FUEL INJECTOR INSPECTION

-

INSPECT FUEL INJECTOR ASSEMBLY

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 11.6 to 12.4 Ω If the result is not as specified, replace the fuel injector assembly.

-

Inspect the injection volume.

CAUTION:

This test involves high-pressure fuel and electricity. Take all precautions regarding safe handling of both the fuel and the electricity. Perform this test in a safe area and avoid any sparks or flames. Do not smoke.

-

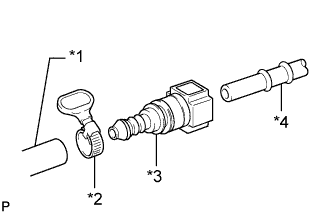

Text in Illustration *1 SST (Hose) *2 SST (Hose Band) *3 SST (Fuel Tube Connector) *4 Fuel Pipe Connect SST to the fuel pipe.

- SST

- 09268-31014 ( 09268-41500, 09268-41700, 95336-08070 )

-

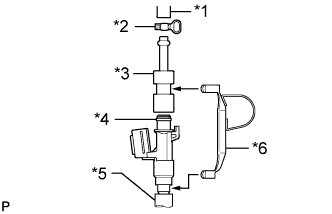

Text in Illustration *1 SST (Hose) *2 SST (Hose Band) *3 SST (Adapter) *4 O-ring *5 Vinyl Tube *6 SST (Clamp) Install the O-ring to the fuel injector.

-

Install SST and the tube to the fuel injector.

- SST

- 09268-31014 ( 09268-41300, 09268-41600, 09268-41700, 95336-08070 )

-

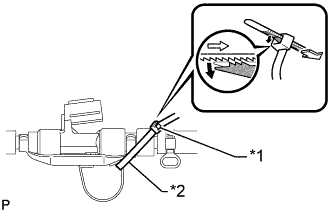

Text in Illustration *1 Lock *2 Tie Band Pass SST (tie band) through the loop on the handle of SST (clamp) to secure SST (clamp) to SST (adapter).

- SST

- 09268-31014 ( 09268-41800 )

Note

-

As SST (tie band) does not completely prevent SST (clamp) from becoming loose, do not subject the parts to any impacts while using them.

-

Before using SST (tie band), make sure that there is no deterioration, damage or cracks. If there are any abnormalities, replace SST.

Tech Tips

When removing SST (tie band), disengage the lock.

-

Check that SST (clamp) and SST (adapter) cannot be easily separated.

-

Install a vinyl tube to the injector.

-

Put the injector into a graduated cylinder.

CAUTION:

Install a strong rubber tube to the injector to prevent gasoline from splashing.

-

Operate the fuel pump Click here.

-

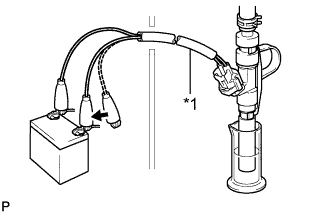

Text in Illustration *1 SST (EFI Inspection Wire I)

Connect Connect SST (EFI inspection wire I) to the injector and battery for 15 seconds, and then measure the injection volume with the graduated cylinder. Test each injector 2 or 3 times.

- SST

- 09842-30090

Standard injection volume 82 to 99 cc (5.0 to 6.0 cu in.) per 15 seconds Difference between each injector 17 cc (1.0 cu in.) or less Note

-

Make sure that SST (EFI inspection wire I) is securely connected.

-

Always turn the voltage on and off on the battery side, not the fuel pump side.

If the injection volume is not as specified, replace the injector assembly.

-

-

Check for leakage.

-

In the condition above, disconnect the tester probes of SST (wire) from the battery and check for fuel leakage from the injector.

Standard fuel leakage 1 drop or less in 12 minutes

-

-