pedal stroke sensor (Clutch pedal stroke sensor) adjustment

Calibration Electric parking brake system does not operate properly - Skid control ECU (Brake actuator assembly) Calibration DTC C1288/88 is output - Brake fluid Bleeding air from brake system Brake performance problem - Power steering ECU assembly Rotation angle sensor initialization and torque sensor zero point calibration

-

EPS warning light comes on

-

Power assist stops

- Steering column assembly Rotation angle sensor initialization and torque sensor zero point calibration Steering effort different between steering wheel to turning left and right -

-

Steering lock actuator assembly

-

Certification ECU

-

ID code box

-

Key

Code registration

-

Wireless door lock control system

(w/ Entry and Start System)

-

Entry operation

-

Engine start

(w/ Entry and Start System)

-

Steering lock and unlock

Refer to the Service Bulletin for the registration procedure.

-

Transponder key ECU

-

Key

Code registration Engine start

(w/o Entry and Start System)

Refer to the Service Bulletin for the registration procedure.

-

AFS ECU

-

Rear height control sensor

-

AFS ECU registration

-

Rear height control sensor registration

AFS function -

-

Door control receiver assembly

-

Key

Code registration Wireless door lock control system (w/o Entry and Start System) -

-

Front power window regulator motor LH

-

Front power window regulator motor RH

-

Rear power window regulator motor LH*2

-

Rear power window regulator motor RH*2

Motor initialization

-

Jam protection function

-

Power window control system

-

-

Sliding roof drive gear

-

Roof shade trim

Roof sunshade system initialization

-

Jam protection function

-

Auto operation

-

-

*1: except CCo

-

*2: w/ Rear Door Power Window

-

-

INITIALIZATION RELATED TO ECD SYSTEM

-

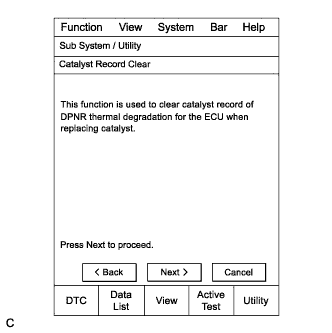

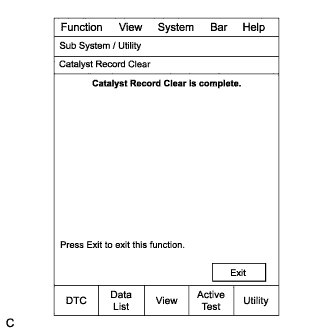

CATALYST RECORD OF DPNR/DPF THERMAL DETERIORATION CLEAR FUNCTION (except CCo)

Tech Tips

When the DPNR/DPF catalyst is replaced, the catalyst record of DPNR/DPF thermal deterioration stored in the ECM must be cleared.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the menu options in this order: Powertrain / Engine and ECT / Utility / Catalyst Record Clear.

-

Press "Next".

-

Press "Exit".

-

-

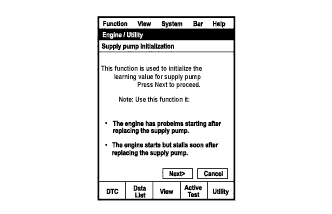

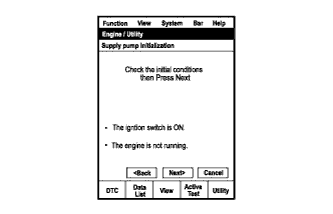

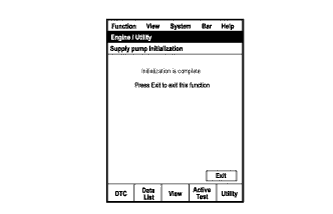

SUPPLY PUMP INITIALIZATION PROCEDURE

Tech Tips

After replacing the supply pump and/or ECM:

-

If the engine is defective or stalls immediately after startup, the learned values of the ECM must be initialized. The engine can be initialized through the intelligent tester or by short circuiting DLC3 terminals.

-

If the engine starts normally, initialization is not necessary. Perform steps procedure "A" and procedure "B" only.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Supply Pump Initialization.

-

Press "Next".

-

Press "Next".

-

Press "Exit".

-

Start the engine to check if the initialization is complete. If the engine cannot be started, repeat the initialization procedures from the beginning. (Procedure "A")

-

Idle the engine for at least 1 minute under the following conditions: (Procedure "B")

-

The engine coolant temperature is 60°C (140°F) or higher.

-

The fuel temperature is 20°C (68°F) or higher.

Note

Do not race the engine immediately after starting the engine. After warming up the engine, racing the engine is acceptable.

Tech Tips

-

The engine coolant temperature can be estimated by touching the outlet hose.

-

The fuel temperature can be estimated by using the ambient temperature as a substitute.

-

If the engine coolant temperature is difficult to estimate, use the intelligent tester and enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

-

-

Initialization is complete.

-

-

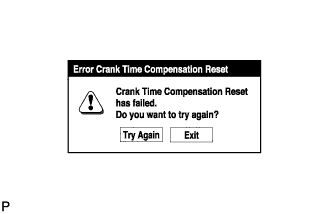

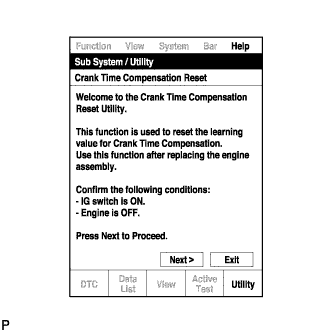

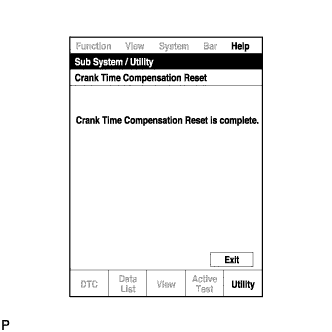

CRANK TIME COMPENSATION RESET FUNCTION

-

This procedure uses the intelligent tester to perform "Crank Time Compensation Reset".

-

When replacing the timing rotor (engine assembly), perform "Crank Time Compensation Reset".

Tech Tips

-

If an error occurs during compensation reset, check the vehicle condition, and then perform compensation reset again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Crank Time Compensation Reset.

-

When the first screen is displayed, check the vehicle condition and push "Next".

-

When the screen indicating reset completion is displayed, push "Exit".

-

-

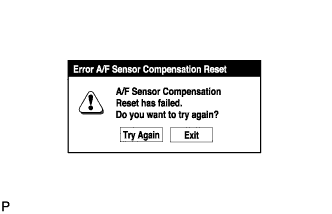

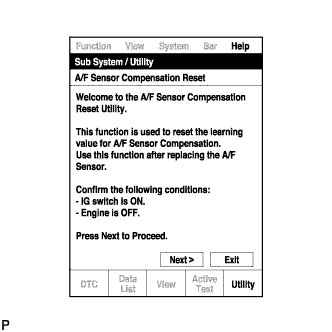

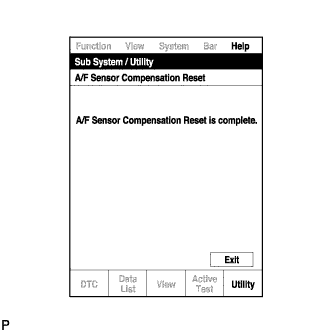

A/F SENSOR COMPENSATION RESET FUNCTION (except CCo)

-

This procedure uses the intelligent tester to perform "A/F Sensor Compensation Reset".

-

When replacing the A/F sensor, replace the sensor and then perform "A/F Sensor Compensation Reset".

Tech Tips

-

If an error occurs during compensation reset, check the vehicle condition, and then perform compensation reset again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / A/F Sensor Compensation Reset.

-

When the first screen is displayed, check the vehicle condition and push "Next".

-

When the screen indicating reset completion is displayed, push "Exit".

-

-

-

REGISTRATION RELATED TO ECD SYSTEM

-

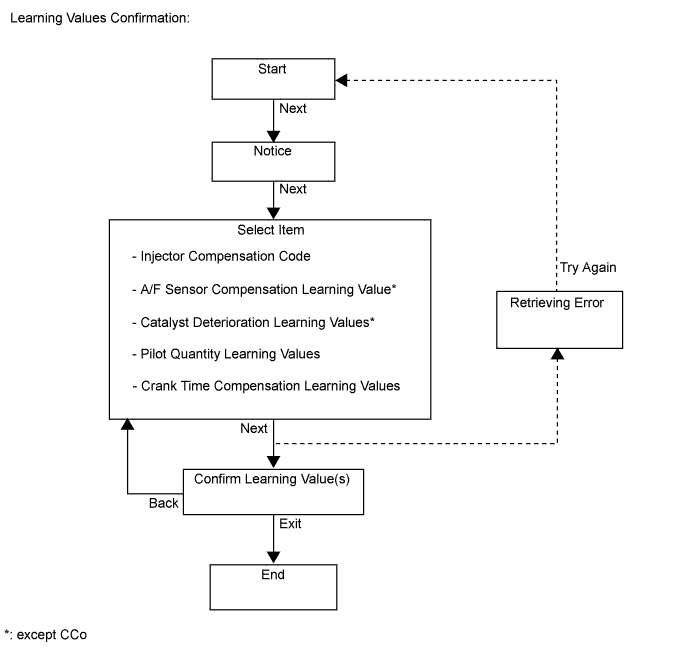

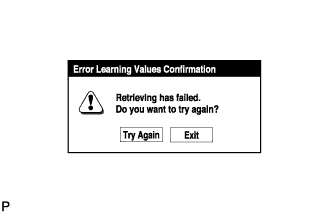

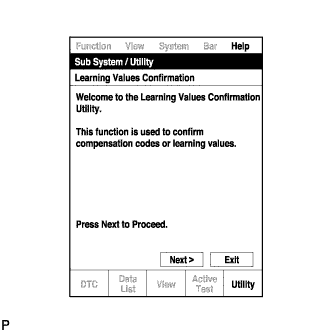

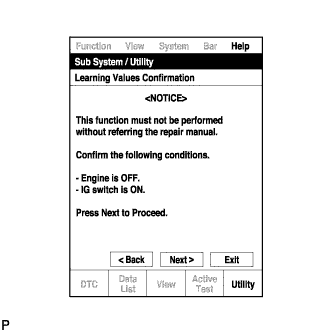

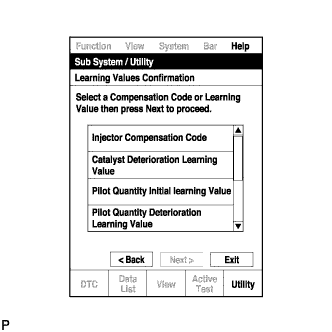

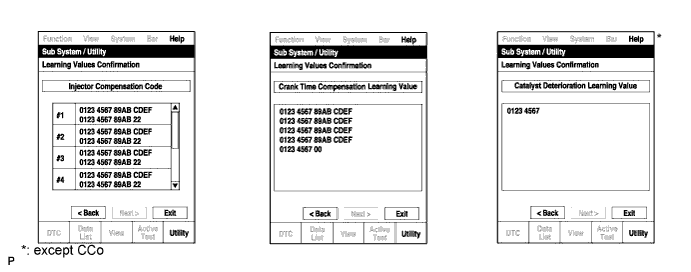

LEARNING VALUES CONFIRMATION

This procedure sues the intelligent tester to display the learned values (injector compensation code, pilot quantity learning value, crank time compensation learning value, catalyst deterioration learning value and A/F sensor learning value) stored in the ECM.

Tech Tips

A malfunction may occur when reading the values if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Learning values confirmation.

-

Press "Next".

-

Press "Next" again to proceed.

-

Select the value to confirm and press "Next".

-

When the next screen is displayed, confirm the contents and press "Exit".

-

-

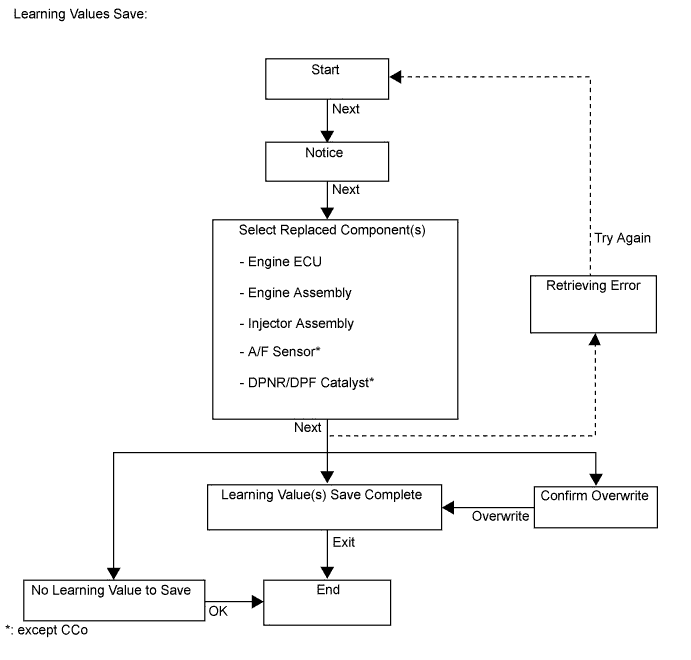

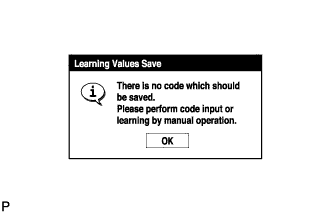

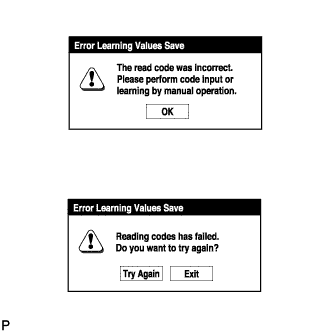

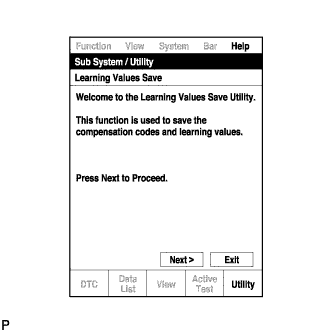

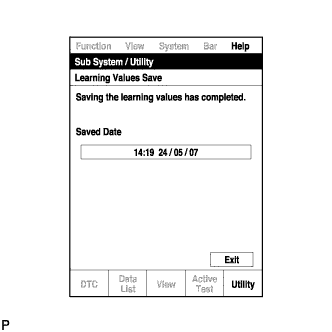

LEARNING VALUES SAVE

*1: except CCo

This procedure uses the intelligent tester to save the learned values (injector compensation code, pilot quantity learning value, crank time compensation learning value, catalyst deterioration learning value and A/F sensor learning value) stored in the ECM in the intelligent tester depending on the components being replaced.

*2: for CCo

This procedure uses the intelligent tester to save the learned values (injector compensation code, pilot quantity learning value, crank time compensation learning value) stored in the ECM in the intelligent tester depending on the components being replaced.

Tech Tips

-

When replacing the engine assembly, injector assembly, catalyst converter or the A/F sensor together with the ECM, this function automatically determines the data which can be transferred (old data) and saves the data in the intelligent tester.

-

When there is no data to read from the ECM, manually perform the procedure to register each compensation code and learning value in the ECM.

-

A malfunction may occur when reading the values if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Learning values save.

-

Press "Next".

-

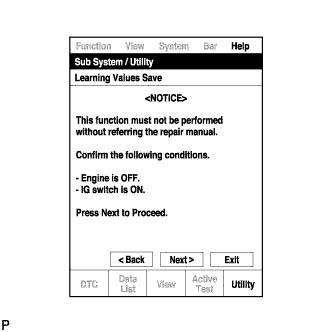

Press "Next" again to proceed.

-

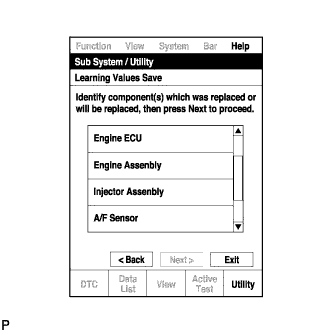

Select any components being replaced and press "Next". If no applicable components are displayed, press "Next" without selecting anything.

-

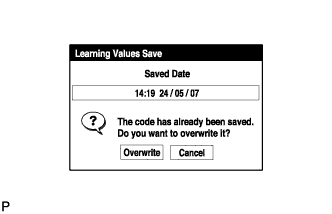

If the overwrite confirmation screen is displayed, press "Overwrite".

-

When the operation is finished, confirm the date and time of the save operation, and press "Exit".

-

-

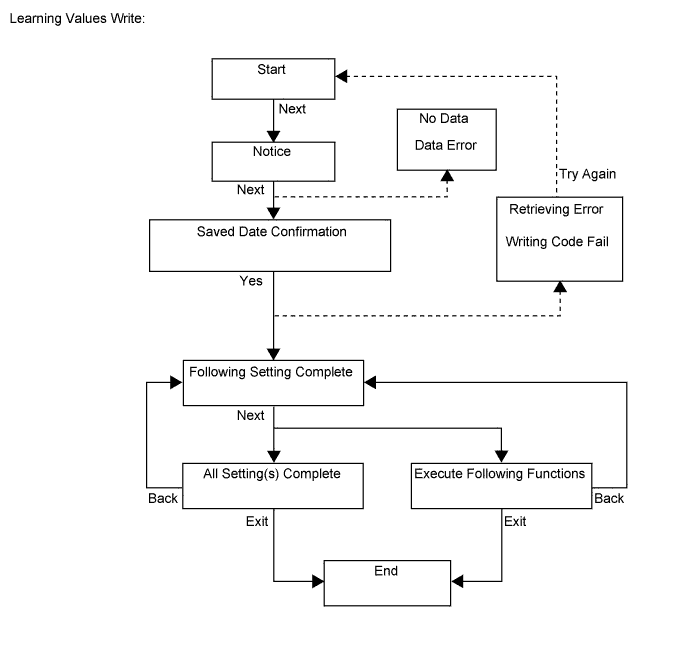

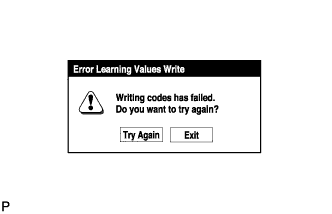

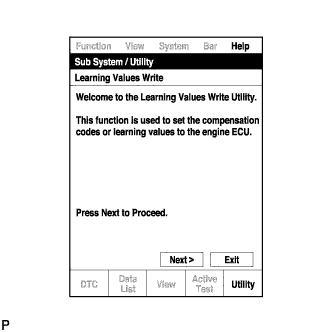

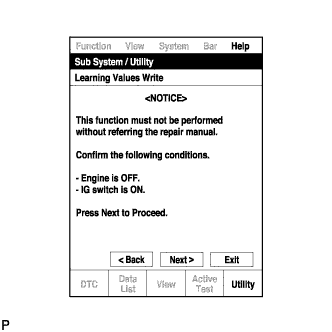

LEARNING VALUES WRITE

This procedure uses the intelligent tester to write all of the learned values (injector compensation code, pilot quantity learning value, crank time compensation learning value, catalyst deterioration learning value and A/F sensor learning value) stored in the intelligent tester to the ECM.

Tech Tips

A malfunction may occur when writing the values if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Learning values write.

-

Press "Next".

-

Press "Next" again to proceed.

-

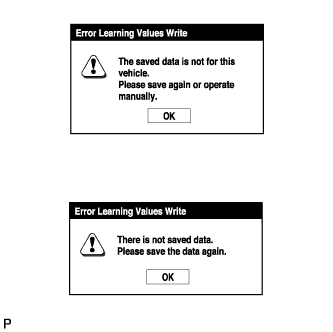

If the "Error Learning Values Write" screen indicating a problem with the saved value(s) or that there are no saved values is displayed, perform "Learning Values Save" again.

-

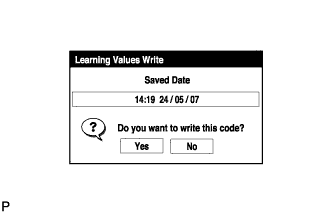

Confirm the date and time of the save operation, and then press "Yes".

-

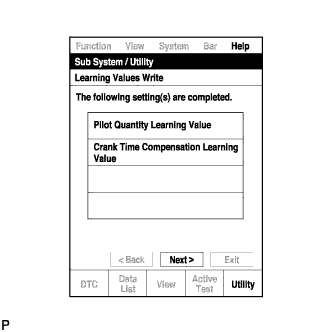

Confirm the contents, and then press "Next".

-

If any instructions are displayed on the tester, manually perform the procedure to register each applicable compensation code or learning value in the ECM.

-

Clear the DTCs.

-

-

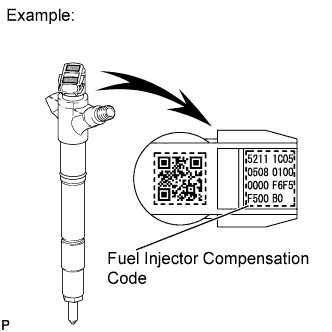

INPUT INJECTOR COMPENSATION CODE(S) INTO ECM

Note

-

When a fuel injector is replaced, the new fuel injector compensation code must be input into the ECM. When the ECM is replaced, all of the existing fuel injector compensation codes must be input into the new ECM.

-

Fuel injector compensation codes are unique, 30- digit, alphanumeric values printed on the head portion of each fuel injector. If an incorrect fuel injector compensation code is input into the ECM, the engine assembly may rattle or engine idling may become rough. In addition, engine failure may occur and the life of the engine may be shortened.

-

When a fuel injector compensation code is input into the ECM, the pilot quantity learning values stored in the ECM are initialized. Also, DTC P1601 is stored when the pilot quantity learning values are initialized.

-

After replacing fuel injector(s) with new one(s), input compensation code(s) of the fuel injector(s) into the ECM as follows:

Tech Tips

-

Each fuel injector has different fuel injection characteristics. In order to optimize the fuel injections, the ECM uses the compensation codes to balance the different fuel injections between each fuel injector.

-

When only one or more fuel injectors are replaced, input the fuel injector compensation code(s), perform pilot quantity learning, and then clear the DTCs.

-

When the ignition switch is turned to ON after replacing the ECM, DTC P1601 is stored. This indicates that the fuel injector compensation code(s) need to be registered. Manually clear the DTC upon completion of pilot quantity learning.

-

Input the compensation code(s), which is/are imprinted on the head portion(s) of the new fuel injector(s), into the intelligent tester.

-

Input the new compensation code(s) into the ECM using the tester.

-

Turn the tester off and turn the ignition switch off.

-

Wait for at least 30 seconds.

-

Turn the ignition switch to ON and turn the tester on.

-

Perform pilot quantity learning.

-

Clear DTC P1601 stored in the ECM using the tester.

Note

If the DTCs are cleared without performing pilot quantity learning, DTC P1601 is stored the next time the ignition switch is turned to ON.

-

-

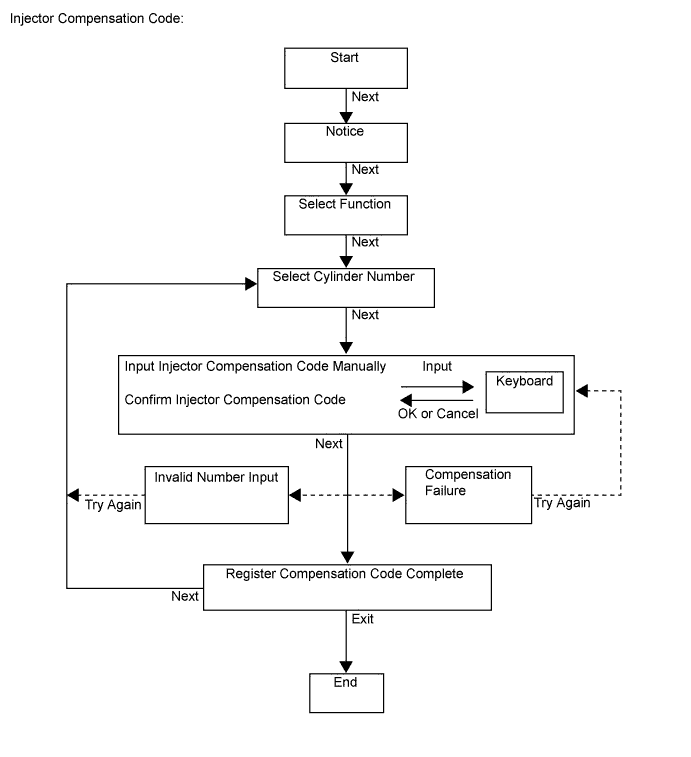

Register compensation codes.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the tester on.

-

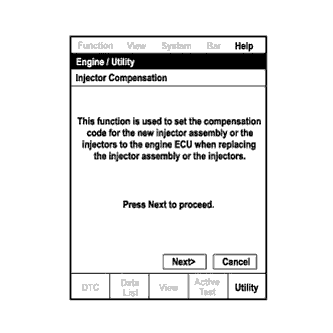

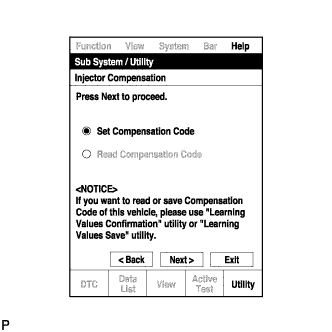

Enter the following menus: Powertrain / Engine and ECT / Utility / Injector Compensation.

-

Press Next.

-

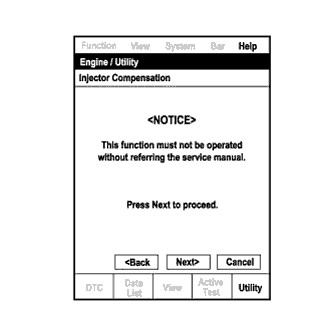

Press Next again to proceed.

-

Select "Set Compensation Code".

-

Press Next.

-

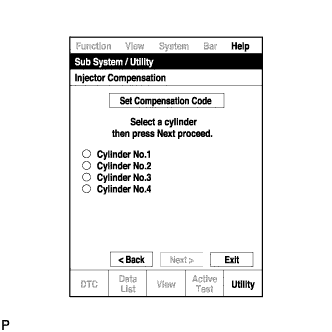

Select the number of the cylinder corresponding to the fuel injector compensation code that you want to register.

-

Press Next.

-

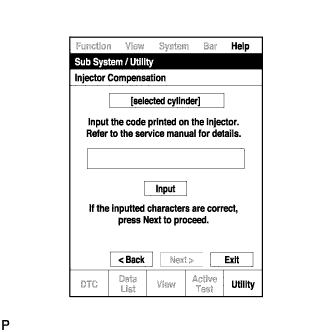

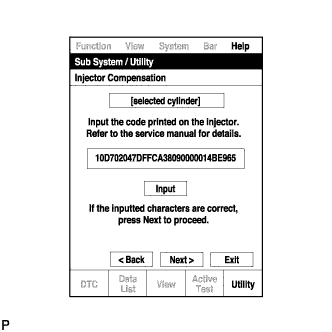

Register compensation code. 1. Press Input.

1. Press Input.

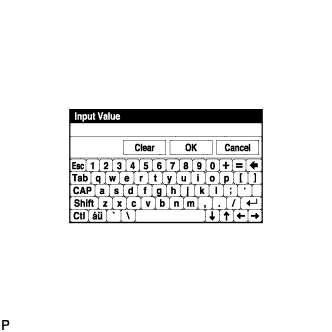

2. Manually input the cylinder compensation code using the keyboard on the tester screen. The code is a 30-digit, alphanumeric value printed on the injector head portion. HINT: Each fuel injector compensation code is unique. The compensation code for each selected cylinder must be input into the tester correctly.

3. Confirm that the compensation code for the selected cylinder is correct, and then press OK.

-

Check that the compensation code displayed on the screen is correct by comparing it with the 30-digit alphanumeric value on the head portion of the fuel injector.

Note

If an incorrect fuel injector compensation code is input into the ECM, the engine may rattle or engine idling may become rough. In addition, engine failure may occur and the life of the engine may be shortened.

Tech Tips

-

If a wrong compensation code is input or read, return to the Input Value screen by pressing Input.

-

The saving process may fail due to a problem with the wire harness or a bad connection with the DLC3. Check the wire harness and DLC3 connection. If no problem is found with either, the ECM may be malfunctioning. Check the ECM and repeat this operation.

-

-

Press Next to register the compensation code in the ECM.

Tech Tips

-

If the registration process fails, the compensation code may be incorrect. Check the compensation code again.

-

If the input compensation code fails to register even though it is input correctly, there may be a problem with the wire harness or a bad connection with the DLC3. Check the wire harness and DLC3 connection. If no problem is found with either, the ECM may be malfunctioning. Check the ECM and restart this operation.

-

-

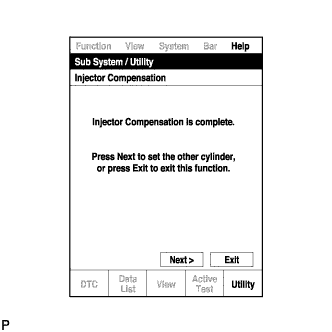

If you want to continue with other compensation code registrations, press Next. To finish the registration, press Exit.

-

Turn the ignition switch off, and then turn the tester off.

-

Wait for at least 30 seconds.

-

Turn the ignition switch to ON, and then turn the tester on.

-

Perform pilot quantity learning.

-

Clear DTC P1601 stored in the ECM using the tester.

Note

NOTICE: If the DTCs are cleared without performing pilot quantity learning, DTC P1601 is stored the next time the ignition switch is turned to ON.

-

-

-

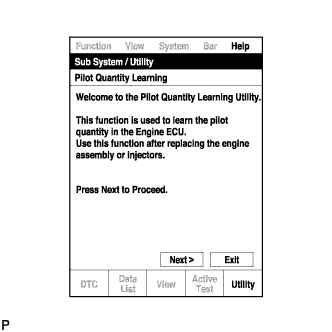

PILOT QUANTITY LEARNING

-

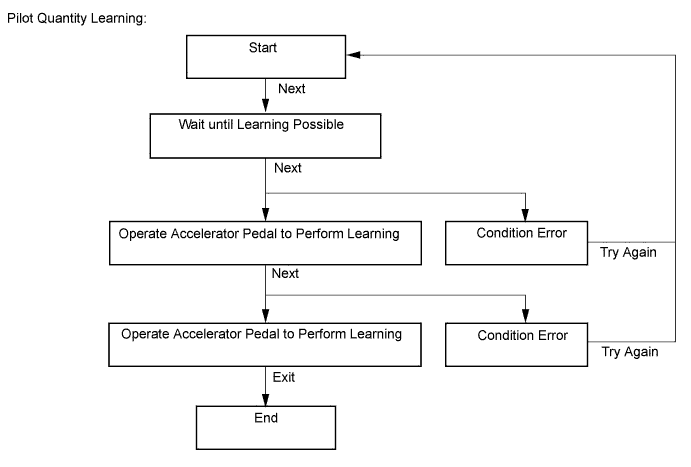

This procedure uses the intelligent tester to perform "Pilot Quantity Learning".

-

When replacing the injector assembly, engine or ECM, perform this procedure after performing injector compensation (manual ID code registration).

Note

After completing this procedure, clear the DTCs using the intelligent tester.

Tech Tips

-

If "Exit" is pushed during the step where the accelerator pedal is operated and "Pilot Quantity Learning" is canceled, turn the ignition switch off, wait 10 seconds, check the vehicle condition, and then perform learning again.

-

If an error occurs during learning, check the vehicle condition after turning the ignition switch off, and then perform learning again.

-

If learning is canceled and DTCs are output due to excessive racing of the engine (depressing the accelerator pedal for 2 seconds or more), turn the ignition switch off, and then perform learning again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Start the engine.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Pilot quantity learning.

-

Press "Next".

-

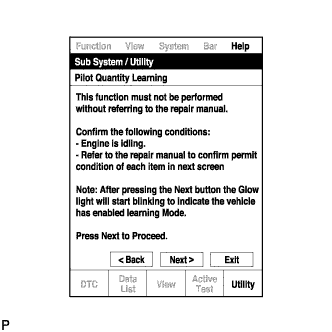

Press "Next" again to proceed.

-

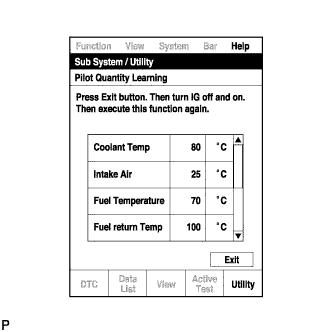

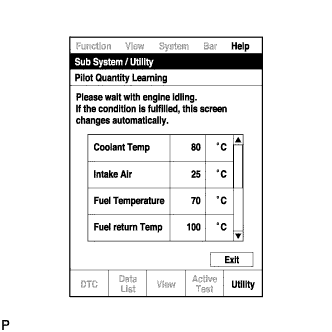

Confirm the condition of the engine and wait until learning can be performed.

Essential Conditions for Learning Tester Display Standard Coolant Temp 70 to 100°C Intake Air -25 to 120°C Fuel Temperature 30 to 96°C Fuel Return Temp 35 to 110°C Battery Voltage 10 V or higher Reju Pilot Quantity Learning READY Tech Tips

-

If the values deviate from the standard above, "Pilot Quantity Learning" enters a standby state or is canceled.

-

When the display indicates that "Reju Pilot Quantity Learning" is prohibited, perform "Pilot Quantity Learning" after performing the "Activate the DPF Rejuvenate (PM)" Active Test using the intelligent tester. (except CCo)

-

When the essential conditions to perform learning are met, the screen will change automatically.

Note

-

If "Activate the DPF Rejuvenate (PM)" is performed after an injector compensation code is input but before "Pilot Quantity Learning" is performed, DTC P1601 is stored and the MIL illuminates due to "Pilot Quantity Learning" being incomplete. (except CCo)

-

Using the intelligent tester, make sure that DTCs other than DTC P1601 are not output.

-

If DTCs other than DTC P1601 are output, perform troubleshooting for those DTCs, and then perform "Activate the DPF Rejuvenate (PM)". (except CCo)

Tech Tips

DTC P1601 is stored when the value registered in the ECM for an input injector compensation code, catalyst deterioration learning value and/or pilot quantity deterioration learning value is the initial value.

-

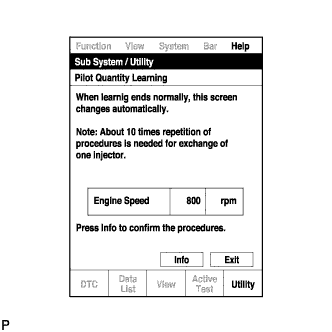

-

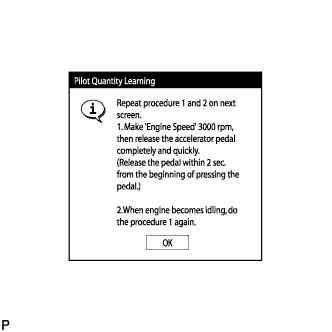

Follow the prompts on the screen and repeat the following procedure until the screen changes: Starting with the engine idling, race the engine until the engine speed is 3000 rpm or more for no more than 2 seconds, and then let the engine return to idling.

Tech Tips

-

After confirming that the engine speed has reached 3000 rpm, completely release the accelerator pedal in order for the throttle opening amount to become 0%.

-

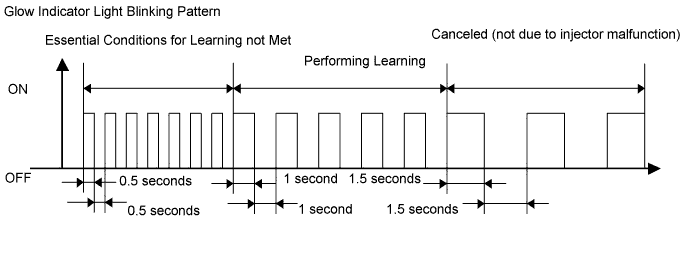

It is possible to confirm the status of the learning operation during "Pilot Quantity Learning" by observing the blinking pattern of the glow indicator light.

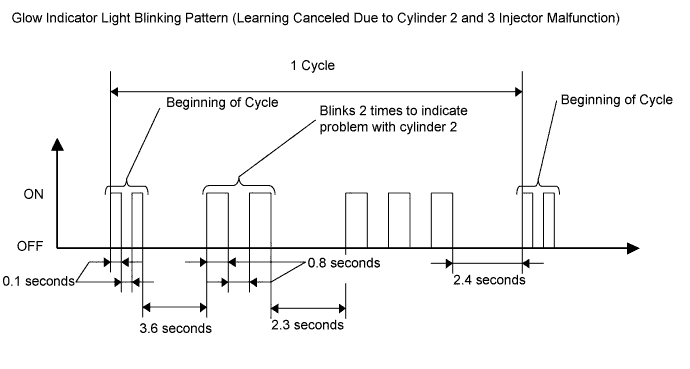

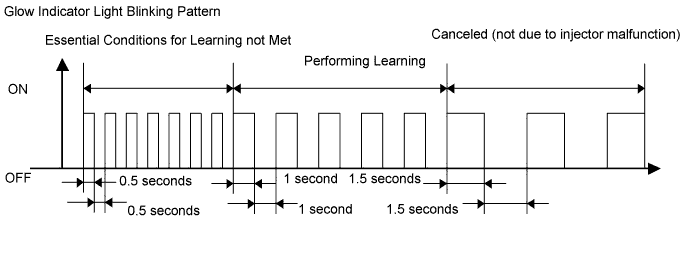

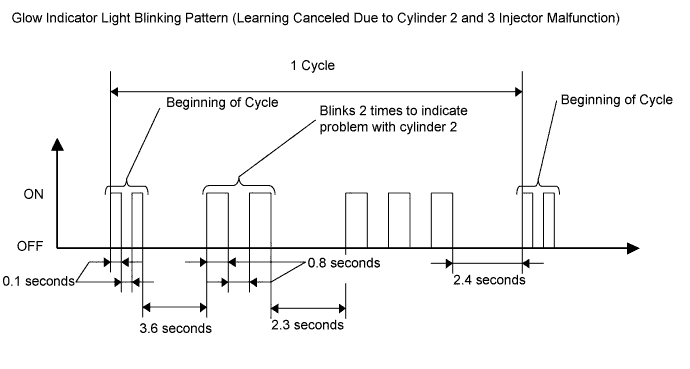

Glow Indicator Light Blinking Pattern Learning Status Glow Indicator Light Condition Conditions essential to start learning have not been met Blinking at 0.5 second intervals Conditions essential to start learning have been met Blinking at 1 second intervals During racing (learning is being performed) Blinking at 1 second intervals Learning is finished Off Learning has been canceled Blinking at 1.5 second intervals Learning has been canceled (malfunctioning cylinder is indicated by blinking pattern) Blinking at 0.8 second intervals (2.3 second intervals between each set of blinks representing the number of a malfunctioning cylinder)

-

-

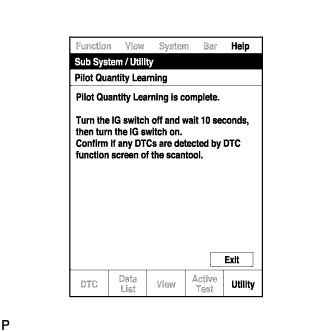

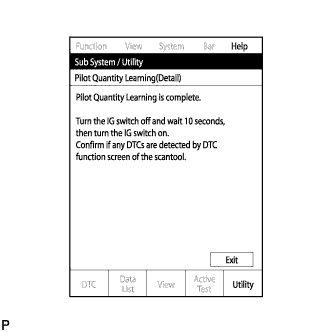

When the screen changes, push "Exit".

-

Turn the ignition switch off, and then turn the tester off.

-

Wait for at least 10 seconds.

-

Turn the ignition switch to ON, and then turn the tester on.

-

Clear the DTCs.

-

Turn the ignition switch off.

Note

Do not disconnect the cable from the negative (-) battery terminal for 30 seconds after turning the ignition switch off.

Tech Tips

-

The main relay turns off after the learned value is stored in the ECM.

-

The main relay turns off within approximately 5 to 10 seconds of turning the ignition switch off.

-

-

-

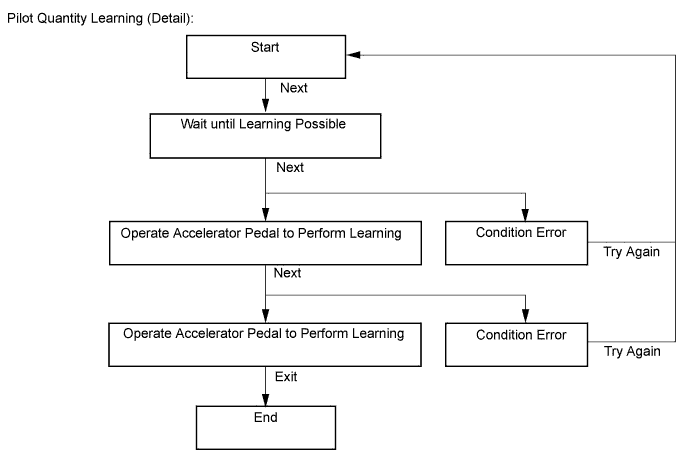

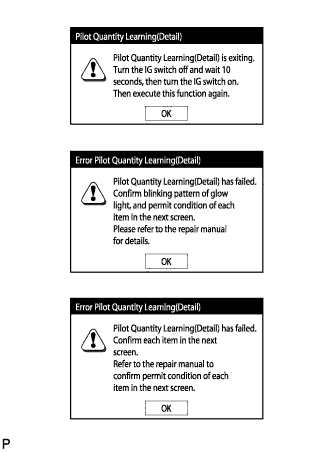

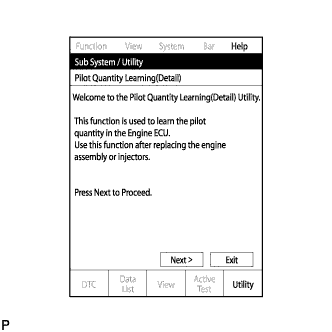

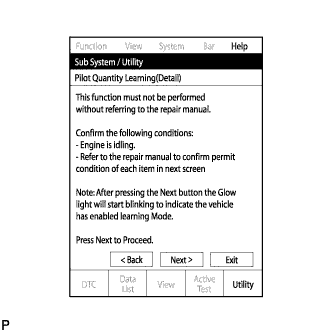

PILOT QUANTITY LEARNING (DETAIL)

-

This procedure uses the intelligent tester to perform "Pilot Quantity Learning (Detail)".

-

When replacing the injector assembly, engine or ECM, perform this procedure after performing injector compensation (manual ID code registration).

Note

After completing this procedure, clear the DTCs using the intelligent tester.

Tech Tips

-

If "Exit" is pushed during the step where the accelerator pedal is operated and "Pilot Quantity Learning (Detail)" is canceled, turn the ignition switch off, wait 10 seconds, check the vehicle condition, and then perform learning again.

-

If an error occurs during learning, check the vehicle condition after turning the ignition switch off, and then perform learning again.

-

If learning is canceled and DTCs are output due to excessive racing of the engine (depressing the accelerator pedal for 2 seconds or more), turn the ignition switch off, and then perform learning again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Start the engine.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Pilot quantity learning (Detail).

-

Press "Next".

-

Press "Next" again to proceed.

-

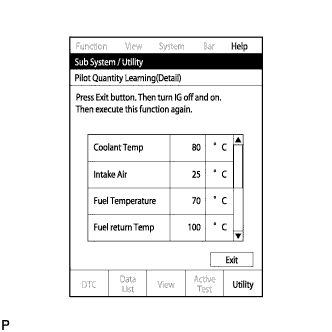

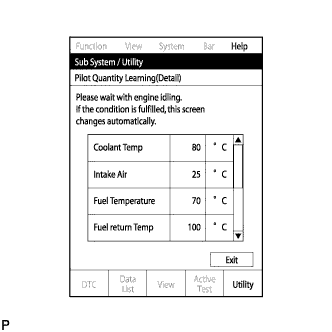

Confirm the condition of the engine and wait until learning can be performed.

Essential Conditions for Learning Tester Display Standard Coolant Temp 70 to 100°C Intake Air -25 to 120°C Fuel Temperature 30 to 96°C Fuel Return Temp 35 to 110°C Battery Voltage 10 V or higher Reju Pilot Quantity Learning READY Tech Tips

-

If the values deviate from the standard above, "Pilot Quantity Learning (Detail)" enters a standby state or is canceled.

-

When the display indicates that "Reju Pilot Quantity Learning" is prohibited, perform "Pilot Quantity Learning (Detail)" after performing the "Activate the DPF Rejuvenate (PM)" Active Test using the intelligent tester. (except CCo)

-

When the essential conditions to perform learning are met, the screen will change automatically.

Note

-

If "Activate the DPF Rejuvenate (PM)" is performed after an injector compensation code is input but before "Pilot Quantity Learning (Detail)" is performed, DTC P1601 is stored and the MIL illuminates due to "Pilot Quantity Learning (Detail)" being incomplete. (except CCo)

-

Using the intelligent tester, make sure that DTCs other than DTC P1601 are not output.

-

If DTCs other than DTC P1601 are output, perform troubleshooting for those DTCs and then perform "Activate the DPF Rejuvenate (PM)". (except CCo)

Tech Tips

DTC P1601 is stored when the value registered in the ECM for an input injector compensation code, catalyst deterioration learning value and/or pilot quantity deterioration learning value is the initial value.

-

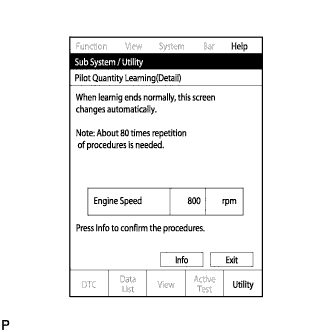

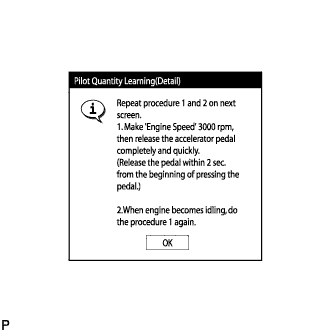

-

Follow the prompts on the screen and repeat the following procedure until the screen changes: Starting with the engine idling, race the engine until the engine speed is 3000 rpm or more for no more than 2 seconds, and then let the engine return to idling.

Tech Tips

-

After confirming that the engine speed has reached 3000 rpm, completely release the accelerator pedal in order for the throttle opening amount to become 0%.

-

It is possible to confirm the status of the learning operation during "Pilot Quantity Learning (Detail)" by observing the blinking pattern of the glow indicator light.

Glow Indicator Light Blinking Pattern Learning Status Glow Indicator Light Condition Conditions essential to start learning have not been met Blinking at 0.5 second intervals Conditions essential to start learning have been met Blinking at 1 second intervals During racing (learning is being performed) Blinking at 1 second intervals Learning is finished Off Learning has been canceled Blinking at 1.5 second intervals Learning has been canceled (malfunctioning cylinder is indicated by blinking pattern) Blinking at 0.8 second intervals (2.3 second intervals between each set of blinks representing the number of a malfunctioning cylinder)

-

-

When the screen changes, push "Exit".

-

Turn the ignition switch off, and then turn the tester off.

-

Wait for at least 10 seconds.

-

Turn the ignition switch to ON, and then turn the tester on.

-

Clear the DTCs.

-

Turn the ignition switch off.

Note

Do not disconnect the cable from the negative (-) battery terminal for 30 seconds after turning the ignition switch off.

Tech Tips

-

The main relay turns off after the learned value is stored in the ECM.

-

The main relay turns off within approximately 5 to 10 seconds of turning the ignition switch off.

-

-

-

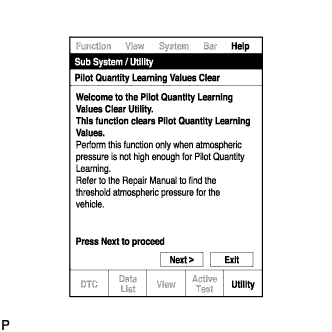

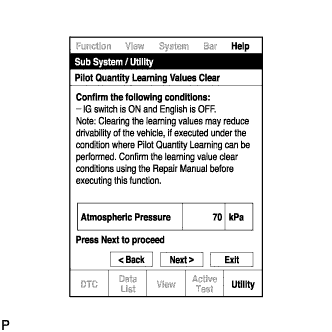

PILOT QUANTITY LEARNING VALUE CLEAR

Tech Tips

-

If the atmospheric pressure is below the threshold value, "Pilot Quantity Learning" will not be completed and DTC P1601 is stored. After "Pilot Quantity Learning Value Clear" is performed, DTC P1601 will not be stored.

-

Clear the learned values using the following procedure.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON, and then turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Pilot Quantity Learning Value Clear

-

Press "Next".

-

Confirm that the atmospheric pressure screen is displayed.

-

Confirm the displayed atmospheric pressure.

Standard Atmosphere Pressure is below 85 kPa Note

-

If the atmospheric pressure is higher than the standard range for performing "Pilot Quantity Learning Value Clear", do not clear the learned values. Instead, perform "Pilot Quantity Learning".

-

When the atmospheric pressure is higher than the standard range, perform "Pilot Quantity Learning" without initializing the learned values using "Pilot Quantity Learning Value Clear". If the learned values are initialized when the atmospheric pressure is higher than the standard range, the following symptoms may appear. Be sure to correctly follow procedures.

-

Driveability problems

-

Rough idle

-

Emission of white or black smoke, etc.

-

-

Proceed to the next screen.

-

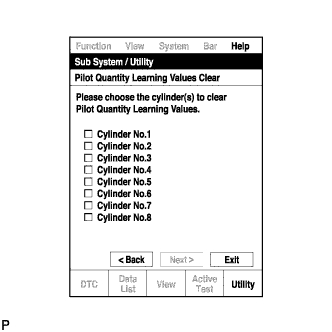

-

Select the cylinders whose learned value will be cleared.

Note

-

Multiple cylinders can be selected.

-

Only the cylinders for which fuel injector compensation codes have been written must have their learned value cleared.

-

-

After selecting the cylinders whose learned value will be cleared, press "Next" to begin the initialization.

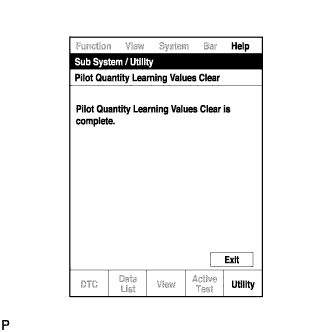

-

When the screen changes, push "Exit".

-

Turn the ignition switch off, and then turn the tester off.

-

Wait for at least 10 seconds.

-

Turn the ignition switch to ON, and then turn the tester on.

-

Clear the DTCs.

-

Turn the ignition switch off and leave the vehicle for 30 seconds or more.

-

Turn the ignition switch to ON for 1 second.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read the DTCs.

-

Confirm that no DTCs are output.

-

-

-

INITIALIZATION RELATED TO AUTOMATIC TRANSAXLE SYSTEM

-

RESET TRANSAXLE COMPENSATION CODE

Note

-

If the following parts have been replaced, initialize the TCM and perform the following "Reset Memory" and "Perform Road Test to Allow TCM to Learn" steps.

- Valve body assembly

- Shift solenoid valve SL3

- Shift solenoid valve SL4

- TCM

-

The transaxle compensation code can only be initialized with the intelligent tester.

Tech Tips

The TCM memorizes the vehicle conditions when the ECT controls the automatic transaxle assembly. Therefore, when the automatic transaxle assembly or TCM has been replaced, it is necessary to reset the memory so that the TCM can memorize the new information. The reset procedure is as follows:

-

Move the shift lever to N or P.

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / ECT / Utility / A/T Code Reset.

-

Press "Next" to proceed.

Note

After the transaxle compensation code is initialized, perform the following "Reset Memory" and "Perform Road Test to Allow TCM to Learn" steps.

-

Press "Exit".

-

-

RESET MEMORY

Note

Reset Memory can only be performed with the intelligent tester.

Tech Tips

The TCM memorizes the vehicle conditions when the ECT controls the automatic transaxle assembly.

Therefore, when the automatic transaxle assembly, valve body assembly, shift solenoid valve SL3, shift solenoid valve SL4, or TCM has been replaced, it is necessary to reset the memory so that the TCM can memorize the new information.

-

The reset procedure is as follows.

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Enter the following menus: "Powertrain / ECT / Utility / Reset Memory". Then press "Next".

Note

After performing Reset Memory, be sure to perform "Perform Road Test to Allow TCM to Learn" described earlier.

-

-

-

PERFORM ROAD TEST TO ALLOW TCM TO LEARN

Note

Perform the following procedure while strictly observing all traffic laws and speed limits.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / ECT / Data List / Accel Position from EFI.

-

From a standstill, achieve the highest possible speed with the accelerator pedal depressed 15% or less. Keep the accelerator pedal angle steady while driving the vehicle.

Tech Tips

"Accel Position from EFI": 15% or less

-

Repeat the previous step until shift shock no longer occurs.

-

From a standstill, achieve the highest possible speed with the accelerator pedal depressed 25% to 35%. Keep the accelerator pedal angle steady while driving the vehicle.

Tech Tips

"Accel Position from EFI": 25% to 35%

-

Repeat the previous step until shift shock no longer occurs.

-

-

-

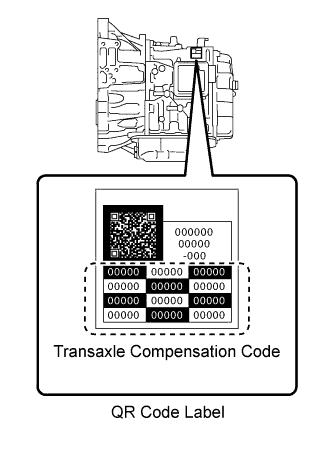

REGISTRATION RELATED TO AUTOMATIC TRANSAXLE SYSTEM

Note

-

When the automatic transaxle is replaced, the transaxle compensation code must be input into the TCM (proceed to Procedure 1). After the automatic transaxle is reinstalled, the Quick Response (QR) code label will be positioned where the code cannot be read. Therefore, before reinstalling the automatic transaxle, record the transaxle compensation codes or input them into the intelligent tester.

-

When the TCM is replaced, the existing transaxle compensation codes must be input into the new TCM (proceed to Procedure 2).

-

INPUT TRANSAXLE COMPENSATION CODE INTO TCM (Procedure 1)

Note

Transaxle compensation codes are unique, 60-digit alphanumeric values printed on a QR label on the transaxle. If an incorrect transaxle compensation code is input into the TCM, shift shock may occur.

-

Record the transaxle compensation code specified on the QR label.

Tech Tips

The transaxle compensation code is imprinted on the QR label.

-

Move the shift lever to N or P.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / ECT / Utility / A/T Code Registration.

-

Select "Set Compensation Code".

-

Register the compensation code.

-

Press "Input".

-

Manually input the transaxle compensation code. The code is a 60-digit alphanumeric value printed on the QR label. After inputting the code, press "Next".

-

-

Check that the compensation code displayed on the screen is correct by comparing it with the 60-digit alphanumeric value on the QR label.

Note

If an incorrect transaxle compensation code is input into the TCM, shift shock will occur.

-

Press "Next" to set the compensation code in the TCM.

Tech Tips

-

If the registration process fails, the compensation code may be incorrect. Check the compensation code again.

-

If the attempted compensation code is correct, a problem with the wire harness or a bad connection with the DLC3 may cause a registration failure. Check the wire harness and the DLC3 connection. If no problem is found, the TCM may be malfunctioning. Check the TCM and repeat this operation.

-

-

Press "Exit".

-

-

-

TRANSFER TRANSAXLE COMPENSATION CODE (Procedure 2)

Note

Transaxle compensation codes are 60-digit alphanumeric values imprinted on a QR label on the transaxle. If an incorrect transaxle compensation code is input into the TCM, shift shock may occur.

Tech Tips

The following operation is available for use with TCMs that can transmit the registered transaxle compensation code to the intelligent tester.

-

Move the shift lever to N or P.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

Note

Do not start the engine.

-

Read the transaxle compensation code.

-

Enter the following menus: Powertrain / ECT / Utility / A/T Code Registration.

-

Select "Read Compensation Code".

-

Press "Save".

-

Press "Save" or "Overwrite".

Tech Tips

When there is existing code data, press "Overwrite".

Note

Do not use the code specified on the transaxle QR label even if the transaxle compensation code cannot be read using the intelligent tester. The code printed on an in-service transaxle may not match its current characteristics. Replace the TCM with a new one and perform a road test to allow the TCM to learn.

-

Press "Exit".

-

Turn the ignition switch off.

-

-

Replace the TCM.

-

Set the transaxle compensation code.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / ECT / Utility / A/T Code Registration.

-

Select "Set Compensation Code".

-

Press "Open".

-

Press "Open" again to proceed.

-

Press "Exit".

-

-

-

-

INITIALIZATION RELATED TO DRIVING SUPPORT ECU

-

INITIALIZE DRIVING SUPPORT ECU

-

If the driving support ECU has been replaced, turn the engine switch off → on (IG) for 10 seconds → off to perform the initialization.

-

-

-

ADJUSTMENT RELATED TO LANE RECOGNITION CAMERA SENSOR ASSEMBLY

Tech Tips

-

Use the same procedure for RHD and LHD vehicles.

-

The procedure listed below is for the LHD.

-

If the lane recognition camera sensor assembly is replaced or removed/installed, or the toe-in is adjusted, perform the lane recognition camera sensor assembly adjustment.

-

ADJUST LANE RECOGNITION CAMERA SENSOR ASSEMBLY

Note

-

Make sure there are no black and white patterned objects in front of the vehicle.

-

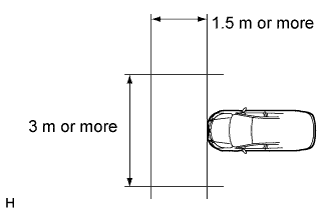

Perform the measurement in a place with no wind, and make sure there is 1.5 m (4.92 ft.) or more in front of the vehicle that has a level surface with no obstacles.

-

Check that there are no reflective materials in the surroundings or on the ground within a 3 m (9.84 ft.) or more x 3 m (9.84 ft.) or more area in front of the vehicle.

-

Perform the inspection in a bright area.

-

Beam axis learning preparation

-

Move the vehicle to a level surface.

-

Make sure the engine oil in the vehicle is at the specified amount.

-

Make sure the engine coolant in the vehicle is at the specified amount.

-

Make sure the fuel tank is full.

-

Make sure the spare tire is in the vehicle.

-

Make sure the standard tools are in the vehicle.

-

Make sure nobody is in the vehicle.

-

Make sure no extra loads are in the vehicle.

-

Adjust the tire pressures to the specified pressure.

-

Clean the front glass.

-

If the lens of the lane recognition camera sensor assembly is dirty, apply a small amount of lens cleaner to a clean, soft cloth and clean the lens.

-

-

Perform the front wheel alignment adjustment

-

Perform the front wheel alignment adjustment.

Note

Perform this procedure as accurately as possible.

-

-

Perform the rear wheel alignment adjustment

-

Perform the rear wheel alignment adjustment.

Note

Perform this procedure as accurately as possible.

-

-

Target sheet creation

-

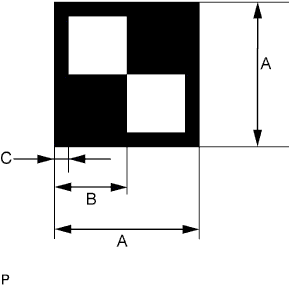

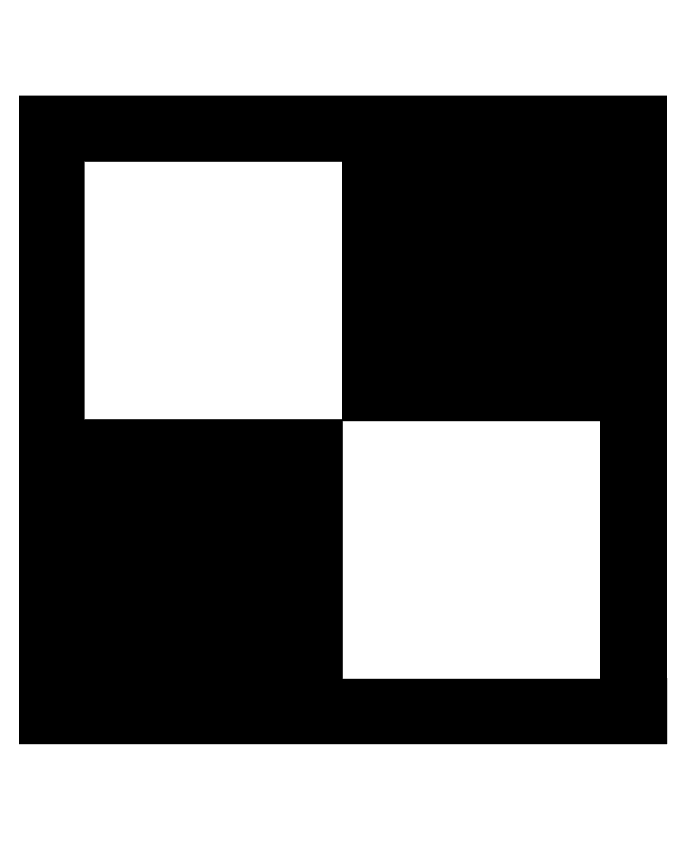

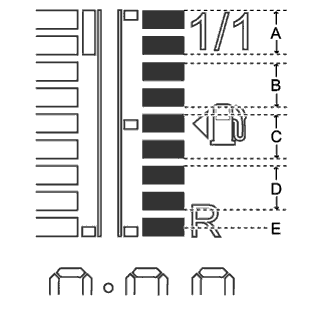

Print or copy the illustration below.

Dimension Area Specification A 160 mm (6.30 in.) B 80 mm (3.15 in.) C 16 mm (0.630 in.) Note

-

Make sure that the black areas of the target sheets are not glossy.

-

Make sure that the borders of the black and white areas on the target sheets are straight, and are not warped or blurry.

If the print or copy's dimensions are not as specified, adjust settings and reprint or recopy so that the print or copy's dimensions are as specified.

-

-

-

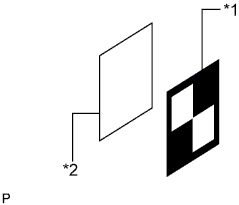

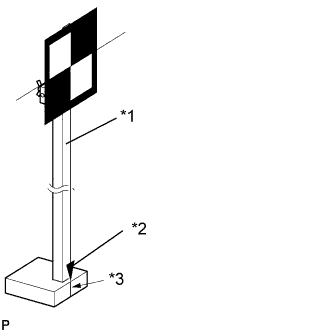

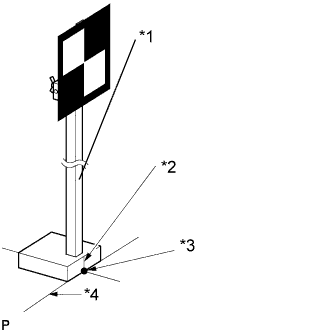

Text in Illustration *1 Target Sheet *2 Cardboard, etc. Target sheet attachment

- SST

- 09870-60000 ( 09870-60010, 09870-60020 )

-

Place the prepared target sheet on a piece of cardboard of the same size with the black area on the top right, as shown in the illustration. Then use double-sided tape to fix the target sheet in place.

Note

Do not attach reflective tape such as scotch tape, etc. to the target face, as this may affect target recognition.

-

Text in Illustration *1 SST (Laser Radar Adjusting Reflector) *2 Pointed Tip Weight *3 Mark-off Line Hang a weight with a pointed tip from the center of the target sheet. Then with double-sided tape, attach the target sheet to the reflector so that the weight aligns with the mark-off line of SST (laser radar adjusting reflector).

Note

-

Perform this procedure as accurately as possible.

-

Attach the target sheet so that it is horizontal with the ground.

-

-

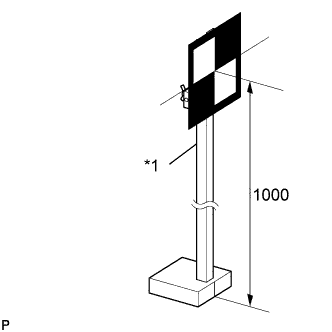

Text in Illustration *1 SST (Laser Radar Adjusting Reflector) Move the reflector up and down to position the center of the target at the height shown in the illustration, and fix it in place.

Dimension A 1000 mm (39.4 in.) Note

Perform this procedure as accurately as possible.

-

Target placement point measurement

Note

-

Do not place black and white patterned objects near the target.

-

Face the vehicle toward a wall with no patterns, or make sure the background behind the target has no patterns.

-

Perform this procedure as accurately as possible.

-

Do not place reflective materials in the area behind the target.

-

Make sure there are no patterns on the wall behind the target.

-

Make sure the distance between the target and wall is within 3 m (9.84 ft.).

-

Make sure the shadow of the target is not on the wall, as the camera may have a recognition error.

-

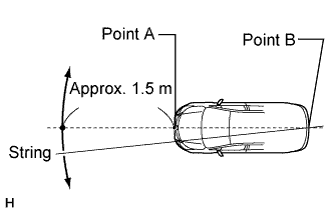

From the center of the front and back bumpers (center of the emblems), hang a weight with a pointed tip, and mark the front bumper center point A and the rear bumper center point B on the ground.

-

Draw a line that connects points A and B, and extend the line approximately 1.5 m (4.92 ft.) beyond the front of the vehicle.

Tech Tips

Secure the end of a string to point B. Then hold the other end of the string approximately 1.5 m (4.92 ft.) in front of the vehicle, and move it to the left or right to align the string with point A to make a straight line.

-

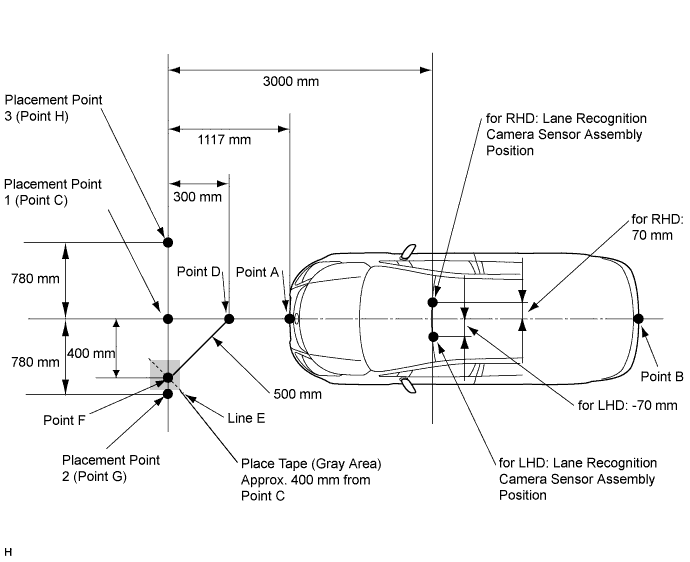

Mark point C 1117 mm (44.0 in.) from the front bumper center point A (placement point 1).

-

From point C, move 300 mm (11.8 in.) towards the front bumper center point A and mark point D.

-

From point C, place marking tape at a distance of 400 mm (15.7 in.) on the line perpendicular to the line that connects points A and B.

Note

Place tape so that there is sufficient surface area to clearly and accurately draw line E on the tape in the next step.

-

Using a measuring tape of 5 m (16.41 ft.) or more and point D as the center point, draw part of a circle with a 500 mm (19.7 in.) radius that overlaps the marking tape (line E).

-

Mark point F where the following intersect: 1) from point C, the point that is at a distance of 400 mm (15.7 in.) on the line perpendicular to the line that connects point A and point B; and 2) line E.

-

Extend the measuring tape from point C to point F. Then mark point G 780 mm (30.7 in.) from point C (on the line extending from point C to point F) (placement point 2).

-

Extend the measuring tape from point F to point C. Then mark point H 780 mm (30.7 in.) beyond point C (placement point 3).

-

Set a string between points G and H, and use the string to accurately draw a straight line on the ground connecting points G and H (target placement line).

-

-

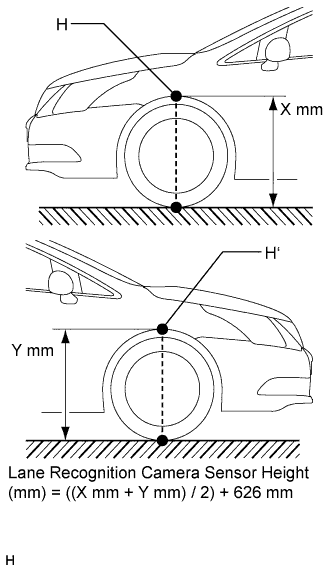

Lane recognition camera sensor height measurement

Note

-

Do not place black and white patterned objects near the target.

-

Face the vehicle toward a wall with no patterns, or make sure the background behind the target has no patterns.

-

Perform this procedure as accurately as possible.

-

Do not place reflective materials in the area behind the target.

-

Make sure there are no patterns on the wall behind the target.

-

Make sure the distance between the target and wall is within 3 m (9.84 ft.).

-

Make sure the shadow of the target is not on the wall, as the camera may have a recognition error.

-

Measure the distance (X mm or in.) from the ground to point H for the front left wheel arch.

-

Measure the distance (Y mm or in.) from the ground to point H' for the front right wheel arch.

-

The average of the 2 distances (X mm or in, Y mm or in.) plus 626 mm (24.6 in.) is the height of the lane recognition camera sensor.

-

-

Memorize camera/target position

Note

-

Close all doors.

-

Perform the procedure with no one in the vehicle.

-

During the procedure, do not lean on the vehicle.

-

Do not illuminate the headlights.

-

When using intelligent tester:

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).*1

-

Turn the intelligent tester main switch ON.

-

Select "LKA System" from the display screen.

-

Select "Utility" from the display screen.

-

Select "Camera/target position memory" from the display screen.

-

Follow the tester display, and select "Next".

-

Input the measured height of the lane recognition camera sensor assembly and the horizontal position of the camera into the input screen. Then press the "Next" button on the display screen.

Tech Tips

-

for RHD: 70 mm (2.76 in.)

-

for LHD: -70 mm (-2.76 in.)

-

-

Input "3000 mm (118 in.)" for the distance from the camera to the target and "1000 mm (39.4 in.)" for the height of the target into the input screen. Then press the "Next" button on the display screen.

-

Press the "Exit" button to finish the camera/target position memory mode.

Note

If "Error Camera/target position memory" is displayed on the screen, press the "Try Again" button, and repeat procedures *1 again.

-

-

Beam axis learning

-

Select "LKA System" from the display screen.*1

-

Select "Utility" from the display screen.

-

Select "Camera axis adjust" from the display screen.

-

Follow the tester display, and select "Next".

-

Text in Illustration *1 SST (Laser Radar Adjusting Reflector) *2 Mark-off Line *3 Point C *4 Target Placement Line Align SST (laser radar adjusting reflector) sheet with the target placement line, and align the mark-off line with placement point 1 (point C).

-

Check that the screen displays beam axis learning for target 1, then press the "Next" button on the display screen.

-

Text in Illustration *1 SST (Laser Radar Adjusting Reflector) *2 Mark-off Line *3 Point G *4 Target Placement Line Align SST (laser radar adjusting reflector) sheet with the target placement line, and align the mark-off line with placement point 2 (point G).

-

Check that the screen displays beam axis learning for target 2, then press the "Next" button on the display screen.

Note

Within 3 minutes after the screen displays the beam axis learning for target 2, move the target and press the "Next" button on the display screen.

-

Text in Illustration *1 SST (Laser Radar Adjusting Reflector) *2 Mark-off Line *3 Point H *4 Target Placement Line Align SST (laser radar adjusting reflector) sheet with the target placement line, and align the mark-off line with placement point 3 (point H).

-

Check that the screen displays beam axis learning for target 3, then press the "Next" button on the display screen.

Note

Within 3 minutes after the screen displays the beam axis learning for target 3, move the target and press the "Next" button on the display screen.

-

Press the "Exit" button to finish the beam axis learning mode.

Note

-

Height of the target.

-

Distance from lane recognition camera sensor assembly to target.

-

Orientation of target (black area positioned on top right).

-

If surrounding area is bright enough.

-

If black and white patterned objects are placed near the target.

If "Error camera axis adjust" is displayed on the screen, press the "Exit" button. Then after checking the conditions below, turn the engine switch on (IG) and off, and repeat from procedure *1 again.

-

-

-

-

-

ADJUSTMENT RELATED TO MILLIMETER WAVE RADAR SENSOR

-

ADJUST MILLIMETER WAVE RADAR SENSOR ASSEMBLY

CAUTION:

Exposure to radio frequency emissions is hazardous to your health. It is hazardous to be within 20 cm (7.87 in.) of the device's radio frequency aperture.

Note

-

This device complies with FCC radio frequency emission regulations.

-

Perform adjustment on a level surface.

-

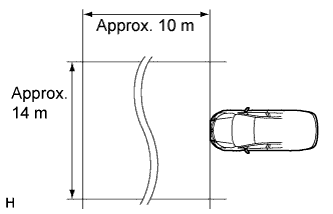

Make sure that no large pieces of metal are within a 10 m (32.81 ft.) x 14 m (45.93 ft.) area in front of the vehicle. If possible, the surrounding area should also be free of large metal objects.

-

Before adjusting the radar beam axis, prepare the vehicle as follows.

-

Check the tire pressure and adjust it if necessary.

-

Remove all excess weight from the vehicle (luggage, heavy objects, etc.).

-

-

Check and adjust the vertical direction of the radar sensor.

-

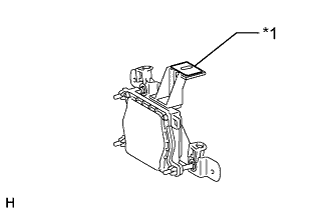

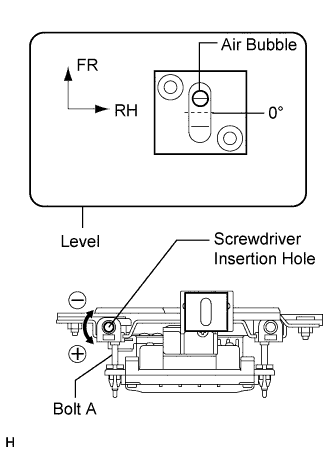

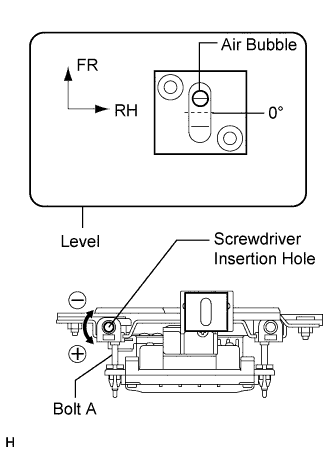

Text in Illustration *1 Level Remove dust, oil and foreign matter from the radar sensor's level rack.

-

Set a level on the radar sensor's level rack.

-

Check that the level's air bubble is within the red frame.

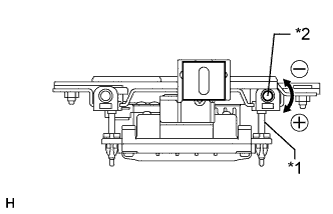

OK Level's air bubble is within red frame. If the bubble is not within the red frame, use a screwdriver to adjust bolt A until the level's air bubble is within the red frame.

Tech Tips

-

The adjustable range within the red frame of the level is +/-0.2°.

-

The target angle is +0.2° (upward angle of 0.2°).

Result Adjustment Direction Adjustment Procedure Adjustment Angle Vertical adjustment Upward direction: Turn bolt A to positive (+) side For every 8.6 rotations of adjustment bolt, sensor moves about 1° Downward direction: Turn bolt A to negative (-) side -

-

-

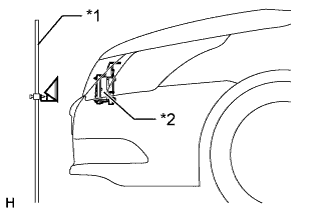

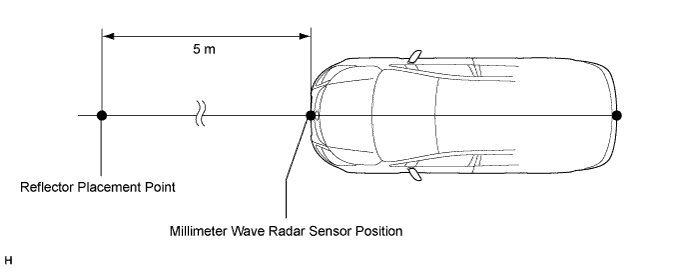

Text in Illustration *1 SST *2 Millimeter Wave Radar Sensor Assembly Adjust the reflector height.

- SST

- 09870-60000 ( 09870-60010 )

- 09870-60040

-

Adjust the reflector so that the center of SST reflector is the same height as the millimeter wave radar sensor.

Tech Tips

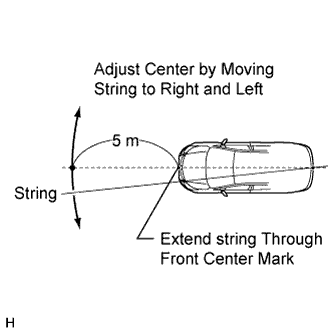

Prepare a 10 m (32.81 ft.) string, a string with a sharp-pointed weight (plumb bob), and a 5 m (16.41 ft.) tape measure.

-

Place the reflector.

-

Hang the string (with weight) from the center of the vehicle rear's emblem. Mark the vehicle rear's center point on the ground. Repeat for the front of the vehicle.

-

Set one end of the more than 10 m (32.81 ft.) string on the vehicle rear's center point. Run the string over the vehicle front's center point to a position 5 m (16.4 ft.) beyond the vehicle front's center point, as shown in the illustration. Mark the 5 m (16.4 ft.) position.

-

Place the reflector (SST) at the marked position.

Note

Perform the operation as precisely as possible.

-

-

Check the radar beam axis.

Tech Tips

If a screen indicating an error is displayed while performing this procedure, perform the procedure again from *1.

-

Connect the intelligent tester to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the intelligent tester main switch on, and turn the cruise control main switch on.

-

Select "Auto" from the intelligent tester display screen. *1

-

Select "Radar Cruise" from the display screen.

-

Select the appropriate menu item.

-

For vehicles with lane recognition camera: select "w/ LKA System" from the display screen.

-

For vehicles without lane recognition camera: select "w/o LKA System" from the display screen.

-

Select "Radar Cruise" from the display screen.

-

Select "Utility" from the display screen.

-

Select "Beam Axis Adjustment" from the display screen.

-

Follow the tester display, and select "Next".

Note

-

Turn the cruise control main switch ON before pressing Next.

-

Make sure there is at least 20 cm (7.9 in.) between the radar sensor and any nearby individuals.

CAUTION:

Do not come within 20 cm (7.9 in.) of the radar sensor.

-

-

Check the following items on the radar cruise divergence data screen.

CAUTION:

While using the intelligent tester's beam axis adjustment mode, the actual direction and angle of the radar sensor may be different from the intelligent tester's data. In such a case, the deviation is displayed on the combination meter's multi-information display.

-

Confirm that the distance value is approximately 5 m (16.4 ft.).

Tech Tips

-

A value between 0.0 and 6.3 m (20.67 ft.) is indicated.

-

If the distance is 0 m (0 ft.), the sensor cannot detect the target. Reconfirm that there is no metal in the specified area in front of the vehicle (refer to the NOTICE at the beginning of this adjustment procedure).

-

-

Confirm that the left/right side value is between 0.0 and 6.3.

Tech Tips

If the distance is 0 m (0 ft.), the sensor cannot detect the target. Reconfirm that there is no metal in the specified area in front of the vehicle (refer to the NOTICE at the beginning of this adjustment procedure).

-

-

Check and adjust the horizontal direction of the radar sensor.

-

Check that the divergence of the radar beam axis is 0°.

Standard 0° (Both right and left) If the axis is not as specified, use a screwdriver to adjust bolt B until the divergence of the radar beam axis is 0°.

-

Text in Illustration *1 Bolt B *2 Screwdriver Insertion Hole Based on the measured divergence of the beam axis, turn and adjust bolt B for horizontal adjustment of the millimeter wave radar sensor using a screwdriver.

Result Adjustment Direction Adjustment Procedure Adjustment Angle Horizontal adjustment Right direction: Turn bolt B to positive (+) side. For every 14.8 rotations of adjustment bolt, sensor moves about 1° Left direction: Turn bolt B to negative (-) side. Tech Tips

-

If "LEFT SIDE: 1.0°" is displayed, the divergence is 1.0° in the left direction. Turn bolt B approximately 14.8 turns to the negative (-) side.

-

If the value does not change to 0°, it is possible that the sensor is aiming at something different. Reconfirm that there are no reflective materials in the surrounding area.

-

-

Select "Next". The driving learning value is automatically reset.

Tech Tips

A buzzer will sound for 10 seconds or more.

-

Disconnect the intelligent tester from the DLC3.

-

-

Recheck and readjust the vertical direction of the radar sensor.

-

Text in Illustration *1 Level Set a level on the radar sensor's level rack.

-

Check that the level's air bubble is within the red frame.

OK Level's air bubble is within the red frame. If the bubble is not within the red frame, use a screwdriver to adjust bolt A until the level's air bubble is within the red frame.

Tech Tips

-

The adjustable range within the red frame is +/-0.2°.

-

The target angle is +0.2° (upward angle of 0.2°).

Result Adjustment Direction Adjustment Procedure Adjustment Angle Vertical adjustment Upward direction: Turn bolt A to positive (+) side For every 8.6 rotations of adjustment bolt, sensor moves about 1° Downward direction: Turn bolt A to negative (-) side -

-

-

-

-

CALIBRATION RELATED TO CLUTCH SYSTEM (for 1AD-FTV)

-

INSPECT DRIVE AWAY RELEASE FUNCTION

-

Before removing the clutch release with bearing cylinder assembly, brake pedal stroke sensor (clutch pedal stroke sensor), clutch master cylinder assembly, or clutch pedal sub-assembly, check the operation of the drive away release function of the electric parking brake.

Tech Tips

-

Perform the inspection on as level a surface as possible.

-

Check the current behavior of the vehicle when accelerating from rest.

-

Check the timing of the electric parking brake release.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*1)

-

Accelerate the vehicle slightly more rapidly than in step *1 after operating the electric parking brake, and then check when the electric parking brake is released.

-

-

-

PERFORM CLUTCH ENGAGEMENT POINT LEARNING

Note

Under the following conditions, it is necessary to perform clutch engagement point learning.

-

When replacing or removing/installing the clutch cover assembly.

-

When replacing or removing/installing the clutch disc assembly.

-

When replacing the clutch release with bearing cylinder assembly.

-

When replacing or removing/installing the brake pedal stroke sensor (Clutch pedal stroke sensor).

-

When replacing or removing/installing the clutch pedal sub-assembly.

-

When replacing or removing/installing the clutch master cylinder assembly.

-

Warm up the engine.

-

While driving the vehicle at a speed of 50 km/h (37 mph/h) or more, downshift from 4th to 3rd gear and check that the engine speed increases. (*1)

Note

Do not operate the accelerator pedal at this time.

-

Perform step *1 five times.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*2)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

Accelerate the vehicle slightly more rapidly than in step*2 after operating the electric parking brake and then check the time it takes for the electric parking brake to be released. (*3)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

If there is any abnormal feeling, repeat step *1 twenty times.

-

Perform steps *2 and *3.

-

-

-

CALIBRATION RELATED TO CLUTCH SYSTEM (for 2AD-FTV)

-

INSPECT DRIVE AWAY RELEASE FUNCTION

-

Before removing the clutch release with bearing cylinder assembly, brake pedal stroke sensor (clutch pedal stroke sensor), clutch master cylinder assembly, or clutch pedal sub-assembly, check the operation of the drive away release function of the electric parking brake.

Tech Tips

-

Perform the inspection on as level a surface as possible.

-

Check the current behavior of the vehicle when accelerating from rest.

-

Check the timing of the electric parking brake release.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*1)

-

Accelerate the vehicle slightly more rapidly than in step *1 after operating the electric parking brake, and then check when the electric parking brake is released.

-

-

-

PERFORM CLUTCH ENGAGEMENT POINT LEARNING

Note

Under the following conditions, it is necessary to perform clutch engagement point learning.

-

When replacing or removing/installing the clutch cover assembly.

-

When replacing or removing/installing the clutch disc assembly.

-

When replacing the clutch release with bearing cylinder assembly.

-

When replacing or removing/installing the brake pedal stroke sensor (Clutch pedal stroke sensor).

-

When replacing or removing/installing the clutch pedal sub-assembly.

-

When replacing or removing/installing the clutch master cylinder assembly.

-

Warm up the engine.

-

While driving the vehicle at a speed of 50 km/h (37 mph/h) or more, downshift from 4th to 3rd gear and check that the engine speed increases. (*1)

Note

Do not operate the accelerator pedal at this time.

-

Perform step *1 five times.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*2)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

Accelerate the vehicle slightly more rapidly than in step*2 after operating the electric parking brake and then check the time it takes for the electric parking brake to be released. (*3)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

If there is any abnormal feeling, repeat step *1 twenty times.

-

Perform steps *2 and *3.

-

-

-

CALIBRATION RELATED TO CLUTCH SYSTEM (for 2AD-FHV)

-

INSPECT DRIVE AWAY RELEASE FUNCTION

-

Before removing the clutch release with bearing cylinder assembly, brake pedal stroke sensor (clutch pedal stroke sensor), clutch master cylinder assembly, or clutch pedal sub-assembly, check the operation of the drive away release function of the electric parking brake.

Tech Tips

-

Perform the inspection on as level a surface as possible.

-

Check the current behavior of the vehicle when accelerating from rest.

-

Check the timing of the electric parking brake release.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*1)

-

Accelerate the vehicle slightly more rapidly than in step *1 after operating the electric parking brake, and then check when the electric parking brake is released.

-

-

-

PERFORM CLUTCH ENGAGEMENT POINT LEARNING

Note

Under the following conditions, it is necessary to perform clutch engagement point learning.

-

When replacing or removing/installing the clutch cover assembly.

-

When replacing or removing/installing the clutch disc assembly.

-

When replacing the clutch release with bearing cylinder assembly.

-

When replacing or removing/installing the brake pedal stroke sensor (Clutch pedal stroke sensor).

-

When replacing or removing/installing the clutch pedal sub-assembly.

-

When replacing or removing/installing the clutch master cylinder assembly.

-

Warm up the engine.

-

While driving the vehicle at a speed of 50 km/h (37 mph/h) or more, downshift from 4th to 3rd gear and check that the engine speed increases. (*1)

Note

Do not operate the accelerator pedal at this time.

-

Perform step *1 five times.

-

Accelerate the vehicle after operating the electric parking brake, and then check when the electric parking brake is released. (*2)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

Accelerate the vehicle slightly more rapidly than in step*2 after operating the electric parking brake and then check the time it takes for the electric parking brake to be released. (*3)

Note

Make sure that there is no sticking or abnormal feeling due to a delayed release of the electric parking brake.

Tech Tips

Check that the vehicle behaves in approximately the same fashion as it did when the vehicle behavior upon acceleration from rest was checked before performing this step.

-

If there is any abnormal feeling, repeat step *1 twenty times.

-

Perform steps *2 and *3.

-

-

-

CALIBRATION RELATED TO ELECTRIC PARKING BRAKE SYSTEM

-

DESCRIPTION

-

Follow the chart below to perform calibration.

Parts to be Replaced/Operation Necessary Operation Electric parking brake ECU (Parking brake with bracket actuator assembly)

-

Yaw rate sensor zero point calibration

-

Brake pedal stroke sensor (Clutch pedal stroke sensor) zero point calibration (for M/T)

Yaw rate sensor

-

Clearing zero point calibration data

-

Yaw rate sensor zero point calibration

Brake pedal stroke sensor (Clutch pedal stroke sensor) (for M/T)

-

Clearing zero point calibration data

-

Brake pedal stroke sensor (Clutch pedal stroke sensor) zero point calibration

Brake pedal stroke sensor (Clutch pedal stroke sensor) adjustment (for M/T) Clutch pedal (for M/T) -

-

-

CLEAR ZERO POINT OF YAW RATE SENSOR AND BRAKE PEDAL STROKE SENSOR (CLUTCH PEDAL STROKE SENSOR)

-

Clear the zero point calibration data (when using intelligent tester).

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the intelligent tester on.

-

Enter the following menus: Chassis / Electric Parking Brake / Utility / Reset Memory.

-

Follow the intelligent tester display and perform reset memory.

Tech Tips

When the reset memory procedure is completed, the brake system warning light (yellow indicator) turns on.

-

-

Clear the zero point calibration data (when not using intelligent tester).

- SST

- 09843-18040

-

Turn the ignition switch off.

-

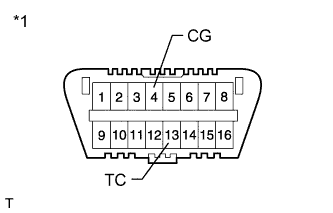

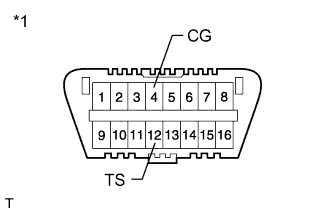

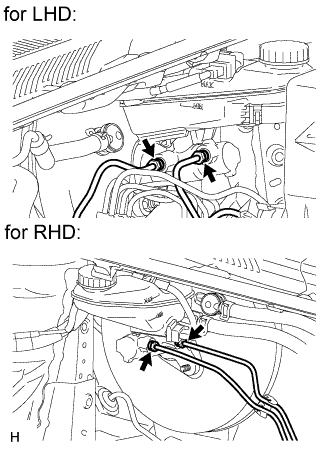

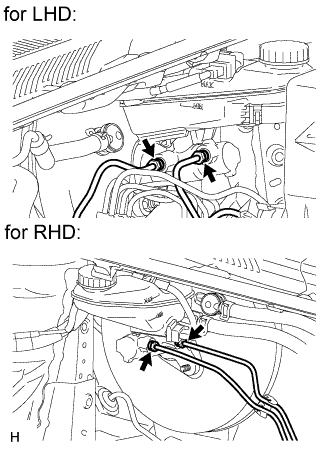

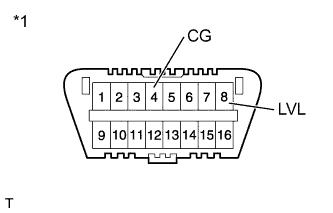

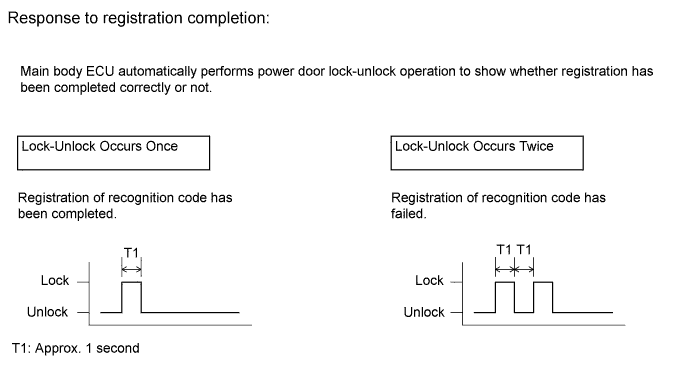

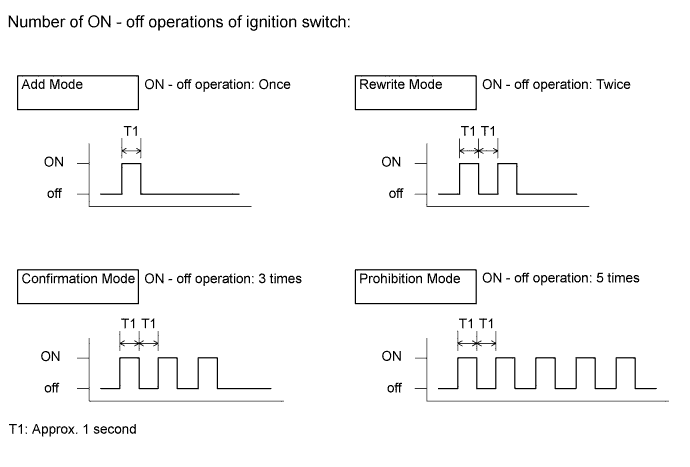

Text in Illustration *1 Front view of DLC3 Using SST, connect terminals 13 (TC) and 4 (CG) of the DLC3.

Note

Do not connect the wrong terminals, as this will cause parts to be damaged.

-

Turn the ignition switch to ON.

-

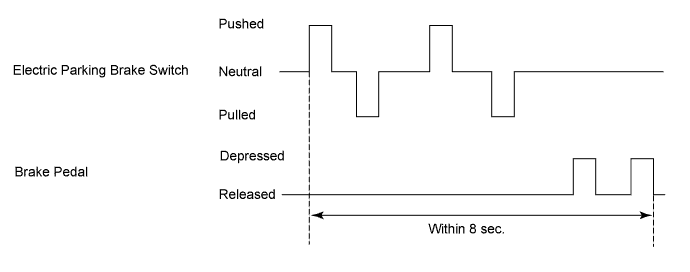

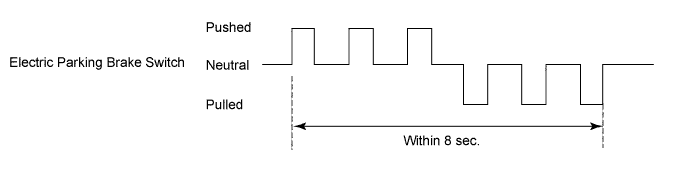

Perform both of the following procedures within 8 seconds:

-

-

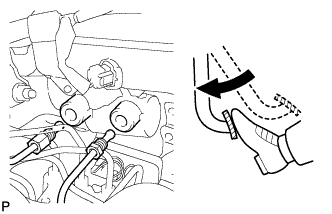

Perform the following electric parking brake switch operation: push → pull → push → pull.

-

Perform the following with the brake pedal: depress → release → depress → release.

-

-

With the ignition switch ON, disconnect the connection of terminals 13 (TC) and 4 (CG) of the DLC3.

-

Check that the brake system warning light (yellow indicator) turns on.

-

-

OBTAIN ZERO POINT OF YAW RATE SENSOR AND BRAKE PEDAL STROKE SENSOR (CLUTCH PEDAL STROKE SENSOR)

- SST

- 09843-18040

Note

-

Before performing calibration, make sure that the vehicle is on a horizontal surface.

-

Do not press the clutch pedal during test mode. (for M/T)

-

Turn the air conditioning system off.

-

Turn the ignition switch to ON.

-

Check that the brake system warning light (yellow indicator) turns on.

Note

If the brake system warning light (yellow indicator) does not turn on, perform the Clear Zero Point of Yaw Rate Sensor and Brake Pedal Stroke Sensor (Clutch Pedal Stroke Sensor) procedures.

-

Enter test mode.

-

Turn the ignition switch off.

-

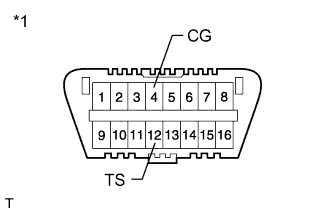

Text in Illustration *1 Front view of DLC3 Using SST, connect terminals 12 (TS) and 4 (CG) of the DLC3.

Note

Do not connect the wrong terminals, as this will cause parts to be damaged.

-

-

Turn the ignition switch to ON.

-

Perform the following procedures with the electric parking brake switch within 8 seconds:

-

Push the electric parking brake switch 3 times and then pull it 3 times.

-

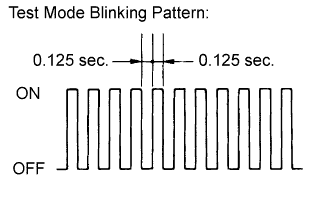

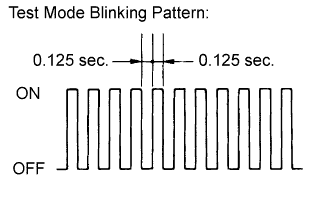

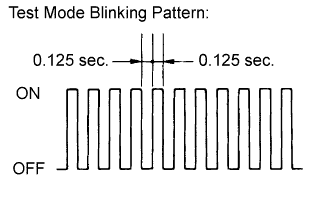

Check that the PARK warning light blinks in test mode.

-

-

Check that the brake system warning light (yellow indicator) turns off.

Note

The brake system warning light (yellow indicator) does not turn off if confirmation of the vehicle specifications and/or sensor calibration fails.

If the brake system warning light (yellow indicator) does not turn off, repeat the procedure from entering test mode. If the procedure fails multiple times, proceed to Failure Investigation to determine the cause of the failure.

-

FAILURE INVESTIGATION

Tech Tips

*: If the electric parking brake switch is operated too quickly, it does not operate properly.

-

Turn the ignition switch to ON.

-

Apply the electric parking brake.*

-

Release the electric parking brake after the PARK warning light turns off.*

-

Check for DTCs.

-

Refer to Diagnostic Trouble Code Chart.

-

-

-

CALIBRATION RELATED TO VEHICLE STABILITY CONTROL SYSTEM

-

DESCRIPTION

Follow the chart below to perform calibration.

Parts to be Replaced Necessary Operation Skid control ECU (Brake actuator assembly) Engine variant learning -

ENGINE VARIANT LEARNING (Using the Intelligent Tester)

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Switch the skid control ECU to Test Mode using the intelligent tester. Enter the following menus: Chassis / ABS/VSC/TRC / Utility / Test Mode.

Tech Tips

-

Engine variant learning is automatically performed immediately after test mode is entered.

-

If the engine variant learning has not been done yet, the ABS warning light begins blinking in the test mode blinking pattern, the multi-information display changes to the test mode display, and then the ABS warning light and brake system warning light (red indicator) turn on for approximately 3 seconds.

-

When the engine variant learning is correctly completed, the ABS warning light resumes blinking in the test mode blinking pattern, and the multi-information display shows the test mode display.

-

-

-

ENGINE VARIANT LEARNING (Using SST Check Wire)

-

Turn the ignition switch off.

-

Text in Illustration *1 Front view of DLC3 Using SST, connect terminals 12 (TS) and 4 (CG) of the DLC3.

- SST

- 09843-18040

-

Turn the ignition switch to ON.

Tech Tips

-

Engine variant learning is automatically performed immediately after test mode is entered.

-

If the engine variant learning has not been done yet, the ABS warning light, brake system warning light (red indicator) and slip indicator light turn on for approximately 5 seconds.

-