MONOLITHIC CONVERTER INSTALLATION

-

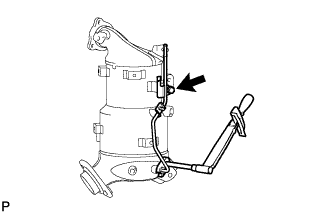

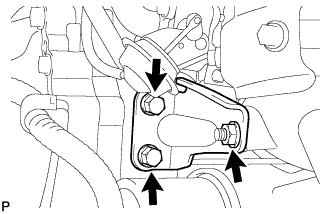

INSTALL NO. 2 MANIFOLD CONVERTER INSULATOR

-

Install the No. 2 manifold converter insulator with the 3 bolts.

- Torque:

- 29 N*m { 291 kgf*cm, 21 ft.*lbf }

-

-

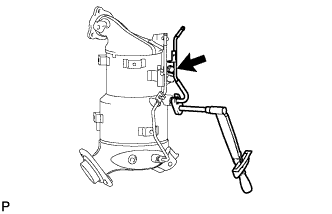

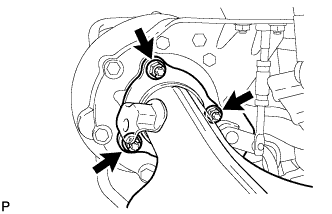

INSTALL NO. 2 VACUUM PIPE

-

Temporarily install the No. 2 vacuum pipe with the union nut and bolt.

-

Tighten the bolt.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

-

Using a 14 mm union nut wrench, tighten the union nut of the No. 2 vacuum pipe.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

INSTALL NO. 1 VACUUM PIPE

-

Temporarily install the No. 1 vacuum pipe with the union nut and bolt.

-

Tighten the bolt.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

-

Using a 17 mm union nut wrench, tighten the union nut of the No. 1 vacuum pipe.

- Torque:

- 48 N*m { 489 kgf*cm, 35 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

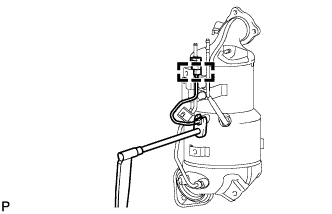

INSTALL EXHAUST GAS TEMPERATURE SENSOR (for Upper Side)

Note

If the sensor is dropped, replace it with a new one.

-

Using a 14 mm union nut wrench, install the sensor.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Attach the sensor connector clamp.

-

-

INSTALL EXHAUST GAS TEMPERATURE SENSOR (for Lower Side)

Note

If the sensor is dropped, replace it with a new one.

-

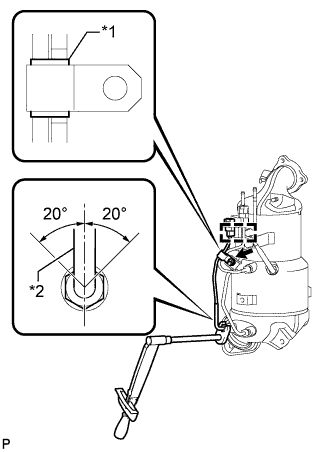

Text in Illustration *1 White Tube *2 Protective Tube Temporarily install the sensor with the union nut.

-

Attach the sensor connector clamp.

-

Temporarily install the clamp with the nut.

Note

Make sure the clamp is aligned with the white tube of the wire harness as shown in the illustration.

-

Tighten the nut.

- Torque:

- 6.4 N*m { 65 kgf*cm, 57 in.*lbf }

-

Using a 14 mm union nut wrench, tighten the union nut of the sensor.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

Note

-

When tightening the union nut, make sure that the protective tube of the sensor is within the range shown in the illustration.

-

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

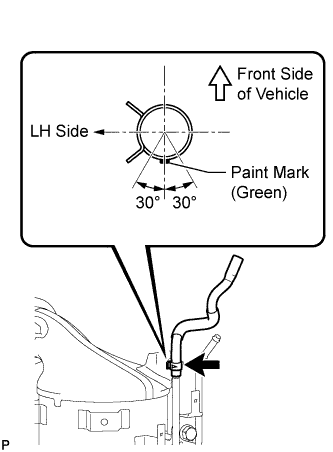

INSTALL NO. 2 VACUUM TRANSMITTING HOSE ASSEMBLY

-

Install the No. 2 vacuum transmitting hose to the No. 2 vacuum pipe.

Tech Tips

The direction of the hose clamp is indicated in the illustration.

-

-

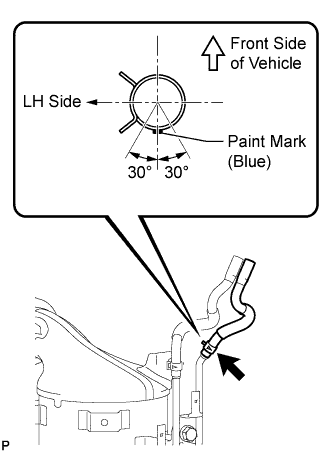

INSTALL VACUUM TRANSMITTING HOSE ASSEMBLY

-

Install the vacuum transmitting hose to the No. 1 vacuum pipe.

Tech Tips

The direction of the hose clamp is indicated in the illustration.

-

-

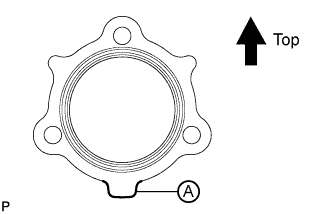

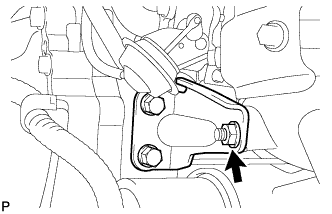

INSTALL EXHAUST MANIFOLD CONVERTER SUB-ASSEMBLY

-

Install a new gasket to the turbocharger.

Tech Tips

Make sure that the part labeled A is facing downwards as shown in the illustration.

-

Temporarily install the exhaust manifold converter with 3 new nuts.

-

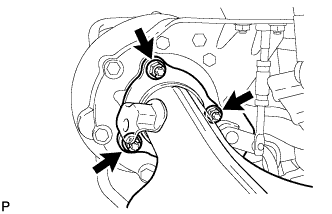

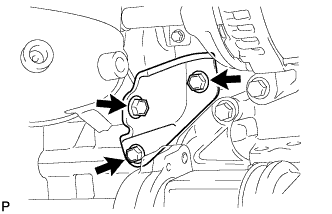

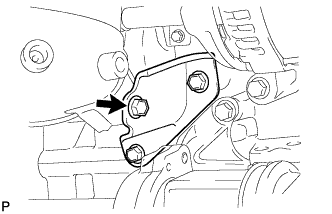

Temporarily install the No. 2 exhaust manifold stay with the 2 bolts and nut.

-

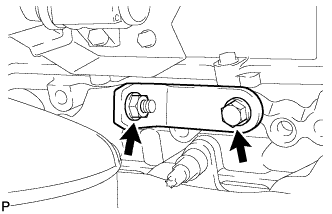

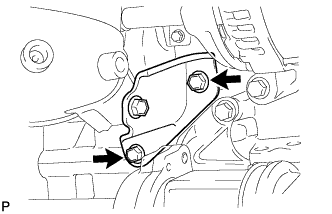

Temporarily install the No. 2 manifold stay with the 3 bolts.

-

Temporarily install the manifold stay with the bolt and nut.

-

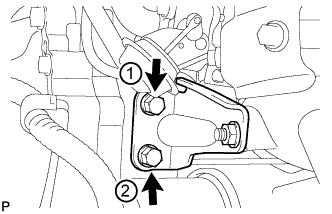

Tighten the 2 bolts of the No. 2 exhaust manifold stay in the order shown in the illustration.

- Torque:

- 56 N*m { 571 kgf*cm, 41 ft.*lbf }

-

Tighten the 3 nuts of the exhaust manifold converter.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

Note

Tighten the nuts while pressing the exhaust manifold converter against the engine.

-

Tighten the nut of the No. 2 exhaust manifold stay.

- Torque:

- 56 N*m { 571 kgf*cm, 41 ft.*lbf }

-

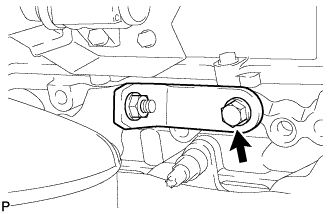

Tighten the bolt of the No. 2 manifold stay shown in the illustration.

- Torque:

- 56 N*m { 571 kgf*cm, 41 ft.*lbf }

Note

Tighten the bolt while pressing the No. 2 manifold stay against the exhaust manifold converter and cylinder block.

-

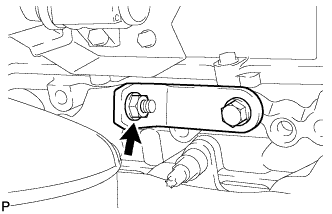

Tighten the 2 bolts of the No. 2 manifold stay shown in the illustration.

- Torque:

- 56 N*m { 571 kgf*cm, 41 ft.*lbf }

-

Tighten the bolt of the manifold stay.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

Note

Tighten the bolt while pressing the manifold stay against the exhaust manifold converter and cylinder block.

-

Tighten the nut of the manifold stay.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

-

Connect the 2 connectors.

-

-

INSTALL NO. 1 MANIFOLD CONVERTER INSULATOR

-

Install the No. 1 manifold converter insulator with the 5 bolts.

- Torque:

- 29 N*m { 291 kgf*cm, 21 ft.*lbf }

-

-

INSTALL ENGINE ASSEMBLY

-

PERFORM CATALYST RECORD OF DPF THERMAL DETERIORATION CLEAR FUNCTION

-

Perform the catalyst record of DPF thermal deterioration clear function.

-

w/ Gear Shift Indicator: Click here

-

w/o Gear Shift Indicator: Click here

-

-