FUEL SYSTEM ON-VEHICLE INSPECTION

-

CHECK FUEL PRESSURE

-

Read the Data List.

Note

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

Tech Tips

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List.

-

Read the Data List.

w/ DPF: Tester Display Measurement Item/Range Normal Condition Common Rail Pressure Fuel pressure/

Min.: 0 kPa, Max.: 250000 kPa

30000 to 80000 kPa when idling. Target Common Rail Pressure Target common rail pressure/

Min.: 0 kPa, Max.: 250000 kPa

25000 to 200000 kPa when the engine is running. w/o DPF: Tester Display Measurement Item/Range Normal Condition Common Rail Pressure Fuel pressure/

Min.: 0 kPa, Max.: 250000 kPa

30000 to 40000 kPa when idling. Target Common Rail Pressure Target common rail pressure/

Min.: 0 kPa, Max.: 250000 kPa

30000 to 180000 kPa when the engine is running.

-

-

-

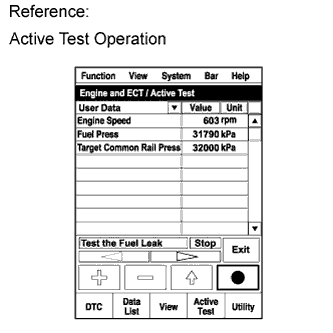

INSPECT FOR FUEL LEAK

-

Perform the Active Test.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test.

-

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurize common rail interior and check for fuel leaks Stop/Start

-

Fuel pressure inside common rail increased to specified value and engine speed increased to 2000 rpm when Active Test is performed

-

Above conditions preserved while Active Test is being performed

-

-

-

-

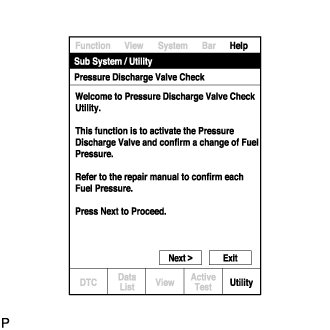

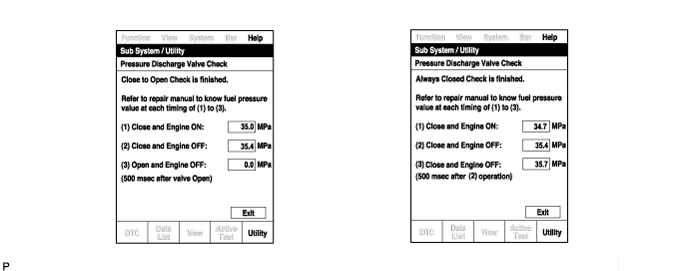

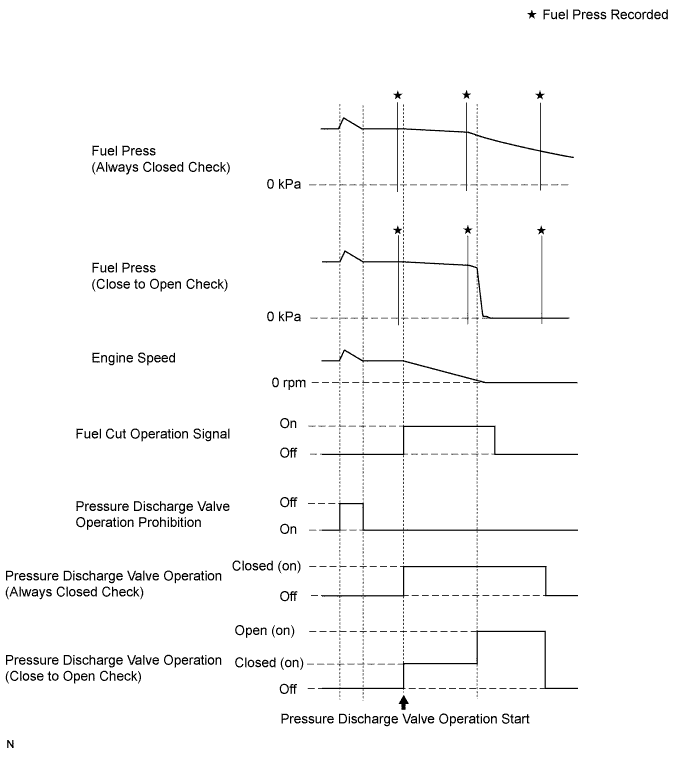

CHECK PRESSURE DISCHARGE VALVE

Tech Tips

-

This is the procedure for troubleshooting fuel pressure control malfunctions and combustion problems.

-

Malfunctions can be determined by checking the fuel pressure when performing fuel cut and operating the pressure discharge valve with the GTS.

-

During "Pressure Discharge Valve Check", the GTS measures the fuel pressure while the engine is running, after the engine is stopped and after the pressure discharge valve operates.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

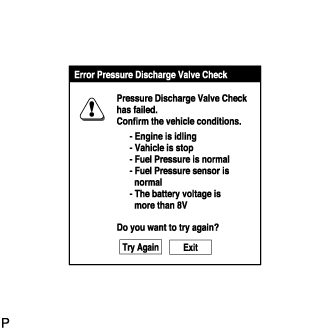

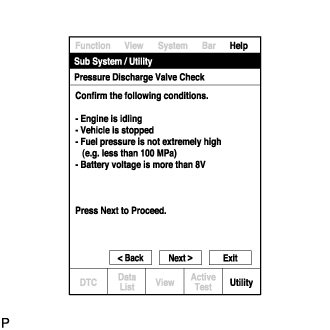

Note

Confirm the following conditions:

-

Engine is idling.

-

Vehicle is stopped.

-

Fuel pressure is not extremely high (below 100 MPa).

-

Fuel pressure is not extremely low (higher than 26 MPa).

-

Fuel pressure sensor is normal.

-

Battery voltage is higher than 8 V.

Tech Tips

When the common rail pressure is unstable, the fuel pressure may decrease to a level where the test cannot be performed. In this situation, wait until the common rail pressure meets the test condition, and then perform the test.

-

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Pressure Discharge Valve Check.

-

Press "Next".

-

Press "Next" again to proceed.

-

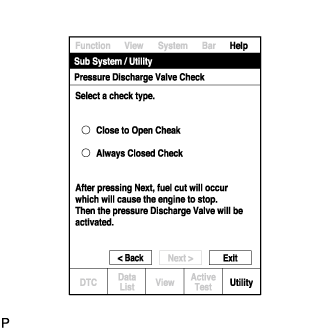

Select "Close to Open Check".

-

Press "Next".

-

Read the value of "Open and Engine OFF".

OK 0.5 MPa or less Tech Tips

-

When the system is normal, the value of "Open and Engine OFF" should be at or close to 0 MPa.

-

When the fuel pressure value of "Open and Engine OFF" does not become equal to or less than 0.5 MPa, the pressure discharge valve may be stuck closed.

-

When the fuel pressure values of "Close and Engine OFF" and "Open and Engine OFF" are both 0 MPa, the pressure discharge valve may be stuck open or there may be a fuel leak.

-

Perform "Always Closed Check" if the value is not 0 MPa when the pressure discharge valve is open during "Close to Open Check". If the results are the same as during "Close to Open Check", there is a pressure discharge valve operation malfunction.

-

-

-

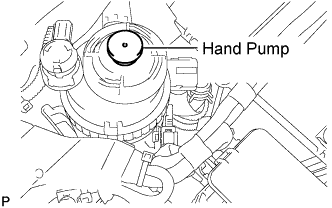

BLEED AIR FROM FUEL SYSTEM

-

Using the hand pump mounted on the fuel filter cap, bleed air from the fuel system. Continue pumping until the pump resistance increases.

Note

-

Hand pump pumping speed: Max. 2 strokes/ sec.

-

The hand pump must be pushed with a full stroke during pumping.

-

When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

-

If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

-

If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

-

If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

-

-

Check if the engine starts.

Note

-

Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

-

Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

-

Use a fully-charged battery.

-

When the engine can be started, proceed to the next step.

-

If the engine cannot be started, bleed air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

-

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs.

-

w/ DPF: Click here

-

w/o DPF: Click here

-

-

Start the engine.*1

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

-

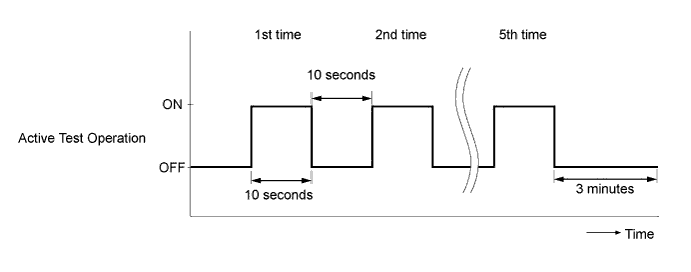

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

-

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time.

Tech Tips

When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

-

Clear the DTCs.

-

w/ DPF: Click here

-

w/o DPF: Click here

Tech Tips

It is necessary to clear the DTCs as DTC P1604 or P1605 may be stored when air is bled from the fuel system after replacing or repairing fuel system parts.

-

-

Repeat steps *1 to *3.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

OK No DTCs are output.

-