CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY REMOVAL

-

REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

-

Remove the engine with transaxle Click here.

-

-

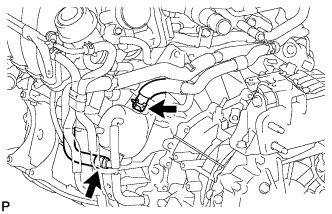

DISCONNECT WATER BY-PASS HOSE

-

Disconnect the 2 water by-pass hoses from the oil cooler.

-

-

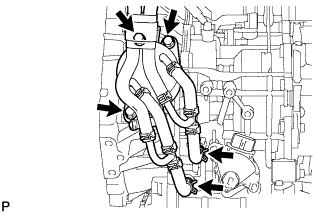

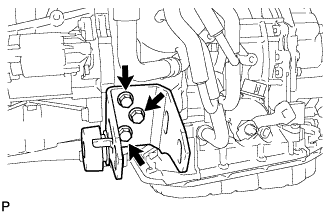

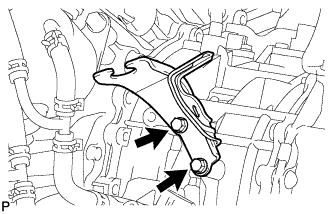

REMOVE OIL COOLER

-

Disconnect the 2 oil cooler hoses from the continuously variable transaxle.

-

Remove the 3 bolts and oil cooler from the continuously variable transaxle.

-

-

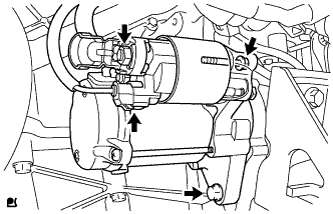

REMOVE STARTER ASSEMBLY

-

Disconnect the terminal cap.

-

Remove the nut and disconnect the starter wire.

-

Disconnect the connector.

-

Remove the 2 bolts and starter.

-

-

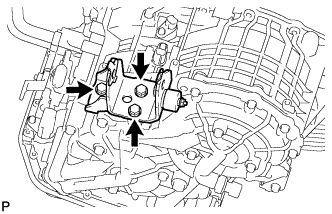

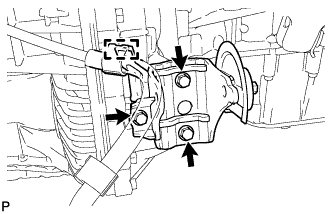

REMOVE ENGINE MOUNTING BRACKET LH

-

Remove the 3 bolts and engine mounting bracket LH from the continuously variable transaxle.

-

-

REMOVE FRONT ENGINE MOUNTING BRACKET

-

Remove the 3 bolts and front engine mounting bracket from the continuously variable transaxle.

-

-

REMOVE REAR ENGINE MOUNTING BRACKET

-

Detach the engine wire clamp from the rear engine mounting bracket.

-

Remove the 3 bolts and rear engine mounting bracket from the continuously variable transaxle.

-

-

REMOVE GROUND CABLE

-

Detach the clamp.

-

Remove the bolt and ground cable.

-

-

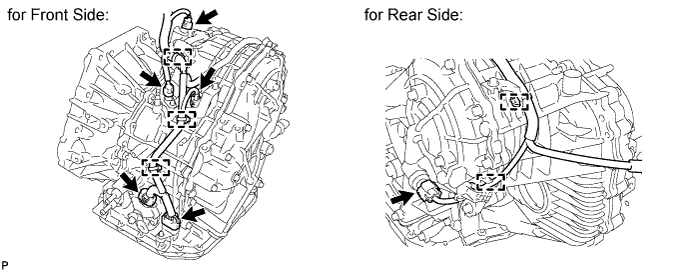

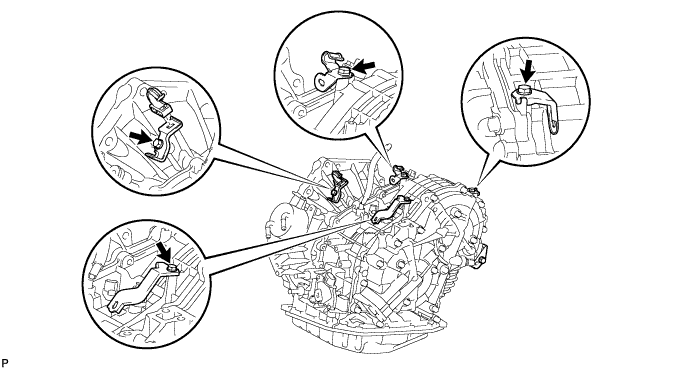

DISCONNECT ENGINE WIRE

-

for Front Side:

Disconnect the transmission wire connector, park/neutral position switch connector, and 3 revolution sensor connectors, and detach the 3 wire harness clamps from the continuously variable transaxle.

-

for Rear Side:

Disconnect the oil pressure sensor connector and detach the 2 wire harness clamps from the continuously variable transaxle.

-

-

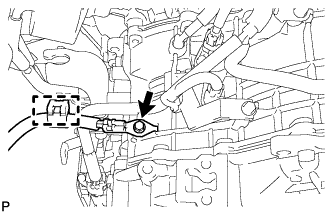

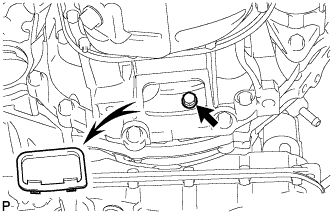

REMOVE DRIVE PLATE AND TORQUE CONVERTER SETTING BOLT

-

Remove the flywheel housing under cover.

-

Turn the crankshaft to gain access to the 6 bolts and remove each bolt while holding the crankshaft pulley bolt with a wrench.

Tech Tips

There is one black colored bolt.

-

-

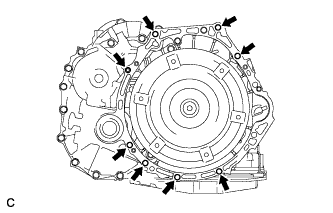

REMOVE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY

-

Remove the 8 bolts and continuously variable transaxle from the engine.

Note

To prevent damage to the knock pins, do not pry between the transaxle and engine.

-

-

REMOVE NO. 1 TRANSMISSION CONTROL CABLE BRACKET

-

Remove the 2 bolts and transmission control cable bracket from the continuously variable transaxle.

-

-

REMOVE WIRE HARNESS CLAMP BRACKET AND TRANSMISSION CONTROL CABLE SUPPORT

-

Detach the water by-pass hose clamp from the wire harness clamp bracket.

-

Remove the 4 bolts, 3 wire harness clamp brackets and transmission control cable support from the continuously variable transaxle.

-

-

REMOVE TORQUE CONVERTER ASSEMBLY

-

Remove the torque converter from the continuously variable transaxle.

-

-

REMOVE CVT OIL PUMP TYPE T OIL SEAL

Note

-

Do not remove the front oil pump assembly from the CVT main body, as there is the possibility of the entry of dust and foreign matter.

-

Clean the work area, the tools to be used, and other equipment, etc. thoroughly before the operation, as there is the possibility that a CVT malfunction, which could prevent the vehicle from running, could occur if dust or fine foreign matter enters the CVT.

-

Do not use cotton work gloves, cloths, or paper towels, etc. that may produce lint, etc.

-

Perform the operation as quickly as possible, as dust and foreign matter could enter the CVT while the torque convertor is not attached to it.

-

Do not use the air gun until the torque convertor has been installed, as it could cause dust and foreign matter to be stirred up.

-

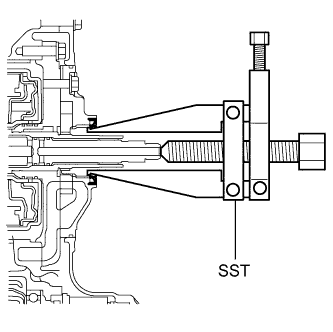

Clean the tips of both the claws of the SST and the center bolt.

-

Using the SST, remove the CVT oil pump type T oil seal.

- SST

- 09308-10010

Note

Pay attention to the angle of the claws when opening them, and ensure that they do not come into contact with the oil pump housing, as there is the possibility that metal particles could be produced if they do.

-